A concrete trash can is a universal product that is installed in various territories, areas, streets, and objects in order to reduce the amount of garbage waste scattered on the ground. When there is a special container within walking distance, much less papers, leaves, cigarette butts and other garbage are simply thrown onto the streets and roadsides, thereby maintaining the cleanliness of cities and towns: squares, squares, local areas, parks, etc.

The main advantage of this type of product is that a street waste container made of concrete retains its parameters and appearance for a long time, without fear of weather conditions, vandals, or wear. Thanks to its heavy weight and special fastening, the urn demonstrates good stability, and it is not so easy to move it, which protects it from hooligans.

Concrete ballot boxes can be made in a variety of shapes and configurations, be small or large, and require different types of fastenings. Urns are often made with decorative patterns and other decorations, painted in different colors, and covered with moisture-resistant coatings.

Garbage bins have long become an integral part of modern settlements and even private areas. Such products of small architectural forms perform not only a utilitarian function, significantly reducing the amount of garbage on the ground and increasing the time between periodic cleaning of streets and territories, but also serve as a kind of decoration.

Original and compatible with other elements, urns can elevate and complete the overall appearance of the ensemble. Modern urns often resemble real works of art, which, however, does not prevent them from successfully performing their main function.

Purpose

The main function that a concrete street trash can performs is to maintain the cleanliness of the surrounding space. Thanks to the presence of containers specially designed for garbage on the streets, it is possible to avoid freely lying waste and significantly reduce the volume of everything that can usually be found in the grass, among fallen leaves, on roadways, roadsides, playgrounds, on paths in parks, etc.

Despite the fact that the trash can does not educate people and is unlikely to force anyone to change their behavior on the street, statistics prove that the presence of garbage containers within walking distance becomes for many people a subconscious signal that an ice cream paper or a cigarette butt is needed throw it here. When there is no trash can nearby, most often everything is thrown underfoot.

It is also important that the trash can protects animals and children from the possibility of interacting with dangerous objects: everything that can poison oneself, cut oneself, etc., is securely hidden in the container and small children, dogs, and cats do not have access to garbage. It is especially important to place concrete ballot boxes in places where there is a regular concentration of people: areas around shopping centers, gas stations, transport hubs, beaches, parks, various organizations, etc.

Street trash cans made of concrete, as a rule, do not accumulate waste: special buckets are prudently inserted into them, which are easily and quickly cleaned. This makes it easier to maintain cleanliness even if some garbage was not brought to the trash bin: rarely does anyone pick up pieces of paper and take it home, but if there is a trash bin nearby, there is a high probability that people themselves will clean up after each other.

Any modern reinforced concrete urn also acts as a decorative element - it complements the landscape and architectural ensemble. Beautiful trash cans installed near benches, cafes, waiting areas and made in the same style and color with other elements add aesthetics and originality to the space.

In addition, a concrete element can zone a space and act as an obstacle for cars and people where passage or passage needs to be blocked. This technique is often used to block passage to embankments, children's play areas, pedestrian sections of streets, etc.

Anti-vandal stone urns from the manufacturer GrillRock wholesale and retail

Over the period of its existence since 2010, our team has accumulated vast experience in the production of outdoor furniture from architectural concrete. Our products meet international standards and are ideal for the climatic conditions of Russia.

The trash cans collected in the catalog of our online store are distinguished by increased strength, real European quality, resistance to low temperatures and environmental safety (production using “washed concrete” technology). Similar urns made of other materials gradually lose their appearance and require constant care (painting, cleaning). Ours do not fade over time, do not fade, do not crack or peel - they just need to be washed with water. And thanks to the variety of shapes, sizes and shades, they will organically fit into any interior.

The entire range presented on the website is in stock and the products are ready to ship. Prices are current as of 02/05/2020. Additional discounts and special delivery conditions are available to wholesale customers. Call and order right now! We are happy to answer any questions daily from 7:00 to 22:00. You can also order a call back, and our managers will contact you at any convenient time.

Stylish, modern GrillRock urns are perfect for landscaping and landscaping any objects:

- cafes and restaurants, hotels, tourist centers, shopping centers and complexes (shopping and entertainment centers)

- summer areas of various establishments, city squares

- embankments, boulevards, avenues, parks and squares, recreation areas

- gardens, courtyards, summer cottages

- personal and adjacent territories

Customer Reviews

Vanya, Vyazma, Smolensk region

Yesterday I noticed new trash cans in my park with the “GrillRock” label on them, found your website, and decided to leave a review. Great update! For the first time, I’m happy with what they’re doing with our park. Really powerful and brilliant.

Farhad, Orel

My bistro is always crowded. Even at night the flow of people does not subside. Why are trash cans overflowing? I installed 2 large “Dublin” urns - the problem was solved and I think it will last for a long time. And savages won’t beat you like that. You will break your bones sooner than this colossus).

Gurgen, Moscow region

We chose your trash cans because... they are roomy and cute. Our restaurant is located in a crowded place and there is a large flow of passers-by. Everyone tries to throw a bottle, a cigarette butt - they didn’t have time to empty the bucket. The most important thing is that the hexagons fit our façade one to one (towers with a grainy stone surface)! Just a big thank you!

Heinrich Stulz, Bryansk

Thank you for the promptly completed order - 24 urns made of sea pebbles. Truly presentable, it’s even a pity to throw garbage in them) This is what I was looking for.

Vladislav Ilyich, Astrakhan region

Hello. At work I was tasked with decorating the front part of the house. The estimate included a specific amount and I was able to meet it with the help. Local suppliers were not pleased with their size and cost, but the capital ones were very expensive. Really unusual and very powerful garbage cans are new to our village.

Marfa, Penza

We opened our own bistro at the bus stop. The flow of customers was very large and everyone was throwing away napkins and food wrappers. Moreover, they were thrown near the counter and the wind carried the garbage throughout the entire area! Now they have placed 2 Hermes urns on the sides. The situation quickly improved) And the place, it seems to us, has become more memorable).

Kirill, Gelendzhik

I took it for my cottage to match the style of the fence. Satisfied.

Advantages of concrete urns

The concrete version of the urn is considered the most reliable, strong, durable and resistant to various influences. A concrete urn can last for many years, withstand sudden changes in humidity and temperature, precipitation and ultraviolet radiation. Such an urn is difficult to move, and if installed correctly, it is completely impossible to damage or steal.

In view of these features of reinforced concrete products, the ballot box is considered the best choice for installation in public places - where many people pass by every day and it is necessary to ensure the cleanliness and safety of all elements of the architectural ensemble.

The main advantages of a concrete urn:

- Strength and reliability - the product is not afraid of mechanical influences, static loads, and can withstand various impacts easily and without deformation damage.

- Durability – a properly made and installed urn will last for several decades.

- Frost resistance is high enough for the urn to stand for many years without visible damage.

- Beautiful appearance, the ability to give the urn any shape, color, style, configuration, or decorate it with images.

- Possibility to update the surface with a new coat of paint at any time.

- Heavy weight - from several tens of kilograms, which allows the ballot box to be invulnerable to vandals.

- It is of no interest to hooligans - concrete cannot be scrapped or sold, and when dismantled, the ballot box may be damaged, so there is no point in stealing it.

- Safety for human health and life, environmental friendliness - concrete is a composite material made on the basis of natural components, therefore it does not involve toxic emissions, changes in structure and chemical reactions under different influences.

- Functionality - the container is easy to maintain; caring for it simply involves cleaning it from external/internal debris.

- Equipped with additional elements - a metal container, a replaceable durable bag, etc., which simplifies the operation of the product.

- The relatively low cost of the urn, which is explained by the simplicity of execution, the availability of materials, and the ability to make a product yourself with the required parameters.

- Low water absorption - thanks to this, the urns are not afraid of moisture, water (rain, snow).

- Resistance to a variety of aggressive substances.

Wooden ballot box on reinforced concrete base

The wooden cylindrical urn is made on a metal frame made of a strip 40 mm wide, installed on a reinforced concrete base 100 mm thick. The frame is equipped with wooden boards with a cross-section of 50x30 mm.

Wooden parts must be carefully sanded, primed and painted with professional two-component paints in the factory.

001312 – Wooden trash can on reinforced concrete base

Units of measurement are in millimeters

Overall dimensions: D = 420 mm, H = 680 mm Material: wooden board made of coniferous wood, subjected to special treatment and drying to a furniture humidity of 7-10%, metal elements coated with powder paints or galvanized, galvanized fasteners, reinforced concrete.

What types of concrete urns are there?

Concrete urns can be of any size, shape, color, configuration, type of installation, features and operating conditions.

Types of trash cans by type:

- Open and closed - with or without lids, visors of various configurations.

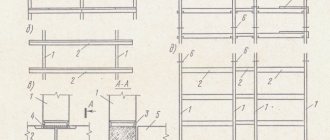

- Floor-mounted and wall-mounted - the first are intended for periodic movement or installation by pouring concrete, other mounting options (with anchors on the pavement, for example) in a certain place, wall-mounted are usually mounted on the walls of buildings, supports in groups or individually (where they will be accessible for maintenance and operation).

- Stationary and mobile - suggesting and allowing transfer to another place or fixed immovably on a specific site.

- Through or with a bottom - bins with a bottom are easier to operate; through ones require the mandatory installation of a bucket.

- Fire resistance - such an urn is not afraid of fire, so throwing an unextinguished cigarette butt into it will not lead to dire consequences.

All urns can be equipped with special elements that cover the neck of the urn with a honeycomb or solid canopy. Small-sized containers are made of concrete and reinforced concrete (reinforced with reinforcing elements to increase strength and reliability). The reinforcement inside the product can be unstressed or stressed. According to the type of assembly, ballot boxes can be prefabricated, monolithic, prefabricated-monolithic.

The raw materials for filling the urn may include cement, polycement, silicate compositions, gypsum, special slag-alkaline components, etc. Monolithic urns are usually poured in large sizes, but small-sized products are most often made in the format of prefabricated structures.

The geometric shapes of the necks and side faces can be made in the form of an oval, rhombus, rectangle, circle, triangle, square, etc. Permanent designer containers can even form the building envelope of an area. The standard dimensions of a small urn are width and depth 40 centimeters, height 52 centimeters.

Popular today are urns in the shape of various animals, with city coats of arms, company logos, ornaments and geometric patterns, and text inscriptions. Products can be painted in any color - coloring is carried out at the stage of mixing the solution (the pigment is added to the liquid mixture) or after the product has hardened (the surface is covered on top).

In texture and appearance, a garbage container can resemble a product made of pebbles, granite, standard concrete (the most common option); clinker tiles, brick panels, and natural stone are often used for cladding.

The cost of both finished products and those made independently can vary within noticeable limits and depends on the pouring technology, the size and shape of the urn, the complexity of manufacturing, decor, etc.

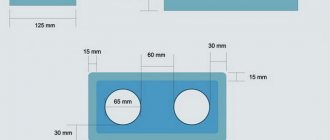

Drawing of a trash can with dimensions

Drawing of a simple conical sheet metal trash can with layout and dimensions

When the workpiece is cut, the reamer is bent along the lines in three places, and the joint is connected by welding. Without experience in such work, thin metal can be damaged, burned, not welded, or deformed by sagging on the reverse side. Therefore, it is better to practice on scraps of steel. To get a thin seam, you need to use electrodes no thicker than 2mm.

Next, the triangular ends are folded towards the center to obtain an even cone and the resulting joints are welded together. For ease of emptying, a U-shaped piece of metal sheet is welded at the bottom, which will serve as a handle.

To make the structure stable, a stand is assembled. Two T-shaped parts are welded from a square section profile, which can be fastened together with a horizontal section for rigidity.

Holes are drilled in the upper part of the finished tank and stand, and the parts are connected with bolts and nuts. The finished assembly is cleaned with sandpaper and painted with powder paint. The joints with the legs must be protected with a coating of copper, graphite or lithol grease.

In a similar way, you can make a large bin for collecting waste according to the following scheme:

Drawing of a truncated metal trash can with dimensions

Instead of a profile for stands, you can use iron pipes or corners. When you need to cut large workpieces, it is better to use electric sheet metal shears.

If you don't have a welding machine, you can make a trash can from a water barrel. First, remove rust from the surface, dry it, apply primer and paint. You can put a garbage bag inside to make emptying the container more convenient. If the barrel is too high, you can reduce the length using a circular saw.

An old barrel can be converted into a waste incinerator. To do this, you need to punch 5-6 holes in the body. This will create strong draft when burning waste, which will reduce emissions of harmful substances into the air. Burning garbage in this way is allowed on personal plots if the territory is not adjacent to agricultural land.

How to do it yourself?

Buying an urn in Moscow and the regions is not difficult, but many craftsmen prefer to make the container themselves, implementing the design idea and obtaining a product of the desired shape, color, and design. The production of a concrete urn involves several stages: first, a form suitable for the parameters is selected (it must be completely sealed), then it is filled with concrete mortar and waits for it to dry.

Before pouring, the mold must be covered with a special mastic so that the product can be easily removed. Next, concrete of grade M200 and higher is prepared; you can immediately add pigment (if you plan to give the urn some kind of shade). A solution of cement and sand is prepared according to the classic recipe, but the easiest way is to take a ready-made dry mixture, to which you just need to add water. A reinforcement cage is placed in the formwork (mold), which is needed to increase the strength and reliability of the entire structure.

After completing the preparatory work, the solution is poured into the mold in a layer 5-7 centimeters thick. At the bottom of the form, the concrete should get into all corners; it is also advisable to check that the reinforcement is completely covered with the solution. If necessary, the frame can be adjusted.

Then a metal container, pre-wrapped in polyethylene, is placed into the mold to the full depth in the center. The container should be placed inside so that there is an equal distance between the walls along the entire perimeter of the mold.

The remainder of the solution is poured up to the top cut of the formwork, the mixture must be compacted using the bayonet method, then it is allowed to set in the shade for 2-3 days. After this time, the metal container is removed from the mold, the concrete is moistened for two weeks several times a day and kept until it gains strength (at least 28 days from the moment of pouring). Then the urn can be freed from its shape and decorated as desired.

Wooden ballot box on reinforced concrete base

The wooden urn is made on a metal frame made of a 40 mm wide strip and a 32x32x3 corner, installed on a reinforced concrete base 100 mm thick. The frame is equipped with wooden boards with a cross-section of 50x30 mm.

Wooden parts are carefully sanded, primed and painted with professional acrylic paints in the factory.

001311 – Wooden trash can on a reinforced concrete base

Units of measurement are in millimeters

Overall dimensions: 420x420 mm, H = 680 mm Material: wooden board made of coniferous wood, subjected to special treatment and drying to a furniture humidity of 7-10%, metal elements coated with powder paints or galvanized, galvanized fasteners, reinforced concrete.