Type of cement subject to certification

To obtain a certificate of conformity for PC cement (cement passport) 400, 500 or any other brand, you need to know which types are subject to testing:

- slag;

- aluminous;

- hydraulic;

- superphosphate;

- Portland cement;

- mixtures of natural color or dyed.

The examination of each of the listed types of building materials is carried out on the basis of GOST 56836-2016 regulations. The main purpose of certification is to confirm the quality and safety of products.

The tested cement samples are examined in accordance with a number of requirements related to:

- degree of grinding of raw materials;

- chemical composition of the substance;

- speed of setting or crystallization of the cement mixture;

- changing the volume of the dry mixture after hardening;

- resistance to mechanical stress.

Cement testing

Portland cement is tested to ensure it meets certain general quality standards and specific characteristics specific to the specified grade and grade. So, for example, M400 cement cannot demonstrate the properties of M200 or M350 material - it will not pass the test and will not receive a document of conformity.

Currently reading: Concrete grade M450, class B35

What properties are checked during testing:

Chemical composition of the material. Grinding fineness is the degree of cement grinding. Setting speed in solution. Uniformity of volume change after the setting process. Resistance to mechanical forces of test samples made both from pure cement and from a cement-sand mixture. Additional characteristics: specific gravity, dough yield, mass per unit volume of cement in a loose and compacted state (since 1925, the determination of specific gravity is not included in the technical specifications; instead of this parameter, losses during the calcination process are determined, where the indicator should not be higher than 4%).

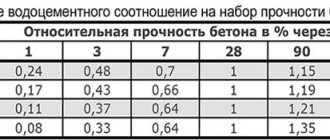

Cement testing is carried out in accordance with GOST 10178-85, which sets the main condition to determine the compressive strength of cement and compressive strength after steaming after 3/28 days. In this regard, the time for testing cement cannot be less than 28 days after taking product samples.

In addition, in the process of laboratory research, radiological tests can be carried out with the results of a special protocol issued. When importing cement outside the country, customs authorities have the right to require a radiological test report, but a quality certificate may not be needed.

To obtain a quality passport, you must contact the certification center with a complete package of documents, wait for all studies and checks to be completed, and then receive a certificate.

Algorithm for cement certification:

Application by a representative of the applicant company to a special accredited certification center, drawing up an application according to the established form. Collection of all documentation, provision of certification center employees. Carrying out sampling of cement, performing examinations in an independent laboratory equipped with all the necessary equipment. Checking production capacity (in certain cases, depending on the scheme chosen by the entrepreneur). If the material passes all checks, a certificate is drawn up and issued to the applicant.

Voluntary certification

To effectively advertise their own products, many entrepreneurs use a simple and accessible method - before starting production, they issue a certificate of conformity for M500 cement or any other brand. The procedure is not similar to certification, but will provide the manufacturer with a number of advantages. It allows you to:

- freely enter the international market with your product;

- participate in large tenders on special conditions;

- increase the competitiveness of the product among similar ones;

- increase the profitability of production and the attractiveness of products among buyers.

Cement certification rules - nuances

Cement certification is carried out to confirm the conformity of the quality and safety of the material. The procedure is mandatory - cement is included in the first section of Government Decree No. 982 of December 1, 2009. The rules for cement certification are enshrined in the provisions of GOST R 56836-2016. This standard applies to the following types of building materials:

- Portland cement;

- aluminous;

- supersulfate;

- slag

For the listed types of cement, a certificate of conformity is issued within the framework of the GOST R system. Thus, the requirements for cements used for the preparation of mortars are enshrined in GOST 25328-82. If we are talking about aluminous and high-alumina types of materials, their quality is determined according to GOST 969-2019 (comes into force in June 2020).

It should be noted that cements and their mixtures, which are intended for road construction, are subject to mandatory assessment according to TR CU 014/2011. A declaration of conformity is issued for the specified products.

Important! The absence of mandatory certificates and declarations inevitably entails the application by supervisory authorities of administrative liability measures in the form of a fine and confiscation of goods under the Code of Administrative Offenses of the Russian Federation.

Required documents

The list of documents for domestic manufacturers and importers is somewhat different. For Russians you must provide:

- the company's charter with the latest amendments, certified by the head of the enterprise and seals;

- TIN, OGRN, OKPO;

- lease agreements or documents certifying that the production space is owned by the company;

- application for certification;

- Specifications required if products are not manufactured in accordance with GOST.

For importers:

- contracts and invoices;

- product description and production diagram;

- statutory documents if the applicant is a Russian company.

Need instant expert advice?

Just call the toll-free number Or in the feedback form: Or write to us in instant messengers and get an instant response from an expert:

Storage conditions

In accordance with GOST 30515-2013 “Cements. General technical conditions", the following storage conditions are defined:

- Separate storage by type and brand (mixing is not allowed).

- Dry ventilated area.

- Plus temperature.

- Sealing of packaging.

Reference! Mixing different brands of building materials is unacceptable. Each type has its own level of humidity that is not suitable for the other.

It is possible to create the right storage conditions at home. For long-term storage of building materials both in winter and summer, it is important to adhere to the following rules:

- Prepare the storage room. It should be dry, warm, with good ventilation. Cement does not react well to temperature fluctuations, so it is important to ensure that its values remain constant in both winter and summer (not lower than 5 degrees).

- Install a pallet for stacking bags. There should be a gap of about 30 cm between the pallet and the floor for free access of air.

- Hermetically pack the building material in its original packaging in thick plastic bags.

- The bags are placed on pallets up to 1.8 m high. Access from all sides must be free.

- The folded bags are covered on top with tarpaulin or thick polyethylene. The sides are left open for free air circulation.

- It is necessary to turn all bags over once every 2 months to avoid caking of the material.

- The bags in which cement will be stored must not have ruptures, punctures, or poor-quality seams that compromise the seal of the package.

- The cement must be of high quality, purchased from a reliable, trusted manufacturer or from a direct supplier.

In summer, it is allowed to store building materials for a short time in soft containers or waterproof bags outside under a canopy.

Before use, you need to make sure that the material is suitable for the job.

Reference! Good quality cement flows through your fingers like sand and has a uniform structure.

The seller is required to have a document confirming the quality of the material to present it to the buyer. The consumer also has the right to receive information about the results of all tests to which the product was subjected.

The quality document contains the following information:

- name, trademark and address of the manufacturer;

- symbol or full name of the product;

- name and quantity of additives and main components of building materials;

- batch number and shipment date;

- number or name of transport for transportation of cement;

- warranty period for material compliance with standards (in days);

- designation of the regulatory document (if it is not present in the designation of the cement itself);

- indication of signs of false seizure (if any).

Sample document on cement quality:

Stages of obtaining a certificate

The document is prepared by an authorized, accredited body. The procedure occurs in several main stages:

- submitting an application to the certification center;

- filing an application of the established form;

- selection and provision of product samples for examination;

- testing in laboratory conditions;

- recording the received data.

If all points are completed, a certificate of conformity is issued - a document drawn up on an official form certified by the seals and signatures of authorized persons. The maximum validity period of the document is 3 years, after which the entrepreneur must go through the entire procedure again.

Fire certificate for cement

This type of document is not considered necessary for this building material. However, manufacturers interested in high demand for mixtures arrange it at their own request. These are papers confirming the product’s resistance to open flame and high temperatures. This criterion is one of the most important for the construction of buildings and structures today.

The specialists of the Sertiki.ru portal will help you at any stage of cement certification, from collecting documents to obtaining a certificate form from the authorized bodies, or will take over the entire process. All you need to do is email your application, details, GOST or specifications according to which the products are manufactured (if there are no specifications, we will help you develop and register them). Permits will be ready in 2-3 days.

Cement quality requirements for Russian construction

In modern construction, one of the main materials are reinforced concrete and concrete. They are used in the construction of monolithic and prefabricated buildings and structures. Improving the quality characteristics of concrete helps solve a number of issues, including:

- the possibility of using high-quality cement, modern aggregates, mortar and concrete mixtures;

- ensuring high quality of construction and installation work during monolithic construction of structures;

- compliance with the requirements for the care of hardening concrete reflected in the regulatory and technical documentation;

- organization of quality control of raw materials, concrete mixtures and structures (input, acceptance, operational control);

- providing laboratories with modern equipment and highly efficient instruments;

- use of advanced technologies for the production of concrete mixtures.

Based on the information presented above, the main focus of technical policy in the field of construction production is to stimulate advanced technologies and the use of efficient materials.

One of the most significant factors ensuring the reliability of concrete structures (monolithic and prefabricated) is the use of high-quality cement.

Today, mixtures that meet the requirements of GOST 31108-2003 are in demand.

Requirements for cements are reflected in Technical Recommendations TP-166-04, which were developed by JSC NIIZhB and SUE NIIMosstroy, to ensure the quality of concrete mixtures and prevent corrosion of concrete and structures created using it.

The main requirements for cement quality include:

- Grinding fineness:

- the permissible particle size is no more than 350-380 m2/kg;

the percentage of residue on sieve 009 is not higher than 5%.

- The setting time of the solution must comply with the following standards:

- onset - within 2.5-3 hours;

end - 3.5-4.5 hours.

- The normal density of the prepared mixture should be approximately 25-26.5%.

- The percentage of alkali content in the mixture must comply with the requirements of SNiP 2.03.11-85 and not exceed 0.6%, which eliminates the formation of efflorescence and cracks in concrete structures.

This eliminates water separation in the concrete mixture and the cost of additional finishing of the upper surface of the products.

This ensures that the required strength is obtained within the specified time frame.

More information on the topic:

offers to buy European cement at competitive prices.