Currently, two types of bricks are used in construction. It is silicate and ceramic. The raw materials for the first are lime, quartz sand and water. This type of brick has long been known to mankind and is distinguished by good sound insulation. Compared to ceramic, silicate is more dense, but you need to understand that such a material has a number of disadvantages, so it is not used for the construction of furnaces and foundations. Ceramic is made from ordinary clay. It is fired in a drying chamber. However, the firing technology may be different. The properties of this brick will depend on this characteristic. Ceramic material can be ordinary or facial.

Thus, both types of bricks can have good characteristics. But recently, aerated concrete has become in great demand. It also has a number of advantages. Therefore, the question of what is better - brick or aerated concrete for the construction of a residential building is always relevant. Well, let's compare these two materials in detail.

Features of aerated concrete

What it is? Aerated concrete is a type of cellular concrete. This is an artificial material with evenly mixed air pores. The aerated block consists of aluminum powder, quartz sand, cement, lime and water. Sometimes waste is added to the composition - ash and slag. This reduces the cost of production, but it also negatively affects the quality of the building material.

The manufacturing technology of this material is quite simple. The composition is mixed with water and poured into the mold. In this case, aluminum powder reacts with lime. As a result, the mixture rises and then takes on a solid form. This mass is cut into blocks, which are then processed under pressure in an autoclave. Aerated concrete first appeared 85 years ago. Due to its porous structure, this material has thermal insulation properties. In terms of physical properties, aerated concrete resembles wood. This is a warm, breathable and environmentally friendly material. It is easy to saw and drill. At the same time, the material is fire resistant and not prone to rotting.

Thus, aerated block is a durable building material that allows the construction of various buildings. Wall thickness and thermal conductivity may vary. But it is not recommended to build buildings higher than three floors from aerated concrete.

House made of aerated concrete

Aerated concrete is cellular porous concrete in which closed pores of 1-3 mm are evenly distributed. Aerated concrete block is made of sand, cement and lime. The material is in demand due to the ease and speed of wall construction, as well as its affordable cost.

Technical specifications

Aerated concrete blocks are manufactured using autoclave and non-autoclave methods. Non-autoclaved block is a naturally dried, hardened, expanded mixture. Autoclave is the same non-autoclave block, which additionally undergoes a firing process in an oven to improve its qualities.

Main parameters of aerated concrete:

Density

Aerated concrete material, due to its porosity, is lightweight and low-density. The block is marked by density (letter D).

| Structural | Construction of external walls | Brand D900. D1000. D1100. D1200 |

| Structural and thermal insulation | Construction of walls, ceilings, houses up to 3 floors | Brand D800. D700. D600 |

| Thermal insulation | Interior partitions, building insulation | Brand D500. D400. D300 |

Strength

Aerated concrete is highly durable and is used for laying load-bearing external walls. Such a block lacks elasticity. Therefore, special attention should be paid to the foundation. Cracks in the foundation will lead to deformation of the entire house. Strength is marked with the letter B and is divided into the following classes:

Important! To build a private house, use an aerated concrete block of class B1.5 and higher.

Thermal conductivity

The higher the brand class, the better heat-saving indicator the material has. Thus, the D500 block has low thermal conductivity, sufficient for the construction of an all-season house in cold regions.

Soundproofing

According to SNiP, the sound level in the room should not exceed 52 dB. The aerated concrete block of the D500 brand meets the standards. For good sound insulation, a wall of 15 cm and a layer of plaster on each side is sufficient.

Frost resistance

The frost resistance parameter allows you to determine how many freezing and thawing cycles the block can withstand. This is an important indicator for a region with variable cold and hot weather. Marked with the letter f.

Thus, the D500 brand is characterized by frost resistance class f35. Those. an aerated concrete block can withstand 35 cycles. In reality there may be more.

Video instructions on types of aerated concrete blocks

A private house made of aerated concrete blocks has the following pros and cons.

Advantages:

- The house has high strength and low specific gravity.

- Low thermal conductivity, which allows you to save on heating.

- Frost resistance and moisture resistance.

- Air permeability – the walls of the house “breathe”.

- The service life of a well-built house without the need for repairs is 70 years.

- Simple and quick processing of the material, which directly affects the speed of building a house.

- Good sound insulation.

- Environmentally friendly.

- Fireproof.

Flaws:

- Houses higher than 3 floors are not built from aerated concrete blocks due to their limited compressibility.

- Construction is accompanied by preliminary accurate calculations.

- It easily absorbs moisture, so the walls require additional external frame cladding. Moreover, you should not delay the exterior decoration of the house.

- When finishing the inside of a house, dowels are used for fastening. And these are additional costs. Otherwise, all interior finishing work will soon become unusable.

Comparative Specifications

To understand which is better – brick or aerated concrete, let’s compare their technical characteristics:

- Tensile strength. For brick, this parameter ranges from 110 to 120 kilograms per square centimeter. Gas block is less durable. This parameter does not exceed 50 kilograms per square centimeter.

- Weight. The weight of one cubic meter of brick is from 1.2 to 2 tons. The gas block will weigh from 200 to 900 kilograms.

- Thermal conductivity. For masonry made of aerated blocks, this parameter is 0.09-0.12 W/μ. For brick - 0.46 W/μ.

- Frost resistance. For aerated block – 50 cycles, for brick – from 75 to 100.

- Water absorption. For aerated concrete, water absorption is 20 percent by weight, for brick - no more than 12. This means that the first material needs additional protection. But we'll talk about this a little later.

- Fire resistance. Here is a description by class. Both are first class. We'll look at what this means a little later.

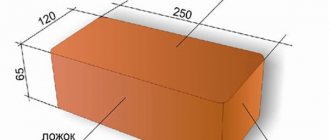

- Size. The gas block has the following dimensions: 20x30x60 centimeters. Brick – 6.5x12x25 centimeters.

- Quantity. There are 28 pieces of gas block or 380 bricks per cubic meter.

What is better - brick or aerated concrete for building a residential building? Knowing these characteristics, everyone can accurately determine whether a particular material is suitable for building a house. But in order to better understand the answer to the question, next we will make a detailed comparison of aerated concrete and brick according to their characteristics.

The difference between brick and aerated concrete

To finally decide which is better, aerated concrete or brick for building a house, it is necessary to compare these materials.

Compressive strength index

This parameter will determine the strength of the object under construction and the maximum load that the walls can withstand. For brick, this value ranges from 110 to 220 kg per sq. cm. But aerated concrete can only boast an indicator of 25 - 50. Hence the conclusion is drawn that the foam block is not suitable for constructing a load-bearing wall.

Ability to conduct heat

The thickness of the wall made of brick material must be at least fifty centimeters. This will be enough to ensure that the thermal insulation is within normal limits. To increase this parameter, it is allowed to install an insulating layer.

Block walls, which have a similar effect, are forty centimeters thick. And if you have to live in regions with cold climatic conditions, then you can easily understand which house is better, made of aerated concrete or brick.

Resistance to low temperatures

This value is characterized by the ability of a building material to retain its original properties during numerous cycles of freezing and thawing and in a state of high humidity.

Brick resists sharp temperature fluctuations of up to five dozen cycles; for aerated concrete this figure is 25–30 periods. It turns out that in this regard the brick lasts longer.

Moisture absorption

This parameter determines the duration of the operational period of the object. With significant absorption, water accumulates in the pores, and fungus and mold appear. For an aerated concrete block this figure is 100%, while brick can boast a value of 6–14%. It is possible to reduce the water absorption of the block by finishing the surface of the walls with waterproofing material and plaster mortar.

Construction work of this nature is carried out exclusively in dry weather.

Fire resistance

All materials under consideration belong to the group of non-combustible materials assigned class A.

Shrinkage

Aerated concrete blocks are susceptible to this characteristic, which can cause cracks to appear on the surface of the walls. This phenomenon is not typical for a brick wall if a solid foundation is prepared.

Example

For example, we need to build a two-story country house with a basement. The height of each house is 2.5 meters. In this case, the floors between floors are made of reinforced concrete slabs. In this case, the load-bearing walls must be made of brick, since this material can withstand heavy loads. But aerated concrete will not withstand such loads. After construction, such a house will come apart at the seams (cracks are guaranteed). It is also not recommended to make a foundation from aerated concrete. However, in this case, non-load-bearing walls made of aerated concrete can be erected. This will be a fairly economical solution and not at the expense of reliability.

Brick

Sand-lime brick is made from quartz sand, lime and water. It is not waterproof enough and will crack when heated. It should not be used in the construction of foundations, furnaces and sewer wells. But this material is durable, frost-resistant, has good sound insulation, and in terms of density it is ahead of ceramic brick. Retains color perfectly and does not contain harmful substances.

Ceramic brick is the oldest building material. It is made from clay by firing. The frost resistance and strength of the brick depends on this procedure. The resulting material can withstand heavy loads without deformation and has good sound insulation. A high coefficient of thermal conductivity means a pronounced ability to transmit heat, so good thermal insulation is required.

There are construction and facing bricks.

Building bricks differ in the degree of voidness: solid (with voids up to 13%) and hollow (14-50% voids). Hollow brick retains heat better and is lighter in weight than solid brick, but more expensive.

Facing brick is used for finishing walls made of brick, aerated concrete and foam block, cladding plinths, interior walls, and fireplaces. This is an excellent decorative material.

Coefficient of thermal conductivity

This parameter is no less important. The thermal conductivity coefficient will determine the ability of the wall to transmit heat through itself. The higher this parameter, the better the properties. Previously we provided comparative characteristics. What is better - brick or aerated concrete? In this case, aerated concrete is clearly in the lead. Its thermal conductivity is four times higher than that of brick. That is why, according to the requirements, it is necessary to erect brick walls with a thickness of at least one meter. For a gas block, a thickness of 50 centimeters is sufficient. Reviews say that the cost of building a brick house will be higher, since the issue of thermal insulation will additionally have to be addressed. If you use gas block for the walls, there is no need for additional thermal insulation. The thermal conductivity coefficient of such walls is minimal. Inside such a house, warm air will linger for as long as possible. And with brick walls, the house “gets cold” very quickly.

Brick or aerated concrete

What is better brick or aerated concrete ? This is one of the most common questions that future developers of country houses ask themselves when choosing wall material. Currently, the most popular country house is made of brick or aerated concrete : 1) aerated block - in another way (the same thing) - aerated concrete, aerated concrete block, produced using an industrial autoclave method (not to be confused with foam blocks, which are most often made in a handicraft way to create a competitive attractive price, but with lower technical characteristics), 2) ceramic block - in a different way (the same thing) - brick, ceramics, ceramic blocks, ceramic stone, warm ceramics, large-format brick, porous brick, porous stone, porous block.

Brick or gas block are the 2 most popular materials fighting for leadership in the market of modern building materials. Being different materials in their composition and properties (aerated block - sand, cement and lime, brick - clay), they have some similar qualities:

- They are used for the construction of single-layer walls for individual residential buildings in the Leningrad and Moscow regions without the additional use of insulation,

- They have a high load-bearing capacity and a high reliability coefficient, therefore they are more than sufficient for the construction of 2-3-story country houses,

- They have, to one degree or another, the property of steam and air exchange, which is important for comfortable living in cottages built from these materials,

- Safe for the health of residents and the environment, because do not contain harmful, toxic compounds,

- Both materials are 100% minerals, so they are durable, fire- and bio-resistant.

Aerated concrete or ceramics - what is the difference between them then? To answer this question, let's look at the following table:

Comparative estimates for the construction of a 2-story cottage with a total area of 165.8 m2

This is important to know!

The differences are most important for the consumer (aerated concrete vs. brick )

- A house made of brick sells better and more expensive than one made of aerated concrete (aerated concrete brick)

With the same values for the thermal insulation of walls for individual residential buildings for permanent residence (when walls made of both materials are equally warm):

- the thickness of a single-layer brick wall should be from 440mm (Porotherm ceramic block with external and/or internal plaster) to 640mm (ceramic blocks RAUF format 14.3NF 510mm + facing brick 120mm),

- The thickness of a single-layer aerated concrete wall should be from 375mm to 400mm (with external and/or internal plaster) depending on the brand and density of the blocks.

With the same thickness = the walls of a house made of aerated concrete are warmer than brick ones.

That. If you compare 2 houses - made of brick and aerated concrete with the same layout and area of rooms, then to build a brick house you will need a foundation with a larger area than for a similar house made of aerated concrete. In addition, for a brick house all other construction volumes increase - the areas and volumes of all walls, ceilings, rafter system, roofing. In general, building a house made of brick is on average 10-15% more expensive than a house made of aerated concrete.

There are more negative reviews on the Internet about aerated concrete houses than about brick ones (aerated concrete brick)

Some developers, when considering ceramic block as a wall material, are afraid that “later” they won’t be able to hang anything on the walls, because A hammer drill and ordinary fasteners are not enough. This is true - to hang heavy objects and structures (ladders, shelves, wall cabinets, wall bars, horizontal bars, etc.) on the walls, after their construction is completed, you will need special fasteners. But at present this property is not a big drawback, because Almost any hardware store or construction hypermarket offers special anchors (plastic, chemical) for walls made of ceramic blocks. In addition, during new construction, even at the design stage, concrete or metal embedded elements are provided for future suspended structures. Professional builders know all this and will take it into account when building walls.

Ceramic block or aerated concrete, expert opinion.

Over 11 years of work, the Full House company has built more than 80 houses made of large-format bricks and more than 130 houses made of aerated concrete. Ceramic block or aerated concrete ? Both materials have proven themselves in practice as reliable wall materials. Ceramic blocks or aerated concrete, which is better ? Both materials are good, however, each of them has features that must be taken into account during masonry work, anchoring, finishing and insulation. Compliance with special technology when working with both ceramic blocks and gas blocks is the main component in the construction of a reliable and comfortable residential building.

We told you about the main properties of ceramic block and aerated concrete, now the choice is yours. There will always be clients who choose a house made of aerated concrete and those who will always remain staunch supporters of brick house construction.

Estimates for building a house made of brick and/or aerated concrete (including comparative estimates) are prepared by our specialists free of charge and in just 1 day. To receive an estimate, simply fill out the form at the bottom of the page.

Water absorption coefficient

How is this parameter determined? It is determined by the ability of a building material to absorb water and retain it inside itself. Due to water absorption, the properties of the material deteriorate. First of all, this design becomes less durable. What is better - brick or aerated concrete? In this case, the brick wins. The gas block absorbs one and a half times more moisture. Therefore, aerated concrete walls need additional waterproofing. It is imperative to clad the façade of the house. Usually plaster is used for this. As for a brick house, it does not need additional cladding. Although today they very often use some kind of cladding for such walls. This is siding or the same plaster.

Characteristics of aerated concrete

A comparison of brick and aerated concrete is only possible if all the features of the blocks are known. Today they have become popular in the construction industry.

For production use:

- quartz sand;

- aluminum powder;

- cement;

- quicklime;

- water.

Some manufacturers, in an effort to increase income, mix slag, ash and other industrial waste into the feedstock.

During the manufacturing process, the components are mixed, water is added, and the finished mass is poured into molds. Due to water and aluminum, a reaction occurs, the result of which is considered to be numerous pores. At this time, the mixture increases in volume and begins to harden. The blanks are cut into blocks and sent to autoclave units to impart final strength.

The porosity of the structure allows the thermal insulation qualities to be several times higher than that of brick material. The blocks are light, so a wall made of brick and aerated concrete will be the best choice.

Aerated concrete blocks have good sound insulation properties. The material's characteristics are similar to wood - it breathes, retains heat, and is environmentally friendly.

Fire resistance

This is the ability of a material to resist high temperatures. In other words, this coefficient shows after what period the structure will collapse in a fire. According to the technical requirements, both materials here correspond to the first class. What does this mean? First class materials have a time reserve for fighting fire of at least 2.5 hours.

Advantages and disadvantages

The main advantages of brick:

- Environmental friendliness

- Excellent soundproofing and thermal insulation characteristics

- Low temperature resistance

- Long service life

- Durability and reliability

So, when considering which is cheaper (brick or aerated concrete), there is no need to perform complex calculations: definitely aerated concrete. Typically, sand-lime brick is not used for the construction of foundations, fireplaces, chimneys, wells, and stoves.

- Relatively low cost

- Large size and light weight for easy installation

- Ecological cleanliness

- Good thermal and sound insulation properties

- Possibility of performing any finishing process

The thermal conductivity of aerated concrete is low, so the house will be warm.

How much does aerated concrete block and brick cost?

This question interests many. How much does an aerated concrete block cost? The price of one cubic meter is about 4 thousand rubles. Yellow brick will cost about 7 thousand rubles per cubic meter. The number of blocks and bricks per cube will be different. The speed of work completion also differs. It takes quite a long time to build a house using yellow brick. As reviews note, a good brick should correspond to a class of at least M200. And he is expensive. In addition to the price of the material itself, you need to take into account the cost of installation work. The cost of building a brick house will definitely be higher. This is even though such a house will not be lined with plaster. It must also be said that the soundproofing properties of aerated concrete are higher.

A house made of brick and aerated concrete: which material is better to choose for construction?

Both materials are quite popular materials for construction, and choosing between them can sometimes be difficult. Each product has its own set of advantages and disadvantages, giving the building certain characteristics.

In this article we will try to figure out which material should be preferred, based on the qualities that are the highest priority for a private building. We will also consider options for combining both products in construction, taking into account maximum efficiency of use.

So, a house made of brick and aerated concrete: in whose favor will the choice be the most justified and how can you combine the products in the most practical way?

Let's sum it up

In fact, a brick is 13 times smaller than an aerated block, but weighs four times more. The weight of aerated concrete masonry is 400 kilograms, and that of brick is 1800. In practice, this means that laying brick will take at least twice as long. The cost of a house made of aerated concrete will be lower. But what is better to choose? Let's briefly summarize the above:

- A high-quality aerated block will always be cheaper than a high-quality brick. In addition, it is difficult to find good bricks today. Many are trying to save money on production. The cost of a house made of aerated concrete will be lower.

- Ceramic brick has been used as a building material for more than five centuries. Many people know how such houses behave. They are really strong. But how a building made of aerated block, which appeared relatively recently, will behave is a big question.

- In terms of technical characteristics, aerated block is superior to brick. There is no need to make a thick wall and provide thermal insulation. But since the material is capable of absorbing moisture, it is impossible to do without waterproofing aerated concrete. Therefore, external finishing is mandatory. A brick wall can stand “naked” for quite a few years.

- Brick has a high load-bearing capacity. Therefore, load-bearing walls are always made of it.

As you can see, these materials have several differences. It’s impossible to say unequivocally which is better – aerated block or brick. Both have their positive and negative qualities. But still, many people prefer to use a gas block. Some have formed a strong belief in their minds that a durable house should only be made of brick. This is wrong. If you need to erect a structure in a short time and at the same time it must be reliable, you can proceed as follows. Brick is used for load-bearing walls, and gas block is used for all others. This is the best option for building a private house. Although some also make load-bearing walls from aerated concrete. Experts say that this can be done, but only if it is a one-story house with an attic.

Brick house

Wooden, aerated block, foam block, frame, reinforced concrete panels - the choice of materials for building a house is great. But the leading position is still held by the classic – brick, proven over centuries. There are several types of this material and corresponding markings according to their properties.

Technical specifications

Brick is characterized by two key performance properties according to GOST: frost resistance and strength.

Frost resistance is the number of freeze-thaw cycles that a material can withstand without external deformation and a decrease in strength by no more than 20%. The frost resistance of bricks is marked with the letter “F” and a number (number of cycles).

For example! Brick F25 indicates low frost resistance and is used only for interior work.

| Marking | Decoding |

| F35 | Average. Used for building construction in warm mild climates |

| F50 | Frost resistance level is above average. Used for cladding work |

| F75 | High criterion. Popular in the construction of multi-story buildings |

| F100 - F300 | Used for the construction of houses exposed to low temperatures |

On a note! For regions with snowy winters and extremely low temperatures, consider bricks from the F75 mark.

Strength indicates the permissible load that 1 cm² of brick surface can withstand. The designation is marked with the letter “M” and a number.

| Brand | Characteristic |

| M75 | Low strength of the material. Used, for example, to build a fence. Low cost |

| M100 | Brick of this brand is used for simple construction of up to 3 floors. Low price |

| M125 | High-strength brick for building houses up to 3 floors, partition columns |

Thus, brick M150 and higher are considered for the construction of multi-storey buildings. The base of the building, foundation, plinth, elevator shafts, chimneys are laid with M200-M300 grade bricks.

Types of bricks

There are several varieties of this building material, each of which is characterized by its own operational characteristics.

- Ceramic. The brick is made from red clay and fired in a kiln at a temperature of 1000°C. Resistant to any weather. Is used for:

- masonry of interior partitions and load-bearing walls;

- house cladding: inside and outside;

- interior decoration.

- Sand-lime brick consists of a mixture of sand + lime. Frost resistance is lower than ceramic ones, but thermal conductivity is higher. A house made of sand-lime brick will turn out cold. Walls easily absorb moisture. Not suitable for building a foundation. This material is best used for laying partitions inside the house.

- Clinker. A homogeneous product without voids is obtained from refractory clays and fired at a temperature of 1200°C.

The brick is frost-resistant, water-permeable, and does not react to aggressive substances: alkali, salt. Is used for:

- facing the facade of the house;

- paving areas;

- arrangement of drains.

Brick also happens:

- Full-bodied. It is characterized by high strength. It is used where the load is colossal - in the masonry of the base and plinth of the house, external load-bearing walls and columns. Solid brick walls require insulation.

- Hollow. There are holes in the material. The more voids with air, the better the product retains heat. In demand for masonry of internal and external walls of low-rise buildings.

A private brick house, based on the quality of the chosen material, has pros and cons.

Advantages:

- The main advantage is durability and strength. A well-built house does not require major repairs for more than a century.

- Brick housing is not afraid of natural weather: frost, wind, rain.

- Eco-friendly house.

- The brick structure “breathes”. Therefore, it is not hot in summer and not cold in winter.

- Fireproof.

- High sound insulation.

- Simple masonry technology. If desired, a non-specialist can also master it.

Video instructions on types of masonry

Flaws:

- A high-quality brick house is an expensive pleasure. Costly not only in terms of money, but also in terms of construction time.

- A brick house requires a strong, deep foundation. The base must be resistant to the forces of frost heaving. Otherwise, the walls will crack.

- Expensive work for a mason.

- A brick house requires additional insulation.

Brick properties

Brick is an environmentally friendly, strong and durable building material. There are brick buildings whose age has long exceeded a thousand years. It is made from natural materials: water, lime and quartz sand, if we are talking about silicate sand, and clay, which is the raw material for ceramic bricks.

Sand-lime brick has a higher density than ceramic brick and is a good sound insulator, and its strength and frost resistance are far superior to all lightweight concrete existing today. Houses built from it are not afraid of either heat or cold and have been pleasing the eye with their elegant appearance for decades.

Table of brick strength limits.

The only thing that sand-lime brick is afraid of is excess moisture, since it softens the lime contained in the brick. It also does not like constant exposure to high temperatures, and therefore is not suitable for the construction of stoves, fireplaces, sewer wells, chimneys and underground parts of foundations.

But when it comes to brick houses, they often mean a house made of baked clay bricks. Over its long history, this brick has repeatedly proven its strength and durability. Clay bricks are divided into two types - ordinary or regular and front. The latter is manufactured using a special technology that makes it ultra-durable and virtually invulnerable to adverse environmental influences.

Both types of clay bricks are characterized by high frost resistance, increased strength and stability. Despite the fact that they are made exclusively from clay, such bricks absorb little moisture, and if this happens, they dry quickly without losing their original properties. Pressed and fired clay provides the brick with a high density, allowing it to withstand significant loads.