Aluminum formwork for walls and columns - prices, purchase and rental

Aluminum formwork for walls, columns and panels are used in monolithic housing construction and are modular frame structures made from aluminum profiles using high-precision technology. The thickness of the profile is 14 cm. The deck of the panels is a special waterproof plywood 18 mm thick, laminated with a melamine film, the ends of which are protected from moisture by an aluminum profile mounted on a sealant.

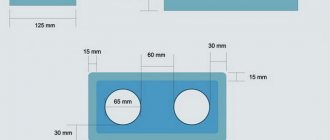

The assembled aluminum wall formwork is shown in the figure.

It consists of the following elements:

- main and additional linear shields;

- external and internal corner panels;

- hinged shields;

- universal shields;

- one- and two-level struts;

- couplers, coupling screws and nuts, pivots and angles;

- wedge locks, eccentric, extended;

- brackets for fastening scaffolds.

Component fasteners are made from durable steel grades. The various sizes of panels allow us to assemble formwork from them suitable for all types of buildings. By combining different types and dimensions of panels, you can choose the optimal formwork for non-standard wall panels and partitions.

Construction and dimensions of aluminum formwork

The frames of aluminum panels can have a rectangular or special profile with transverse stiffening ribs located parallel across the width in increments of 29 cm.

The protruding edges of the front side of the frame, into which a deck of laminated plywood sheets is inserted and fastened, are designed to protect the vulnerable end part of the plywood sheets from mechanical damage.

The ribs provide the strength and rigidity of the formwork necessary to support the load of the concrete layer.

The panels are produced by welding a pressed profile from A-7 grade aluminum. The holes for the tie bolts are located along the long side of the frame profile symmetrically from both sides, which makes it possible to articulate them vertically and horizontally. Quick and convenient connection of panels is ensured by leveling locks. The deck can be birch plywood grade FK, FSF with laminate or ISOPLYFORM with a plastic outer layer.

The main linear panels have a height (length) of 3000 or 3300 mm. Additional panels are available in heights of 600, 1200 or 2500 mm. The width of all panels has a standard range of standard sizes: 25, 30 cm and then in increments of 10 cm to 120 cm. It is possible to manufacture aluminum formwork of other dimensions according to individual projects.

Characteristics of aluminum formwork

Main technical characteristics of aluminum panels:

- withstandable pressure of concrete solution - up to 80 kPa;

- permissible span deflection - no more than 0.25%;

- maximum load per 1 sq.m. scaffolding - 180 kg;

- number of cycles of use: plywood deck with a laminated surface - up to 80, plywood deck with a plastic surface - up to 250, aluminum frame - up to 300;

- average mass of the assembled shield - 35 kg/m2;

Aluminum panels have distinctive features that give them advantages over other similar products, which are expressed in the following:

- they have very high anti-corrosion resistance and have a long service life;

- the versatility of the design makes it possible to use various combinations of panels to assemble non-standard formwork;

- high strength and stability of prefabricated formwork;

- high resistance to wear, allowing the panels to be reused a large number of times, without compromising the quality, use used frames and decks;

- the small weight allows the installation of formwork to be carried out in practice without the involvement of cranes and similar mechanisms.

Aluminum formwork weight

| Shields 2.5 m high (additional) | Shields 3.0 m high | Shields 3.3 m high | |||

| Size (W*H), m | Weight, kg | Size (W*H), m | Weight, kg | Size (W*H), m | Weight, kg |

| Linear aluminum panel formwork | |||||

| ShchD 1.2x2.5 | 100 | Shield 1.2x3.0 | 114 | Shield 1.2x3.3 | 121 |

| ShchD 1.0x2.5 | 87 | Shield 1.0x3.0 | 97 | Shield 1.0x3.3 | 105 |

| ShchD 0.9x2.5 | 80 | Shield 0.9x3.0 | 90 | Shield 0.9x3.3 | 99 |

| ShchD 0.8x2.5 | 73 | Shield 0.8x3.0 | 82 | Shield 0.8x3.3 | 86 |

| ShchD 0.74x2.5 | 70 | Shield 0.78x3.0 | 79 | Shield 0.78x3.3 | 85 |

| ShchD 0.7x2.5 | 68 | Shield 0.74x3.0 | 76 | Shield 0.74x3.3 | 82 |

| ShchD 0.6x2.5 | 60 | Shield 0.7x3.0 | 73 | Shield 0.7x3.3 | 79 |

| ShchD 0.5x2.5 | 53 | Shield 0.7x3.0 | 69 | Shield 0.65x3.3 | 75 |

| ShchD 0.4x2.5 | 46 | Shield 0.65x3.0 | 65 | Shield 0.6x3.3 | 71 |

| ShchD 0.3x2.5 | 38 | Shield 0.6x3.0 | 61 | Shield 0.55x3.3 | 67 |

| ShchD 0.25x2.5 | 34 | Shield 0.55x3.0 | 58 | Shield 0.5x3.3 | 63 |

| * | * | Shield 0.45x3.0 | 53 | Shield 0.45x3.3 | 59 |

| * | * | Shield 0.4x3.0 | 50 | Shield 0.4x3.3 | 55 |

| * | * | Shield 0.3x3.0 | 42 | Shield 0.3x3.3 | 47 |

| * | * | Shield 0.25x3.0 | 39 | Shield 0.25x3.3 | 44 |

| Universal formwork panels (SCF) | |||||

| Control room 1.2x2.5 | 114 | Control room 1.2x3.0 | 126 | Control room 1.2x3.3 | 138 |

| ShchU0.8x2.5 | 83 | ShchU 0.8x3.0 | 90 | ShchU 0.8x3.3 | 99 |

| Corner formwork panels | |||||

| SHCHUV 0.3x0.3x2.5 | 49 | SHCHUV 0.6x0.6x3.0 | 104 | SHCHUV 0.6x0.6x3.3 | 109 |

| * | * | SHCHUV 0.5x0.3x3.0 | 75 | SHCHUV 0.5x0.3x3.3 | 83 |

| * | * | SHCHUV 0.4x0.4x3.0 (external) | 75 | SHCHUV 0.4x0.4x3.3 | 78 |

| Hinged formwork panels (ShchSh) | |||||

| ShchSh 0.5x0.5x2.5 | 77 | ShchSh 0.5x0.5x3.0 | 93 | ShchSh 0.5x0.5x3.3 | 102 |

| ShchSh0.3x0.3x2.5 | 57 | ShchSh 0.3x0.3x3.0 | 68 | ShchSh 0.3x0.3x3.3 | 78 |

| * | * | ShchShN 0.1x0.1x3.0 (external) | 33 | ShchShN 0.1x0.1x3.3 (external) | 36 |

To make it easier for buyers to find organizations where they can buy or rent aluminum prefabricated panels without intermediaries, we provide a table with estimated prices for these products from various companies.

Source: https://opalubka-tut.ru/opalubka-sten/alyuminievaya-opalubka-dlya-sten-i-kolonn-ceny-pokupka-i-arenda

Panel aluminum formwork

Sale price: from 3200 rub. / m2

Rental price: from 15 rub. / 1 m2 per day

In order to buy or rent aluminum panel formwork, call our number in Moscow. We will answer all your questions and place your order as quickly as possible. Delivery is carried out throughout Russia and the CIS countries.

[contact-form-7 404 “Not Found”]

Aluminum panel formwork is widely used in the construction of monolithic reinforced concrete structures for residential, industrial and hydro-industrial construction, small and multi-storey buildings.

Specifications

Under the influence of the perceived load, the load-bearing elements and the forming surface should not exceed a deflection of 1/400 of the span

The pressure exerted on the formwork by concrete is 80 kPa.

Formwork turnover:

- Shield decks – does not exceed 80 cycles.

- Shield frame - does not exceed 300 cycles.

Shield dimensions:

- Height - 0.6, 1.2, 2.5, 3.0, 3.3 meters.

- Width - from 0.25 to 1.2 meters.

Fastening wall formwork panels

With a tie rod, the shields are connected through tapered holes with a nut and washer. To prevent concrete from getting onto the tie rod, a tube is placed over it, and cones are placed to seal its holes.

Wedge locks are used to fasten the panels together. Their number is directly related to the size of the shields.

Using two wedge locks, the shields are connected: the main one and the additional one. If the height of the additional shield exceeds 2.7 meters, then they are fastened with locks with a kingpin and a leveling beam.

Dismantling

Before the aluminum wall formwork is dismantled, it is necessary to ensure that the concrete has hardened at least 70%. This usually happens three weeks after pouring the solution. First of all, the elements are removed from the corners of the structure, since they bear the smallest load. After 24 hours, the external brackets and fastenings are removed, and only then can the shields be removed. But this must be done extremely carefully and carefully, otherwise the edges or concrete coating of the structure may be damaged. In other words, the quality of the structure depends not only on careful and high-quality assembly, but also on careful dismantling.

Panel aluminum wall formwork

This formwork is used in the construction of monolithic residential and industrial buildings. This is a multifunctional structure consisting of frame modular panels that are assembled directly on construction sites.

Shields come in the following types: linear, internal corner, external corner and hinged. All of them are needed to shape the surface of concrete structures.

The frames of the panels are made with a closed contour from a high-precision aluminum formwork profile and are made from a special and rectangular profile.

A special profile is needed to form the perimeter of the entire frame; a rectangular profile is placed inside. When pouring concrete, it is needed to form a stiffening rib.

The production of aluminum formwork is carried out in accordance with strict technological standards, so the final products are durable and of adequate quality. In our company you can buy or rent new or used aluminum wall formwork at competitive prices, save money and quickly get everything you need.

Prices

Name Weight, kg. S, sq.m. Used price, rub. New price, rub.

| Linear shield 1.2x3.0 | 114 kg. | 3,6 | 9000 | 13 389 |

| Linear shield 1.0x3.0 | 105.5 kg. | 3,3 | 8900 | 12 771 |

| Linear shield 1.0x3.0 | 97.0 kg. | 3,0 | 8000 | 12 164 |

| Linear shield 0.9x3.0 | 90.0 kg. | 2,7 | 6750 | 11 012 |

| Linear shield 0.85x3.0 | 86.5 kg. | 2,55 | 6375 | 10 929 |

| Linear shield 0.8x3.0 | 82.0 kg. | 2,4 | 6000 | 10 638 |

| Linear shield 0.78x3.0 | 79.0 kg. | 2,34 | 5850 | 10 192 |

| Linear shield 0.76x3.0 | 77.0 kg. | 2,28 | 5550 | 10 016 |

| Linear shield 0.75x3.0 | 76.0 kg. | 2,25 | 5250 | 9912 |

| Linear shield 0.7x3.0 | 73.0 kg. | 2,1 | 4875 | 9351 |

| Linear shield 0.65x3.0 | 69.0 kg. | 1,95 | 4500 | 8874 |

| Linear shield 0.6x3.0 | 65.0 kg. | 1,8 | 4125 | 8438 |

| Linear shield 0.55x3.0 | 61.0 kg. | 1,65 | 4455 | 8075 |

| Linear shield 0.5x3.0 | 58.0 kg. | 1,5 | 4050 | 7670 |

| Linear shield 0.45x3.0 | 53.4 kg. | 1,35 | 3645 | 7400 |

| Linear shield 0.4x3.0 | 50.0 kg. | 1,2 | 3252 | 7000 |

| Linear shield 0.3x3.0 | 42.3 kg. | 0,9 | 2700 | 6176 |

| Linear shield 0.25x3.0 | 38.8 kg. | 0,75 | 2250 | 5823 |

| Linear shield 0.2x3.0 | 34.5 kg. | 0,60 | 2100 | 5250 |

| Internal corner panel 0.3x0.3x3.0 | 56 kg. | 1,8 | 5400 | 9497 |

| Internal corner panel 0.3x0.5x3.0 | 69 kg. | 2,4 | 7200 | 11 106 |

| Internal corner panel 0.4x0.4x3.0 | 75.4 kg. | 2,4 | 7200 | 11 022 |

| External corner panel 0.5x0.5x3.0 | 104 kg. | 3 | 9000 | 14 458 |

| External corner panel 0.6x0.6x3.0 | 114 kg. | 3,6 | 10 800 | 15 226 |

| Universal shield 0.7x3.0 | 70 kg. | 2,1 | 7350 | 12 050 |

| Universal shield 0.75x3.0 | 73 kg. | 2,25 | 7875 | 12 434 |

| Universal shield 0.8x3.0 | 77 kg. | 2,4 | 8400 | 13 586 |

| Universal shield 0.9x3.0 | 84 kg. | 2,7 | 9450 | 13 835 |

| Universal shield 1.0x3.0 | 91 kg. | 3 | 10 500 | 14 852 |

| Universal shield 1.1x3.0 | ?? kg. | 3,3 | 11 550 | 15 932 |

| Universal shield 1.2x3.0 | 107 kg. | 3,6 | 12 600 | 16 638 |

| Hinged shield 0.3x0.3x3.0 | 67.5 kg. | 1,8 | 6300 | 11 721 |

| Hinged shield 0.5x0.5x3.0 | 92.7 kg. | 3 | 10 500 | 14 325 |

Classification

Aluminum formwork is conventionally divided into several types according to different parameters.

By type of product design there are:

- Universal.

- Linear.

- Corner.

In this case, corner products are hinged, rectangular, external and internal. But they can be replaced by ordinary linear models, which are positioned in relation to one another at an angle of 90°, after which they are firmly fixed. To correctly adjust the size of the system to the parameters of a specific design, additional elements are used.

According to their purpose, products are divided into the following types: universal, flow, wall, column. But regardless of the type and type of system, its main characteristics are the highest precision of shape and versatility.

Removable aluminum formwork

Panel aluminum formwork

Modern removable formwork systems consist of a metal frame and a plywood laminated deck. In this case, both steel and aluminum are used as materials for the manufacture of the frame.

Steel has long proven itself as a structural and building material: it is strong, durable, has high load-bearing capacity, etc.

, but at the same time it also has relative disadvantages: a tendency to corrosion, a significant specific gravity.

Today, a number of foreign and domestic companies specializing in the production of construction formwork offer consumers a choice of steel or aluminum formwork systems. At the same time, aluminum confidently holds its position in the domestic market and is even gaining momentum.

The design of aluminum formwork systems is similar to steel formwork. In the production of formwork, the same frame (strapping contour) with stiffening ribs and a plywood deck are used. The overall and connecting dimensions of aluminum formwork are unified with steel formwork systems. That is, both types of removable formwork can be used on the same object under construction.

Advantages of aluminum formwork

Ready-made aluminum formwork panels

Among the main advantages of aluminum formwork for monolithic construction are its high corrosion resistance and low specific gravity.

Aluminum has high corrosion resistance; it does not rust even with prolonged exposure to precipitation or moisture in the air; instead, it is covered with an oxide film, which protects the metal from the effects of the external environment more reliably than any paint coating.

The density of aluminum is three times less than that of steel (2.7 g/cm3 - aluminum, 7.85 g/cm3 - steel).

Accordingly, the formwork frame in the first case will be three times lighter, which in turn facilitates and simplifies installation work during the construction of the formwork system and loading and unloading operations when transporting formwork from one facility under construction to another.

Depending on the dimensions of the aluminum panel formwork module, assembly work can even be carried out manually, without the use of special lifting equipment and mechanisms.

Despite the fact that aluminum is three times lighter than steel, in terms of strength characteristics it is not much inferior to it - aluminum is only 10% “weaker”.

As a chemical element, aluminum has poor resistance to alkaline solutions. Cement-based building mixtures are characterized as alkaline, and, at first glance, it may seem that the use of aluminum as formwork is unacceptable.

But, firstly, the oxide film covering the aluminum surface reliably protects the metal from a chemical reaction with concrete, and secondly, alloyed aluminum is used in the production of formwork: silicon, magnesium or zinc.

Alloying additives significantly reduce the sensitivity of the metal to alkalis.

The disadvantages of construction removable formwork made of aluminum include higher cost compared to steel and relatively more complex repairs (special equipment and materials are required for soldering aluminum profiles).

Installation of aluminum formwork

Formwork panels based on an aluminum frame are mounted into a single formwork system in the same way as steel structures. Formwork panels for monolithic construction are installed in a vertical position using telescopic one- or two-level struts.

Rough adjustment of the strut is made by extending the telescopic pipes, finer adjustments are made using a screw pair. Aluminum formwork panels can be expanded both horizontally and vertically.

Adjacent panels are installed end to end and tightened with special formwork locks until they form a tight, durable fit.

All possible types of formwork elements are made from aluminum profiles: linear, corner and universal panels, support beams for floor formwork, etc.

Repair of aluminum formwork panels

During operation, construction formwork is subjected to static loads. Depending on the construction mixture and the thickness of the poured floor, the pressure on the formwork can reach 70 kPa or more.

Aluminum, compared to steel, has a lower elastic modulus (approximately 33% of the elastic modulus of steel), that is, there is a greater likelihood of plastic deformation rather than elastic deformation.

If the calculation of the formwork is carried out incorrectly, or the actual loads when pouring concrete exceed the permissible ones, the aluminum panels may be deformed and even burst at the places where individual elements are welded.

The difficulty of repairing aluminum formwork is that special welding machines and higher qualifications of the welder are required.

When repairing aluminum formwork, the original geometric shape of the frame is first restored (using manual or hydraulic leveling machines). In this case, elements that cannot be restored are removed in order to subsequently be replaced with new ones (for example, stiffeners).

Chamfer edges are cleaned mechanically using an electric or pneumatic machine and an abrasive stone. In this case, the cleaned edges are instantly covered with an oxide film. The melting point of aluminum is 659°C, while the oxide film melts only at 2055°C.

The boiling point of pure aluminum is 2519°C; accordingly, the welder is forced to operate within a narrow temperature range in order to make a reliable weld.

Wedge lock and coupling bolt with nut

Aluminum is welded in a protective gas environment, for example, under argon. During welding, gases protect the processing area from the effects of atmospheric oxygen, thus preventing the formation of an oxide film at the welding site. Violation of welding conditions or technology leads to a poor-quality weld, which will not support the load determined by the formwork calculation.

Repair of aluminum formwork by welding can occur either using consumables (solder) or special non-consumable electrodes.

Construction contractors rarely have the technical ability to carry out formwork repairs themselves and are forced to resort to the services of third parties. If a formwork lease has been issued, then, as a rule, the lessor has the necessary equipment and qualified labor to efficiently restore aluminum formwork panels.

The turnover rate (number of concrete pouring cycles) of aluminum formwork is about 300 cycles, while the turnover rate of a deck made of laminated construction plywood is about 80. Timely overhaul of the formwork allows you to extend its “life” by about 1.5 times.

Aluminum formwork

\ Wall formwork \ Aluminum formwork

- download the price list for wall and column formwork

Frame - high-precision aluminum profiles. Deck - laminated plywood (thickness 18 mm, p = 120 g/m2). Design pressure load of the concrete mixture - 80 kPa

Large-panel aluminum linear formwork panels (board height 3.0 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

Linear formwork panel | 1.20 x 3.0 | 3,60 | RUB 21,252.00 | Find out the cost |

| 1.10 x 3.0 | 3,30 | RUB 20,446.00 | Find out the cost | |

| 1.00 x 3.0 | 3,00 | RUB 19,858.00 | Find out the cost | |

| 0.90 x 3.0 | 2,70 | RUB 19,250.00 | Find out the cost | |

| 0.85 x 3.0 | 2,55 | RUB 17,198.00 | Find out the cost | |

| 0.80 x 3.0 | 2,40 | RUB 16,640.00 | Find out the cost | |

| 0.78 x 3.0 | 2,34 | RUB 16,040.00 | Find out the cost | |

| 0.76 x 3.0 | 2,28 | RUB 15,760.00 | Find out the cost | |

| 0.75 x 3.0 | 2,25 | RUB 15,600.00 | Find out the cost | |

| 0.74 x 3.0 | 2,22 | RUB 15,450.00 | Find out the cost | |

| 0.72 x 3.0 | 2,16 | RUB 15,083.00 | Find out the cost | |

| 0.70 x 3.0 | 2,10 | RUB 14,720.00 | Find out the cost | |

| 0.65 x 3.0 | 1,95 | RUB 13,960.00 | Find out the cost | |

| 0.60 x 3.0 | 1,80 | RUB 13,280.00 | Find out the cost | |

| 0.55 x 3.0 | 1,65 | RUB 12,806.00 | Find out the cost | |

| 0.50 x 3.0 | 1,50 | RUB 12,270.00 | Find out the cost | |

| 0.45 x 3.0 | 1,35 | RUB 11,840.00 | Find out the cost | |

| 0.40 x 3.0 | 1,20 | RUB 11,260.00 | Find out the cost | |

| 0.30 x 3.0 | 0,90 | RUB 9,720.00 | Find out the cost | |

| 0.25 x 3.0 | 0,75 | RUB 9,260.00 | Find out the cost |

** - custom item

Large-panel aluminum linear formwork panels (board height 3.3 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| 1.20 x 3.3 | 3,96 | 23,700 rub. | Find out the cost | |

| 1.10 x 3.3 | 3,63 | RUB 22,420.00 | Find out the cost | |

| 1.00 x 3.3 | 3,30 | RUB 11,623.00 | Find out the cost | |

| 0.90 x 3.3 | 2,97 | RUB 19,500.00 | Find out the cost | |

| 0.85 x 3.3 | 2,81 | RUB 18,900.00 | Find out the cost | |

| 0.80 x 3.3 | 2,64 | RUB 18,300.00 | Find out the cost | |

| 0.76 x 3.3 | 2,51 | RUB 17,800.00 | Find out the cost | |

| 0.75 x 3.3 | 2,48 | RUB 17,380.00 | Find out the cost | |

| 0.74 x 3.3 | 2,44 | RUB 16,980.00 | Find out the cost | |

| 0.72 x 3.3 | 2,38 | RUB 16,620.00 | Find out the cost | |

| 0.70 x 3.3 | 2,31 | RUB 16,570.00 | Find out the cost | |

| 0.65 x 3.3 | 2,15 | RUB 15,785.00 | Find out the cost | |

| 0.60 x 3.3 | 1,98 | RUB 15,000.00 | Find out the cost | |

| 0.55 x 3.3 | 1,82 | RUB 14,300.00 | Find out the cost | |

| 0.50x 3.3 | 1,65 | RUB 13,600.00 | Find out the cost | |

| 0.45 x 3.3 | 1,49 | RUB 13,130.00 | Find out the cost | |

| 0.40 x 3.3 | 1,32 | RUB 12,400.00 | Find out the cost | |

| 0.30 x 3.3 | 0,99 | RUB 10,900.00 | Find out the cost | |

| 0.25 x 3.3 | 0,83 | RUB 10,215.00 | Find out the cost |

** - custom item

Universal panels for aluminum large-panel formwork (board height 3.0 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| 1.20 x 3.0 | 3,60 | RUB 28,350.00 | Find out the cost | |

| 1.15 x 3.0 | 3,45 | RUB 27,600.00 | Find out the cost | |

| 1.10 x 3.0 | 3,30 | RUB 26,850.00 | Find out the cost | |

| 1.05 x 3.0 | 3,15 | RUB 26,100.00 | Find out the cost | |

| 1.00 x 3.0 | 3,00 | RUB 25,350.00 | Find out the cost | |

| 0.95 x 3.0 | 2,85 | RUB 24,728.00 | Find out the cost | |

| 0.90 x 3.0 | 2,70 | RUB 23,700.00 | Find out the cost | |

| 0.85 x 3.0 | 2,55 | RUB 22,950.00 | Find out the cost | |

| 0.80 x 3.0 | 2,25 | RUB 22,200.00 | Find out the cost | |

| 0.75 x 3.0 | 2,25 | RUB 20,450.00 | Find out the cost | |

| 0.72 x 3.0 | 2,16 | RUB 19,640.00 | Find out the cost | |

| 0.70 x 3.0 | 2,10 | RUB 18,920.00 | Find out the cost | |

| 0.65 x 3.0 | 1,95 | RUB 18,390.00 | Find out the cost | |

| 0.60 x 3.0 | 1,80 | RUB 17,678.00 | Find out the cost | |

| 0.55 x 3.0 | 1,65 | RUB 17,290.00 | Find out the cost | |

| 0.50 x 3.0 | 1,50 | RUB 16,900.00 | Find out the cost |

** - custom item

Universal panels for aluminum large-panel formwork (board height 3.3 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| 1.20 x 3.3 | 3,60 | RUB 31,185.00 | Find out the cost | |

| 1.15 x 3.3 | 3,45 | RUB 29,925.00 | Find out the cost | |

| 1.10 x 3.3 | 3,30 | RUB 28,586.00 | Find out the cost | |

| 1.05 x 3.3 | 3,15 | RUB 27,326.00 | Find out the cost | |

| 1.00 x 3.3 | 3,00 | RUB 25,988.00 | Find out the cost | |

| 0.95 x 3.3 | 2,85 | RUB 24,728.00 | Find out the cost | |

| 0.90 x 3.3 | 2,70 | RUB 23,388.00 | Find out the cost | |

| 0.85 x 3.3 | 2,55 | RUB 22,860.00 | Find out the cost | |

| 0.80 x 3.3 | 2,25 | RUB 22,540.00 | Find out the cost | |

| 0.75 x 3.3 | 2,25 | RUB 22,050.00 | Find out the cost | |

| 0.72 x 3.3 | 2,16 | RUB 21,442.00 | Find out the cost | |

| 0.70 x 3.3 | 2,10 | RUB 20,920.00 | Find out the cost | |

| 0.65 x 3.3 | 1,95 | RUB 20,170.00 | Find out the cost | |

| 0.60 x 3.3 | 1,80 | RUB 19,445.00 | Find out the cost | |

| 0.55 x 3.3 | 1,65 | RUB 19,072.00 | Find out the cost | |

| 0.50 x 3.3 | 1,50 | RUB 18,590.00 | Find out the cost |

** - custom item

External corner panels for aluminum large-panel formwork (board height 3.0 and 3.3 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| height 3.0 meters | ||||

| 0.6 x 0.6 x 3.0 | 3,6 | RUB 20,800.00 | Find out the cost | |

| 0.5 x 0.5 x 3.0 | 3,00 | RUB 19,600.00 | Find out the cost | |

| 0.4 x 0.4 x 3.0 | 2,4 | RUB 18,730.00 | Find out the cost | |

| height 3.3 meters | ||||

| 0.6 x 0.6 x 3.3 | 3,96 | RUB 26,850.00 | Find out the cost | |

| 0.5 x 0.5 x 3.3 | 3,30 | RUB 25,650.00 | Find out the cost | |

| 0.45 x 0.45 x 3.3 | 2,97 | RUB 24,400.00 | Find out the cost |

** - custom item

Corner panels for internal aluminum large-panel formwork (board height 3.0 and 3.3 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| height 3.0 meters | ||||

| 0.4 x 0.4 x 3.0 | 2,40 | RUB 17,306.00 | Find out the cost | |

| 0.3 x 0.3 x 3.0 | 1,80 | RUB 15,700.00 | Find out the cost | |

| height 3.3 meters | ||||

| 0.4 x 0.4 x 3.3 | 2,64 | RUB 17,480.00 | Find out the cost | |

| 0.3 x 0.3 x 3.3 | 1,98 | RUB 16,280.00 | Find out the cost |

** - custom item

Aluminum large-panel hinged formwork panels (board height 3.0 and 3.3 meters)

| View | Size | Area, sq.m. | Retail price | Wholesale price |

| height 3.0 meters | ||||

| 0.5 x 0.5 x 3.0 | 3,00 | RUB 22,540.00 | Find out the cost | |

| 0.3 x 0.3 x 3.0 | 1,80 | RUB 21,500.00 | Find out the cost | |

| 0.1 x 0.1 x 3.0 | 0,60 | RUB 14,760.00 | Find out the cost | |

| height 3.3 meters | ||||

| 0.5 x 0.5 x 3.3 | 3,3 | RUB 22,000.00 | Find out the cost | |

| 0.3 x 0.3 x 3.3 | 1,98 | RUB 20,800.00 | Find out the cost | |

| 0.1 x 0.1 x 3.3 | 0,66 | RUB 16,350.00 | Find out the cost |

** - custom item

Panels for additional aluminum large-panel formwork (board height 3.3 meters)

| Width | Height | ||||||||

| 0,6 | 0,8 | 1,0 | 1,2 | 1,5 | 1,8 | 2,0 | 2,5 | 2,6 | 2,7 |

| 1,20 | |||||||||

| 1,10 | |||||||||

| 1,00 | |||||||||

| 0,90 | |||||||||

| 0,85 | |||||||||

| 0,80 | |||||||||

| 0,78 | |||||||||

| 0,76 | |||||||||

| 0,75 | |||||||||

| 0,74 | |||||||||

| 0,72 | |||||||||

| 0,70 | |||||||||

| 0,65 | |||||||||

| 0,60 | |||||||||

| 0,55 | |||||||||

| 0,50 | |||||||||

| 0,45 | |||||||||

| 0,40 | |||||||||

| 0,30 | |||||||||

| 0,25 |

Source: https://fws.ru/aljuminievaja-opalubka

Steel formwork

Steel formwork can be small-panel or large-panel. It is characterized by high rigidity and strength and reliably holds its shape even with high pressure of the concrete mixture. A special feature of the designs is that the basis of the shields is a high-strength steel frame.

Steel formwork is the ideal choice for solving the most difficult problems in monolithic construction! Its main advantages are durability, wear resistance and versatility of use. The formwork joints are of very good quality, which does not require additional treatment of the walls.