Since 2006, it has been designing and manufacturing equipment for the production of building materials on a small and medium scale: stationary brick making machines for the production of paving slabs, automatic brick making press lines with dosing complexes for the production of cinder blocks, curbs, paving slabs and other equipment. The price of a brick making machine for paving slabs is affordable for small and medium-sized entrepreneurs.

| № | Name of forming equipment | Image | Number of products on a pallet, pcs. | Description | |

| "Zlatic" | "Zlatic-Mini" | ||||

| 403 | PT "Katushka" | 15 | 6 | Has high adhesion properties between tiles. This form of tile is effective in areas with heavy traffic of cars and trucks. Thanks to its configuration, it allows you to create various designs and mosaics. | |

| 401 | PT "Hexagon" | 10 | 4 | A mold for tiles that is ideal for covering streets and sidewalks. Its advantage is ease of installation and maintenance. | |

| 430 | PT “100x200” | 25 | 12 | Classic rectangular tiles for sidewalks and paths. | |

| 419 | PT "Volna" | 16 | 8 | A form of universal paving slabs with an original design. | |

| 407 | PT "Romb" | 12 | — | A form for bold design solutions that can be used to create unique three-dimensional textures. | |

| 405 | PT "Fat" | 10 | — | Matrix for paving slabs, which is intended for laying sidewalks, garden paths, pedestrian areas and public catering areas. | |

Zlatstroy LLC offers:

- business plan calculation;

- creation of a project plan for placing equipment in the customer’s workshop;

- development of recommendations on technologies for the production of paving slabs using vibrocompression;

- delivery and commissioning;

- training to operate the equipment;

- wide payment options;

- the ability to lease goods;

- warranty and service.

By ordering vibration pressing equipment for the production of paving slabs from our company, you get a reliable partner who undertakes post-warranty support and repairs, as well as delivery of failed components. The starting configuration of a brick making press for tile production is suitable for modernization and can be supplemented with units as production grows. Additional units can also be ordered from Zlatstroy LLC.

Reliable brick making press from the manufacturer

In order for cinder blocks to meet all existing standards, for cinder blocks to have a long service life, it is necessary to select only proven and high-precision equipment for their production, which can confidently include a brick making machine from the COTTO company.

If you need to make paving, facade slabs or cinder blocks, the equipment from our company is ideal for realizing this idea. Many years of experience have proven that equipment for the production of paving stones, cinder blocks, paving slabs is highly profitable and reliable

Hyperpressing

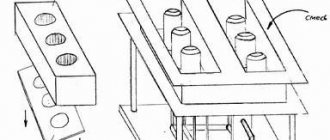

To ensure the same strength of FEM throughout the thickness, a hyper-pressing technology has been created. It uses two presses, one presses on the punch from above, the second pushes the matrix from below. In this case, the vibrator becomes superfluous, so it is excluded from the design of the press.

Or a single-acting press with high compression force is used. This option is used only for FEMs of small thickness 4 – 6 cm.

To provide a wide range of paving stones - smooth, rough, textured, gray, colored, luminous, hyperpresses of various designs can be used:

- counter pressing two-sided symmetrical - rough front surface, high density of the product, coloring in the mass or only the top layer;

- double-sided asymmetrical counter pressing – “floating table”;

- symmetrical double-sided counter-pressing with vibration - smooth front surface, layer-by-layer painting, including luminescent and fluorescent compounds;

- one-sided pressing with a lower cylinder - high geometry accuracy, flash-free production, maximum possible productivity;

- one-sided pressing with filtration – production of paving slabs of complex configuration, large size, small thickness.

This business is, by default, highly profitable, since instead of sand, the concrete filler is screenings, amounting to 85% by weight. In many industries, screenings are waste, which helps reduce costs. In addition to cement, you need pigment for colored tiles or special paint for luminous paving elements.

Gravity concrete mixers are not suitable for automatic lines. Instead, forced-action concrete mixers are used.

In them, the drum remains motionless, and the blades rotate inside it. The quality of the mixture is higher than in gravity mixers, but the energy consumption is noticeably higher, which increases the cost of production.

For mini-factories, additional equipment of the following types becomes relevant:

- store feeders for pallets/pallets;

- vertical pallet stackers;

- transfer hydraulic grabbers;

- pallet unstackers;

- cement silo;

- automatic pallet packer.

At intermediate stages, equipment is used for removing flash, turning over FEM, packaging roller tables, power cabinets, hydraulic stations, conveyors, racks, synchronizers, and frequency converters.

The equipment allows the production of cinder blocks and other concrete products

Cinder blocks are produced from natural and crushed sand, cement grades M500 and M400, plasticizers and light-resistant pigments.

There is an opinion that cinder block equipment requires bulky equipment that occupies a large area. This is not at all true, our equipment for the production of cinder blocks, the production of paving slabs, paving stones ( vibropress machines ) come in different sizes, for example, the VP-600 vibropress machine is distinguished by its compactness and low weight.

Another advantage that equipment for the production of paving slabs, cinder blocks, and paving stones provides is the possibility of its fairly easy transportation from one site to another, and a well-thought-out design makes vibropress machines suitable for long-term operation, in other words, you can produce high-quality cinder blocks every day for for many years.

How a brick press works and cinder blocks are produced

Cinder blocks are produced using the vibrocompression method, and the VP-600 vibropress. allows you to produce cinder blocks from sand-concrete, expanded clay-concrete mixtures, reinforced polystyrene concrete and some other types of concrete.

Almost every brick making machine is distinguished by its versatility, which means that by purchasing a brick to produce cinder blocks, you can easily start making paving slabs or paving stones.

If you have any questions about how to make a cinder block, purchase equipment or configure it, please contact our managers and specialists for advice.

With our help, you can select equipment for the production of paving slabs, paving stones, cinder blocks and set up production in a short time.

Paving slabs and laying paving slabs at low prices

Tel., 8 (926) 043-00-60

A very serious competitor to traditional asphalt is now paving slabs , which many developers and homeowners are now trying to buy. Paving slabs are perfect for arranging driveways to houses and pedestrian paths.

for paving slabs is quite reasonable, and the advantages of this material are quite obvious. If the laying of paving slabs is done correctly, such a coating will last a very long time. , just like vibropress paving slabs are durable and resistant to external influences, and they look much more beautiful than asphalt. By and large, the main question for many home owners, builders and designers comes down to what type of paving slabs to choose.

Vibratory casting and vibropress paving slabs differ from each other in the method of their production. It must be said that there is no clear answer to the question of which tile is better and which method is more reliable. In addition to the fact that one type of tile is created using casting, and another by pressing, these materials have other differences. Therefore, the choice of which paving slabs to buy is determined, first of all, by the tasks set.

Vibratory casting paving slabs

Vibro-cast paving slabs are made on a vibrating table with constant vibration through prolonged hardening of a mass of sand and cement. The result is a product with a smooth surface, which means that the coating of such tiles will be very easy to clean from snow, dirt and dust. Laying paving slabs of this type is also not difficult. These paving slabs have bright, rich colors and look great in any weather and lighting.

Therefore, it is not surprising that vibration-cast paving slabs are in high demand in the capital and beyond. As the experience of our company shows, paving slabs to the Stupinsky district, as well as to the Domodedovo and Ramenskoy districts, where diverse development and landscaping , although other districts are also trying to keep up.

Another feature of vibration-cast paving slabs is that they can be produced in any shape, which means designers have every opportunity to realize their interesting ideas. Cast paving slabs are acceptable both in small private areas and in wide urban areas - on streets, in public gardens, and even in central squares. Moreover, the price for paving slabs is not exorbitant. And if both the material and the laying of paving slabs , the cost will ultimately be even lower.

The master will be able to lay out from such tiles , which can represent a very sophisticated architectural accent in any area : from a building in the city to a small garden gazebo.

Laying paving slabs is an excellent solution for those who do not like the dull grayness of asphalt.

If you need vibration-cast paving slabs , you have the opportunity to buy them from us at the manufacturer’s price. We will deliver paving slabs to the Domodedovo district, Ramenskoy district, Stupinsky district and any other areas, freeing our clients from unnecessary markups and overpayments.

Vibropressed paving slabs

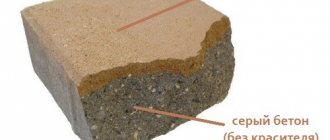

Vibropress paving slabs differ from cast in that during their production, the cement-sand mass is continuously subjected to blows from a special hammer, and the concrete in the mold hardens under high pressure. As a result, the tile, in fact, turns out to be an original artificial stone with a unique texture.

Vibropress paving slabs have a rough, porous surface and are an excellent choice for areas where there is constant heavy traffic. This type of paving slab is unique in that it is able to withstand very high loads, comparable to the load of a heavy tank - from 300 to 600 kilograms per square centimeter.

However, vibropress paving slabs are not only resistant to physical stress. Due to its porous structure, this material is “breathable”, which means that the number of freezing and thawing cycles increases from 200 to 250, which is very significant for harsh winters. Vibropressed paving slabs are characterized by a low water-cement ratio, which means they are immune to chemical influences.

Previously, many who were interested in paving slabs the price , and it was not easy to buy them. Nowadays this material is very common in different countries. Its production is automated to the maximum, production volumes are large-scale, and quality is constantly being improved.

If the laying of paving slabs using a vibrating press is carried out by a professional, such a coating will last a long time. If you need vibropressed paving slabs, you can buy them at the best price and also order installation from our company.

So, vibro-cast paving slabs are good for areas where special aesthetics are required and special importance is attached to the creation of a general architectural ensemble. And for city streets where massive paving of sidewalks is required, vibropress paving slabs .