For the construction of any object, brick is required; the solid ceramic version occupies a leading position. With its help, walls are erected both inside and outside the building. It has unique characteristics that allow it to retain heat indoors and also resist negative environmental factors.

Solid ceramic bricks are made from environmentally friendly clay; several types of raw materials are rarely used in production. After harvesting and shaping, it is fired at high temperatures in a kiln. It has a matte surface and produces a ringing sound when struck. There are practically no voids inside the product.

Advantages and disadvantages

//www.youtube.com/watch?v=gbaS4bKKlJo

Builders highlight both positive and negative aspects of this material. The advantages include:

- According to international standards, the product should have no more than 13% voids. The surface has smooth or embossed sides, making it very convenient to use and easy to join one material to another.

- Thanks to the monolithic structure, it is very strong in bending and compression.

- A small number of voids contributes to a small amount of moisture absorption, which allows the brick to withstand severe frosts perfectly.

- They are used in the construction of fireplaces and stoves, since high temperatures do not destroy the integrity of the bar.

Despite the positive aspects of this building material, it also has a downside:

- walls made of such bricks are quite cold and require additional insulation;

- expensive material compared to other types;

- Ceramic solid bricks are very heavy; therefore, much more clay is required for production.

If you plan to build walls using ceramic solid bricks M 150, then they can be insulated using hollow facing material.

Dimensions and specifications

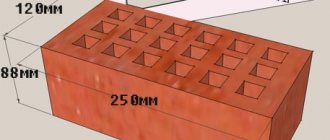

The dimensions of the M 150 brick are nominal. A single block is 250 mm long, 120 mm wide, 65 mm high, a one-and-a-half block measures 250*120*88 mm, and a double block measures 250*120*138 mm. There are also non-standard sizes: quadruple, eighth, restoration, European. The weight of one single block is from 3.6 to 4.5 kg.

The main distinctive characteristics of the building material are strength and frost resistance. Strength is considered the ability of a material to resist internal stress and external changes in shape. Conventional letter designation M (brand) and a number indicating the load that the block can withstand per 1 cm2. Brick brand M 150 is durable, capable of withstanding significant loads - 150 kg in compression and bending. Products with grades lower or higher are also produced, for example, M75 or M200. Frost resistance is indicated by the letters Мрз, is calculated in cycles and means the ability of a product to withstand loads of freezing and thawing at time intervals.

Types of blocks

According to their intended purpose, KR bricks are divided into ordinary (also known as construction or ordinary) and facing (facing). Depending on the filling density, it can be solid or hollow. The solid product is durable, voids account for less than 13% of the total volume. There is also a separate type of porous red brick, which is also made from clay by extrusion with the addition of various fillers, which form pores (chambers). Thanks to the air holes of the porous block, its thermal properties are higher and the weight is significantly less.

Sand-lime brick has largely similar characteristics. It is also durable, resistant to temperatures, but is susceptible to moisture. The raw material for production is a mixture of 85-90% lime and sand. Hence its color from white to ivory. Silicate brick of the SORPo M150 brand is used for finishing facades. Painted white, smooth in texture, highly durable.

Characteristics

The building block has the following characteristics:

- Compressive strength. Indicates the expected load in kg on a surface in cm². According to the standards, bricks are produced with the markings M75, M100, M125, M150, M250. The numbers show the magnitude of the tensile strength. This characteristic allows you to select a material in accordance with the planned load on the structure.

- Frost resistance degree. The ability of a bar to withstand a certain air temperature. Designated F. Bricks produced are F15, F25, F35, F50. In countries with a warm southern climate, material with characteristic F15 is used. For northern regions with low average annual temperatures, the use of F50 is mandatory.

- Moisture absorption rate. Solid brick has this indicator of at least 8%, and porous brick - 6%.

- Size. Ceramic M bar can be made both in standard sizes and in individual sizes for decorative purposes. It all depends on what purpose the material is used for. One-and-a-half or double bricks can be made. However, such production is discussed in advance with the buyer. Thicker products are used for the construction of load-bearing structures, fireplaces, and stoves.

- Appearance. Building bricks must have smooth edges, straight edges and a flat surface of the edges. The finished bars should be free of stones and lime. If the building material contains large particles, they will eventually become wet, swell, and the product will subsequently begin to allow large amounts of moisture to pass through. The production of bricks with rounded edges is allowed.

- Weight. The weight of this type of brick should not be more than 4.3 kg. If the block weighs more or less than the standard value, then it already loses all its universal characteristics and the quality deteriorates.

On the front side of the product there should be no cracks, dents, chips, stains, or discolorations that are noticeable at a distance of less than 10 m. Such defects will lead to further damage to the building block, and accordingly the structure will have poor characteristics.

Product Specifications

The manufacturing technology for M 125 bricks can be different: semi-dry pressing or plastic molding. But in any case, according to GOST, the product is fired in a kiln at high temperatures. There are various modifications of the product. There are:

- private;

- facing;

- full-bodied;

- hollow.

The choice depends on the purpose of the material.

Facing brick M 125

Hollow brick M 125 has a textured surface, and is usually used as a facing material for the external and internal walls of buildings of various heights. They are used to decorate surfaces that have high aesthetic requirements.

Technical characteristics of facing bricks:

- size – 250x120x65 mm;

- weight – from 2.2 kg to 2.5 kg;

- water absorption – up to 8%;

- thermal conductivity - from 0.2 to 0.26 W/m.deg.C.

The even color of the product indicates its high quality. Experts recommend buying bricks for finishing from one batch. The facing brick has ideal proportions, so when laid it looks very neat and aesthetically pleasing.

Solid brick M125

Solid brick M 125 has a relatively small volume of voids, the value of which does not always reach 13%, therefore it is used for the construction of residential buildings, industrial and administrative buildings, columns, garages, outbuildings and outbuildings, warehouses. The advantage is the ability to operate the material in different climatic conditions. The product has a rough, rough surface, so during the construction of buildings it is recommended to additionally plaster the walls.

The use of the product for the construction of load-bearing structures of buildings gave it the following names: ordinary, construction, ordinary brick M 125.

Technical characteristics of solid brick M 125 correspond to GOST 530-2007, and have the following values:

- brick dimensions M 125 – 250x120x65 mm;

- bending and compressive strength - 1.4-1.6 MPa;

- weight of brick M 125 – 3.4-3.5 kg;

- water absorption – from 6% to 8%;

- frost resistance – from F50 to F75;

- thermal conductivity – 0.513 W/m.deg.S.

The porosity of a brick affects its thermal conductivity, water absorption and the quality of the resulting adhesion to the mortar. Judging by the characteristics given, brick M 125 has low thermal insulation properties, so walls built from this material must be additionally insulated.

Varieties

//www.youtube.com/watch?v=KyYhUwxBHZs

Ceramic solid brick has varieties:

- Ordinary material. It is one of the cheapest and most popular products, used for the construction of a wide variety of structures, for example, it is excellent for both internal and external walls.

- Fireclay or fireproof. It is made from a refractory type of clay, can withstand temperatures up to 800ºC, and is used for the construction of stoves and fireplaces.

- Facade or facing. They have a smooth or corrugated surface and are used for external finishing of structures.

- Shaped. It has a non-rectangular shape, can be beveled, rounded or another shape, used for the construction of arches and columns.

Construction of a structure involves the use of a certain type of material. Therefore, its choice must be approached carefully so that it corresponds to the declared characteristics and functions.

Brick M-350

This grade of strength is found only in clinker bricks. it is used for cladding building facades or decorative finishing of arches, vaults and columns. Due to its high strength and density, M-350 brick also has very high frost resistance (150 freezing and thawing cycles), low hygroscopicity (water absorption coefficient - 5%) and phenomenal durability (up to 100 years).

Now you know what brand of brick there is and where a brick of one brand or another is used. We wish you good luck!

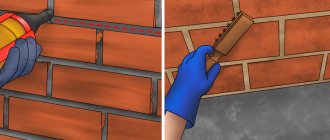

How to make

During production, solid brick goes through a number of important processes that determine its further features and characteristics.

During production, brick M 150 goes through a number of stages:

- Preparation of raw materials. It is necessary to prepare the clay, clean it of various impurities, and also treat it with steam until it becomes plastic.

- Molding. This production stage is fully automated. Using special equipment, the prepared raw material strip is cut into pieces of a certain size, and they are taken slightly larger than the final product. This is done because the manufactured bar goes through a series of processes that contribute to the shrinkage of the raw material.

- Drying. At this stage you should be extremely careful. The temperature must be added gradually so as not to damage the workpiece. Carrying out this process quickly can have a negative impact on the product; the brick will crack or burst due to a sudden change in temperature.

- Burning. It is carried out in special ovens, the temperature in which reaches 10,000ºС. The requirements for the operation must be strictly observed so as not to damage the building block.

Despite the popularity of the main production method, M150 ceramic bricks can be produced using the semi-dry pressing method:

- procurement and preparation of raw materials;

- moisturizing clay with steam;

- grinding raw materials into powder;

- filling special molds to obtain raw bricks;

- After molding, the workpiece is sent for firing.

The production method does not affect the quality of the finished product. With any production method, clay bricks must have high strength and excellent characteristics.

Types of bricks and their strength grade

<

Depending on the composition and technological features, brick is divided into two main types:

- Ceramic (made from refractory plastic clay and goes through a firing stage at a temperature of 1000 degrees);

- Silicate (made by semi-dry vibrocompression from sand (90%) and lime (10%)).

At the same time, sand-lime brick has a characteristic white color, and in order to diversify its color range, the manufacturer often adds chemical dyes to the composition.

Sand-lime and ceramic bricks have the same standard of strength grades. Therefore, let's look at each of them in more detail.

Popular types of ceramic bricks

Among the wide variety of characteristics of M150 bricks, the main types are used in construction:

- M100. It is made from environmentally friendly raw materials that are safe for human health, and is used for the construction of buildings no higher than 3 floors.

- M125. Made from high-strength raw materials, it is used to erect load-bearing structures, which subsequently need to be plastered or lined with ceramic hollow bricks; the bars are laid on special adhesive compounds.

- M150. Brick grade 150 is considered a universal building material; it is used for multi-storey buildings; it is characterized by high strength, moisture resistance and reliability, and is produced in various colors, with a smooth or corrugated surface.

Other brands of brick are less in demand in construction. Bars with greater compressive strength are used only for load-bearing structures.

Material advantages

The popularity of red brick M 125 is due to its strength and quality characteristics. The buildings erected with its help are distinguished by their reliability, durability and neat appearance. The material breathes, which eliminates the appearance of fungus and mold on the surface of the walls.

Brick is produced in various sizes:

- single;

- double;

- one and a half.

The weight of the structure and the load it will put on the foundation depend on what type of material, solid or hollow, is used during construction. When constructing walls, solid bricks are usually used, and hollow or facing bricks are used for finishing. Such masonry will add originality and neatness to the structure. If you want to save on cladding, you can use silicate stone, which looks very impressive in combination with red brick.

When purchasing material, you should pay attention to the price of M 125 brick, which is an important factor when choosing. It may vary depending on the type of product, delivery region, and the wishes of the seller. Therefore, it is worth looking for the best deals.

- Using M 125 brick, you should lay a wall whose thickness will be at least 2.5 bricks. This will eliminate unnecessary heat transfer.

- The core of a quality stone has a more saturated color than its edges.

- The ringing sound produced by the product upon impact indicates its high quality. A dull sound and a light brown color of the product indicate non-compliance with GOST.

- When purchasing a brick, you must require a certified copy of the accompanying document: a quality certificate or passport. If you do not have the necessary papers, it is better to refuse such an acquisition.

- It is advisable to familiarize yourself with the entire batch of goods. The presence of minor defects, chips, and cracks is not acceptable.

You can choose a high-quality brick by comparing its technical characteristics, which will be indicated by the labeling of the material or its description. In the passport or certificate, those interested will be able to find the weight of the product required to calculate the purchase, the quantity in the package and the name of the manufacturer.

It should be remembered that at different stages of construction, the use of different types of material will be required.

Brick grade is an indicator of strength that determines the load (in kg) per 1 sq. cm that the brick can withstand. The industry produces brick grades: 75, 100, 125, 150, 200, 250, 300. ***

How to store

Ceramic building bricks can be purchased at any time of the year, as they are weather-resistant. Products should be stored in stacks under a canopy with gaps for ventilation. If the material is in bulk, this may contribute to the appearance of chips and cracks.

The bars cannot be transported in bulk or thrown out of a dump truck, as they will become chipped and may crack and break. Proper transportation is transport on pallets.

Solid ceramic brick is a universal building material that can be used for any structure. It has excellent characteristics that allow it to be used in a variety of fields. In addition, the dimensions of the material can be different, which allows you to realize any idea of the architect.

//www.youtube.com/watch?v=GZESfATiHsM

Deviations from GOST

Brick processing is carried out according to a set time. Excessive processing, as well as insufficient heat treatment time, does not allow the product to be used for its intended purpose, since its technical properties are lost and the product is considered defective.

There are several disadvantages of bricks, due to which the products are classified as defective:

- Unburned

- Burnt out

- Inflated

- With salt stains.

You can identify an unburned brick by its mustard color and dull sound. This product is afraid of moisture and does not protect against frost.

Burnt brick has a stronger structure, but may have some deviations from the usual shape, since when burnt, the clear edges of the brick melt. The black color of this brick does not allow it to be used for construction.

Blown brick is made by adding poorly ground lime to the brick mixture, which subsequently attracts moisture. Those parts of the brick where pieces of lime come across will chip off over time. According to the standards, bricks with small chips may be allowed for sale, but they are not allowed to be used as facing bricks.

It is impossible to notice efflorescence on bricks at the stage of purchase and delivery of bricks. This deficiency manifests itself over time when the salts present in the cement, brick and environment begin to interact.

The appearance of efflorescence is promoted by poor-quality storage and laying of bricks. During storage and during the construction phase, bricks and unfinished objects must be protected from moisture.

Strength grade is the main characteristic of brick quality. Any – both ceramic and silicate. It is determined by the results of testing the finished product for bending and compression. The most popular building brick used in low-rise construction is M100.

To choose the right material for the construction of any object, be it a residential building, an outbuilding or a fence, you need to understand its features, and not focus only on appearance. This will help you avoid unnecessary expenses and be confident in the quality and durability of the constructed structure.

Where is this brand of brick used?

The higher the brand, the higher the price of the brick. Therefore, when building private houses and outbuildings, there is no point in spending money on expensive material if a cheaper one can cope perfectly with the load placed on it.

It can also be used for constructing internal non-load-bearing walls and partitions during multi-storey construction. But the scope of application is determined not only by the brand, but also.

Types of M100 bricks according to their hollowness

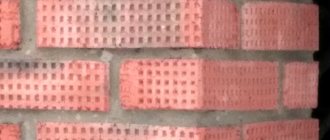

Artificial stone of any composition and any brand can be solid or hollow.

- Solid products are those in which there are no pores or voids at all or their volume does not exceed 13%. This is an ordinary brick with a very wide range of applications. It is used for the construction of load-bearing walls, the construction of foundations and plinths, being the main material for such structures.

Note. The thermal insulation properties are lower than those of hollow walls, so walls made of it require additional insulation.

- In hollow or void volume is more than 13%. The presence of air-filled voids increases the thermal insulation capabilities of the material, so it is used mainly for the construction of external walls, as well as for their cladding. However, the same voids make the brick insufficiently resistant to moisture: when water penetrates into them, it increases in volume and leads to its destruction. For this reason, it cannot be used for the construction of plinths and foundations, wells and wet walls.

Voids can be either through or not through, and their shape is oval, square, round or slot-like.

Both solid and hollow M100 products do not have very good wear resistance, which is why there are instructions that do not recommend them for the construction of multi-story buildings.

Unlike facing brick, which has high-quality, smooth edges, regular brick has a rough surface, which provides good adhesion to the mortar and plaster mixture used for exterior and interior decoration.

Types of M100 bricks by composition

Both ceramic and sand-lime bricks can have the M100 grade.

Despite their external identity, these are completely different materials in terms of technical parameters, each of which also has its own area of application.

- Ceramic stones

of this brand are used very widely; restrictions are associated only with the presence of voids and the conditions described above. The technical characteristics of M100 ceramic bricks make it possible to use it for the construction of structures operating at high temperatures or in direct contact with fire. For example, for household stoves and fireplaces. - Silicate stones

of similar strength, regardless of the presence of voids, are not allowed for the construction of objects in contact with moisture or high temperatures. This is due to their low moisture and heat resistance. Of these, only walls and partitions are erected, which are distinguished by excellent noise-absorbing properties.

Thus, when choosing a brick of the brand specified in the project, it is necessary to take into account the specific requirements for the object. This will allow for the most rational use of finances and will be the key to the quality of the finished structure.