Fences, or fences as they are commonly called, come in different forms. They are built from wood, metal, mesh structures, and stone. But lately concrete decorative fences have become the most popular. This material is durable and manufacturable. Considering the good demand for such products, the production of decorative concrete fences has become a profitable business for many entrepreneurs.

Register for a free marathon

How to create passive income in 4 days

A marathon where you will create passive income live from scratch and learn specific strategies for investing in apartments, houses, garages, cars and even profitable sites

Begin

Concrete fence: production technology

The popularity of concrete products among residents of private households is explained primarily by the low price of fencing. In addition, manufacturing technology allows us to create stylish products of different textures and designs. With the help of concrete fences, you can make any home more attractive, add individuality to the overall exterior and emphasize the style. To all these advantages should be added the unpretentiousness of the structures during operation. They require virtually no maintenance and do not require the application of protective or decorative coatings. The production of decorative concrete fences has the right to exist as a separate business or can be combined with the production of other concrete products, for example, paving slabs.

What equipment to choose for the production of concrete fences

The minimum set of equipment for the production of decorative fences includes:

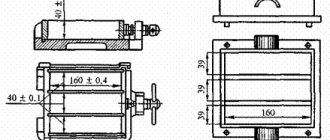

- Vibrating table for forming concrete structures with two electric vibrating motors;

- Concrete mixer (concrete mixer);

- Vibrating sieve for sifting sand and cement;

- A set of molds for the manufacture of panels and pillars;

- Pallets for drying finished products.

The most expensive cost item when starting a business is purchasing a set of forms. Forms are divided into two types: forms for panels (solid, openwork, double-sided) and forms for pillars. Since the fence comes in different thicknesses, heights, designs, etc. To create a wide range of concrete structures, a variety of forms themselves is necessary. Plus, in order to produce a normal volume in one working cycle, up to 5 molds of the same type are required. Thus, the total number of forms, even in a small enterprise, can be over 50 pieces.

The cost of one mold for a panel is on average 15 thousand rubles, molds for pillars are 8 thousand rubles. a piece. Thus, the total cost of purchasing forms alone will be about 500 thousand rubles.

In addition to molds, production will require a vibrating sieve, a concrete mixer and a vibrating table. A mechanical vibrating sieve costs around 15 thousand rubles. The vibrating sieve is designed for cleaning sand, cement and other bulk materials from debris. The number of such machines depends on the planned production volume. If the volumes are not large, one or two pieces will be enough.

The price of concrete mixers depends on the power of the machine. Based on power and productivity, concrete mixers are divided into gravity and forced. The first option refers to portable models and is used in small industries. Gravity concrete mixers do not require a high voltage connection (380V) and do not consume a lot of electricity. The price range for such devices is from 9 to 50 thousand rubles. If the enterprise requires large production volumes, then portable concrete mixers are purchased. They are much more expensive than other models - from 60 to 500 thousand rubles. At the same time, they have increased productivity. Often require installation on a foundation.

To pour and compact concrete in plastic forms, you will need a forming vibrating table, and to remove the finished concrete fence, you will need a stripping vibrating table. The cost of both is from 15 – 18 thousand rubles. The total cost of purchasing two vibrating tables is 30 -36 thousand rubles.

Thus, the total cost of purchasing equipment will be at least 600 thousand rubles. The total investment for starting a business reaches 1 million rubles, or even higher.

Types of reinforced concrete fences

By type, reinforced concrete structures are divided into the following types:

- monolithic - for monolithic structures, smooth monolithic slabs are used, which, at the request of the owner, can be decorated to look like stone, brick, slate;

- sectional – prefabricated sectional fences made of reinforced concrete consist of separate stacked slabs and support pillars. The design can be made according to an individual design, since enterprises produce reinforced concrete slabs for fences of various shapes, patterns, and color shades.

- block - for this type of fencing, small concrete blocks are used, which are connected to each other with cement mortar. The structure must be decorated with tiles or other facing materials.

Thus, any of these fences can be not only a reliable fencing of the local area, summer cottage, industrial areas, but also a structure with an interesting decor.

Figure 2. Monolithic reinforced concrete fencing

Which room to choose for the production of concrete slabs

The total area of the premises for opening production is at least 300 m2. The minimum size of the production premises is 50 m2. The recommended production area is 250 m2. In addition to the production space, it is necessary to have a warehouse for inert materials with an area of at least 50 m2; storage warehouse for finished products, also at least 50 m2; a procurement area for cutting and welding reinforcement and a warehouse for finished products. All areas, except the warehouse, must be heated and connected to a 220V power supply.

According to legal requirements, production must be located at a distance of at least 150 meters from residential complexes, schools, kindergartens and other social institutions. The ideal location is suburban and industrial areas. The cost of renting a heated room with an area of 300 m2, depending on the region, will be from 50 thousand rubles per month.

Raw materials

The main raw materials for the production of concrete fences consist of: cement (Portland cement) grade 500-D0; construction sand GOST 8736-93; wire (reinforcement) and various plasticizers designed to speed up the setting process of concrete. For one concrete pillar 2m high, 11 linear meters of 8mm thick wire are consumed. Also, during direct installation, facade paint is used to give the desired color to the fence.

All raw materials must be of high quality, especially cement. High-strength concrete can only be obtained from special cements. Otherwise, you may end up with low-quality products and, even worse, dissatisfied customers.

Design features of a reinforced concrete fence

Compared to fences made from other reinforced concrete materials, fences have the following design features:

- the presence of an internal reinforcement frame - when pouring sections of such a fence, a special frame of corrugated reinforcement is laid inside the mold;

- use of high-quality high-strength concrete as the main material;

- resistance to temperature changes - fences made of reinforced concrete slabs can withstand both very severe frosts and heat. This allows the use of reinforced concrete fencing in various climatic zones.

- impressive weight - the weight of one section of such a fence can reach 60-70 kg.

Technology for the production of concrete fences

The most common technology for the production of decorative concrete fences is production by vibration casting. This method is considered the most effective in the production of concrete products of small thickness. The products are durable, waterproof, frost-resistant, which has a positive effect on the durability of the fence.

The technological chain for the production of concrete fences consists of the following stages:

- Preparation of concrete mixture in a concrete mixer;

- Loading the concrete mixture into a pre-lubricated mold, which is located on a vibrating table;

- Compaction and spreading of concrete mixture in a mold with the vibrator turned on. Excess concrete mixture formed during laying is removed from the mold;

- Laying reinforcement in sections of a concrete fence. The reinforcement cage is laid with the vibrator turned on;

- Vibrating the concrete mixture for 1 minute until the release of excess air stops;

- Stripping (removing) products from the mold on the stripping table;

- Place the mold back on the vibrating table to repeat the cycle;

- The finished product is transferred to a rack for further storage and imparting the required strength. Natural hardening of the product to 70% of the design strength occurs within 48 hours.

In order for the product to gain the required strength, it is recommended to maintain the room temperature at least +15 degrees. The humidity of the room is also important, which should be close to 100%. As a rule, after 5 days the product can be transported to the construction site. Although full maturity of concrete occurs only after 28 days.

The hardening time of concrete fences can be reduced by installing a drying chamber. After the drying chamber, the concrete product is ready for transportation in less than a day. Purchasing a drying chamber will require additional investment in the amount of 10 - 20 thousand dollars.

Instant stripping

Materials used

Concrete panels used for the construction of fences are produced using the vibrating cassette casting method. In this case, two different technological schemes can be used: “exposure” and “instant demoulding”. For the inexperienced reader, the difference in these technological schemes is small, but the final product is very different in quality and performance characteristics.

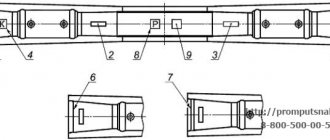

Mold for making a panel

“Instant formwork” involves casting a specially prepared mixture into high-strength matrices. At the same time, for effective work it is necessary that we have a sufficient number of stripping pallets at our disposal.

Note! The required number of pallets can be calculated by multiplying the planned daily number of cast slabs by two.

As a rule, for the production of fencing slabs using this technology, fiberglass matrices with a metal frame are used. Such forms for the production of concrete fences have a sufficient margin of safety and weigh more than 50 kg.

Preparing the solution in a concrete mixer

To produce fences using this method, a special potting mixture is used:

- Concrete grade M300 and higher.

- The water-cement ratio is 0.35.

- Filler – crushed stone no more than 5 mm.

If you plan to produce panels for fences, then the use of plasticizers is mandatory. You can also use fillers that speed up the process of strength gain and give the finished panel different shades.

To lubricate molds, you can use such compositions as “Lerossin”, “Separen” and similar ones. It is also possible to make artisanal lubricant mixtures based on mineral oils with used motor oils, fuel oil or diesel fuel, but the quality of the surface of the slab in this case is quite low.

Sequence of operations

The process of manufacturing fences using the “instant formwork” technology occurs according to the following scheme:

- The form is placed on the vibrating table, which is turned on in operating mode. The mold must be pre-cleaned and lubricated to avoid cement sticking and the formation of a defective surface.

- A mixture of the required consistency is poured into the mold. Excess mixture is cut off using a long rule, flush with the sides of the mold.

- A reinforcing mesh of rods is laid on the pouring surface, after which, under the influence of vibration, it is pressed deep into the slab. You should try to place the reinforcement as close to the center of the part as possible.

- When the compaction process is completed (this is indicated by the absence of bubbles on the pouring surface), the table is turned off .

- Two workers lift the form and place the finished section of fence on a stripping pallet.

- The form is cleared of concrete residues , washed and lubricated for the next pour.

Drying the product

Making a concrete fence with your own hands by stripping it on a pallet involves obtaining a fairly cheap material, which, however, does not have high aesthetic characteristics.

If you are more impressed by the high-tech production of concrete fences, then you should consider the technology of exposure casting.

Recruitment and remuneration

Depending on the planned production volumes, it will be necessary to hire at least 4 people - 2 people for each shift. In one work shift, 2 workers can produce from 100 to 150 m2 of concrete fence or 10 linear meters. Simple production technology does not require hiring highly qualified craftsmen. All the subtleties of production technology can be understood directly in the process of manufacturing the fence.

Labor compensation is the highest cost item in an enterprise. The wage system in such production is predominantly piecework-bonus. The master receives a salary based on the number of products he makes per shift, for example, 15 rubles per 1 m2.

Installation of reinforced concrete fence

Each type of fence is installed using a specific technology.

Often heavy monolithic fences are made in the form of spans in the form of slabs with wide horizontal bases. For such a fence, a foundation is not needed. Each slab is installed directly onto the ground using a crane. Sometimes, to install a monolithic reinforced concrete fence, its slabs are mounted in special concrete cups

The following steps are provided for the installation of a precast concrete fence:

- They first make markings for the contours of the fence - for this they use small pegs and a thick nylon cord of white or red color.

- They pour a shallow foundation - using a bayonet shovel, they dig a trench that is small in depth and width, at the bottom of which they pour a sand cushion and compact it. To fill the foundation, formwork made of smooth edged boards is installed in the trench.

- They install support posts - after a certain distance in the trench they dig or make holes for the posts using a hand drill. Support posts are installed in these holes and concrete mixture is poured. To prevent the column from tilting when it hardens, it is fixed with several pegs and wire.

- When the concrete solution hardens, the stacked slabs are sequentially inserted into the grooves of the pillars.

No special equipment is required, since the weight of the slabs does not exceed 60-70 kg, and the weight of the pillars does not exceed 90 kg. It only takes a few people to install them.

To install a reinforced concrete fence, perform the following work:

- They set up a strip foundation - to do this, they dig a small trench the width of a spade bayonet and a depth of 30-40 cm, which, after installing the formwork from edged boards, is filled with concrete mortar.

- After the concrete in the formwork has hardened, the blocks are laid on cement mortar.

- Apply a decorative coating - plaster, tiles.

How much can you earn by making concrete fences?

The main customers of such production are private households and organizations, as well as administrative structures. In other words, your client is any building or structure that requires the installation of normal fencing.

The cost of producing one linear meter of concrete fence averages 400 rubles. The selling price to the consumer is at least 1200 rubles. Profit per linear meter is 800 rubles. Fences, as a rule, are built from 1.5 meters high and several tens of meters long. Total income is not difficult to calculate.

You can make a profit not only through production, but also through the provision of fence installation services. To do this, it is necessary to create a separate team dedicated to installing fences. The cost of installation depends on the region, and averages 600 rubles per linear meter. This will naturally only increase your profits.

Features of manufacturing and operation

The production of such fences is based on a solution of cement, sand and water, which, thanks to the skills of our craftsmen, results in durable and beautiful fences. Before installing a fence made of concrete slabs, you should determine the height of the fence. As a rule, fences are made from 1m to 2-2.5m in height. If you are planning to install a fence in a small area with a compact house, it is advisable to choose a small or medium height of 1.5-2 m, while for large areas we recommend a higher height of the structure.

An undoubted advantage is the fact that a concrete fence costs less than a brick or stone one, so this choice is also profitable. offers such fences at affordable prices, and if you decide to install it, you will not need significant funds for this. In addition, we have special offers for large orders for owners of large territories and industrial facilities.

Why should you order from us?

Warranty for all products - 2 years

We are responsible for the quality of our products and fulfill our warranty obligations.

Own production base

Allows us to fulfill orders of any complexity level

Upon conclusion of the contract - free visit of a surveyor

You only pay for installation and manufacturing work

No hidden or additional fees

Our work scheme is transparent - no additional payments beyond the initial amount will be required

Financial aspect of organizing the production of decorative fences

Every aspiring entrepreneur, planning to organize a new business, is interested, first of all, in how much money is needed to implement this business project. If you decide to start producing decorative concrete fences, you will need an amount of 15-30 thousand dollars. Main expense items:

- purchase of equipment;

- business registration;

- rental of premises (advance payment);

- advertising and website creation;

- purchase of office equipment and furniture.

Additional financial injections are necessary to maintain it until it reaches the level of self-sufficiency.

Paperwork

In the process of creating a business plan, special attention should be paid to potential buyers of your products. If these are individuals, it is enough to register an individual entrepreneur, and in the case of cooperation with construction companies or government agencies, it is necessary to draw up LLC documents. In addition, to legally produce decorative concrete fences you must have:

- permits from the fire inspection and Rospotrebnadzor;

- premises rental agreement;

- labor contracts with personnel;

- documents for raw materials;

- agreements with counterparties.

Good news for budding businessmen - this line of commercial activity does not require licenses or other additional permits. Note! Even at the initial stage of registering a business, you will be asked to indicate an activity code, according to the all-Russian classifier. For manufacturers of concrete fences, this is OKVED 23.61.