Expanded clay concrete wall panels are widely used in construction. Many developers prefer expanded clay concrete due to its high quality, low level of thermal conductivity, resistance to chemicals and budget price. However, expanded clay concrete blocks have a porous structure, so it is not advisable to use them for the construction of large objects and foundations. Wall panels are used in the construction of internal partitions and the design of facades.

general information

According to GOST 32488-2013, expanded clay concrete is classified as lightweight concrete. The production technology involves the use of a special filler - expanded clay, which is made from baked foam clay. Installation of expanded clay concrete products does not require excessive effort, time and installation equipment. But panels and blocks based on expanded clay concrete must be handled with extreme caution. Despite the fact that they can withstand heavy loads, they are fragile and resistant to sudden mechanical damage. Due to their porous structure, expanded clay concrete slabs actively absorb moisture, which in excessive quantities can negatively affect their quality. Therefore, the laying of such elements requires the use of additional moisture-resistant and heat-insulating materials.

Moisture does not harm expanded clay concrete, but it can stagnate in the pores and, under the influence of sub-zero temperatures, turn into ice. And this is fraught with destruction of the panel.

More often, expanded clay concrete products are used for the installation of walls of above-ground floors, basements, undergrounds, parapets and attics. The slabs are produced in one-, two- and three-layer, monolithic or with openings. Developers use them as enclosing internal partitions, for façade design, and also fill the frames of reinforced concrete structures with expanded clay concrete panels.

View "GOST 32488–2013" or

Description of material

It is based on natural ingredients. Foamed clay that has undergone heat treatment hardens and is turned into granules by a special device. Due to the compaction of the texture, the base becomes durable and strong. The porosity of expanded clay concrete is also one of the advantages of the material, because this reduces the overall weight of the building, but the technical characteristics do not suffer.

For the price, the panels are an excellent alternative to brick and other building materials. Also, clay granules can be used as a filler for concrete, which reduces the cost of the procedure but does not affect the quality.

Expanded clay concrete wall panels have a number of advantages:

- Good thermal insulation characteristics. Thanks to the porous texture and compressed air inside, the material retains the cold and does not allow it to enter the room.

- Moisture resistance. The panels do not need to be additionally treated with protective and sealing agents, since their base is already protected from water absorption.

- Resistant to chemicals.

- Availability in terms of price.

Disadvantages include low strength for the construction of multi-story buildings and pouring foundations. Expanded clay concrete wall slabs can only be used to create interior partitions and walls.

The technology for producing the material consists of producing blocks, the sizes of which can be different and depend on the type of cutting. Standard generally accepted dimensions are 7300 mm in length and 8300 mm in height. Due to their technical characteristics, the blocks can be used as fillers for iron structures.

Technical characteristics of panels

Although the base of the material is protected from water ingress and loss of strength, the blocks are “steam-breathing”, which creates favorable climatic conditions in the room. High frost resistance can also be distinguished. Expanded clay concrete wall panels can withstand up to 500 freezing and thawing cycles.

- Resistance to mechanical loads. On average, the material can withstand pressure up to 100 kg per square centimeter.

- Although the weight of the material depends on the brand and type of concrete, when compared with other building elements, it still stands out for its light weight and dimensions. Masters classify it as a light type of concrete.

- Environmentally friendly. The composition contains only natural ingredients, mixed and frozen without the addition of chemicals and substances harmful to health. The panels can be used both for the construction of technical premises and for residential buildings.

The material can be combined with others, is well processed, and can be given the desired shape. Such modifications and changes in appearance are possible due to the voids inside the panel. During processing, expanded clay concrete produces virtually no waste due to its compacted texture and strength.

Classification according to various parameters

Expanded clay wall panels are divided into several types according to their characteristics. Among the application options, they can be intended for the basement, above-ground floor, or construction in the attic. By type of static work there are:

- Hanging structures.

- Self-supporting.

- Bearers.

The material is also classified according to the type of device. Expanded clay concrete is:

- Solid.

- Prefabricated - consisting of several elements that form a complete surface. To bind the original parts, a solution, glue or special astringent mixtures can be used.

The purposes for using such plates also vary. According to purpose, the material is divided into the following types:

- Structural. Used to create elements that can withstand heavy loads (parts of bridges, houses). Due to its porosity and high durability, the material has low weight, therefore it is used for reinforced concrete structures.

- Structural and thermal insulation. Suitable for the production of single-layer panels and blocks of large parameters. Frost resistance is characterized by 15−50 cycles.

- Thermal insulation. Used to create interior partitions.

The method of manufacturing the panels is also important. According to GOST they are divided into the following types:

- External elements based on expanded clay concrete. Suitable for rooms that are not heated, the porosity of the material is lower than in other types, which provides greater durability.

- Layered. To create them, a material with a heat insulator is used or single-layer panels are created.

- Partition panels, for the manufacture of which different proportions of the mixture can be used.

The dimensions of the ramzit concrete panels also play an important role in the selection. Large parameters make it possible to construct buildings faster.

Requirements and Standards

The material is allowed for work only if it fully complies with the working drawings and documentation approved in the prescribed manner. Project documentation usually indicates minor deviations or external inconsistencies with the drawings. The surface may have protrusions, recesses, reinforcement outlets and steel tabs to connect several elements into one.

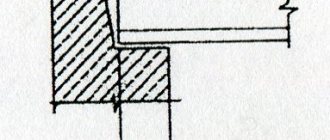

Cutouts and recesses along the contours of window and door openings are also allowed on the surface for securing frames, window sill boards and other elements. There may also be architectural elements and grooves to connect with other parts.

Regarding dimensional requirements, they must comply with modular coordination. The nominal thickness is determined subject to the requirements for strength, rigidity, thermal protection, sound insulation and resistance to cracking. For the load-bearing layer, a thickness of 100 mm will be sufficient, for the thermal insulation layer - 75 mm.

The thickness of the protective and decorative layer depends on the type of application. For ground panels this is 15 mm, for basement and technical panels - 30 mm. During testing, the mounting hinges of the panels must comply with the design documentation and withstand the test loads specified in the drawings.

When making a mixture, it is important to adhere to the percentage of materials. For the supporting layer, a composition of expanded clay concrete with intergranular voids of no more than 3 percent is used. If the porosity is higher, the panel will not be strong enough to withstand the typical load in load-bearing panels.

In some cases, it is possible to produce a mixture with voids up to 6 percent, provided that there is a decorative protective layer and an internal finishing layer. This compacts the texture and makes the panel more durable, and also protects well from the absorption of excess moisture.

The strength of the decorative-protective layer for single-layer elements must be no lower than grade M 100, and for two-layer panels - no lower than M 300. When inspecting the working documentation for the material, you should pay attention to the indication of the structure of expanded clay concrete, the type of coarse and fine aggregates, and the indication of the maximum granule size .

What are they made of?

In the manufacture of building materials, expanded clay is used, with a fraction of five to forty millimeters.

In the structure of expanded clay concrete, the binding component is Portland cement of a grade not lower than M 400. The composition also includes large aggregate - expanded clay, the dimensions of which vary from 5 to 40 mm, as well as fine aggregate, water, and additives. The components of the building material are exclusively natural ingredients that are not capable of harming human health; any chemical substances are completely excluded.

Application area

The scope of use of expanded clay concrete blocks is related to the purpose of the products. They are divided into the following types:

- Blocks used for the construction of partitions.

- Products used for the construction of capital and internal walls.

Expanded clay block is used when performing construction work related to the construction of:

- structures that can withstand increased loads;

- outbuildings;

- industrial facilities;

- partitions that perform soundproofing functions;

- premises for vehicles;

- monolithic structures.

When deciding to use expanded clay-based composite concrete, pay attention to the weight of the expanded clay block associated with the correctly selected composition of the material. The weight of one block depends on the design features and ranges from 5.1-34.3 kg.

The construction industry is constantly evolving: new technologies, materials and methods are being introduced to make work easier

Varieties and characteristics

Expanded clay concrete slab has different types and one of the distinguishing criteria is weight. There are panels that are heavy, large-porous and light. The latter is usually used for arranging wall panels. Building materials are distinguished by purpose:

- Structural. These include bridges, houses and other buildings that are regularly subjected to heavy loads. Product density is up to 1.8 t/cubic meter.

- Structural and thermal insulation. Used in the production of wall panels of 1-layer and large blocks. It has a density of 0.7-1.1 t/m3.

In addition, the series and functionality of expanded clay concrete elements are different (load-bearing, hinged, self-supporting), and they are also distinguished by their thickness:

- panels for upper floors - 0.24 m and 0.32 m;

- elements for the construction of cellars and other premises below ground level - 22 cm;

- slabs for laying the plinth - 220 and 300 mm.

The sizes and types of wall panels depend on their functional purpose and compliance with the project.

Expanded clay concrete wall panels have less weight than concrete and are divided into row, horizontal, corner, and vertical. There are products with grooves and recesses that are intended for fastening and communications. The dimensions of the wall panels depend on the functional purpose of the building and customer requirements.

Variety of expanded clay concrete wall slabs

If you see the marking 1НСН, then in front of you is an external single-layer wall panel with a single-row cut, which can become a load-bearing panel.

The fact that this is an external single-layer horizontally cut wall panel is indicated by the 1NGO marking. Double-layer horizontally cut external wall panels are products with the designation 2NGP. If production is carried out according to state standards, then this means that the numbers and letters indicate the type of panel, and the class of expanded clay concrete in terms of compressive strength is mentioned through a hyphen. Symbols in the third group indicate additional characteristics, such as the presence of cutouts and holes.

If you saw the marking 2НСН Its length is equal to mm, while the height and thickness are equal to and mm, respectively. As for the compressive strength class, these products correspond to B. The thickness of expanded clay concrete wall panels was mentioned above, but this characteristic is not the only one that you should know about before purchasing the described material.

As for thermal conductivity, for these products it is similar to brickwork, the thickness of which varies from to cm. The number of layers affects the density.

The brand of the concrete component affects the weight, and the same can be said about the dimensions. The products make it possible to reduce the weight of reinforced concrete structures. Expanded clay concrete wall panels, the dimensions of which are mentioned in the article, are quite frost-resistant; they are able to undergo approximately freezing and thawing cycles.

The thermal conductivity of expanded clay concrete wall panels may vary depending on the purpose of the products.

If we are talking about thermal insulation panels, then they are used for insulation during the construction process. But the thermal conductivity is 0. On sale you can find structural and thermal insulation products that are used for the construction of facilities where it is necessary to reduce the weight of structures. This provides the material with high strength, which is especially true when compared with thermal insulation products.

However, thermal conductivity in this case is higher and can be equal to 0.

Such expanded clay concrete wall panels, the GOST for the manufacture of which was mentioned above, have less impressive frost resistance; it can correspond to the MP3 limit. Such blocks are the most durable, they are used for the construction of houses and industrial premises. The density is quite high and depends on the type of material. Frost resistance can be equivalent to MP3.

Add a review

When insulating a wall made of expanded clay concrete, it is advisable to do this from the outside of the structure. Mineral wool boards with medium or low density are well suited for this purpose. To correctly calculate the required thickness of insulation, try using a thermal conductivity calculator if you know how to do this.

Republic of Adygea, Takhtamukaisky district, town. Enem st. Perova, call me back. 3-hollow expanded clay concrete wall block Home Catalog Brick 3-hollow expanded clay concrete wall block.

Advantages of expanded clay concrete blocks

Format: 3-hollow Type: Expanded clay concrete Size: xx Weight: Description Characteristics Reviews Recommended. There are no reviews. Advantages of expanded clay concrete blocks Expanded clay concrete blocks significantly simplify the work of builders. Expanded clay concrete blocks are usually larger than bricks, so the construction of a building takes less time, and the number of blocks is also less than the number of bricks for the construction of the same wall.

Advantages and disadvantages

Experienced and novice developers prefer expanded clay concrete wall panels because they have a whole list of advantages:

- Affordable price. Unlike similar building materials of similar high quality, the price of expanded clay cement slabs does not hit your pocket too much.

- Low thermal conductivity. Wall panels based on expanded clay concrete do not release heat outside, keeping it indoors.

- High moisture resistance. Does not change its characteristics under the influence of moisture, and is also not subject to the influence of an aggressive chemical environment.

- A light weight. Thanks to this criterion, it is easy to work with such building materials and there is no need to use special expensive equipment for installation.

- Environmentally friendly. Expanded clay concrete does not contain harmful impurities and is safe for the human body.

- Soundproofing. Perfectly absorbs noise from outside.

- High strength. Despite the porous structure, expanded clay cement panels are durable and of high quality.

- Resistance to mold and fungi. The surface of expanded clay walls does not become moldy or become covered with fungal spores.

The building material has few disadvantages, but they cannot be ignored. So, one significant disadvantage is insufficient resistance to shock loads. When working with expanded clay concrete or during transportation, it can easily be damaged. The appearance of such walls, which requires decorative cladding, is also considered an imperfection.

Wall panels

An air gap is called a screen. If we are talking about single-layer panels, then they have low thermal conductivity qualities. The panels can also be divided according to the cut of the walls; they can be uniform, angular, strip and vertical. As mentioned above, expanded clay concrete panels are classified according to a number of characteristics, so manufacturers have adopted many designations.

If you see the marking 1НСН, then in front of you is an external single-layer wall panel with a single-row cut, which can become a load-bearing panel. The fact that this is an external single-layer horizontally cut wall panel is indicated by the 1NGO marking.

Double-layer horizontally cut external wall panels are products with the designation 2NGP.

Description of material

If production is carried out according to state standards, then this means that the numbers and letters indicate the type of panel, and the class of expanded clay concrete in terms of compressive strength is mentioned through a hyphen. Symbols in the third group indicate additional characteristics, such as the presence of cutouts and holes.

Reinforced concrete wall panels are one of the main elements of modern buildings, serving as load-bearing elements of walls, and are also used for some auxiliary operations. All high-quality wall panels offered by our company are divided into load-bearing, self-supporting and suspended.

If you saw the marking 2НСН Its length is equal to mm, while the height and thickness are equal to and mm, respectively. As for the compressive strength class, these products correspond to B. The thickness of expanded clay concrete wall panels was mentioned above, but this characteristic is not the only one that you should know about before purchasing the described material.

As for thermal conductivity, for these products it is similar to brickwork, the thickness of which varies from to cm. The number of layers affects the density. The brand of the concrete component affects the weight, and the same can be said about the dimensions.

Expanded clay concrete is often used in construction work and has a number of qualities that set it apart from the rest. Due to their low thermal conductivity, increased moisture resistance and protection from destructive environmental factors, expanded clay concrete panels are popular in both industrial and domestic construction. Due to the large dimensions of the elements, the building construction process will be fast and of high quality. It is based on natural ingredients.

The products make it possible to reduce the weight of reinforced concrete structures. Products have standardized sizes, which are determined by the type of cutting. Their length is within 30 cm, height - 30 cm. The AI series includes products for basement structures with a width of 22, 30 cm, basements - 22 cm, upper floors with a width of 24, 32 cm.

Series with designation codes and ,8 are basic for the construction of residential real estate, public and industrial buildings. The customer can determine the dimensions of the panels of an individual series of products. Series of external wall panels 1. The characteristics of the product must correspond as closely as possible to the location in the structure of the building for which it is intended: load-bearing, self-supporting wall, partition, ground floor, basement, attic.

Thus, three-layer panels have increased sound insulation and minimal vapor permeability, but they should be preferred to single-layer products for fencing residential premises.

Where are they used?

The load-bearing capacity of expanded clay concrete lies within wide limits, so for a specific part of the building it is necessary to calculate the load that the manufactured slabs with the given characteristics will accept. Storing wall panels requires protection from moisture and freezing; violations lead to their damage already in the structure of the building. The relatively light weight of expanded clay concrete slabs reduces the load on the foundation and simplifies installation and rigging work. They and the partition panels are attached to the embedded parts of the supporting columns and other elements.

Before installing the next top panels, installation joints are laid with a vapor barrier, and vertical joints are also laid with cement mortar, which increases the durability of the structure. The construction of buildings from expanded clay concrete panels involves the use of products only for their intended purpose in accordance with their characteristics.

The house can be built entirely from panels with specified properties, which are made according to the customer’s dimensions, which will significantly reduce the cost and duration of construction. Variety of expanded clay concrete wall slabs Contents.

Where are they used?

Main characteristics and properties of expanded clay concrete panels

Today, expanded clay concrete material is widely used in the construction industry. It is equated to concrete raw materials, but expanded clay concrete has better technical characteristics, which include a low level of heat conductivity, resistance to chemical compounds, and resistance to water. The structure of expanded clay concrete products is porous, so it is not recommended to use it in the construction of large objects and foundations. The construction market today offers expanded clay concrete panels, the features of which must be analyzed separately.

Expanded clay concrete wall panels - dimensions, weight and other characteristics

Construction from large-sized panels is attractive due to the speed of construction of buildings and the reduction in costs. But conventional reinforced concrete products do not meet modern thermal insulation requirements.

Instead, expanded clay concrete wall panels are often used - the dimensions, weight, strength and performance characteristics of these elements allow the construction of inexpensive and warm houses in the shortest possible time.

Advantages of blocks:

- do not require special care during operation;

- quick laying due to light weight and large dimensions;

- are not exposed to aggressive environments;

- improve noise and heat insulation;

- The decorative side simplifies finishing.

The company's catalog includes blocks of strength grades M35, M50, M75, M100 and higher.

| No. | Name of product | Strength grade | Size, mm | Weight, kg | Number of pieces/m3 including masonry | Quantity on pallet, pcs. | Pickup cost, rub. | |

| per piece | per m3 | |||||||

| Expanded clay concrete blocks | ||||||||

| 1 | 4 - HOLLOW WITH LONGITUDINAL VOIDS | M30 | 390x190x190 | 7 | 63 | 120 | 42,50 | 2 677,50 |

| 2 | 2 - EMPTY | M30 | 390x190x190 | 9 | 63 | 105 | 46,00 | 2 898,00 |

| 23 | 2 - VOID HEAVY | M35 | 390x190x190 | 12 | 63 | 105 | 40,00 | 2 520,00 |

| 3 | 4 - EMPTY | M35 | 390x190x190 | 9,5 | 63 | 105 | 48,00 | 3 024,00 |

| 4 | 4 — HOLLOW “ECONOMY” | M35 | 390x190x190 | 12,5 | 63 | 105 | 45,50 | 2 866,50 |

| 5 | 4 – HOLLOW “ECONOMY” WITH LONGITUDINAL VOIDS | M35 | 390x190x190 | 11 | 63 | 105 | 45,50 | 2 866,50 |

| 6 | 4 — HOLLOW “ECONOMY” | M50 | 390x190x190 | 15 | 63 | 90 | 43,00 | 2 709,00 |

| 7 | 7 - SLOT | M35 | 390x190x190 | 11,5 | 63 | 120 | 51,00 | 3 213,00 |

| 8 | 8 - EMPTY | M35 | 390x190x190 | 11,5 | 63 | 90 | 51,00 | 3 213,00 |

| 9 | 10 - SLOT | M35 | 390x230x190 | 15 | 50 | 90 | 57,00 | 2 850,00 |

| 10 | 13 - SLOT | M35 | 390x280x190 | 19 | 43 | 60 | 78,00 | 3 354,00 |

| 11 | FULL BODY | M75 | 390x190x190 | 17 | 63 | 90 | 66,00 | 4 158,00 |

| 24 | FULL BODY | M75 | 390x280x190 | 23 | 43 | 60 | 85,00 | 3 655,00 |

| PARTITION EXPANDED CONCRETE BLOCKS | ||||||||

| 12 | 2 - EMPTY | M35 | 390x120x190 | 7,5 | 96 (12.5 pcs/m2) | 156 | 35,00 | 3 360,00 |

| 13 | HOLLOW (2 or 3 voids) | M35 | 390x90x190 | 6 | 125 (12.5 pcs/m2) | 192 | 27,00 | 3 375,00 |

| 14 | FULL BODY | M35 | 390x90x190 | 6,8 | 125 (12.5 pcs/m2) | 192 | 31,00 | 3 875,00 |

| 15 | 2 - EMPTY | M50 | 390x90x190 | 7,8 | 125 (12.5 pcs/m2) | 180 | 21,00 | 2 625,00 |

| 16 | 2 - EMPTY | M50 | 390x120x190 | 9,3 | 96 (12.5 pcs/m2) | 156 | 32,00 | 3 072,00 |

| 17 | FULL BODY | M50 | 390x80x190 | 8,6 | 125 (12.5 pcs/m2) | 180 | 23,00 | 2 875,00 |

| 25 | 2 - HOLLOW SAND CEMENT | M50 | 390x90x190 | 11,5 | 125 (12.5 pcs/m2) | 120 | 18,00 | 2 250,00 |

| SAND CEMENT, FOUNDATION BLOCKS | ||||||||

| 18 | 4 – HOLLOW SAND CEMENT | M50 | 390x190x190 | 19 | 63 | 75 | 39,00 | 2 457,00 |

| 19 | 4 - HOLLOW SAND-CEMENT WITH LONGITUDINAL VOIDS | M50 | 390x190x190 | 19 | 63 | 75 | 39,00 | 2 457,00 |

| 20 | FULL SAND CEMENT | M75 | 390x190x190 | 30 | 63 | 48 | 52,00 | 3 276,00 |

| 21 | FULL SAND CEMENT | M150 | 390x190x190 | 30 | 63 | 48 | 59,00 | 3 717,00 |

| 22 | FOUNDATION SOLID (WITH CRUSHED STONE) | M200 | 390x190x190 | 32 | 63 | 48 | 65,00 | 4 095,00 |

Weight calculation

To determine the weight of expanded clay concrete blocks, you can use special tables or online calculators. They simplify the calculation process and relieve builders of many problems.

Weight in 1 m3

The thermal insulation type of expanded clay concrete is characterized by a minimum density, therefore it is classified as the lightest class. The volumetric weight of a cubic meter of block is 300-900 kg, and the heat conductivity indicators are 0.2 kcal/m *h*deg.

The structural type can weigh around 1.8t.

Volume weight

This concept characterizes the mass of blocks with the corresponding volume. The standard value is 1 m³. Taking into account the density, the block can have different weights, which is why 1 cubic meter. m of thermal insulation materials is lighter than a similar volume of structural expanded clay concrete.

The former have a minimum volumetric weight, which varies between 500-900 kg/m3. Due to this feature, the design does not have much impact on load-bearing walls or partitions, but cannot boast of high reliability.

Advantages of lightweight concrete sandwich wall panels

Wall sandwich panels made using expanded clay concrete have high thermal insulation characteristics, which allows them to be used for the construction of a private home, as well as various office and industrial buildings.

The thermal insulation qualities of lightweight concrete structures directly depend on the amount of expanded clay used, it follows that the thicker the insulation layer, the lower the thermal conductivity of the material.

The strength characteristics of lightweight concrete structures also deserve deep respect. Sandwich wall panels filled with expanded clay concrete are quite suitable for constructing a three-story house.

Another advantage of using this material for construction is the durability of the house, which is easily explained by the frost resistance of expanded clay concrete panels.

The low water absorption of this material also has a huge impact on the performance of the building, which makes it possible to build houses even in places characterized by high levels of soil moisture and even in wetlands.

Due to the fact that the wall panels contain concrete, which is highly resistant to moisture, houses in the construction of which expanded clay concrete panels were used, even with prolonged contact with moisture, do not collapse and do not lose their original characteristics.

The absolute environmental friendliness of expanded clay concrete blocks also plays an important role when choosing a material for building a house. Due to the fact that exclusively natural materials are used in the manufacture of this wall material, it does not emit any substances or fumes hazardous to human health into the environment.

The low weight of the elements guarantees amazingly simple and quick installation of a building with any parameters and geometric shapes. In addition, the low weight of the blocks does not require pouring a reinforced foundation, which makes it possible to significantly reduce the financial costs of pouring the foundation and erecting walls.

Maximum comfortable living in a house made of expanded clay concrete blocks is ensured by the high noise and heat insulation characteristics of the material, as well as the high chemical inertness and fire resistance of the blocks.

to contents ^

Installation

Expanded clay concrete products for walls and partitions are attached to support pillars and other structures using embedded elements.

To increase the durability of the object, it is recommended to arrange horizontal joints before installing the next top row with vapor barrier material and perform vertical treatment of the joint areas with cement mortar.

As a rule, installation of expanded clay concrete wall panels does not cause difficulties.

During storage, expanded clay concrete slabs should be protected from moisture to avoid damage to the structure.

To carry out independent repairs of expanded clay concrete material, certain methods are used:

- To eliminate cracks, the product is embroidered and treated with a solution of cement, sand and lime. The density of the mortar mass must correspond to the density of the slab being repaired;

- if there are internal delaminations, it is recommended to use dowels, tie bolts, and mesh for plastering work;

- When the exposed reinforcement cage begins to corrode, the bars are cut out and replaced. In this case, the new elements are tied with wire and coated with an anti-corrosion compound. Deformed sections of the panel are removed, restoration is carried out using the cork or masonry method.