Home |Construction |Do-it-yourself bathhouse made of foam blocks

Date: April 24, 2017

Comments: 0

Most owners of private property want to realize the dream of building a bathhouse on the territory of a private house or summer cottage. A relaxing holiday is necessary after hard work at the dacha or a week of work. Most people associate a bathhouse with a wooden structure - a log house. Unfortunately, it is not always possible to purchase expensive wood, as well as brick, the use of which as walls of a building requires special skills and knowledge. It is advisable to reconsider the approach to choosing material for construction. After all, there is a proven alternative solution - a bathhouse made of foam blocks, the construction of which is easy to do on your own.

There is no need to doubt whether it is possible to build a bathhouse from foamed concrete. Foam block has many undeniable advantages that make it possible to use foam concrete for construction. The implementation of your plan can be done with your own hands from foam blocks, which are affordable. This will allow construction to be carried out with minimal expenditure of financial resources.

Let's take a closer look at how to build a bathhouse from foam blocks. Let us dwell in detail on the characteristics, positive aspects and disadvantages.

You can build a bathhouse from foam blocks without any extra effort, due to the fact that this material can be easily sawed, cut and even planed with a traditional hacksaw or hatchet

A little about the foam block

Among the many materials in demand in the construction of buildings, blocks made of foam concrete occupy a special position. The products are a type of porous concrete that hardens under natural conditions and are distinguished by their cellular structure. The blocks are highly environmentally friendly due to the use of natural raw materials in their production:

- Portland cement;

- water;

- sand.

The formation of a cellular structure is achieved by using a foaming agent, the introduction of which creates air cavities in the hardening concrete mass. The popularity of the material is due to its affordable price, the ability to build reliable walls from foam blocks with your own hands, as well as many undeniable advantages. Let's look at them in detail.

Types of foam blocks

Foam blocks, depending on the manufacturing technology, may have different properties and some differences in appearance. The table below provides a description of the main varieties of this material.

Foam blocks are different

Table. Types of foam blocks.

TypeDescription

| Aerated concrete | This version of foam blocks is made from cement with the addition of aluminum powder. During the chemical reaction that occurs due to the addition of powder, pores are formed in the mixture. The future block is placed in an autoclave, where great pressure is applied to it, and the concrete hardens. The sizes of such blocks may differ from each other, this is due to the peculiarities of their manufacture. But deviations from the standards (average block dimensions 30x25x60 cm, weight - 30 kg) are, as a rule, insignificant, which makes it possible to obtain a minimal seam when laying blocks. Also, this version of foam blocks is called gas block or autoclaved foam concrete. The material is quite often used for the construction of baths and other structures. It is lightweight, conducts heat well, does not burn, and is not afraid of frost. It is also a fairly economical material and easy to process - it can be cut with a hacksaw. |

| Silica concrete | This type of block has a white color due to the addition of lime to the composition from which it is made. It is necessary to bind the mixture. This version of foam blocks has the highest hygroscopicity. There are a lot of pores in the structure of each block - 50% of the total volume. Due to the presence of a large number of voids, the blocks are very light and can be used for construction on light foundations. This material has excellent heat and sound insulation properties, so a bathhouse made from it will keep warm for a long time. |

| Foam concrete | This version of the foam block is produced in almost the same way as conventional aerated concrete, but without the effects of temperature. Concrete hardens naturally, but a special foaming agent is added to the mixture from which the block is made, after which the finished mass is poured into molds, in which it hardens naturally. |

| Sand block | These are blocks made of cement, water and sand. This is the standard mixture for creating concrete. Such blocks are economical, resistant to external factors, and environmentally friendly. They also have voids, but the blocks almost do not absorb water. The main disadvantage of the material is its low thermal conductivity, so a bathhouse made from it will have to be additionally insulated. And their mass is large, so it is not recommended to lay them on a weak foundation. |

Structural and thermal insulation block

Note that each of these types of materials is suitable for building a bathhouse for any project. It’s just that some materials need to be well protected from moisture during the construction process.

We suggest you read How to make a screen with your own hands [tips with photos]

Advantages of foam concrete blocks

When deciding to build a bathhouse from foam blocks with your own hands, it is advisable to consider the advantages of this building material:

- Increased frost resistance, allowing foamed concrete products coated with plaster to maintain integrity as a result of deep freezing and subsequent thawing. This characteristic is relevant for a wet room in a bathhouse, the heating of which is carried out occasionally.

Foam block is similar in properties to wood, but is more fire-resistant and has a lower level of radioactivity

- High thermal insulation characteristics, providing a comfortable microclimate indoors. This is due to the cellular structure of foam concrete. In terms of thermal protection, the material is similar to wood.

- Resistance to elevated temperatures and open fire, which is important for a heated room in which there is a heating device.

- Increased dimensions of a standard block made of foam composite with a low weight of the product, providing the opportunity to reduce construction time, reduce labor intensity and facilitate transportation.

- An affordable price that reduces the estimated cost of construction work, allowing a family with an average income to build a bathhouse from foam blocks. Compared to purchasing wood, the cost of purchasing blocks is 2 times less.

- Strength of cellular composite used for the construction of main walls of a building.

- There is no need for special construction preparation, which makes it easy to lay foam blocks with your own hands.

- Easy to process blocks using a standard hacksaw or power tool.

- Foam concrete is resistant to the development of fungi and mold, which is important for a bathhouse.

- Increased sound insulation characteristics, making it difficult for noise from external sources to penetrate into the room.

An alternative to timber has become a bathhouse made from foam blocks, which are made from cellular concrete

Insulation, waterproofing, finishing and cladding

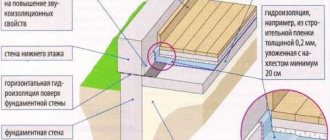

It is always worth remembering the peculiarity of foam blocks: porous structure. Therefore, it is so important to install a vapor barrier layer for the internal insulation of the bathhouse, and complete waterproofing on the outside.

It is extremely undesirable to leave the walls of block baths without finishing at all, since the external influences of weather conditions, as well as the internal influences of steam and heat, can negatively affect the strength of the structures.

Interior decoration

Do-it-yourself finishing of a foam block bathhouse inside.

Foil materials are suitable for waterproofing from the inside, and it is also necessary to leave a ventilated gap (can be arranged using a counter-lattice, the gap can be up to 5 cm).

Lining works well as finishing materials: it gives the interior a classic look.

REFERENCE. It is recommended to treat lining and other finishing wooden materials with specialized impregnation compounds or oils.

If you are not a supporter of the classic look of a bathhouse, then a wide range of ceramic or soapstone tiles are at your service: they fit perfectly on foam block walls. It's a matter of your taste and preference.

Exterior decoration

Hydrophobic impregnations or primers can serve as a waterproofing layer on the outside. The use of plaster on walls will not be sufficiently effective, since it will not provide sufficient protection from moisture.

The outside of the bathhouse can be sheathed with any material: siding (plastic and metal), wooden finishing materials, or use imitation stone, timber, etc.

If you have a good budget, you can consider options for using hinged ventilated facades; this largely meets the requirements for vapor protection of blocks.

For finishing a bathhouse made of foam blocks, see separate material.

Like any other, a foam block bathhouse also needs interior decoration. As a rule, the material is wooden lining. The dressing room is lined with one of the coniferous species: pine or spruce.

It is better to decorate the steam room with linden or aspen, which retains heat well without overheating under the influence of excessively high temperatures.

Furnace installation

It is very important to choose a suitable stove for a bathhouse made of foam blocks. Additionally, you will need to build a brick partition.

To lay the foundation for the furnace you will need:

- dig a pit about 70 cm deep, its width should exceed the width of the foundation by 10 cm on both sides;

- a 15-centimeter layer of sand is poured into the bottom of the resulting hole and filled with water;

- after this, the sand is filled in again and again filled with water;

- after the water has been completely absorbed, broken bricks are thrown onto the base and everything is filled with water;

- then proceed to compaction, followed by filling with sand and pouring water;

- after the sand has settled, fill in 10 cm of crushed stone and compact it;

- now formwork is installed in the pit and reinforced lattice is laid;

- a 15 cm layer of cement mortar is poured on top - the level should converge with the upper level of the soil.

Door installation

At this stage, they begin to install doors to the entrance and to the washing room.

A frame made of 50x50 cm timber is attached to the walls at intervals slightly smaller than the width of the insulation sheets. After this, the insulation is laid and covered with foil, securing it in the right places.

First, the lining must be treated with an antiseptic. Next, 25x25 cm beams are packed onto the foil covering to create an air gap, and only then proceed to fastening the lining.

conclusions

A bathhouse made of foam blocks will cost the owner much less than a wooden one. However, this option can be considered ideal value for money.

It’s easy to calculate how much a finished bathhouse made of foam blocks will cost. All components for such a bath will have a reasonable price, so a small bath will cost very little. And by doing the entire list of work with your own hands, everyone can save even more while maintaining the excellent quality of the finished bath.

The walls are insulated with expanded clay (for example, pouring it into the gap between elements of lightweight masonry), mineral wool - on the outside, under the façade cladding.

The attic floor also needs to be thermally insulated if the bathhouse is to be used all year round. The insulation is laid on a vapor barrier material.

One of the reasons for the premature destruction of bathhouse walls made of cellular concrete is excessive water saturation of the wall material.

The wall gets wet due to poorly executed hydro- and vapor barriers, leaks in the roof, as well as due to the insulation of the bathhouse from foam blocks from the inside.

In addition, a wet wall should have the opportunity to dry. Foam concrete walls are not insulated with expanded polystyrene.

Foam concrete has significant water absorption. Where foam blocks come into contact with water, they are coated with bitumen mastic and covered with rolled waterproof material.

The remaining surfaces are hydrophobized and plastered with a material with a porous filler: expanded clay, pumice. (The plaster is applied from the inside along the beacons - vertical guides).

Vapor barrier materials include foil, polyethylene film, and glassine. The facade finishing of the bathhouse will prevent corrosion of foam concrete - a response to environmental aggression, and will protect the insulation and windproof shell.

The facade system can be made without breaking the continuity (like covering plaster on a heat-insulating layer glued to the wall or mechanically fastened to it). For a bathhouse made of cellular concrete, façade structures with a gap ventilated through vents in the cladding are preferred.

Foam concrete is directly covered with plaster or facade tiles. Before plastering, the wall is cleaned, degreased and primed. The surface of foam blocks is often not rough enough for coating, then it is covered with a special mesh.

The insulation is covered with plaster if its strength characteristics allow it. The final finishing is painting materials or a thin layer of decorative plaster.

Interior decoration of walls is carried out 1–2 years after construction.

The porous structure of foam concrete is due to closed bubbles throughout the entire volume. Its components are sand, cement and foaming agent. Foam concrete gets wet less than aerated concrete, but retains heat better.

Its strength is an order of magnitude less than that of ordinary, even non-reinforced concrete. Therefore, spacious and high baths made of foam blocks are built with an additional supporting frame.

The durability of buildings made of foam blocks with one or two floors requires competent design, high-quality work and the use of elements with the same physical characteristics. The uniformity of the material is especially important in the front layer of the masonry, in the joints of the structural elements of the bathhouse.

Weak sides

Any building material has pros and cons. Let us dwell on the disadvantages of foamed concrete:

- increased ability to absorb moisture, which requires mandatory plastering of the foam concrete surface and the use of high-quality waterproofing coatings;

- the environmental friendliness of foam blocks is reduced compared to natural wood.

You should think carefully about whether a bathhouse should be built from a foam block? Along with many positive aspects, there are serious disadvantages. Carefully evaluate the pros and cons, and if you have made a final decision, begin developing the project, determine the need for raw materials and prepare to carry out the work.

Advantages and disadvantages

There is an opinion that the main advantage of foam blocks as a material for construction is their exceptional low cost. Is this true or is it much more complicated? We’ll find out right now when we subject this material to a scrupulous analysis to identify obvious pros and cons.

Advantages

- high fire safety;

- fast construction;

- simple installation that does not require any special skills;

- very low cost;

- decent sound insulation;

- low thermal conductivity.

As you can see, foam blocks are not only available due to their low cost, but also impress with their impeccable fire safety and absolute ease of installation. Their closest competitor is expanded clay concrete blocks. It is no coincidence that DIY bathhouses made of expanded clay concrete are among the most popular projects. However, both some blocks and others have disadvantages. And they are very similar.

Flaws

- very low frost resistance;

- high water absorption;

- the material is exposed to fungus and rodents;

- average level of tightness.

Fortunately, these disadvantages are not critical, and the myths about the release of harmful substances into the air have long been successfully dispelled by experts.

In general, foam blocks are a completely reasonable solution for implementing a bathhouse project if you want to get by with a minimum investment. But you still have to take into account the costs of interior and exterior decoration, including insulation and waterproofing. This is the only way you can really enjoy a comfortable steam, and not shiver from the cold and complain about the rapidly falling temperature and dampness all around.

What is needed for the job?

To carry out construction, prepare tools and materials according to the list:

- Foam concrete blocks, the need for which is provided for by the design part of the project.

- Materials for finishing and waterproofing protection of premises.

- Ingredients for making the concrete mixture necessary for pouring the base. You will need crushed stone, Portland cement, sand and water.

To build a bathhouse from foam blocks, you will need the following tools: hammer, mallet, level, concrete mixer

- Concrete mixer to speed up the mixing process.

- Cement solution, which will be required for laying foam concrete blocks.

- Electric tool for making cavities required when installing fittings.

- A tape measure, a level, a square, which allows you to control the correctness of the foam concrete masonry.

- The beams necessary for the manufacture of the rafter structure and installation of the roof.

Construction of a foam block bathhouse

Since we have become familiar with the features of the material, it’s time to move on to considering the construction itself. So, is it possible to build a bathhouse from foam blocks?

Of course you can. Moreover, based on the characteristics, this material is very suitable for this. It can perfectly preserve the body, and its strength and durability can make the construction practical and have high performance characteristics.

Preparatory work

Of course, you need to start with a project and purchasing the necessary materials. Since the topic of our article is directly related to blocks, let’s look at an example of how you can calculate the required number of them.

The calculations are quite simple and anyone can make them:

- Let's assume that our bathhouse will have dimensions 6*8, the ceiling height will be 3 meters.

- We will use blocks of size 625*400*250.

- Perimeter and area of the building: 6*2+8*2=28, 28*3=84 m2.

- Block area=0.625*0.40.25 m2

- 84/0.25=336 pieces.

Convert to m3:

- Volume of one block = 0.625*0.4*0.250.0625. 1/0.0625=16 pieces of blocks in 1 m3.

- We will need 336/16=21 m3 block.

Note! Masonry specialists recommend purchasing products with a small margin. Some may be damaged during transportation and during construction.

Window and door openings should be subtracted from the total quantity; also, do not forget about partitions, for the construction of which a partition block is used.

As for the adhesive composition, according to the recommendations of most manufacturers, its consumption is 1 bag per 1 m3 of block. But, in reality, no one has enough of this amount, so it is worth purchasing a little more glue than this calculation, primarily based on the planned thickness of the seam.

When the project is ready and the materials have been purchased, you can begin geodesy and the subsequent construction of the foundation (see Building a foundation from foam blocks for a bathhouse). You should start by clearing the area and removing the fertile top layer of soil.

Foundation structure

The type of base for a bath directly depends on the type of soil. Also important is the chosen material and the height of the building, on which the level of load on the future foundation depends.

The most common option is a strip foundation, since it can be used in almost any type of soil and can withstand considerable loads. When constructing a one-story, low-weight structure, its shallow-depth version is quite suitable.

Let's take a step-by-step look at the progress of the work:

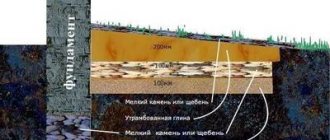

- First of all, a trench is dug to the required depth. Usually it ranges from 50 to 100 cm. It is worth considering not only the depth for pouring the concrete mixture, but also for installing the cushion. The width of the base depends on the thickness of the future wall, the most common is 40 cm.

Advice! The width of the foundation should be slightly greater than the thickness of the wall; the possibility of installing insulating layers on both sides of the building should be taken into account.

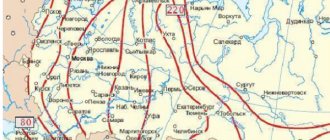

Not only the type, but also the depth of the foundation depends on the type of soil. For example, if the soil is clayey, then deeper digging should be done. It is worth paying attention to the soil’s ability to heave, and also check for the presence of melted groundwater located close to the ground.

- After digging a trench, a cushion (sand or gravel) is placed at the bottom. The material should be compacted by moistening and compacting. The layer thickness should be about 25-30 cm.

- Next, the formwork is installed. It is usually made of wood. It is also possible to use permanent formwork, complete with elements for installation.

- The next step will be the installation of the reinforcing mesh.

- The last step is preparing the concrete mixture and pouring the foundation. And after the latter hardens - stripping.

Note! During pouring, air bubbles may form in the concrete mixture. They can be removed by bayoneting or using a deep vibrator.

The foundation must harden. Usually this takes about 3-4 weeks. Much, in this case, depends on weather conditions.

If the weather is rainy, it is recommended to protect the base with waterproofing in the near future. In any case, after the foundation is ready for use, it is covered with several layers, for example, roofing felt.

Foundation, scheme

Formwork for the foundation

Ready foundation

Masonry work

The process of masonry work is simple and does not take much time - however, strict adherence to the technology is mandatory.

You will need the following tools:

- Rubber hammer (mallet);

- Building level;

- Thread or cord;

- Bucket scraper;

- Grater;

- Wall chaser;

- Corner;

- Drill and attachment - mixer;

- Hand saw or hacksaw for foam concrete.

Tools for laying foam blocks

The work order looks like this:

- You should start from the highest angle. The layer of solution in this place will be minimal.

- The blocks are placed in the corners, and a thread is pulled between them, which, like the products themselves, will serve as a kind of guide.

- The first row is laid out completely. It is recommended to use a solution in order to better fix it with the base and give strength to the structure.

- If there remains a gap that does not correspond to the size of the block, the latter is trimmed using, for example, a hacksaw.

- The second and subsequent rows are laid on glue. This will help significantly reduce cold bridges.

- Do not forget about the seam displacement by about 25-30%.

- The first and every fourth row must be reinforced.

- After laying all the blocks, it is recommended to install an armored belt.

Note! During laying, it is necessary to control and adjust the evenness using a building level and a rubber hammer. You should do this as often as possible so that the glue does not have time to harden. It is not possible to disassemble the wall later.

Laying the first block

Application of adhesive composition

Laying the second and subsequent rows

Levelness control

Foam block reinforcement

Armopoyas

Roof installation

Now it’s time to start installing the roof.

Brief instructions look like this:

- Installation of the rafter system. A reinforcing belt is constructed along the top of the masonry using U-shaped blocks. The outer wall of the channel, formed by recesses in the blocks, is laid with strips of polyurethane foam, and then filled with reinforcement and concrete.

- During the process of embedding, vertical metal studs with threads are installed in the armored belt, which will connect the Mauerlat to the wall. The distance between the rods should not exceed 120 cm.

- Next, along the entire perimeter of the wall, a layer of waterproofing is laid - usually a double layer of roofing felt.

- Beams with a cross section of 100*150 mm are used as a Mauerlat. Holes are drilled in them by analogy with the arrangement of metal rods in the wall.

In the picture below you can see schematically how the mauerlat and floor beams are connected to the walls. True, it states that the wall is aerated concrete, but this diagram is also relevant for foam concrete.

Connection unit between the Mauerlat and the top of the wall

Note! All wooden elements must first be treated using specialized compounds that protect the wood from harmful atmospheric and biological influences.

Next, rafters are assembled from beams, also with a cross-section of 100*150 mm.

- Next, the outer trusses are installed; they form the gables of the building. These structures are strengthened with the help of temporary stops, by fixing the board vertically. A cord is pulled between the trusses.

The outer trusses are attached to the mauerlat. Metal plates and corners are used. The remaining trusses are installed in increments of 1 meter, focusing on the stretched cord.

- The next stage is the installation of the counter-lattice, which is formed by slats secured along the rafters.

- Sheets of plywood are installed on top of them.

- Next, protective materials are installed: hydro- and vapor barriers.

- The last stage will be the installation of the final roofing covering.

Frame for the roof of a bathhouse

Installation diagram

Finished roof

The video in this article on the topic: “Is it possible to build a bathhouse from foam blocks” will tell you in more detail about all the stages of building a bathhouse.

General cycle of events

The set of works according to which a foam concrete bathhouse is erected contains the following stages:

- the preparatory stage, during which the project is developed, the need for materials is determined;

- formation of a foundation, the strength of which determines the reliability of the entire structure being erected;

- erection of walls, installation of truss structure and roof, forming the entire building box;

- interior finishing work related to waterproofing and insulation, as well as installation of plumbing equipment and interior items.

Project part

If you want to build a comfortable bathhouse with your own hands from foam blocks, take a responsible approach to developing the project. Please note the following points:

- Internal breakdown into functional rooms.

Bathhouse project made of foam blocks

- Connection features, location coordinates of plumbing equipment and electrical communications.

- Type of building foundation, features of its concreting.

- Use of reliable materials for waterproofing protection.

- A method of finishing a foam concrete surface on the outside and inside of a building.

- External dimensions of the bathhouse, taking into account the required capacity for comfortable relaxation. For a small family, room dimensions of 4x6 m with a height of 2.3 m are suitable.

- Determining the required amount of building materials to allow the building to be erected quickly.

Foam blocks: features and characteristics

One of the interesting qualities of foam blocks is their resistance to fire. In many ways, this is what makes them suitable for construction in this case. But this material has both its pros and cons, which must be taken into account when adopting it:

- In terms of thermal protection, foam blocks are three times better than conventional bricks. They remain durable at high temperatures.

- They are safe in an environmental sense. They don't rot. Rodents do not show interest in them.

- They do not require treatment with antiseptic or anti-flammable agents.

- They weigh relatively little and are easy to saw, which makes them convenient for construction.

- Requires small financial costs for the installation of a building box.

We suggest you familiarize yourself with How to grease pies to make them rosy and appetizing.

This can lead to a decrease in its strength characteristics and, finally, to destruction. Therefore, additional efforts are required to prepare foam blocks for existence in conditions of high humidity.

When developing bathhouse projects, you need to take care of good ventilation, possible measures for forced ventilation in the building, as well as organizing the slope of the drains so that water drainage is reliable.

It is also necessary to keep in mind that if the project includes the use of foam blocks of twenty or thirty centimeters thick, you will not have to take additional efforts to insulate the building. And if the bathhouse is used only in the summer, in order to heat it without using too much firewood, blocks even ten centimeters thick will be enough.

During construction, the walls inside are covered with foil or special vapor barrier membranes.

To insulate the outside, the walls are covered with mineral wool. This material does not burn, is environmentally friendly, and does not contain mold. Another option is to cover the walls with polystyrene or foam plastic, reinforce them with mesh and cover them with special plaster that does not allow moisture to pass through, but only air.

Traditionally, a bathhouse is built from wood materials, such as timber, logs, etc. They are good for everyone, except perhaps the need for constant maintenance, since the wood begins to rot quite quickly under the influence of dampness. Without some care, a wooden bathhouse will very quickly lose its original appearance.

Foam block bath projects

But recently, bathhouses are often built from foam blocks. This material is an excellent alternative to traditional wood, as it has a lot of advantages and in some cases even surpasses wood in its characteristics. A foam block is a block of a certain size made from foam concrete or cellular concrete.

Foam block

However, the presence of porosity is the main feature of such materials. Thanks to it, foam blocks have an excellent level of thermal insulation, are able to perfectly retain heat in any structure, and are not too heavy materials. The pores inside the block can have different sizes and are located randomly throughout its entire interior.

Foam concrete - production process

Construction of the foundation

The strength of the foundation determines the reliability of the building being constructed and the long service life of its use. In order for a bathhouse made of foam blocks to remain stable for a long time, use a strip foundation installed along the contour of the bathhouse. Considering the reduced mass of the foam composite, the choice of a strip base buried shallowly in the ground is justified. Carry out construction activities to form a strip-type foundation according to the following algorithm:

- prepare the site for construction by clearing the surface of vegetation and debris;

During the construction of a bathhouse made of concrete-containing foam, the foundation should be laid correctly

- remove the surface layer of soil and level the area;

- mark the outline of the bathhouse corresponding to the developed sketches;

- form a pit for pouring the foundation 50 cm deep, level the base of the trench;

- ensure that the side walls of the pit are vertical;

- mount the wooden formwork frame, ensuring the vertical position of the side surfaces;

- immerse a reinforcement frame made of steel reinforcement into the pit;

- mix the ingredients, prepare the mixture for concreting, ensuring the grade of concrete is M300–M400;

- fill the trench with concrete, compact the concrete mass, provide air outlet - use deep vibrators or steel rods;

- wait until the concrete acquires operational strength, dismantle the wooden formwork frames;

- waterproof the base surface using roofing felt or bitumen-based mastic.

Work on the construction of walls should be carried out after the concrete mass has completely hardened.

Laying foam blocks

Laying foam blocks with your own hands is carried out according to the given sequence of operations:

- Prepare a cement-sand mixture, ensuring a sand to cement ratio of 3:1.

After laying waterproofing (polymer films or layers of fiberglass) on top of the base of the bathhouse, the stage of wall construction begins

- Lay the lower level of foam concrete blocks on the surface of the base, starting from the corner part of the foundation. Distribute the solution evenly over the surface of the foundation. The thickness of the mixture makes it possible to form a horizontal surface of the first tier of blocks by pressing the products into the cement mass.

- Install strips in the corners of the masonry, to which tie a cord to control horizontality.

- Continue installing the blocks with a shift of 15–20 cm when laying the walls. Use a building level to check the levelness of the masonry.

- Reinforce every fourth block level using reinforcing bars with a cross-section of 8–10 mm. This will increase the resistance of the structure to deformations that cause cracks.

- Reinforce door and window openings with steel rods with a diameter of 10 mm. Use U-shaped elements to provide frame reinforcement.

- Form an armored belt on the final row of masonry, ensuring proportional distribution of the load on the walls from the mass of the rafter structure.

If it is necessary to refine the blocks, use a hand tool that allows you to quickly remove the excess part of the foam concrete product.

Foam blocks should be laid on edge, and the seams should be kept minimal - this is required so that the building does not lose its heat through them

Final stages of work

Having completed the construction of the main walls, you can begin the final stages of construction activities. To complete construction, complete the following work:

- mount the supporting structure for the roof, paying special attention to the reliability of fastening the beams to the reinforced belt of the upper level of the masonry;

- install a roof covering whose angle of inclination should not impede the removal of snow cover. Ensure an acceptable combination of the roof and the exterior of the existing buildings on the site;

- finish the interior of the bathhouse and the external surface of the building using waterproofing coatings;

- use proven materials for wall decoration that improve the aesthetic perception of the building;

- reliably insulate the internal surfaces of the bathhouse walls. Provide reliable protection from high humidity by using liquid glass;

- install a heat-insulating layer located between the decorative finish and the waterproofing layer;

- decorate the walls with wooden “lining”, which, when the temperature rises, will saturate the room with unforgettable aromas;

- Install a covering on the floor surface to prevent falls due to sliding. Use ceramic tiles that are easy to clean.

When carrying out activities that complete construction, follow the recommendations of the developed project. Once finishing is completed, install plumbing fixtures.