Which foundations are better for houses made of arbolite blocks?

The use of wood concrete blocks lost popularity for a while, but is gradually beginning to return to the construction of private houses.

The point is not only in the lightness and excellent thermal insulation properties of the material, but also in its cost, availability, and the possibility of self-production.

Before constructing a structure made of wood concrete, many people think about what kind of foundation to make for it. Next, we will consider which foundation to choose and its features for a house made of wood concrete.

So which one should you choose?

For arbolite structures, bored piles are better suited. They provide the same base strength as screw ones, but cost about 1,500 rubles. cheaper per support.

Horizontal reinforcing rods of bored piles have a cross-section of 4-5 mm, and vertical ones - 10-12 mm. It is recommended that they protrude above the pile caps to secure the grillage.

The grillage combines all load-bearing elements and evenly distributes the load. For buildings made of arbolite blocks, two types of grillage are used:

- immersed 0.2 m into the ground;

- hanging above the surface level at a height of 0.1 m.

The second option is considered more preferable: due to the ability of wood concrete to absorb moisture, such a grillage eliminates contact of the lower parts of the walls with water on the surface of the earth.

Despite some nuances, all of the above types of foundations are suitable for building houses made of wood concrete. The final choice is made based on the financial capabilities and personal preferences of the customer.

Features of the foundation for an arbolite house

The service life of the structure depends on the bearing capacity of the foundation, so it must be built in strict accordance with the characteristics of a particular house. In general terms, the construction of arbolite buildings is not particularly different from buildings made of other materials, but the characteristics of arbolite still have some influence on the choice of foundation:

- When building a house from wood concrete blocks, it is irrational to use solid monolithic structures as the foundation. The weight of the structure will be quite small. A strip or bored foundation can cope with such a load quite simply, while their construction requires a small amount of money (relative to other types of foundations).

- The characteristics of the material also provide a wide range of options for choosing a foundation. It is able to withstand high tensile loads without failure due to its flexural strength and ductility. The walls will retain their properties even in cases of subsidence of the base. It turns out that a house made of wood concrete can be erected in places on different types of soil, using the foundations that are preferable for the latter.

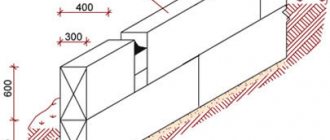

- Wood concrete contains a large number of wood products that are capable of swelling. This can lead to destruction of the structure, so the walls must be protected from moisture. For such purposes, it is necessary to build a foundation that rises above the soil at a distance of at least half a meter.

It is better not to make a wood concrete base for the construction of a private house. Even if it is well waterproofed, there is a high probability of losing the desired characteristics, which will significantly shorten the life of the structure.

Choosing a foundation to ensure the strength of the structure of a house made of wood concrete is necessary not only for reasons of load-bearing capacity, but also for protection from moisture.

What should a plinth made of arbolite blocks be like?

Base for an arbolite house

The base, made of arbolite blocks, can be built using a combined method, or, using the most durable option, a monolithic one. Such a foundation, as a rule, completely protects against the penetration of capillary moisture. Therefore, it is recommended to make the foundation of the house a little higher than the stipulated standard. In addition, it is not recommended to deepen this type of structure base too much.

Today, a simple builder has a huge number of different variations of foundations to choose from. Among them, there are optimal solutions that will help significantly save the family budget. As for permanent structures made of arbolite blocks, it is recommended to give preference to a shallow strip foundation. You can build an arbolite structure from the following building materials:

- Ceramic brick;

- concrete.

Which foundation is preferable for wood concrete houses?

In the case of the construction of buildings with a small mass of wall structures underneath, from a financial point of view, it is advisable to use pile or strip foundations.

Pile foundation

A foundation with such design features is relevant when building in areas with low soil density or an uneven ground surface (complex terrain, quicksand, or significant differences in height).

Piles are special rods made of reinforced concrete or steel, which are buried into the soil to the depth of its layers with sufficient strength to ensure the required level of bearing capacity.

The type of piles used has a significant influence on the characteristics of the foundation for a wood concrete house. There are bored and screw rods.

Bored piles

Such piles are monolithic reinforced concrete structures that are erected within the construction site. To install them, you need to make special holes in the ground of the required diameter and at the distance specified in the design documentation. Next, special reinforcement structures are installed in the niches, after which the final stage of pile manufacturing is performed - pouring concrete of a certain grade, followed by compaction. It is necessary to calculate the distance of each element of the base for specific construction conditions, but generally, when constructing houses from wood concrete, the step is 2.5-3 meters.

Screw piles

Such rods look like pipes with blades, the ends of which are pointed. Such features allow the supports to be screwed into the ground. The presence of blades further increases the load-bearing capacity. For installation, a head is used, which will also become the support of the new structure.

If you make a choice between types of piles, then in the case of arranging a wood concrete house, it is preferable to choose bored piles. This will allow you to save as much as possible without significantly compromising the strength of the base. By comparing analogues, we can calculate that a reinforced concrete structure will be 1,500 rubles cheaper than a steel structure (meaning 1 support).

To reinforce bored elements, rods with a diameter of 1-1.2 and 0.4-0.5 cm are used for vertical and horizontal components of the structure, respectively.

It is recommended to increase the strength of bored supports by using vertical reinforcing rods that will protrude beyond the top of the post. This allows it to be more firmly connected to the grillage.

As for the grillage, it creates a single structure from all the supporting elements, along the perimeter of which the load from the structure is evenly distributed. To build a house using wood concrete blocks, it is customary to use the following types of grillage:

- Recessed 20 cm into the ground;

- Hanging, which raises the walls to a height of about 9-10 cm from the ground surface.

When choosing the preferred type of grillage, it is worth remembering that wood concrete is hygroscopic and that it requires protection from moisture.

Tape

To build such a foundation, you need to analyze the soil characteristics. If its indicators in terms of structure density are high enough, then a shallow foundation can be made (its depth is in the freezing range).

If the soil characteristics are insufficient, it is preferable to use a buried foundation. It will ensure the durability of the structure for many years. In both cases of foundation construction, heat-insulating material must be laid between its walls and the ground.

It is possible to assert the superiority of one type of foundation over another for a house made of wood concrete only after a detailed study of the conditions for the construction of a particular object. But due to small load-bearing requirements, one can lean towards the most attractive options in terms of cost.

What types of foundations are used for wood concrete buildings?

Tape

Suitable for constructing buildings on soil with non-uniform density. For such a foundation, meter or one and a half meter trenches are dug, the bottom of which is compacted with crushed stone - the so-called cushion. Then reinforcing rods are installed in the trenches, the formwork is assembled and filled with concrete. The depth of penetration depends on the density of the soil. Such a foundation is strong and can withstand significant loads. The disadvantage is the high cost due to the impressive consumption of materials, as well as the need for insulation due to the large area of contact with the soil in the freezing zone.

Pile

Foundations with piles are used when building houses on surfaces with low density or uneven terrain. Piles are reinforced concrete or steel rods driven into the ground to the depth required to securely secure the supporting structure.

Bored and screw supports are used for arbolite walls.

Bored

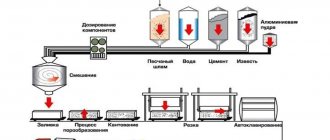

These are solid reinforced concrete rods that are assembled directly on the site. Pile installation consists of five stages:

- Immersion of the casing string into the ground.

- Removing soil from the casing.

- Immersion of the reinforced frame into the resulting well.

- Well concreting.

- Removing casing pipes.

For arbolite houses, the density of piles is every 2.5-3 m.

Screw

They are steel rods with pointed blades at one end and a tip at the other. They are screwed into the ground like screws into a part. The blades secure the piles well in the soil. The piles are screwed in at the head, which also serves as the supporting platform for the future building.

Foundation for a house made of wood concrete: advantages and disadvantages of various types

Wood concrete has been successfully used for quite some time as a material for the construction of private buildings. Today, the ever-increasing demand for such products is due to the light weight of wood concrete, as well as its good thermal insulation properties. It is thanks to the light weight of the blocks that the foundation for a house made of wood concrete, or rather its arrangement, does not require large financial costs, which can be attributed to one of the main advantages of structures made from this material.

In this article we will determine which foundation for a house made of wood concrete blocks is the most optimal in terms of technical characteristics for its construction, and also consider in detail the features of each type of “foundation”. But first, I would like to talk about the types of soil, the composition of which has a significant impact on the choice of foundation for the future structure.

What is the difference between a foundation for a building made of wood concrete blocks?

The foundation is the base, the load-bearing part that supports the walls of the building. The duration of operation of the building depends on its quality. When building houses from wood concrete slabs, the following nuances must be taken into account:

- Since arbolite blocks have less weight compared to other materials, the foundation can be used not as a monolithic one, but as a pile or strip foundation. These types of bases are cheaper than monolithic ones.

- Due to the good strength and ductility of wood concrete, walls can withstand subsidence of the foundation. Thus, they can be erected on various soils.

- Due to the wood fibers contained in wood concrete, the slabs can swell from moisture, which will lead to rapid deformation and destruction. To prevent these processes, the walls must be protected from excessive moisture, and the foundation must be erected at least 0.5 m above the soil level.

How does soil composition affect the choice of foundation?

Depending on their composition, all soils are divided into four main categories:

- sandy, which have a low heaving index and belong to one of the best categories of soils for building the foundation of a house. On such “soil” you can build a foundation for a house made of wood concrete, a foundation for buildings made of aerated concrete, cinder block, brick and other materials. The main advantages of sandy soil are their ability to pass moisture well, compact and compact, which prevents the foundation of a wood concrete house from getting wet, and also contributes to the stability of the entire structure;

- clayey, characterized by its high degree of heaving. It should be noted that in a dry state such soils are an excellent basis for a foundation. However, if there is close groundwater, it gets wet and swells greatly, thereby destroying the foundation of the house. In this case, to prevent deformation of the structure, before laying the foundation, you can pour a sand cushion or use a pile foundation for a house made of wood concrete;

- rock, which, in fact, is a ready-made foundation. Such soils do not lose their physical properties under the influence of moisture and other climatic factors. However, constructing a foundation for a house made of sawdust concrete (another name for wood concrete) on such “soil” is a rather labor-intensive and costly (in terms of finances) process;

- sands with a fine-grained structure. Such soils are rarely used for building houses due to their heaving nature and large freezing depth. At the same time, we note that one of the ways to build a foundation for a house made of monolithic wood concrete on such soil is to use piles.

Arbolite thermal insulation options

- Insulation of walls with panels 820 x 620 x 100 mm. They have optimal sizes: such that the elements are easy to install yourself, while reducing the number of seams to the possible minimum.

- Floor insulation with panels 820 x 620 x 80 mm. This panel differs from the previous one in thickness: practice shows that 80 mm is enough to insulate any ceiling.

Arbolite is a universal thermal insulation material that works equally well where it is necessary to keep warm or, conversely, cool. The house itself made of wood concrete does not need to be insulated.

The foundation for the house is made of wood concrete. Which one is better to choose?

Depending on the design and method of arrangement, all foundations are usually divided into four main categories: strip, columnar, pile, slab.

Arbolite block is one of the lightest wall materials. If the soil does not have the weakest bearing capacity, a lightweight foundation is suitable. The height of the foundation for a house made of wood concrete (one-story or two-story) is usually 50 cm - if the distance between the ground and the floor is smaller, if the waterproofing is poor, the wood concrete will begin to absorb moisture from the ground.

The design is chosen only after geological surveys: it is not worth focusing on neighboring buildings, much less determining the required type “by eye.” The earlier a mistake is made during construction, the more serious its consequences. A reliable option is to use the services of specialists.

Below we note the types that are more or less suitable for buildings made of wood concrete. At the same time, of the pros and cons, we will note only those that are fundamental specifically for this material. For example, we are not interested in the ability of the foundation to withstand the load of a high-rise building, since wood concrete is intended for low-rise construction.

Strip foundation

Such a foundation consists of “ribbons” dug into the ground, which, in turn, rest on foundation slabs. Thanks to this design, the load from the walls of the house is evenly distributed over a fairly large area. However, this type of foundation is not recommended for buildings more than two floors high.

Depending on the method of arrangement, a strip foundation for a house made of wood concrete, or any other building material, is divided into:

- prefabricated, which is made from reinforced concrete blocks and requires the use of special equipment to transport the blocks from the factory and install them at the construction site;

- monolithic, installed immediately on the construction site.

The advantages of a strip foundation include:

- No need for special soil preparation before pouring the foundation;

- Ability to withstand fairly large loads.

But along with the advantages, this type of foundation also has some disadvantages:

- The need to attract specialized equipment;

- Quite a long and financially expensive (compared to pile) construction process.

To summarize, we can say that the use of a strip foundation for a house made of wood concrete blocks can hardly be called the optimal solution, since for such a structure there is no need to equip a foundation that can withstand heavy loads from the walls. As for the cost of such a structure, we will provide a comparative analysis of prices for the arrangement of one or another type of foundation at the very end.

The foundation for a house made of wood concrete can be shallow, since the weight of the building is light.

Columnar foundation

A columnar foundation for a house made of wood concrete or other building materials consists of pillars that are installed in pre-drilled wells or directly into the ground. After installation, the pillars are connected to each other using reinforced concrete beams.

Perhaps the cheapest foundation for a house is made of wood concrete. It consists of support pillars connected by a grillage - a frame of a rigid structure. Can be made of brick, rubble stone or flagstone; There are solutions made of wood or steel and asbestos-cement pipes with concrete filling.

Such structures are installed only on stable soils and are designed for a relatively small load. The advantages of this type of foundation include:

- Costs less than others - approximately 18% versus the standard 30% of the cost of the entire construction;

- Does not require major excavation work: this means that the likelihood of soil movement and shrinkage is reduced.

However, this foundation has many more disadvantages:

- Low strength indicator;

- Ability to withstand only light loads;

- Inability to install on heaving soils;

- Does not allow for a basement or ground floor.

As you can see, using a columnar foundation for wood concrete blocks is also not the best option.

Slab foundation

This type of foundation is a monolithic reinforced concrete slab, which is laid at a certain depth. Such a foundation for walls made of arbolite blocks, or any other building material, can have a thickness of thirty to one hundred centimeters, and a sand cushion is poured as a base for it or a layer of concrete is poured.

A slab foundation for a house made of wood concrete, brick, cinder block or wood has the following advantages:

- The load from the walls of the building is evenly distributed over the entire surface of the base;

- Due to the solidity of the structure, it tolerates deformations quite well, both in the horizontal and vertical planes;

- Possibility of using foundations on weak types of soil.

The disadvantages of this basis include:

- The cost and complexity of its construction are quite high.

Therefore, such a design also cannot be classified as the optimal foundation option for a house made of wood concrete.

Pile foundation

According to statistics, a pile foundation is the most common type of foundation for walls made of arbolite blocks. This design consists of a series of piles connected to each other by a special tape - a grillage, which is made of concrete and can be additionally reinforced to give the product strength. They are perfect for heaving and peaty soil. Also, this foundation will ideally support a house on a difficult piece of soil with pronounced relief, as well as level changes.

Depending on the materials used for manufacturing, piles can be:

- wooden, made from pine, which is processed using special technologies. Such products are ideal for the construction of small and light buildings;

- reinforced concrete, which can be used not only for arranging the foundation for a house made of wood concrete, but also act as a foundation for heavy concrete buildings;

- metal, used when for some reason the use of concrete piles is impossible;

- combined, combining metal and concrete.

The main advantage of using a pile foundation for a wood concrete house is that such structures can be installed on almost any type of soft soil (except peat soil). Therefore, as practice shows, a pile foundation is the most optimal solution, thanks to which you will save a lot of time and money, and your house will stand firmly on the ground, regardless of its composition.

Construction of a foundation from arbolite blocks

Scheme of a foundation for arbolite walls

The process of building a foundation from arbolite is as follows. For a monolithic base, the finished solution is poured into the constructed formwork. The production process is not much different from the standard method of pouring concrete.

Step-by-step instructions for pouring a wood concrete foundation

- We select a site for a residential or permanent building and carefully mark out the future strip foundation made of wood concrete blocks.

- We make a control check of the markings and, according to the given dimensions, dig a trench about half a meter deep.

- We construct formwork for pouring under the foundation. As a rule, reliable formwork is made from boards or wooden panels. The height of the formwork should be half a meter higher than the trench dug under the foundation.

- We pour sand into the bottom of the created structure. We moisturize well and compact thoroughly. For these purposes, as a rule, a special tool is used - a vibrating plate. The thickness of the sand cushion should be at least 20 centimeters.

- We pay special attention to waterproofing. This approach will help to reliably protect the basement of the house from precipitation. For high-quality waterproofing of the base, it is important to use the most modern building materials. They will significantly extend the service life of the foundation, and therefore the entire permanent residential building.

- Next, after waterproofing work, we construct a reinforcing frame. Typically, such a structure is made up of metal rods with a diameter of 10 cm. Then, we fill in a monolithic reinforced tape. This type of work is carried out strictly according to the approved building design. After, when the foundation has hardened and strengthened, we waterproof it, inside and out.

- We fill the formwork with concrete mortar, grade no lower than M-300. It is worth worrying in advance about laying the necessary plumbing and electrical communications. Also, instead of concrete, you can use wood concrete mortar for pouring.

PS As can be seen from the above, building a foundation for a private house from wood concrete blocks with your own hands is not very difficult. And for many ordinary people, this should not be a big deal. If there is even the slightest doubt about success, then use the services of professional builders.

SHARE ON SOCIAL NETWORKS

Wood concrete house: creating a foundation and plinth

The foundation for a house made of wood concrete is one of the types of modern materials for creating not only foundations, but also houses. It is ideal for construction projects with two or even three floors, which indicates its high strength and reliability. This material is created from cement or clay and wood chips. The resulting mixture is poured into molds and blocks or panels are obtained, which are used to construct buildings or foundations. In our article we will discuss how to make a foundation for a house from wood concrete with your own hands.

Products made of wood concrete and sawdust concrete

Since its invention, different product options have been tried, but only the most convenient and relevant ones have survived to this day. These are cement bonded particle board (CSP) and wall blocks.

DSP

Cement particle board is a factory product that is made by pressing a mixture of cement mortar and large (10-50 mm) wood filler - bast and wood chips. The result is a medium-hard slab with good thermal insulation properties. DSP is perfect for covering walls under plaster, subflooring and concreting screeds. For a long time, this material was considered obsolete given the abundance of imported products, but over the last 10 years, environmental friendliness and low cost of production have brought CBPB into the Top 10 panel materials.

Arbolite block

It is produced in a similar way to the stove - the mixture is pressed into the shape of a block. As a result, the wood concrete block turns out to be several times lighter than a cinder block (4.5 kg versus 8 kg), but retains its load-bearing capacity. An interesting fact is that up to 60% of the material’s safety margin is required to withstand the weight of the next (upper) rows of the same material. In the case of light wood concrete, this is especially clear.

Due to its low weight, it retains structural rigidity and does not collapse due to its mass even when dropped. To make it yourself, a minimal set of tools is enough - a concrete mixer, a hammer drill or impact drill and a steel mold with a lid. The mixture is loaded into a mold and pressed by hand using vibration.

Video: DIY wood concrete

Monolithic wood concrete

The technology also provides for construction both in separate blocks and monolithic construction with gradual laying of the mixture. This method is fundamentally identical to traditional concreting. However, the main problem of formwork for ordinary concrete is the strength requirements, the ability to withstand the load of heavy concrete. In the case of wood concrete, the mass of filling the formwork is approximately 10 times less - simple boards made of one-inch boards (25 mm) are sufficient.

In the case of the construction of monolithic walls, ordinary plank frames are used as “reinforcement”. They are installed vertically in increments of 1200–1500 mm. This imparts structural rigidity to the entire wall and creates a mandatory expansion joint necessary for uniform distribution of shrinkage loads when humidity changes. The board should first be antiseptic.

Just like any type of material based on cement mortar, wood concrete is perfect for filling cavities. The specific gravity of wood concrete is 300–800 kg/cubic. m, while it is a load-bearing material. Given its good thermal insulation properties, this is relevant for attic and interfloor ceilings. As insulation, it is more than cost-effective - the cost is 1 cubic meter. m of material is about 10 times cheaper than mineral wool. In addition, it does not require mandatory covering - you can walk or store things on the flooded ceiling.

Video: wood concrete flooring

For lightweight monolithic structures made of wood concrete, not all the rules that apply to concrete are valid. For example, reinforcement with metal rods is harmful to them - the difference in density and thermal conductivity is too large. As a result, there is a risk that when the temperature changes, condensation forms on the metal, which is harmful to all materials. Therefore, if there is a need to apply reinforcement, use a polymer road mesh.

Advantages and disadvantages of wood concrete

Today there is an economical variation of the material - sawdust concrete, which has less strength. Wood concrete is popular for its environmental friendliness and cleanliness; it is not prone to rotting and burning. This kind of material is very easy to machine and hammer nails into. We will now talk about all its other advantages. So:

- Light weight, which is 4 times less than brick;

- Has the ability to create an optimal microclimate and air exchange in the house;

- The material is able to retain heat;

- With a small wall thickness, houses with two or three floors can be built;

- Wood concrete is not susceptible to rotting and infection by fungi and microorganisms;

- Does not burn, can withstand temperatures up to 1000 degrees for about forty minutes;

- It is also resistant to mechanical stress;

- The material is easy to saw and holds nails;

- The walls are able to adapt to climatic conditions;

- It is economical in heating terms;

- Arbolite has sound insulation.

Attention! The composition of wood concrete has more wood chips in its design, and therefore has the same technical characteristics as wood.

Despite such a large list of advantages, the material has a number of disadvantages such as:

- Low level of resistance to moisture, and high moisture permeability;

- If you use wood concrete for external decoration, you will need to create a special finishing layer;

- If a large amount of sawdust is present in the material, the risk of damage to argonite from moisture increases. To solve this problem, it is necessary to perform plastering, which will increase the strength of the substance.

- Small rodents can use argonite as a place to live, therefore, to avoid this situation, it is better to create a base of concrete with a layer of 50 cm, and place a chain-link mesh under it.

Classification of block types

The classification of materials is influenced by the following characteristics:

- Density level when completely dry;

- Type and composition of filler;

- Purpose of the material.

According to the first criterion, two types are distinguished:

- Thermal insulation type – 500 kg per cubic meter. m;

- Structural block – up to 850 kg per cubic meter. m.

According to the composition of the filler, wood concrete can be:

- From sawdust or wood chips;

- From rice stalks and cotton, flax or hemp.

- Blocks with a low level of strength find their use in creating a layer of thermal insulation of a building and partitions between rooms, and walls, except for load-bearing types.

- If the strength of the material is high, then it is better to use it when installing load-bearing types of walls.

House kits made from SIP panels

div class=tab_changerinput name=odin checked=checked id=vkl1 type=radio /label for=vkl1Technology for assembling a house from SIP panels. /labelinput name=odin id=vkl2 type=radio /label for=vkl2Construction of a house from sip panels. /labelinput name=odin id=vkl3 type=radio /label for=vkl3Photo./label diviframe width=680 height=525 src=https://www.youtube.com/embed/aoOmNaDiHe4 frameborder=0 allowfullscreen=allowfullscreen/iframe p style=text-align: left;Self-assemblynbsp;housenbsp;fromnbsp;SIP panels./p h2 class=h2_tTechnology for assembling a house from SIP panels./h2/div diviframe width=680 height=525 src=https://www. youtube.com/embed/yo80ZB0IuLM frameborder=0 allowfullscreen=allowfullscreen/iframe p style=text-align: left;Constructionnbsp;housenbsp;fromnbsp;sip panels. Onbsp; technologiesnbsp; productionnbsp; sip panels. br / br /Sip panelsnbsp; – universal material. It is used during the creation of roofs, partitions, walls, ceilings and other elements of the house. br /Constructionnbsp;housenbsp;fromnbsp;sip panels beginsnbsp;withnbsp;installationnbsp;pilenbsp;foundationnbsp;onnbsp;construction site./p

h2 class=h2_tConstruction of a house from sip panels./h2 emIn this section we have collected video stories for you where you can watch the design and construction of sip panels./em/div div div align=center figure tabindex=1 class=vkl2span class= aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej.jpg alt= title= /figcaption/figcaption/span/figure figure tabindex= 1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-0.jpg alt= title= /figcaption/ figcaption/span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-1. jpg alt= title= /figcaption/figcaption/span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty- iz-sip-panelej-2.jpg alt= title= /figcaption/figcaption/span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/ 2016/03/wpid-domokomplekty-iz-sip-panelej-3.jpg alt= title= /figcaption/figcaption/span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www. arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-4.jpg alt= title= /figcaption/figcaption/span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-5.jpg alt= title= /figcaption/figcaption/span/figure figure tabindex=1 class =vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-6.jpg alt= title= /figcaption/figcaption/ span/figure figure tabindex=1 class=vkl2span class=aligncenter size-fullimg src=https://www.arbolit.net/assets/files/2016/03/wpid-domokomplekty-iz-sip-panelej-7.jpg alt = title= /figcaption/figcaption/span/figure /div p style=line-height: 10px; font-size: 10px;emspan style=font-size: 11px; By carefully watching such videos, you can glean quite a lot of useful information from those who consider themselves professionals in this field./span/em/p /div /div p

SIP house with flat roof

Technology for building houses from sip panels

Chalet style house projects

Electrical connection

/p

Technical characteristics of blocks

Which block to choose for construction work? To answer this question you need to know the technical criteria and characteristics of the material. So, the following indicators are distinguished:

- The average density indicator is based on the values of the filler components and binder substances. If the density increases, then the strength of the material increases, and therefore its class.

- The thermal conductivity of wood concrete increases in parallel with the amount of binder material. But it is worth noting that an increase in this indicator leads to a decrease in strength and loss of structural properties.

- Frost resistance is at the level of 25-50 cycles.

- The degree of shrinkage is calculated by the density of the block. If the latter indicator decreases, then it increases.

- Water absorption reaches 80% - this figure is much higher than other materials.

- Vapor permeability – a distinctive feature should be considered a high value, which is equal to that of wood.

- Fire resistance. It also has a high level, since wood concrete does not tend to burn, it can easily withstand high temperatures.

- The level of sound transmission is the same as that of natural wood.

- The maximum number of storeys in a building made of wood concrete is 3.

- The blocks are designed for mass consumption, so their price is affordable for everyone.

News

We talk about the installation of monolithic floors in a house made of wood concrete.

A monolithic floor is a load-bearing structure that divides a building into floors. In fact, it is a floor, so it must meet the requirements for strength and rigidity, and withstand its own weight and the weight of everything that is on it. The ceiling must also have the necessary heat and sound insulating properties and be fire resistant. The construction of a monolithic floor can be divided into stages:

1. Installation of formwork

The formwork consists of a deck and telescopic racks, securely fixed with tripods. The racks are installed at the same distance from each other, which is determined by the thickness of the slab: the thicker it is, the closer the racks are. We lay longitudinal beams on the telescopic racks, then transverse beams perpendicular to them. We check the formwork structure for evenness using a level and a level. The quality of the surface of the future monolithic floor depends on this. Then we make the flooring with laminated plywood sheets 18 mm thick. It performs the function of a deck, which is one of the main structural elements of the formwork panel. The advantages of using laminated plywood include high moisture resistance - the sheets can withstand repeated pouring cycles without deformation; thanks to the laminated surface of the plywood sheet, monolithic floors are smooth and even. We seal the joints between the plywood with film to prevent concrete from leaking into them during pouring.

2. Floor reinforcement

The reinforcement gives the structure rigidity, preventing the monolithic slab from breaking or bending. We install the reinforcement at a distance of 25-30 mm from the end to eliminate interaction between metal and air and prevent corrosion. Special plastic stops and clamps lift the reinforcement and create a protective layer of concrete underneath it. The size of this layer depends on the thickness of the floor, span length and other factors.

3. Pouring concrete mixture

After reinforcement, we perform grouting using a concrete pump. To compact the concrete mixture, we must use an internal vibrator.

In the first days, concrete must be protected from precipitation and loss of moisture, so when it rains, we cover it with a special film, in cold weather we warm it up and use antifreeze additives, and in hot weather, we moisten it to prevent cracks.

4. Dismantling of formwork

Dismantling the formwork, the last stage of installing a monolithic slab, occurs 4 weeks after concreting.

CALL, ASK QUESTIONS and ORDER or on the website

Read more about wood concrete houses here >>>

Base for construction made of wood concrete

The base for such a building can be made of a combined or monolithic type. This base will protect the walls from excessive moisture. The foundation of the house should be done at a height slightly higher than the strip type laying.

Attention! Construction workers do not recommend laying too deeply.

Today there are many ways to build a foundation; in addition, many methods are economical and do not require large financial investments. If the building is made of wood concrete, then it is recommended to install a shallow shallow base. And as materials for this it is better to choose one of the following options:

Wood concrete houses

If the building design involves construction from wood concrete, then the question arises: what kind of floor to use?

Wooden interfloor ceilings in a house made of wood concrete can only be used if the wood is treated with special means.

This way the beams will not rot or collapse. It is also worth worrying about fire safety.

House made of wood concrete: how to cover the first floor? It is better to use lightweight materials that are light in weight but can withstand significant loads. There are ribbed wood concrete floor slabs with load-bearing side edges. They give the structure additional rigidity and stability.

Making blocks with your own hands

Wooden sawdust and shavings of approximately the same quantity are most often chosen as filler. There is a rule: 4 months before the start of work, sawdust must be left in the open air. And treat them regularly with lime solution.

Attention! The treatment process is carried out with a 1.5 lime solution. A cubic meter of raw materials consumes approximately 200 liters of substance. The sawdust is placed in the liquid and kept with constant stirring for two days. This method prevents the material from rotting.

After processing of the raw materials is completed, the process of forming blocks can begin. In order for all the materials to turn out identical, it is necessary to take boxes with a volume of 0.3 cubic meters for the mold. Pour part of the mixture into the container, pour water on top and mix everything with a shovel. Next you need to add cement and repeat mixing again. To carry out the work, you can use a concrete mixer or do it yourself.

Attention! Mix proportions: Cement -1, lime -1, sawdust - 9. If necessary, other impurities can be added. It is worth considering that the greater the amount of cement, the better and stronger the argonite blocks will be.

The prepared material is poured into molds, which are made from 20 mm boards. The dimensions of the cubes are 25 by 25 by 50 cm. The inner surface of the mold can be covered with plywood or linoleum for comfortable use. The use of technology will make it easy to remove blocks from the container. The mixture hardens for about two weeks at a temperature of 22 degrees. After this, the wood concrete is taken out and left in the fresh air.

Making wood concrete blocks with your own hands

Composition of an arbolite house

Making arbolite blocks with your own hands is not difficult, as it seems at first glance. It is only necessary to thoroughly know and understand well the process of production of wood concrete blocks and their components.

The filler used for the working solution is usually simple sawdust with shavings. The ratio of these two ingredients is usually the same. But you can use a different proportion. For example, one part of sawdust and two of shavings.

There are some nuances of making wood concrete blocks with your own hands. Before making the solution, about 3-4 months in advance, shavings and sawdust are placed in the open air. From time to time, they are treated using lime mortar or simply shoveled periodically. The substance is processed as follows: the lime is diluted to a 1.5% solution. For every cubic meter of raw materials, 200 liters of such a solution are introduced. The filler is added to the lime composition. Next, it is aged for 2 to 3 days. Don’t forget to stir it 1-2 times a day. This approach will not allow wood filler raw materials to begin to rot.

Forming wood concrete blocks with your own hands

After the raw materials have reached the desired condition, we begin the formation of wood concrete blocks with our own hands. To ensure that the blocks are even, as a rule, wooden boxes with a volume of 0.3 cubic meters are used for the mold. A certain amount of sawdust is poured into a wooden container, watered and thoroughly mixed with a shovel. Next, cement is added according to the proportion. To facilitate and speed up the process, you can use a concrete mixer.

Proportions of the finished mixture:

- 1 share of cement;

- 1 share of lime;

- 9 shares of sawdust.

If necessary, other, non-contradictory components can be introduced into the solution.

To lay the walls, the mortar is poured into molds constructed from 20 mm boards. The optimal mold dimensions are 250 by 250 by 500 mm. For convenience, the inside of each form can be lined with plywood and a piece of linoleum. This approach to production will significantly simplify the removal of the finished structure from the mold. The process of forming a block of wood concrete takes about 10-14 days. Wood concrete hardens well at a temperature of 20-22 degrees. Afterwards, the finished blocks must be removed from the mold and left under a canopy until they completely harden and gain proper strength.

It’s easy to check whether the wood concrete block is complete and ready for use. A nail is driven into the wide part of the product. Afterwards, the blog is dropped onto any hard surface. If the structure remains intact, then the product can be safely used.

Stages of creating a foundation

For a house made of wood concrete, he installs a strip base. It is made mainly from bricks, concrete or wood concrete. Brickwork must be done on top of the base. 0.5 meters high. The working solution can be filled with wood sawdust in a one to one ratio. The device can be made monolithic by pouring a concrete solution into the formwork. The following procedure must be followed:

- We mark the strip structure along the entire perimeter of the construction site;

- We dig a trench half a meter deep;

- Using boards and wooden panels we build formwork, 50 cm high above the ground;

- Cover the bottom of the pit with a cushion of sand, a layer of 20 cm. Next, moisten the mixture and compact it.

- We lay waterproofing material;

- We install the reinforcement frame. Rods with a diameter of 10 mm.

- We pour grade 300 concrete.

Attention! Before filling, you need to think about laying the communication lines of the house: ventilation, water supply, sewer and electrical systems. You can replace concrete with wood concrete.

The blocks are created measuring 25 by 25 by 50 cm from boards 2 cm thick. To ensure ease of removal of the blocks, the inner surface is lined with plywood and linoleum. When the form is completely filled, excess sections are removed with a ruler or saw. The elements are ready after two weeks of drying.

Insulation of an arbolite house from the inside, outside

Today there are many options for constructing the walls of a private house from wood concrete. In the southern regions, a wall made of wood concrete can be erected 30 cm thick without additional insulation. In the northern regions, an external wall of 30 or even 40 cm will not retain heat well enough. In order to protect the structure from freezing, and the home from possible heat loss, it should be finished from the street with a layer of thermal insulation.

Photo. How to insulate a wood concrete house with your own hands

Insulation of arbolite walls with foam plastic

Expanded polystyrene should be used only for insulating a wood concrete house from the outside. In this case, it will be necessary to improve the air ventilation system in the house, since the use of foam plastic will lead to a decrease in the vapor permeability of the walls. The slabs are attached to the facade using an adhesive composition and are additionally fixed with disc dowels; the seams between the slabs should be carefully foamed to eliminate cold bridges

Photo. Insulation of the facade of a house without cold bridges

Insulation of arbolite walls with mineral wool

Manufacturers of stone wool recommend using a layer of at least 10 cm of insulation to insulate the facade. It is advisable to lay mineral wool slabs in two layers to avoid cold bridges in the structure. To avoid making a mistake in choosing the thickness of the insulation material, use an insulation calculator and do not forget to protect the fiber insulation with a vapor barrier film.

An online dew point calculator will help you calculate the thickness of thermal insulation and see where condensation occurs.

Insulation of wood concrete with sawdust and ecowool

These materials are natural insulation materials consisting of cellulose. Ecowool and sawdust are poured during the construction of walls between the load-bearing wall and the facing brickwork. Expanded clay, polyurethane foam or polystyrene foam boards can also be used as insulation inside the walls. Watch the video below to see how to independently insulate a house from wood concrete blocks from the outside.

Foundation for a house made of wood concrete - the influence of material properties on the choice of design

There are not so many reasons why wood concrete temporarily lost its popularity in the domestic market. But they turned out to be so significant that the production of blocks completely ceased at the end of the last century, although analogues were widely used abroad all this time. Thanks to its unique characteristics and performance properties, the material has managed to revive its former glory today. Let's try to figure out what features a foundation for a house made of wood concrete has, and what they are connected with.

Common mistakes in building a house from wood concrete:

- entrusting construction to non-professionals. The main reason for subsequent dissatisfaction with the operation of a house made of wood concrete. Negative reviews of a house made of wood concrete are quite fair in this case;

- incorrect block selection. A loose block will shrink greatly, causing the walls to bend vertically;

- absence of reinforced block before the ceiling. Leads to uneven distribution of load on the walls - uneven curvature;

- poor block geometry. Leads to excess consumption of masonry mortar and finishing plaster;

- construction of a plinth made of cellular concrete. This does not provide adequate protection of wood concrete from moisture.

As you can see, all errors are caused by an attempt to save money during the construction process. However, you need to save wisely!

Knowing the construction technology, and most importantly its nuances, you can build a high-quality house from wood concrete with your own hands.

Source: moydomik.net

Brief information about the material

Arbolite belongs to the group of lightweight concrete. The blocks contain up to 90% organic fillers, as well as cement and chemical additives that do not allow organic matter to influence the hardening process of the binder. The environmentally friendly material has high levels of heat and sound insulation with a low weight of the erected structure.

The unique characteristics of wood concrete make it possible to significantly reduce the thickness of walls and allow its use in regions with harsh climates. Despite the fact that the production of blocks in the USSR was established in the 60s of the last century, the material did not become widespread, and in the 90s the factories were completely repurposed or simply destroyed. At that time, developers paid little attention to energy-saving technologies, focusing on other areas that seemed more promising.

Modern conditions associated with the search for more economical methods of construction have forced us to remember arbolite concrete. The industry is currently undergoing a revival, and for good reason. Objects erected from wood concrete more than half a century ago are in excellent condition, which means the material has stood the test of time. In Europe and America, analogues were and continue to be used, since ordinary residents of capitalist countries value such concepts as “efficiency” and “energy saving”, “environmental friendliness” and “quality”.

Technologies for the construction of private houses from wood concrete

A house can be built in two ways:

- Construction from arbolite blocks

. In this case, industrially manufactured ready-made wood concrete blocks are used; - Monolithic construction from wood concrete

. The use of this technology involves the formation of permanent formwork and subsequent pouring of wood concrete mortar into it.

Often the decision is made to make wood concrete with your own hands. Before starting work, it is important to make sure that the blocks have gained the strength and hardness necessary for work.

To build a house from monolithic wood concrete, you need to study the technology of constructing monolithic walls. The remaining stages will be identical to block construction.

In this article, we will focus on a detailed description of the first option.

How to build a house from wood concrete blocks with your own hands

The main stages of work in the form of successive steps from A to Z.

Features of wood concrete blocks

Concrete containing wood chips, shredded cotton stalks or crushed rice straw can withstand not only compressive loads, but also flexural loads. In addition, arbolite stone:

- absorbs noise, being a good sound insulator;

- does not burn;

- does not support decay processes;

- is able to restore its previous shape after removing short-term bending loads;

- has low thermal conductivity;

- has low weight;

- easily amenable to mechanical processing - dividing into parts and drilling.

For the construction of load-bearing walls, a structural type of arbolite stones with a density of up to 850 kg/m3 is used.

Among the disadvantages of the material, it should be noted that it is highly hygroscopic, as well as the unclear outlines of the blocks. In addition, in masonry it is necessary to install reinforced belts along the entire perimeter at the level of the plinth, under the interfloor ceiling, above the openings and along the upper cut of the walls. Independent production of wood concrete blocks is practically possible, but the products, in this case, are unlikely to meet the required strength characteristics. High-quality material is obtained only in industrial conditions.

What is wood concrete

Wood concrete is made from wood chips (20–50 mm) and cement mortar. It has low thermal conductivity, but is suitable only for upper floors and lightly loaded masonry. This material has been known for a long time - along with many derivatives of standard concrete, it is the result of an experiment to replace coarse aggregate - crushed stone. As is known, wood has significantly lower thermal conductivity than any stone (except porous), which means that the thermal conductivity of the material in which wood inclusions are used decreases.

Any type of waste when processing pure wood (except bark) with a thickness of no more than 15 mm is suitable for wood filler. It can be bast, shavings, fibers, wood chips. Such filler can be purchased inexpensively at your nearest sawmill. The “classic” composition looks something like this: 1 part cement, 2 parts sand, 6–8 parts wood filler.

Video: properties of wood concrete