The article will provide a complete analysis of such a process as laying paving slabs on sand: the technology of paving slabs has its own characteristics depending on the type of base, these features will be considered. You will be able to study the main types of tiles (shapes), find out the prices for turnkey services, learn how to prepare a dry mixture intended for paving paths, and calculate materials.

Paving slabs are a fairly popular and practical solution for paving walkways.

Laying paving slabs on sand: paving technology for different types of base

Landscaping of the local area in a suburban area begins with planning. To purchase material for laying paving slabs on a turnkey basis, you should take into account some features of paving technology and factors that may influence it.

First of all, pay attention to the following points:

- what soil will be used as a base;

- what loads the coating will presumably be subjected to in the future;

- what kind of relief does the surface allocated for paving have?

- how much area will be covered with tiles;

- what method will the paving of the tiled surface be carried out?

The process of laying paving slabs

Having set the goal of laying paving slabs at the dacha, you first need to determine the budget for such construction. Based on this, it is already possible to select the design, covering option and the base on which the sidewalk will be installed.

There are several paving methods depending on the type of base:

- prancing;

- dropout;

- sand;

- concrete;

- asphalt;

- dry mixture.

At the end of the work, it is necessary to check the surface with a level and hammer in the protruding tiles with a rubber hammer.

Technology for laying paving slabs at the dacha using cutting and screening

The method of paving the surface on a prism is carried out when the sidewalk or area is at a significant slope. In this case, to lay paving slabs on a sand-cement mixture, you will need to maintain a 6:1 proportion of materials, where you need to take 6 parts of sand and 1 part of cement.

Advantages of the technology:

- Ability to set when exposed to liquid.

- High strength of fixation of the tile covering.

- The movement of the tile from its place in the direction of inclination under the influence of gravity is excluded.

The tiles must be placed in such a way that they fit tightly together

The disadvantages include the work process, which should be accelerated. The paving technology becomes more complicated due to the fact that the paving stone cannot be stored for a long time with wet sand. Under the influence of moisture in the cement, setting is activated, so you need to act very quickly, while being careful.

Waste from crushed stone, also called screening, is characterized by less shrinkage than sand. Such a base is easy to level and compact. The advantage of the technology is that screenings can fully replace the crushed stone bed. In addition, high-quality concrete mixture can be made from screenings.

This method also has disadvantages. Using this technique of laying paving slabs in a dacha on unstable soils, you will definitely have to form a cushion of crushed stone in order to organize a drainage layer for normal water drainage.

Tile paving technology for pedestrian areas and roadways

Technology for laying paving slabs on sand and concrete

The use of a concrete base for paving a sidewalk requires the use of reinforcing elements. For these purposes, it is recommended to use reinforced plates with a cellular structure. The concrete mixture will subsequently be poured into these voids.

This paving technology offers two significant advantages. On the one hand, the coating acquires a high level of strength, on the other hand, thanks to this, the pavement is able to withstand serious loads under conditions of intensive use. The only disadvantages include the high cost of such construction.

The technology of paving on a sand cushion is one of the classic methods of designing sidewalks. Even a special rubber coating intended for paths can be laid on this type of base.

Sand cushion for paving stones or paving slabs

Working with sandy surfaces is characterized by simplicity. In this case, you can even make the sidewalk yourself. But this does not mean that the technology does not require some effort and effort on your part.

There are also negative aspects of the technology, which involves paving tiles on sand. The base may wash out from under the tiles during heavy rains. To avoid this, you will need to install special borders along the entire perimeter of the path. Their installation significantly complicates the technology.

Paving slabs are a functional covering for the local area

Using the mixture for laying paving slabs, working with asphalt

In some cases, it is possible to lay paving slabs on an asphalt surface. This technology is performed when there is no desire to dismantle the old asphalt pavement.

The advantage of this method is savings, since paving requires a minimal layer of mortar. A few centimeters will be enough, since the asphalt itself already serves as a base and amplifier.

The downside of the technology, which is based on working with asphalt, is that the preparatory stage involves filling holes and voids in the pavement, sealing cracks and even removing broken areas. It takes a significant amount of time and effort to prepare the work surface for laying the workpieces.

There are many options for laying paving slabs

Dry mix paving technology for laying paving slabs is easy to implement. The main thing is to strictly follow the entire technological process of creating a cushion consisting of crushed stone and sand. Despite its obvious simplicity, you still have to be patient and careful if you want to get high-quality and reliable coverage.

Video tutorials and other instructions will help you figure out how to lay paving slabs on sand.

Site preparation

Before laying tiles, you must carefully prepare the area for it. There are certain surface requirements that must be adhered to. If you decide to do the work yourself, then you need to take into account the following nuances:

- We make a deepening. It should be noted that paving slabs are installed in recesses, but they will protrude several centimeters above ground level;

- Tamping. An area with dense soil is required for laying tiles;

- Alignment. Also, the area for tiles should be level;

- Arrangement of drainage. This is done in two stages. You will need to make a base of sand and gravel, and also arrange a slight slope for natural drainage.

Before laying tiles on sand, you must carefully prepare the soil. There is no need for special equipment for this; everything is done with your own hands. First of all, we remove the top layer of soil, which will help solve the problem with unevenness and compact the soil. Then we make a cushion of sand and gravel. The depth of the structure will depend on its functions. For pedestrian paths, 20 centimeters is enough, but in areas for cars, the depth must be increased by another 8-10 centimeters.

After digging the holes, the soil must be thoroughly compacted. To do this, you need to wet the soil with a hose and walk around the area with a tamper. Thanks to this simple action, you will avoid problems with subsidence of paths and platforms.

Choosing tiles for paths in the country: prices for materials and services

The most popular base for creating sidewalks and paved areas remains a sand cushion. The technology is quite simple and requires minimal effort, so many people prefer the method of laying paving slabs on sand.

Options for decorating the sidewalk area with tiles

This technology will be especially useful in two cases:

Well-groomed garden paths and beautiful areas near the house will give the site an aesthetic appearance

There are several criteria for selecting a material for laying paving slabs on sand and cement. First, you need to look at the performance characteristics of paving blanks. Secondly, you should carefully select the shape of the products, as well as the colors, so that later the coating fits well into the overall exterior of the yard.

Laying paving slabs in the country: rules for selecting blanks

The modern assortment of tiled paving coverings offers a variety of products that differ from each other in shape, color, thickness, manufacturing material, as well as creation technology.

For work you will need rubber knee pads and waterproof gloves.

In order to choose the optimal coating option, you should consider the tiles within the following criteria:

Scheme for laying paving slabs on sand and dry mix

Each type of tile has its own requirements regarding the base. This factor should also be taken into account when choosing a material.

Selection of tiles depending on the purpose of the coating:

| Purpose of coverage | Type of tile blanks | Workpiece thickness, cm | Required type of base (pillow) | Possibility to do the paving yourself | Price level for the purchase of material |

| Pedestrian | Vibrocast | 2,5-4 | Sandy | Yes | short |

| Industrial | Vibro-pressed | 6-8 | Sandy, concrete | No | high |

| Road | Vibrocast | 4-6 | Sand-cement | Yes | average |

Selection of blanks and price for laying paving slabs on a turnkey basis

Almost everyone can lay this covering option, such as paving slabs, correctly on sand. Especially if you use simple forms of blanks and the most common patterns for paving them.

There are many forms of tile products for paving sidewalks, the most common of which are:

Color range of rubber paving slabs

Laying paving slabs (cost per square meter):

| Type of work | Price, rub./m? |

| Paving + formation of sand and crushed stone cushion | from 1600 |

| Paving on a finished base | from 400 |

| Paving + forming a concrete pad | from 3350 |

| Preparing the concrete base | from 1750 |

| Preparing the crushed stone bed | from 100 |

| Paving on a sand-crushed stone cushion using a mixture | from 1700 |

| Installation of curbs (linear meters) | from 120 |

Laying paving slabs: what sand is needed for the job

When starting work, not many people think about what sand to use for laying paving slabs in their yard. The fact is that there are many options for this material, which has different origins, fraction sizes and performance characteristics.

There are even artificial analogues of sand on the market, which have a wide range of applications in construction. Therefore, it is worth seriously thinking about the question of which sand is best to use for laying paving slabs in your work.

Laying paving slabs should be done on a level area

The most commonly used types of sand are river and quarry sand. The latter option is obtained as a result of natural weathering of rocks. Under the influence of strong gusts of wind, the rock is slowly destroyed, and the sand that is formed in the process accumulates nearby.

Fractions (grains of sand) of this bulk material can be either large or small in size. Since quarry sand is a natural material, by definition it cannot be 100% pure. As a rule, quarry sand contains various impurities. Most often, clay is mixed into the material. Due to its uneven surface, quarry sand provides good adhesion to other coating components.

Scheme for preparing the base for laying tiles on sand

River sand is characterized by a smooth surface, which is obtained through prolonged treatment of the stone with water. This material has a beautiful appearance and contains no impurities. River sand can be classified as an environmentally friendly building material.

The smooth surface of river sand allows water to pass through well. Therefore, it should be used to prepare a sand-cement mixture for laying paving slabs and other types of work. Lower cost than quarry material is another advantage to the existing advantages.

Dry mixture for laying paving slabs: consumption and operating features

The preparation of sand-cement mixture for laying paving slabs is carried out in several ways. In the first case, it can be prepared at home for domestic use. The recipe is usually not difficult.

With high-quality installation, tiles can last more than 15 years

In the second case, if it is intended to be used for production purposes, strict compliance with all requirements of the recipe and proportions will be required.

To prepare a mixture at home, on the basis of which you will lay paving slabs with your own hands at the dacha, make sure you have:

- concrete mixer or container for mixing components (volume of at least 25 l);

- a drill equipped with a mixer attachment for mixing the ingredients;

- all components: water, cement, sand.

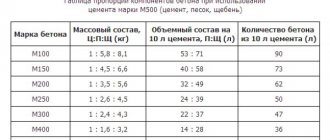

The proportions of the mixture for laying paving slabs can be very different. It depends on the recipe and the characteristics that you ultimately want to achieve.

Laying strips of paving slabs

Common recipes:

- the proportion of sand and cement is 1.5:1, respectively. The ingredients need to be mixed well and gradually add water to them. While adding liquid, be sure to continue stirring the mixture until it reaches the consistency of thick homemade sour cream;

- You can also use the proportions of the dry mixture for laying paving slabs, using buckets as measuring containers. Take a 10 liter bucket and fill it 7 times with sand. After this, fill the same bucket with cement twice. It is better to take cement grade M400 or M500 for these purposes. You will need 15 liters of water. First you need to mix 7 liters of liquid and 2 buckets of sand. Spend at least 30 seconds thoroughly mixing. After this, add another 6 liters of water and the entire volume of cement that you previously measured. After 2 minutes of mixing, the remaining components are added to the composition. The result should be a thick mixture that is not sticky. Before adding, mix all ingredients for 3 minutes;

After laying the paving slabs must be thoroughly compacted

- a formulation with mineral additives is used in cases where it is necessary to increase the level of frost resistance of the coating and give the mixture additional elasticity. To prepare 1 m? mixture, take 550 kg of dry cement brand M500, 5.5 kg of plasticizer S-3 (mineral additive) and 1650 kg of sand. After mixing the bulk ingredients, add water until you get a plastic mass that can be rolled up.

Laying paving slabs: what geotextiles are needed for the job

The use of geotextile for laying paving slabs is due to the large list of advantages that this material provides.

Garden path made of paving slabs at the dacha

Advantages of geotextiles:

- high level of resistance to decay processes;

- resistance to the destructive effects of chemicals, as well as physical factors;

- invulnerability to insects and small rodents;

- increased resistance to ultraviolet radiation.

Thanks to this, the material is in high demand on the market, so the range is striking in its diversity.

The process of laying a garden path

The most popular brands:

- SpunBel, Aquaspan (Belarus);

- Geotex (Czech Republic);

- Secutex (Germany);

- Terram (UK);

- Taipara (USA).

Prices depend on operational characteristics and technical parameters. The price is also affected by the width of the material.

Garden path made of paving slabs of simple masonry