Today, the building materials market provides each client with one or another building material in abundance, and foam blocks are no exception. It is not enough to choose the size and number of foam blocks; it is also important to know how to deliver such bulky material to the construction site.

The question of delivery worries almost every builder. This article will describe in detail how the delivery process takes place and the entire initial stage of purchasing foam blocks for construction.

How many foam blocks are there in a cube?

The first thing you should take care of when purchasing foam blocks is counting the number of blocks that are needed for the construction of a particular object. This question is quite relevant both among professional builders and among newcomers to this business.

In order for the calculation of a certain number of foam blocks to be as accurate as possible, you must rely on the following parameters of the facility under construction:

- Length.

- Width.

- Height.

- Volume.

- Square.

Calculating the number of blocks for the construction of one wall can be very easy and simple; there are several options for this, for example, counting the square meters of the wall and constructing them into cubic meters.

It is worth knowing that foam blocks are sold in cubic meters, which means that in order to order a certain number of blocks, you need to know their number per cubic meter.

The popularity of building houses from this type of material is due to its excellent performance. Foam blocks have proven themselves as a building material that can withstand harsh weather conditions. It is not afraid of either cold or moisture, and besides, blocks of this type, despite their composition, are quite resistant to fire.

These factors determine the presence of special microsubstances that are present in the foam block. In addition, despite their lightness, blocks are good materials for the construction of load-bearing walls in buildings, because they are able to withstand enormous pressure per unit of area.

This resistance to stress is explained by the presence of plasticizers in the foam block. Due to these substances, blocks of this type are quite strong and can withstand high pressure without changing their shape and size.

Depending on the composition of the foam block, experts divide them into the following categories:

- Foam blocks for thermal insulation work outside the premises.

- Structural blocks for the construction of frame works of buildings.

- Soundproofing foam blocks.

As you can see, foam blocks are good in all areas of application, from sound insulation and thermal insulation to the construction of load-bearing walls in massive high-rise buildings.

Each of the specifics of using foam blocks is explained by its production and manufacturing. For example, foam blocks for sound insulation are made using a special technology that foams the polystyrene foam material from the inside. This creates porosity and a sound insulation effect, which is what is needed for this type of foam block.

Building construction blocks are renowned for their strength and durability.

The fact is that such a foam block contains M-500 cement with appropriate mineral and artificial additives that give the block hardness and density. It is worth noting that this type of block is three times heavier than conventional ones. In addition, its price characteristics are also significantly higher than others.

Blocks for increasing the thermal insulation of a house are the cheapest. Such a building element is relatively light in weight, since in the production of such a foam block more attention is paid to the porous base inside the block. Due to the fact that there are small pores inside the block, the effect of solidification of the gases inside is formed, which is why the heat transfer from such a block is at the very minimum value.

How to calculate the number of blocks in a cube?

You can also calculate the number of blocks per cubic meter of supply without much effort, you just need to know the dimensions of the block itself, and this is:

1) Length - 0.6 m 2) Width - 0.3 m 3) Height - 0.2 m

With an easy mathematical calculation we can find out how much the volume of one foam block will be:

0.6*0.3*0.2=0.036 cubic meters.

The only thing left to do is divide one cubic meter by the volume of one block, as a result of which we get that one cubic meter contains 27.78 foam blocks.

By rounding we get that one cubic meter includes 27 blocks.

Exactly the same calculations must be performed with other block sizes.

How many foam blocks are in a pallet?

It must be said that foam blocks are supplied in packed pallets, therefore their quantity in a pallet does not depend at all on one cubic meter.

There are several types of pallets:

- 0.9 cubic meters, which holds 25 foam blocks.

- 1.44 cubic meters, which holds 40 foam blocks.

- 1.8 cubic meters, which holds 50 foam blocks.

Thus, knowing the calculated values of foam blocks and the type of delivery pallet, you can easily calculate how many pallets to order for the construction of the facility. To do this, you need to divide the total volume of all coatings on the object by the volume of the pallet, and only then multiply the resulting number by the number of blocks in the pallet.

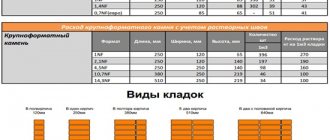

Table of foam block sizes and their number in one cubic meter

| Foam block size | Volume of one foam block | Number of foam blocks in 1 m 3 | Number of foam blocks in one pallet | |

| LxWxH in mm | m 3 | PC | PC | m 3 |

| 600x50x250 | 0,0075 | 133,3 | 192 | 1,44 |

| 600x75x250 | 0,01125 | 88,9 | 160 | 1,8 |

| 600x80x250 | 0,012 | 83,3 | 144 | 1,728 |

| 600x100x250 | 0,015 | 66,7 | 120 | 1,8 |

| 600x125x250 | 0,01875 | 53,3 | 96 | 1,8 |

| 600x150x250 | 0,0225 | 44,4 | 80 | 1,8 |

| 600x200x250 | 0,03 | 33,3 | 64 | 1,92 |

| 600x300x200 | 0,036 | 27,8 | 50 | 1,8 |

| 600x250x250 | 0,0375 | 26,7 | 48 | 1,8 |

| 600x300x250 | 0,045 | 22,2 | 40 | 1,8 |

| 600x350x250 | 0,0525 | 17,8 | 32 | 1,62 |

| 600x375x250 | 0,05625 | 17,8 | 32 | 1,8 |

| 600x400x250 | 0,06 | 16,7 | 32 | 1,92 |

| 600x500x250 | 0,075 | 13,3 | 24 | 1,8 |

How many foam blocks do you need per house?

Any builder by vocation or builder by necessity is constantly trying to calculate as accurately as possible the amount of a particular material that will be required for the construction of an object. Everything is clear with the construction material counting device in specialized organizations, because there these deliveries are monitored by trained people who perform complex mathematical calculations and analyze them.

But what about those who decide to build a house on their own plot of land or in their country house? To do this, it is necessary to make some calculations, which are necessary both to save money and to save time and space for building material. Calculating bag containers will be easier, but when calculating the number of bricks or blocks, not everything is so simple.

If the choice fell on building a house using blocks, then to calculate them you must know the size of one block and the size of the area of the walls that need to be built.

The blocks are stacked in a certain order and this gives some relief in counting. Therefore, if you correctly calculate the required amount of building material, you can save a lot on your own money.

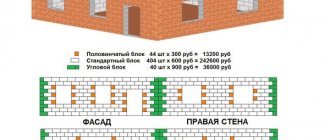

For example, if the house has dimensions:

- Length 6 meters.

- Width 6 meters.

- Height 3 meters.

The first thing you need to do is calculate the perimeter of the building, in our case it is 24 meters. The area of the walls of the house will be 72 square meters. But not everything is so simple, because there are a number of openings on the walls (doors and windows), the size of which is not at all useful for construction. Therefore, their parameters must be subtracted from the total area of the walls.

So, let the total area of the walls, taking into account all the openings, be 58 square meters, then the next step will be to count the number of blocks. A standard foam block has dimensions of 200*300*600 millimeters, and the thickness of the walls in this block will be equal to 30 centimeters.

Now it’s easy to calculate how many blocks will need to be purchased to build walls in the house:

You need to multiply the area of the walls by the thickness of the wall, and it will be equal to 58 * 0.3 = 17.4 cubic meters. Knowing that there are 27 foam blocks in one cubic meter, you can easily calculate how many blocks there will be in 17.4 cubic meters.

And it will be equal to:

27*17.4=481 pieces.

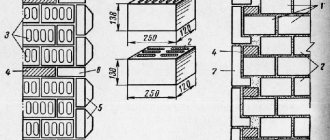

Arrangement of foam blocks flat

If the construction of a house occurs in such a way that the block lies flat on the surface, then for such construction of the house it is also necessary to find out the most accurate number of foam blocks that will be needed to build the frame of the house. To do this, the perimeter of the house - 24 meters must be multiplied by 0.3 and by a height of 3 meters.

As a result, we will have 21.6 cubic meters. Knowing that there are 27 blocks in one cubic meter, it is easy to calculate that 583.2 blocks will be needed. But do not forget that some blocks are deformed or completely defective. Therefore, you will need to purchase several dozen more foam blocks.

Arrangement of foam blocks vertically

If the construction of walls occurs in such a way that the foam block rests on the surface with its smaller side, then to decide the issue of the number of blocks it is necessary:

the perimeter of the house is 24 meters multiplied by 0.2 meters and the height is 3 meters. As a result of the calculation, we will have 14.4 cubic meters of foam block, which is equal to 388.8 blocks.

Properties of aerated concrete blocks (dimensions of aerated concrete blocks)

Standard aerated concrete wall blocks often have a length of 625 mm (H+H, Aeroc) or 600 mm (Bonolit). Their height is usually 250 mm; products with a height of 200 mm are very rare. The maximum height cannot exceed 500 mm. But in terms of width, the range of sizes is very large. This size is the main one when choosing a material, since it determines the thickness of the wall of the future building.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

The thickness of the blocks can be 100, 150, 200, 250, 300, 350, 375, 400, 500 mm.

Calculations

How many foam blocks are required per m3? — It is necessary to divide 1 m3 by the volume of one foam block. One cube consists of 27 blocks. After simple calculations we get 27.7 pieces. In this case, rounding is downward.

Answer: 1 m3 = 27 pieces of foam blocks

Another way to obtain the number of foam blocks in a cube is to do calculations in pieces. The chosen method is performed as follows: the width, height and length of one block are multiplied among themselves, and the resulting total is divided by 1000. As a result, we get how many pieces of the selected type will be in one cube.

Calculation of foam concrete blocks

Reference: in 1 m3 there are 27 units of foam blocks measuring 200 x 300 x 600 mm. You can check by dividing 1 m3 by the volume of one standard unit. The volume is calculated by multiplying all sides of the block.

Density

This indicator is proportional to the grade of concrete. Each type of building element is used to lay structures with different loads. In order not to make a mistake when choosing a brand, you should familiarize yourself with their purpose. Aerated concrete D600 is characterized by high strength.

Monoliths are erected from D500 blocks, D 400 - for arranging insulation when installing openings. Products made from aerated concrete D350, which has high porosity and a loose structure, are used primarily for heat insulation.

The material absorbs moisture, so a moisture-insulating soil ball is applied to the walls. The block manufacturing technology involves mixing the ingredients, which, when interacting, form a porous structure. High-density building elements have more weight.

How much aerated concrete in a cube can be determined by the density of the block. This indicator is designated D, and the numbers after the letter marking indicate the density value. A low index value corresponds to the presence of a large number of air pores, which increase heat conductivity.

The strength index of the D400 gas block is 45% higher than that of D300, but the thermal conductivity is 30% lower. The price of building products of the D400, 200, 300, 600 cm brand in Moscow and other regions is lower than for similar products of higher density.

Currently reading: Recommended concrete pouring temperatures