Normative documents

All piling work is carried out in accordance with SNiP:

- SNiP 2.02.03-85 “Pile foundations”

- SNiP 3.02.01-87 “Earth structures, foundations and foundations”

- GOST 19804-91 “Reinforced concrete piles”

- GOST 5686-94 “Methods of field testing of piles”

- SP 50-101-2004 “Design and installation of foundations of buildings and structures”

- SP 50-102-2003 “Design and installation of pile foundations”

The designs used comply with state standard No. 19804 and are marked as follows:

- “C” – reinforced concrete products with a solid square cross-section. They can be integral or composite. Dimensions: 30*30, 35*35 and 40*40 cm;

- “SG” – rods with a rectangular cross-section. The length of one side is 25 cm, the second is 35. The material for production is also reinforced concrete.

Models of type “C” and “SG” are widely used to strengthen the foundations of houses of different heights. They are universal because they are suitable for all types of soil found in the central regions of the Russian Federation.

Reinforced concrete piles prices

Let's look at the standard marking of solid reinforced concrete piles according to GOST:

- C60.30-2, where: C - type of pile, 60 - length (in decimeters), 30 - section width (in centimeters), 2 - type of reinforcement.

The column “type of reinforcement” indicates what class and diameter of reinforcement was used to create the reinforcement frame of the pile:

- “2” - Reinforcement A1, 10 mm;

- “3” - A3, 10 mm;

- “6” - A3, 12 mm;

- “8” - A3, 14 mm;

- “9” - A3, 16 mm;

- “10” - A3, 18 mm;

- “11” - A3, 20 mm;

- “12” - A3, 22 mm;

- “13” - A3, 25 mm.

If after the marking of the reinforcement class there is “.1”, this means that the pile has a prestressing reinforcement frame.

The price of reinforced concrete piles varies depending on their type, reinforcement class, cross-section and length.

We bring to your attention the current prices for reinforced concrete piles with a cross-section of 30 cm (the table shows prices in Moscow and the region).

| Marking | Length (m) | Height (cm) | Width(cm) | Weight, kg) | Price, rub) |

| S30.30-3 | 3 | 30 | 30 | 681 | 2070 |

| S50.30-6 | 5 | 30 | 30 | 1135 | 3450 |

| S70.30-6 | 7 | 30 | 30 | 1590 | 4830 |

| S100.30-10 | 10 | 30 | 30 | 2271 | 7550 |

| S120.30-9 | 12 | 30 | 30 | 2725 | 9060 |

Prices for driven reinforced concrete piles with a square section of 35*35 cm:

| Marking | Length (m) | Height (cm) | Width(cm) | Weight, kg) | Price, rub) |

| S40.35-3 | 4 | 35 | 35 | 1260 | 4356 |

| S50.35-3 | 5 | 35 | 35 | 1575 | 5445 |

| S60.35-3 | 5 | 35 | 35 | 1890 | 6534 |

| S70.35-6 | 7 | 35 | 35 | 2205 | 7623 |

| S90.35-10 | 9 | 35 | 35 | 2835 | 11158 |

| S120.35-10 | 12 | 35 | 35 | 3720 | 14887 |

| S140.35-10 | 14 | 35 | 35 | 4340 | 17357 |

Types of foundation supports

The choice of foundation type when constructing any structure is directly related to the quality of the soil that is present at the construction site. About 30% of buildings in Russia are built on pile foundations.

There are 4 types of piles:

- Hammers . For driving, the use of a special hammer, loader and pressor is required. The supports have a square cross-section and a solid core.

- Shell piles . Shelled supports are installed in the ground, and the hollow space inside them is filled with concrete mortar

- Drilling rigs . Installation involves digging or drilling a hole in the ground, immersing reinforcement and pouring concrete into the structure.

- Screw . For this type, installation is carried out by screwing the rod into the ground to a certain depth.

How does the installation work?

Reinforced concrete piles are installed quickly and easily, provided that specialists are involved. Their installation requires special machinery and equipment. And yet this is a simpler and more economical technology than a strip or slab foundation.

Installation includes several procedures:

- studying the features of a building under construction;

- design and load calculation;

- soil research;

- determining the depth of driving in supports;

- determination of the method of arrangement of piles (over the entire area, along the perimeter, under load-bearing and external walls, under individual elements of the building)

- marking the site, accurately calculating the location of each support;

- drilling wells for piles;

- installing the pile into the ground.

Features of the pile driving method

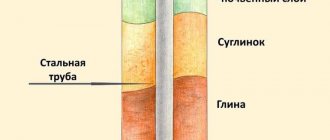

The main purpose of using a pile foundation is to eliminate the possibility of deformation of the building as a result of seasonal heaving and possible flooding. In order for this task to be completed 100%, the piles must be deepened below the soil freezing level. In this way, the support will overcome all unstable layers of the earth and anchor itself in solid and stable levels. This will create a reliable foundation for the foundation.

There are times when the soil in the selected area is too dense, and you need to dive deep enough. In such cases, the washing method is used - a stream of water under high pressure is supplied along with the stand, which erodes the ground, softens it, and reduces friction.

When driving piles into the ground, you need to be 100% sure that they do not rest against a stone or something hard. This is important because with further construction and operation of the building, the load on the supports increases and the foundation settles. All supports will deepen evenly, except for the one that rests on a hard surface. This will entail deformation of the foundation, and hence the distortion of the entire building. The best time for work is considered to be summer, when the soil is completely thawed.

Of course, sometimes work needs to be done during the cold season. You can begin activities only if the soil is frozen no more than 1 meter deep. With deeper freezing, driving can be continued only with special equipment (steam needle). This installation consists of a tube with a recess at the end through which hot air is supplied. A steam needle is immersed in a drilled hole, hot air melts the earth.

Comparison of reinforced concrete piles with other types of foundation

| Driven reinforced concrete piles | Screw piles | Bored piles | Monolithic slab | Strip foundation | |

| Installation time | 1 day | 1-3 days | 5-7 days | 7-14 days | 5-10 days |

| Construction | On the day of construction of the foundation | Needs time to settle | In 20 days | In 20 days | In 20 days |

| Season | Any | Any | Warm, dry | Warm, dry | Warm, dry |

| Load bearing capacity | Up to 40 tons per pile | 2-11 t. For each pile | Max. Pile load 20 t | from 4 to 15 tons per 1 m2 | from 4 to 15 tons per 1 m2 |

| Type of terrain, soil | Any terrain, any soil | Any terrain, all soils except rocky | Any terrain, all soils except rocky | No slopes, only dense soils | No slopes, only dense soils |

| Lifetime | lo 200 years | up to 50 years | from 100 years | from 100 years | from 100 years |

| Type of construction | All types of low-rise buildings | Can't make a basement | Add. work for the construction of the plinth | For buildings with low weight | For a narrow range of buildings |

| The cost of the foundation for a building 8x8 m | from 110,000 rub. | from 100,000 rub. | from 180,000 rub. | from 300,000 rub. | from 200,000 rub. |

Piling technology

Driving reinforced concrete piles is rarely done without a pre-developed scheme. It is necessary for a number of reasons. First of all, this approach helps to evenly distribute loads on the soil and calculate in advance the failure depth of the pile. In addition, the presence of a diagram helps to optimize the time it takes to move the pile driver across the working area in order to speed up the installation process.

There are three main pile driving programs:

- pile bush - the method of arranging piles most often used in private construction for the construction of small structures.

- pile strip - used for the construction of medium-sized private structures.

- pile field - used in the construction of multi-storey buildings and industrial facilities.

Pile installation schemes:

- row scheme - the piles are arranged in several rows, installation is carried out one row at a time.

- sectional scheme - the entire area is divided into several sections, each section uses a row arrangement of supports.

- spiral scheme - piles are installed in a spiral. There are two options: the start of work is carried out in the center of the spiral and then along an expanding trajectory, the second option is in the opposite direction.

Before starting work, a technological map - this is a general scheme for driving piles at a given site.

Pile driving technology:

- Soil preparation;

- Supply of materials to the site;

- Delivery and installation of driving equipment;

- Development of a movement diagram for the pile driving machine, installation sequence in accordance with the design documentation;

- Realization of support installation points;

- Trial installation, dynamic testing;

- Installing the pile in the desired position;

- Driving a pile using the driving method: Applying markings. Piles are marked with paint every meter for visual control of the driving depth.

- Placing the pile in the installation machine. The rod is hooked using a winch, pulled to the pile driver and secured with slings to the mounting loops.

- Raising the pile. It is placed above a given area in a vertical position so that the upper part is next to the head of the hammer. When the minimum distance is reached, the pile is fixed using a pile driver mast.

- Installation at the immersion point. At this stage of pile driving, a control check takes place: the axis of the pile must coincide with the impact part of the diesel hammer, and its tip with the driving point. For the second criterion there is a permissible deviation of 1 cm.

- Immersion of the rod into the soil. The process is carried out through several blows. The first ones are needed in order to set the right direction. They are applied from a height of 20-40 cm. After the pillar goes into the ground to a depth of 1-1.5 meters, the blows intensify - they are applied with greater amplitude.

- Immersion angle control. If during pile driving the planned trajectory changes by more than 1%, then it is corrected with ties or supports. In rare cases, these measures do not help, then the only option to correct the situation is to dismantle the pile and drive it again.

Work methodology

Installation of reinforced concrete supports is carried out by our specialists in accordance with any of the existing methods (shock, vibration, leader drilling, indentation) depending on the type of soil and general working conditions. It is possible to combine techniques to obtain the most effective results. If it is impossible to use one of the above methods, the installation of bored supports is used. Our specialist will advise you in more detail about this.

Work technology

Before starting work on driving products, the soil is checked and the results of trial driving are compared with the initial geological surveys.

This point is very important, as it makes it possible to adjust the entire procedure if necessary, which eliminates shortcomings and errors even before the foundation is formed. Additionally, it is taken into account that the soil may change, in particular seasonally. This also requires data correction and careful selection of necessary materials.

If the preliminary and trial data fully correspond, the filling begins. Operating procedure:

- using a crane, the product is dragged to the pile driving machine, installed in a holder, with which it is pressed in the required direction to the possible depth;

- hammer blows are made on the upper end of the pile;

- after several blows, the correct insertion is checked. If necessary, the pile entrance is adjusted;

- With the help of constant checking, deviations from the required level are not allowed;

- driving to the specified depth.

After the process is completed, the required and received data on the location of the pile in space are verified. Constant adjustments and avoidance of miscalculations lead to the construction of a strong, reliable foundation that will have increased load-bearing capacity and will last for a long time.

The list of special equipment used depends on the number and type of piles, as well as terrain factors. To create a small foundation from driven piles, 1 machine, maintenance personnel and delivery of materials to the construction site are required.

The technology itself is not complicated. The only factor influencing the total time is considered the first stage with checking all the data and terrain features. In most cases, such procedures are necessary when driving piles to great depths under multi-story or massive objects. They require increased stability and high load-bearing capacity. An additional nuance will be the technical characteristics of the piles, since various types can be used as driving elements, each having its own strength characteristics.

Methods for installing piles

- Driving piles through a series of blows to the top;

- Vibration driving;

- Immersion by pressing into the ground;

- Leader drilling;

- Immersion by electroosmosis method;

- Driving piles into softened soil.

Driving reinforced concrete piles is a responsible job, on which the stability and durability of the building as a whole ultimately depends. For the most effective installation, our specialists conduct thorough preliminary research, based on the results of which the optimal immersion method, number and size of supports for each object are selected.

Pile driving technology

Our company’s specialists most accurately calculate the trajectory of movement of pile drivers and the technological chain of work performed, thanks to which the installation of supports is carried out as quickly as technically possible. The dive is carried out strictly according to plan using modern equipment.

Equipment used: hammer, pile driver.

Pile driving technology by indentation

It is carried out using a pressing machine. The method is most effective on dense soils, provides excellent stability of the supports, and promotes additional soil compaction. The indentation method allows the use of fewer supports in the foundation and increases the strength of the building foundation.

Equipment used: press.

Many construction companies use the method of pressing piles when arranging the foundation. Installing supports in this way is advisable in the following cases:

- Conducting construction work in close proximity to dilapidated buildings.

- Driving piles in parks and recreation areas.

- If there are restrictions for carrying out shock work.

- Installation in places where there is a high probability of landslides forming and occurring.

- Near all kinds of historical sites.

- In areas with a large slope.

In conditions with limited space.

Technology for driving piles using a vibratory driver

A clear advantage of installation using the vibration method is a reduction in the dynamic impact on the supports, reduced noise and increased productivity in general. This method is optimal for deepening supports into soils with a wide sand layer.

Our company’s technical capabilities are sufficient to drive piles into the ground at both small commercial and large-scale industrial facilities. We also work with private customers in Moscow and the Moscow region.

Equipment used: vibrator.

During the operation of vibratory hammers, the piles are exposed to high-frequency, low-amplitude vibrations. They are created by a specialized device based on wheeled or tracked vehicles. The vibration loads experienced by the pile are transferred to the soil. As a result, it becomes looser.

There is a sharp tip at the end of each pile. This greatly facilitates the process of loading reinforced concrete products. The tip of the pile reduces the friction force.

When the density of the earth decreases with the help of vibration, the support sinks into the ground due to its own weight. The process of driving piles continues until the support reaches the most dense soil or the desired level.

Pile driving technology using leader drilling

Before driving piles in difficult, dense areas of soil, or in conditions where it is necessary to reduce vibrations that occur during pile driving, or in frozen soil conditions, drilling is carried out before driving piles. A leader hole is drilled in the ground, which will serve as a guide for the subsequent immersion of the pile. The diameter of the leader hole is equal to 70% of the diameter of the driven pile, and the depth is 1 meter less than the immersion level of the support. A pile is installed in the resulting well and then driven.

Equipment used: leader drilling rig, hammer and pile driver.

The technology for constructing leading wells has become widespread. This drilling method has many positive characteristics. Driving piles using the method of creating leader wells has the following advantages:

- If you drill holes in advance, the speed of immersion of piles will increase noticeably. As a result, it will be possible to quickly complete the work on arranging the foundation.

- With the help of leader drilling, it is possible to achieve ideal vertical immersion of piles, or to mount supports with the required slope.

- Thanks to leader drilling, it is possible to obtain a design failure to immerse the pile at the initial stages of work. As a result, there will be no long downtime of equipment and labor due to problems with pile driving.

With the help of leader drilling, it is possible to significantly reduce the dynamic loads on previously erected buildings nearby.

Electroosmosis technology for driving piles

Electric current is used to drive the piles. In this method, the pile acts as a cathode. Under the influence of current, the soil under the pile softens and driving the pile occurs with less effort.

Equipment used: equipment for creating an electrical circuit, hammer, pile driver.

Thanks to the use of electroosmosis, it is possible to speed up the process of immersion of supports during pile driving. With a short-term effect of electric current on wet soils, pore movement of water occurs from the anode to the cathode. If one of the supports is immersed in the usual way, then an anode (plus) is connected to it, and a cathode (minus) is connected to the other, not immersed pile, then a zone with low humidity will appear near the first reinforced concrete material, and a zone with high humidity near the second. As a result, the cathode pile will begin to sink faster, since water-saturated soil has a lower density. This method of driving piles is effective when using hammers, as well as vibratory hammers. In this regard, it is very popular among modern consumers, especially relevant in places with dense soils.

Technology for driving piles into softened soil

The method is based on eroding the soil under the driven pile using water. A special device is placed on the pile to supply water under pressure. The soil density becomes less and the pile sinks to a given depth.

Equipment used: water supply, hydraulic hammer, pile driver.

The main advantages of the driving method

To make it clear whether the installation of piles is necessary on your construction site, you must first familiarize yourself with some of the features of such a foundation. Among the main advantages it is worth highlighting:

- By using high-quality supports and installing them correctly, you can save a lot. Highly efficient equipment is used for driving, which significantly speeds up work processes. Piles can be installed not only in sandy and wetlands, but also in high-density lands.

- If you use the driving method, you can minimize future costs. There is no need to drill the soil at the construction site, there is no need to level the surface in advance, remove bumps and various defects. When performing activities, a large amount of special equipment is not used.

- Using this technology, it is possible to use different types of supports.

- There is no need to perform a preliminary soil test before starting work. All necessary tests are carried out during the installation process.

Driving reinforced concrete piles significantly increases the strength and reliability of the entire structure. The created foundation on reinforced concrete supports will last a long time without changing the original characteristics.

Driven supports in foundations

The foundation on driven piles, where the base is monolithic supports, is the most reliable of all similar technologies. It can be combined with a monolithic slab or tape, and also serve as a support for base blocks. The order of location of driven piles is determined by the type of buildings being built. For example:

- Pile field.

The area for the foundation on driven piles is “strewn” with the ends of reinforced concrete supports

- Rows. The supports are installed under the load-bearing walls of the house, on the corners and other critical components of the building, in accordance with the design of the facility.

- Single supports. Chaotically located monolithic driven piles for a private house will give the future foundation additional rigidity in places where the soil is heaving.

Before determining the type of foundation, geological surveys are first carried out to determine the behavior of the soil in special terrain conditions.

Application area

When and where should piles be driven? Experts note several areas:

- Outside urban areas, when it is necessary to create a foundation with high strength.

- At different elevations and in those areas where there is a high probability of landslides.

- When creating various road junctions and other objects.

- In those areas where it is impossible to use installation technologies other than pile driving.

The driving method is most advantageous to use if construction is carried out on particularly dense or hard soils. The customer has the opportunity not only to build a high-quality structure with a long service life, but also to eliminate its deformation in the future.

Pile driving technology

- Hammer - can be diesel, mechanical, hydraulic or steam-air. The most popular is the first option, which is used by our specialists.

- Koper - used for correct installation of support in the soil.

- Press - installation for pressing piles with a static load.

- Vibratory presser is an installation that allows you to drive piles through vibration and pressing at the same time.

- A leader drilling rig is a drill that allows you to drill wells with a diameter slightly smaller than the diameter of the submersible support.

- A hydraulic hammer is a technique for softening the soil under a pile driven by a directed stream of water under high pressure.

- Electric generators - to create an electrical circuit using the electroosmosis method.

Our organization offers pile driving using a standard method - using a diesel impact hammer. Its design is based on metal heads suspended by cables. A pile driver is used as an additional element of a pile driving machine. Its main function is to set the direction of the hammer and place the piles at the points of immersion into the ground.

The diesel hammer is a type of mounted construction equipment. It is supported by cranes - crawler and wheeled.

The quality of driving is largely determined at the stage of preparatory work. Of these, the layout of piles in consumable warehouses has the greatest influence on the final result. Installation will be successful only if the pile rods are distributed over the working area at an acceptable distance from the pile driver winch. They must be within reach.

Pile driving price

The cost of installation work is calculated for each project individually and depends on the following factors:

- number, size of piles;

- soil type;

- weather and seasonal conditions;

- the presence of restrictions on carrying out certain works in the area;

- remoteness of the construction site;

- scale of construction;

The estimate for installation work is drawn up in accordance with the design documentation. Mandatory survey activities are carried out in advance to determine the composition of the soil, and only then the installation of reinforced concrete or bored piles.

Our specialists have all the necessary permits to work and undergo advanced training in a timely manner. Engineers are professionals in their field whom you can completely trust.

Our company’s employees will help you calculate the exact cost of installing a pile foundation. Call us or leave a request to get advice from our staff. The price is calculated individually for each client. It is worth noting that it will be significantly lower than that of competitors.

Advantages of reinforced concrete piles

When creating a concrete pile foundation, all technical norms and rules are observed. The supports used are widely popular in many regions of Russia because they have many positive qualities:

- Fast and convenient installation.

- A high margin of safety allows the material to cope with heavy loads during operation.

- Installation work can be carried out at any time of the year.

- A reliable basis is created for fast and high-quality construction of a house.

- The material has a long service life.

- It is allowed to use reinforced concrete piles on any type of soil.

Building a house using reinforced concrete piles is an opportunity to obtain ideal technical conditions for the subsequent construction of the structure. An important point is that the material can be easily repaired and restored (if necessary). This way you can extend the service life of a pile foundation, the depth of which can be different, up to 80 years.