The most popular use of bitumen, in which crushed stone is impregnated with a binder, is the construction of asphalt pavement. Another option for using this technology is foundation waterproofing.

There are two main types of bitumen: natural and artificially created petroleum.

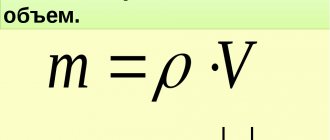

If additional protection of the foundation is necessary, materials such as bitumen and crushed stone can be used. The consistency (petroleum refining product) can be different, liquid and solid. We will consider the remaining nuances of its application and the necessary consumption for impregnation of crushed stone below.

Types and features

Table of physical and mechanical properties of bitumen.

Before we cover the question of what consumption is needed to impregnate crushed stone, let’s find out what bitumen is. This product is a substance with a solid or resin-like consistency.

It consists of various complex mixtures of hydrocarbons and its derivatives. Most often it is a combination of hydrocarbons with sulfur, nitrogen and oxygen. It is impossible to identify all its components.

- This name translated from Latin means “mountain resin”.

Bitumen is characterized by an amorphous structure; they do not have a certain melting degree.

- Resistance to acid, alkaline, and aqueous saline solutions has been proven more than once. But organic solvents, such as gasoline, turpentine, acetone and others, perform their function quite well when exposed to bitumen;

- Another property includes such an indicator as hydrophobicity. To put it another way, they are not exposed to water and do not allow it to pass through, since they have a dense structure and zero porosity.

Scheme for preparing bitumen emulsions.

It is due to these qualities that they remain impenetrable to water and resistant to low temperatures. Thanks to these properties, bitumen is a fairly popular material in construction (roofing, waterproofing) and road paving (for crushed stone). By using this impregnation, you will ensure reliable waterproofing of the foundation.

There are two main types depending on their origin:

- natural character;

- artificially created oil.

Natural bitumen is found in fossil fuels. Their extraction is most often carried out using a quarry method (or a mine), the further process of extracting bitumen from the rock is carried out using an organic solvent or by boiling down.

An artificial analogue (technical) is produced from residues of oil refining products, the coal industry and shale, which have similar compositions to bitumen of natural origin.

Purpose is divided into construction, roofing and road purposes.

Characteristics

Characteristics table

All types have special markings, which have the following meaning:

- For example, BNK is an oil roofing. The first number in the marking indicates the temperature regime at which bitumen softens, the second - penetration. This is the depth to which bitumen penetrates with a special needle, at a temperature of 25 degrees and a load of 100 g (indicated in tenths of a millimeter);

- This type, such as construction, is a flammable substance with a flash point of 220 to 240 degrees, and a self-ignition temperature of 368 degrees. Such bitumen is produced during the oxidation of oil distillation products (as well as its mixtures);

- The use of construction bitumen (BN50/50; BN70/30, BN90/10) is especially in demand in construction waterproofing work;

- Roofing bitumen has a flash point of at least 240 degrees, and a self-ignition temperature of 300 degrees. Produced using the same method as construction. Its application, in accordance with the name, is various roofing materials: glassine, roofing felt and others.

There is also a modified type. It differs from conventional ones in improved qualities due to the addition of specialized additives (polymers).

Now let's look at such an indicator as consumption.

Table for assessing the adhesion of crushed stone and bitumen.

Its consumption will depend on the purposes for which bitumen is used. For example, when installing waterproofing using bitumen, it is required to heat it to a liquid consistency. The recommended application layer is from 1.5 to 2.5 millimeters, the consumption will be from 1 to 1.5 kg per square meter.

- When making a road surface using bitumen, its filling (BND90/130) is carried out at a heating temperature of about 150 degrees, using an asphalt distributor over the entire width of the existing coating.

The surface of the layer is pre-cleaned from dirt and dust. The consumption of the substance corresponds to the following ratio, from 1 to 1.1 l/sq.m per cm of impregnating layer thickness, additional impregnation, i.e. consumption, from 1.5 to 2 l/sq.m for coating installation.

- In order to reduce consumption, asphalt concrete coatings containing activated powder are used. In this case, bitumen consumption is reduced by approximately 25%.

In addition to saving the bitumen component, there is a significant decrease in quality such as plasticity, and this circumstance directly contributes to increasing the degree of resistance of the resulting coating to deformation changes in the form of shears.

Scheme of asphalt concrete pavement installation.

Any asphalt surface is made using a hot bitumen mixture, crushed stone (gravel), sand and mineral powder. The technological order of operations includes the following stages:

- applying a primer mixture, a layer of which is 1 mm on the concrete surface;

- laying an asphalt concrete mixture (can be rigid or cast) and its subsequent compaction.

The construction of a pavement using asphalt concrete requires a mixture of rigid consistency and subsequent compaction using a mechanical roller. Manual compaction of cast asphalt concrete is permitted only when the volume of work to be done is not very large or when compaction is required in areas that are difficult to reach with a mechanical roller.

Table of adhesion of road bitumen to crushed stone surface.

Asphalt concrete, or rather its cast mixtures, is laid when constructing the pavement in strips no more than two meters wide, limited by slats that act as beacons when performing asphalt work, which will allow not to exceed the material consumption.

- It is necessary to level mixtures using a rule. It must be moved along beacons (slats), using further compaction with a roller equipped with an electric heater and weighing 70 kg;

- Completing the compaction of cast asphalt concrete is advisable if its mobility is eliminated under the influence of the roller;

- Each compacted layer, or rather its maximum thickness, cannot be more than 25 mm. Sometimes, in hard-to-reach places, rollers are used to compact the mixture;

- If there was a break in the work on laying the asphalt surface, then the edge of the previously compacted area warms up. The seams must be carefully compacted until they become invisible. Areas with defects (cracks, holes) must be cut down and covered with a hot mixture.

As for the cases when crushed stone is used for the coating, it is necessary to use parts of equal strength of natural origin.

Crushed stone, or rather its size, should correspond to a value from 25 to 75 millimeters. The main thing is not to exceed 0.7% of the thickness of the covering layer. At the initial stage, crushed stone (its layer) is processed using a wedge with a size of 15 to 25 millimeters, or pebbles no larger than 15 mm.

- Crushed stone is laid in layers of 80 to 200 mm. Do not forget that each layer must be leveled, and then compacted using a roller. When performing tamping operations, crushed stone must be treated with water. After the mobility of the crushed stone has completely disappeared and the marks from the roller have become invisible, compaction can be completed.

As noted above, crushed stone, or rather its layer, is covered with a wedge, then with small pebbles, and also with sand no larger than 5 millimeters. Having applied the above materials, the surface is moistened with water and compacted with a roller weighing 12 tons. Please note: If no marks remain after passing the roller, compaction can be completed.

In a similar way, a coating of crushed stone impregnated with bitumen is made. Before starting impregnation, the crushed stone must be dry. If it is wet, you need to dry it. The material consumption does not change, but this is the way it should be according to technology.

Most often, the grade of bitumen BN11 is used for impregnation. Impregnation is carried out by pouring hot bitumen three times in an even layer onto crushed stone (over the entire area).

- When spilled, bitumen should have a temperature of 150 to 170 degrees. After spilling for the first time, it is necessary to immediately sprinkle with a wedge. After the second and third layers of bitumen, small stones are scattered, maintaining a ratio of 1 cubic meter per 100 square meters of surface. Don't forget to distribute the stone evenly between the pieces of crushed stone;

- A coating made in this way (with impregnation) has good strength, roughness and can easily withstand traffic of about 1000 cars per day.

As a disadvantage, we can note the high consumption of the bitumen component and the not always uniform distribution of the binder between parts of the crushed stone. If bitumen is used in large quantities, shifts and wave-like bulges may appear.

And an insufficient amount affects the quality of cohesion of crushed stone and, as a result, contributes to the rapid destruction of the road surface. Therefore, it is advisable to follow the consumption recommended by experts.

Standard Requirements

Table of requirements for crushed stone and bitumen.

As is already known, a component such as crushed stone is used to construct the road surface. It is obtained by crushing rock. Depending on the construction method and type of road surface, one or the other is chosen.

I would like to note that when making a road surface using impregnation, lamellar-shaped grains can be contained in crushed stone, not exceeding 35%.

As for binding materials, the following options can be used for road surfaces:

- viscous road oil in accordance with GOST 22245-76;

- liquid road petroleum bitumen with slow and medium thickening speed (GOST 11955-74);

- road coal tar, corresponding to GOST 4641-74;

- other organic binders.

The choice of brand and type directly depends on what kind of coating is intended to be made, the purpose of the layer, the method of performing the work and other important factors.

Conditions for the operation

In accordance with SNiP 3.04.01-87 - “Finishing and insulation works”:

- Air temperature of 5°C and above at floor level and only after laying crushed stone;

- Impregnation with hot bitumen should be carried out by pouring it over the entire area evenly in three layers;

- Consumption should be from 6 to 8 liters per square meter for the first layer, for the second and third layers - from 2.5 to 3 liters per square meter. The number of degrees of hot rock resin varies from 150 to 170 degrees.

These two materials, bonded together, provide excellent waterproofing. Next, the concrete mixture is poured and the base of the room is formed. It is important to clearly calculate the consumption per 1 m2 of crushed stone and carry out the process in strict accordance with GOST.

Impregnation of crushed stone

If you are planning to build a house with a basement and a ground floor, then you cannot do without waterproofing. This is a very important stage in construction.

If you take care of installing high-quality waterproofing, you will avoid problems with high groundwater levels and inadequate foundation strength in the future.

Therefore, take our advice and take care of installing a waterproofing layer during the construction of the foundation. In any case, by doing this you will only increase the service life of your building and get rid of dampness in the premises of the house.

What consumption is most appropriate was discussed above. Next, you can familiarize yourself with the technological procedure for carrying out waterproofing work.

- Additional protection of the foundation is carried out using bitumen. They pour crushed stone intended for the foundation layer. First, you need to pour crushed stone into the prepared foundation pit for the future basement;

- Experts recommend using larger crushed stone. Filling the remaining empty spaces is done by adding smaller pieces of crushed stone;

- A mandatory action when constructing a foundation is to compact the crushed stone; in the end, its height should be about 40 millimeters. Spilling is now possible.

The layer is poured with hot bitumen, resulting in an even more reliable seal. All voids not filled with small stones must be filled with a binder.

This coating will provide reliable protection from moisture. After finishing the impregnation of the crushed stone, it is necessary to fill it with a concrete mixture.

APPROVED by Glavdortekh (letter dated 05.26.87 N GPTU-1-2/332)

The initial stage of disruption of the smoothness of the roadway is single potholes. To prevent their development, timely ongoing (pothole) repair of road surfaces is necessary. Carrying out repair work is difficult in the cold, wet period of the year, when damage to coatings occurs and progresses most intensively. A method for pothole repair of coatings using the simplest means under adverse weather conditions is proposed.

Recommendations for repairs were developed taking into account copyright certificate N 834303 based on research conducted at the Rostov Civil Engineering Institute. The recommendations were confirmed during experimental production work and introduced into the practice of road repair in the DRSU of the production management of Rostovavtodor, the North Caucasus Highway and other organizations in the country.

The recommendations were developed in accordance with the research plan of the Ministry of Road Transport of the RSFSR on the topic SD-02-76 “Improving the technology and organization of work on the repair and maintenance of highways” in the development and addition of the “Technical Rules for the Repair and Maintenance of Highways” (VSN 24-75*) / Ministry of Road Transport of the RSFSR - M.: “Transport”, 1976 in terms of organizing and performing routine repairs of road surfaces.

________________

*Here and further. “Methodological recommendations for the repair and maintenance of public roads” are in effect. — Note "CODE".

The recommendations were developed by Associate Professor, Candidate of Technical Sciences A.P. Matrosov. with the participation of engineers Shostenko N.G. and Zolotareva K.V.

NPRM Book 27 Highways

Ministry of Construction of the Russian Federation STANDARD INDICATORS FOR MATERIAL CONSUMPTION Collection 27. HIGHWAYS

Developed by engineers Z.N. Akimova, E.P. Akimova, L.G. Kolotilina, V.A. Moiseev. (State Enterprise “Tulastroyproekt”), Kuznetsov V.I., Stepanov V.A., Shutov A.A. (Main Directorate of Pricing, Estimated Standards and Consumption of Construction Materials of the State Committee for Construction of Russia), Kretova V.P., Petrukhina K.M., Rogulkina L.T., Titova V.A., Yurasova T.A. (KTI Tula), Savateev L.A. (TsNIIEUS Gosstroy Rossii).

This collection is recommended by the State Construction Committee of Russia for the development of resource estimates and statements of requirements for materials and products as part of design and estimate documentation at all levels of the investment process according to a specified (brand) nomenclature. Material consumption rates can be used by all parties, regardless of the form of ownership and departmental subordination, to determine the need for resources when performing construction and installation work, to calculate the planned and actual cost of these works based on the calculation of production costs in prices and tariffs for the period for which the estimated and actual cost of work.

GENERAL PROVISIONS

1. GENERAL PROVISIONS

1.1. Routine (pothole) repair of road surfaces is subject to areas of single destruction and deformation of the roadway: potholes, subsidence, breaks, spots, wide cracks, collapse of edges. In order to prevent intensive disruption of the evenness of coatings, routine repairs of damage and deformations should be carried out at an early stage of their development. Untimely (belated) routine repairs lead to an increase in labor and material costs required for repairs, shortens the service life of coatings, reduces the speed and increases the cost of road transportation, and negatively affects the provision of traffic convenience and safety.

1.2. Most of the destruction and deformation of road surfaces occurs in the cold, wet autumn-spring period of the year, when routine repair of pavements with heating or cutting down defective areas and filling the cuttings with asphalt concrete mixtures is difficult due to unfavorable weather conditions for the work and the preparation of repair materials.

1.3. The method proposed by these recommendations for routine (pothole) repair of coatings with crushed stone with reverse impregnation of bitumen is applicable for improved lightweight and permanent types of coatings and is advisable at low positive air temperatures in both dry and wet weather using the simplest means of mechanization and working equipment.

1.4. Repairs are mainly carried out on small-sized (up to 0.5-1.5 m) damage and deformations, mainly with steep edges, with a traffic intensity of less than 5-7 thousand cars per day. With greater traffic intensity, the proposed repair method should be considered as a temporary repair measure, followed, if necessary, by repeated repairs under favorable weather conditions using known methods provided for by the “Technical Rules for the Repair and Maintenance of Highways” (VSN 24-75), including using special road repair machines such as DE-5, DE-5A, MTRDT, MTRD, road repairman 5320, road master 4101, etc.

1.6.* Reverse impregnation of crushed stone with bitumen (from bottom to top, as opposed to impregnation from top to bottom) is based on the foaming effect that occurs when hot bitumen interacts with the cold, damp (natural humidity) surface of repair crushed stone and the coating being repaired. Foaming of bitumen is accompanied by partial displacement of moisture from the surface of the coating and mineral material, which helps ensure the adhesion of the binder material to them. ________________ * Numbering corresponds to the original. — Note "CODE".

1.7. Reverse impregnation allows the use of ordinary stone material, which is unsuitable for impregnation from top to bottom, where pure one-dimensional crushed stone is required.

1.8. The service life of areas repaired by reverse impregnation depends on the materials used, the intensity and composition of traffic and exceeds 2-5 years. The cost of repairing coatings with crushed stone with reverse impregnation with bitumen is on average 1 ruble. by 1 m (Appendix 1).

Asphalt consumption per 1 m2

How to calculate asphalt consumption per 1 m2?

Proper calculation of asphalt when paving is very important. The first advantage is the elimination of spending money on the purchase of unnecessary materials and excess asphalt. The second advantage is that you will not allow the road construction company to inflate the estimate and deceive you.

What affects asphalt consumption per m2?

Asphalt consumption per m2 is based on the following factors: layer thickness and type of asphalt mixture. Asphalt varies in density and grain size. The asphalt composition for each new project is selected individually, after a preliminary inspection of the area by our specialist.

Asphalt consumption per m2 with a layer thickness of 1 cm

Our many years of experience have given us the opportunity to formulate a clear action plan and identify average asphalt consumption values per 1 m2. We did this to facilitate our work and to conveniently calculate asphalt consumption by the customer.

Asphalt consumption per 1 m2 with a layer thickness of 1 cm:

- fine grain raft. type A m I - 25.7 kg.

- fine grain raft. type B m I, m II - 24.6 kg.

- fine grain raft. type B m II - 24.9 kg.

- sand raft type G m II - 25.0 kg.

- sand raft type D m II - 23.2 kg.

- fine-grained pore. m I, m II - 24.8 kg.

- coarse-grained pore. m I, m II - 24.2 kg.

- crushed stone-mastic-15 - 25.8 kg.

- crushed stone-mastic-20 - 25.7 kg.

We can conclude that the approximate consumption of asphalt per 1 sq.m. with a layer thickness of 1 cm it is equal to 25 kg. That is, when paving in 1 layer according to GOST thickness. 4-5 cm, you will need 100-125 kg of asphalt.

Calculation of material consumption

In order to correctly calculate the consumption of asphalt concrete during asphalt paving , you need to know the total area of the territory, thickness. layer and type of mixture. The type of mixture can be determined after a free visit from our engineer.

MATERIALS USED

2.1. To repair coatings with crushed stone with reverse impregnation with a binder material, it is advisable to use petroleum road viscous bitumen: BND 130/200; BND 90/130. In the absence of bitumen, coal tar and resin are used as an exception (experience of Rostovavtodor).

The temperature of bitumen when pouring it onto the repaired coating in order to increase the intensity of foaming should be close to the upper limit of the operating temperature (180-200 ° C).

2.2. Crushed stone obtained by crushing massive rocks, boulder stones, coarse gravel and non-disintegrating metallurgical slags should be used as a mineral material. The grade of crushed stone must be at least 600 in terms of crushability, in terms of wear in the shelf drum no less than I-IV, and in terms of frost resistance no less than Mr3 50.

2.3. Crushed stone can be one-dimensional with a fraction size of 5-15; 10-15; 15-20 mm. You can use crushed stone mixtures of optimal granulometric composition intended for porous asphalt concrete with a crushed stone size of no more than 20 mm. In the absence of these materials, in some cases it is allowed to use ordinary crushed stone, no more than 20 mm in size, containing dust and clay particles in an amount of less than 3% by weight. The crushed stone used does not need to be dried, but it should not be wet or contain free water.

2.4. If there is a shortage of high-quality mineral materials, as an exception, it is possible to use sand and gravel materials (the experience of Rostovavtodor).

2.5. To repair roads with a traffic intensity exceeding 7 thousand cars per day, it is advisable to use durable blackened crushed stone with a fraction size of 15-20 mm (experience of Sevkavavtorog).

Our staff is highly experienced and takes pride in the quality of services provided.

Crushed stone with delivery in St. Petersburg and the Leningrad Region.

You can purchase crushed stone at an optimally low price only directly from the quarry from the manufacturer. The crushed stone quarry carries out wholesale and retail sales of crushed stone and delivery of crushed stone to the site, bypassing a whole network of intermediaries and resellers, which guarantees a benefit in the cost of crushed stone for construction organizations and individuals.

COST OF GRANITE CRUSHED STONE

COST OF LIMESTONE CRUSHED STONE

fraction 20-40 mm

fraction 40-70 mm

fraction 25-60 mm

COST OF CRUSHED STONE-SAND MIXTURES WITH DELIVERY

The exact cost of crushed stone with delivery must be clarified with the company’s managers. The cost depends:

- from the location of your facility (distance from the storage site)

- on the volume of purchased material

- on your preferred form of payment

You can also order from us

Orders completed today

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

Back forward

Crushed stone Koltushi

You need to buy small crushed stone in Koltushi, preferably clean and sifted. It will be used for asphalting a site on the territory of a facility under construction. Upon reaching an agreement on the contract, I am ready to place an order for the purchase and delivery of crushed stone to Koltushi.

Crushed stone Kolpino

Do you have granite crushed stone, fraction 5-10? If yes, then I’m ready to buy 2 tons of crushed stone with transportation to Kolpino. Further cooperation is also possible regarding the purchase of non-metallic materials in St. Petersburg.

Crushed stone Nikolskoye

I am making a path for parking for two cars, in the area in front of the cottage. You need crushed stone in Nikolskoye, it is advisable to deliver crushed stone on the weekend.

Crushed stone Ropsha

We need high-quality crushed stone for backfilling paths at a facility located in Ropsha. We plan to buy crushed stone from you with delivery directly to Ropsha.

Crushed stone Krasnoye selo

I will buy crushed stone, several cars with a fraction of 20 to 40, delivery to Krasnoye Selo. Payment on the spot, crushed stone is needed for a large construction project, further cooperation on the purchase of crushed stone and other non-metallic materials is possible.

Crushed stone Otradnoye

Is it possible to order crushed stone in Otradnoye ? A machine for delivering crushed stone is also needed. Payment on time, ready to buy crushed stone in quite large quantities, about 10 tons needed.

MEANS OF MECHANIZATION AND TOOLS

3.1. A truck with a three-seater cabin or a special repair vehicle is equipped with a bitumen boiler-thermos, a hopper or compartment for mineral material, and a place for tools. Working equipment can be placed on a trailer attached to a transport vehicle. The bitumen boiler can be installed on a separate trailer.

3.2. The boiler, filled with hot bitumen at the base, is equipped with a gas or liquid fuel nozzle for heating the binder. Heating is possible using a dropper and a flame pipe mounted in the boiler (improvement proposal from the Salsky DRSU of Rostovavtodor). It is also possible to use an asphalt distributor.

3.3. A distribution hose with a nozzle for pouring bitumen, and in its absence, a distribution nozzle, is placed in a hot chamber built into the boiler tank.

3.4. The crushed stone compartment or hopper is installed so as to provide good access to the material.

3.5. Hand tools are placed in the body of the vehicle: scrapers, brooms, shovels, trowels, a tamper, a lath, a ruler-feeler, as well as signaling barriers (two signs 1.23 “Road work”, a fencing barrier with signs 3.24 “Maximum speed limit” attached to it) and 4.22 “Avoiding obstacles”). To ensure fire safety, the vehicle is equipped with an additional fire extinguisher, and for labor safety purposes, with an additional first aid kit.