The abbreviation 3D is ubiquitous these days. The construction industry has not been spared 3D graphics either. But if 3D wallpaper doesn’t surprise anyone today, street tiles with such a pattern appeared relatively recently. Modern production of 3D tiles allows you to apply any design, picture or even photograph to the product. Such paving on the path in the garden will turn your garden plot into a real work of art. Tiles with a three-dimensional image have their advantages and disadvantages. Our article will describe the technology for manufacturing 3D paving slabs, as well as the features of their installation.

Business relevance and target audience

An entrepreneur who decides to start producing and selling paving slabs with a 3D coating effect will be among the first in this business.

There are practically no analogues of this unique coating not only in the CIS countries, but also in Europe. The lack of competition will allow you to monopolize the market in the early stages, set the required prices and minimize the risks associated with poor sales. The main customers of the product will be owners of cottages and country houses, elite cafes, clubs and restaurants. You can also enter into agreements with private or government agencies for the improvement of shopping/shopping and entertainment centers, alleys, parks and other places that need to attract increased attention from visitors.

Advantages, disadvantages and characteristics of coating

Production of luminous paving slabs

Thanks to a special manufacturing technology, 3D paving slabs have a lot of advantages:

- This is an environmentally friendly material, since only components of natural origin are used in its composition. As for the paint on the surface, it does not contain toxic substances harmful to the human body.

- The tiles are quite strong, durable and wear-resistant.

- The product is allowed to be used in high humidity and in a temperature range from plus 50 to minus 45°C, so it is ideal for installation outdoors.

- The paving surface is resistant to aggressive substances.

- The tile does not require special care.

- The main advantage in comparison with traditional paving stones is their high aesthetic appeal.

- Prostate styling is an added plus.

- The surface does not accumulate dirt and does not require additional cleaning.

- Even after prolonged exposure to sunlight, the design does not fade.

- You can walk on the super-durable surface in heels, ride a bicycle, rollerblade, or ride a car.

But, despite the unique technology for manufacturing 3D tiles, it was not possible to avoid some disadvantages of such a product:

- The production of 3D tiles uses expensive equipment and materials. This affects the final cost of the product. If you pay $8.3 per square for traditional paving stones, then for products with a 3D pattern you will have to pay from $50 to $135.

- Slabs with a three-dimensional pattern cannot be cut during installation, which leads to some difficulties when planning the site.

- To lay paving slabs with a 3D effect, it is important to prepare a perfectly flat concrete base.

Important! The process of producing 3D paving slabs differs from the method of producing traditional coatings only in the final stages, in which the design is applied and the surface is finished.

Step-by-step plan for the production and sale of paving slabs with a three-dimensional effect

When drawing up a business plan, we use the following steps:

- registration of an individual entrepreneur or LLC, registration of a business in the organizational and legal field;

- analysis of the market, opportunities and risks;

- drawing up a production plan (selecting the required premises, purchasing equipment

- for production, etc.);

- drawing up an organizational plan (selection of specialists, working conditions, schedule, remuneration, development strategy, etc.);

- drawing up a financial plan (initial estimate for entering the market, monthly costs, estimated profit, expected income, profitability and payback periods);

- setting up production, selling finished products to the sales market, concluding agreements for the supply of raw materials and products with sales representatives;

- marketing plan, advertising.

The production of decorative tiles does not require special licenses or certificates.

What are 3D ceramic tiles

You can create an interesting and exclusive interior in the bathroom or kitchen by laying volumetric tiles. The material can be used to finish any surface (floor, walls, ceiling). Ceramics has an unusual structure, which, in combination with 3D printing, gives a stunning effect, bringing the image to life.

The technological process for producing volumetric finishing involves the use of ordinary ceramic tiles, the surface of which is covered with a carbon film, which creates a 3D effect. The drawing becomes quite realistic and original due to the visual relief and convexity of the tile material. Even the image of the sky or the surface of the water looks almost real.

Reference! A special feature of the process of manufacturing three-dimensional tiles is the use of microlens technology. It is the lenses that provoke the fracture of light between the carbon film and the ceramics.

The scope of application of ceramic tiles with a 3D effect is limited to small rooms with high levels of humidity (hallways, bathrooms, kitchens, utility rooms, etc.). Humidity does not have a negative effect on printing; it withstands material and temperature changes.

Manufacturing technology

The production of slabs with a 3D effect does not differ significantly from the production of conventional paving slabs. The simplicity of the technology is another significant advantage of this business. Production can be divided into several stages:

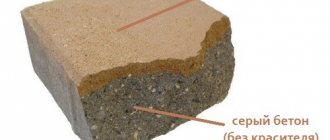

- a solution is created in a certain proportion from sand, cement, thickener and crushed stone of a small fraction;

- the resulting mixture is processed in a vibropress, where it is compacted and molded;

- a thin protective coating and pattern are applied;

- finished products are packaged and packed in special boxes.

The technology for applying the pattern may be different. The most commonly used is sublimation or decal. You can consider the option of using ceramic ink, after which the tiles are fired or use paint that is fixed using UV radiation.

It is recommended to use mineral additives in the solution, which will strengthen its structure and give better performance characteristics to the product.

If your budget allows, you can buy a package of instructions for a novice entrepreneur, which describes the production process. In addition to an introductory video and a catalog of files for photo printing, it also contains molds for the production of tiles, advertising tools and anti-slip coating films.

The process of making 3D paving slabs

You will need the following equipment to produce 3D tiles:

- a concrete mixer or a regular mixer will help to thoroughly mix all the components;

- devices into which the prepared solution is poured are called molds;

- you will also need a machine for compacting raw materials and removing air from it, it is called a vibrating table;

- device for photo printing – digital 3D printer;

- to produce fired paving stones you will need a kiln;

- special pallets for washing molds.

To produce tiles, which are then painted on, one of the following technologies is used:

- Vibrocasting. In this case, a liquid mixture of cement and sand is poured into matrices, which are installed on a vibrating table. After the products have hardened, they are removed from the molds for additional drying.

- Vibration pressing. The semi-dry composition is laid out in the press matrices. They are then mounted on a vibrating machine and subjected to a high-pressure piston. During the exposure process, the molds are additionally subjected to vibration to compact the mixture.

- Hyperpressing. To produce hyper-pressed elements, the semi-dry mass is placed in molds and subjected to high pressure. Vibrations are not used to compact raw materials.

At the end of the 3D paving slab manufacturing process, a pattern is applied to its surface. To do this, use one of the following methods:

Machines for the production of paving slabs

- Flexographic printing involves the use of a photopolymerizing base. It is made from paint or rubber. The effect of a three-dimensional image is achieved through the contrast of the pattern on a dark or light background using shadows and highlights. As a result, the pattern becomes voluminous and realistic. This technology is relatively inexpensive, and the resulting products are strong and durable.

- The UV printing procedure is more expensive. In this case, full-color images are applied to the surface of the tile. The print quality is no different from the flexographic application method, but with UV printing the color rendition of the design is better, since a large range of shades, highlights and halftones are used to give the image three-dimensionality.

After applying the pattern, the tile is subjected to finishing. It is as follows:

- the applied pattern is filled with a polymer composition with high transparency (in some cases, the coating is made of epoxy resin that is resistant to temperature changes);

- Next, the polymer layer is compacted and leveled (at this stage, the seal is tightly pressed into the tile);

- Finally, the product is treated with a stream of air under pressure or cold liquid.

Important! As a result of this finishing effect, the layer of polymer and paint is firmly bonded. The result is paving slabs with a durable surface without the use of chemical treatments.

We legalize business, documents for opening

To legally conduct business, you need to register with the tax authorities by registering as an individual entrepreneur or LLC. In the first case, the list of documents will be as follows:

- passport;

- copy of TIN code;

- application for registration with the specified OKVED codes;

- receipt for payment of state duty.

Individual entrepreneur will be better for a small village, LLC is preferable for a city and large scale of implementation

In order to obtain a quality certificate for manufactured products, you need to visit the appropriate organization. Specialists will analyze the composition and performance characteristics in accordance with GOST.

Sales technology

Wholesale and retail sales can be carried out immediately after setting up the production line. At the same time, the store/warehouse (depending on where the sale will take place) must have the entire range of finished products based on samples. It is necessary to highlight the most popular options, on which to focus the main production capacities, but also to support the production of different types and sizes.

In addition to the production and sales of paving slabs with a 3D effect, it is advisable to provide services for delivery, installation, and the development of design projects.

A good idea would be to create a website and product catalog where the entire range of products will be presented with the possibility of exclusive design and customer offers. New clients can be attracted by advertising: media, as well as by placing city banners. It is better not to use leaflets and other small items.

Advantages and disadvantages

3D tiles are endowed with the same set of advantages as any other tile made on a ceramic base. To begin with, it is worth noting that the material is very durable. As the manufacturers assure, the guaranteed service life of the decorative surface is at least 10 years.

Durability is due to unique strength combined with wear resistance. It is quite difficult to damage tiles in domestic conditions. The finished surface is resistant to high temperature and humidity, and is also not afraid of their changes.

High-quality products are 100% moisture resistant, which means they can be used in wet rooms. They are also fireproof and not afraid of abrasion, which is especially important for floor products - 1 cm2 can withstand a weight of up to 200 kg without crumbling or developing microcracks.

Three-dimensional tiles are practical. It can be cleaned frequently. You just have to take into account that not all options are resistant to abrasive agents, so it is best to use gentle solutions that do not damage the integrity of the top layer.

The material is hygienic. Mold does not form on it and bacteria do not multiply. The composition is safe, which indicates environmental friendliness.

Perhaps the main advantage for which 3D tiles are valued is the ability to visually change the geometry of the room. In addition, the variety of patterns, colors, and textures provide the widest scope for imagination to create an unusual and beautiful interior.

Flaws

- The need for installation only on a flat base surface. This is done so that the stereoscopic effect manifests itself to the maximum extent.

- Impossibility of cutting and laying with an inflection of more than 2°.

In addition, some samples cannot be used as facade cladding and finishing of buildings for seasonal residence.

Equipment for the production of

To produce decorative tiles you will need to purchase a lot of equipment. This is the most expensive part financially. Required:

- mixer for solution;

- vibropress for molding and manufacturing;

- plastic matrices with the required sizes and shapes;

- baths in which molds are washed;

- tools for drawing, working with photoceramics;

- a blast furnace for firing, which improves the quality of the three-dimensional pattern on the tiles;

- scales;

A modern production line includes automated machines and devices that allow several operators and a technologist to control the entire manufacturing process.

You should also purchase raw materials for production: cement, sand, crushed stone, mineral additives and dyes for the solution. The production line must be automated, with minimal human intervention.

3D tile photo

3D tiles are a finishing material, the basis of which is a ceramic plate with several layers of polycarbonate film with a pattern. Thanks to the multi-layering, the effect of a three-dimensional image appears. Layers are laid using microlens technology.

- the first layer is polycarbonate

- the second layer is shock-absorbing,

- the third is reflective with an image.

The function of the lens is ensured by a very thin finishing coating.

The tile gains strength due to the presence of a special protective layer on its surface, which increases the service life of the product.

Material characteristics

3D tiles can be of different types: floor, wall and even ceiling. Depending on the design, it can be mounted where intended. So, on the ceiling you can make a starry sky or clouds, on the floor - a green meadow or the sea coast, and on the walls a city or any landscape. Thanks to its unique external characteristics, the material will allow you to decorate your bathroom in the form of an underwater world or depict other pictures. The images on such a surface are so realistic that when you are indoors, you can forget where you really are.

Positive and negative sides

3D tiles, like any material, have their pros and cons. Let's consider the positive qualities of the material.

- Durability, moisture resistance, hygiene.

- Floor-standing models have high abrasion resistance.

- The ability to change the visual-spatial perception of the room.

- Possibility of creating an exclusive design.

- Durability. The coating can last more than ten years.

- Mold does not form on the surface and in the seams between elements, and fungus does not spread.

- Resistance to temperature changes.

- Possibility of wet cleaning and even using abrasive detergents. Important! Those tiles that are made by sublimation cannot be exposed to abrasives.

- Hypoallergenic.

- Anti-slip top coating.

But there are also disadvantages to such tiles, which the named material has. Thus, laying 3D tiles requires additional preliminary leveling of the base surface. This is necessary so that the visual effect is not distorted by unevenness.

In addition, when laying it is worth taking into account the fact that this material cannot be cut or installed at bends of more than 2 degrees. In no case can 3D tiles be used as exterior finishing or decoration of premises in seasonal homes that are not heated for some part of the year.

The main negative side of the material is its high cost, so not everyone can afford to decorate their bathroom in this way. But you can save money and create only panels on one wall using this finish.

Range

3D tiles can be divided into types according to the type of image applied to it and the specifics of the 3D effects that it has. And it can also be, as mentioned earlier, floor, wall and even ceiling. The first type is flat with a three-dimensional image. It is perfect for installation in bathrooms.

An interesting option for 3D floor tiles is the one that contains a gel filler inside. Due to it, when exposed to the material, a unique image appears. It looks great as a single floor covering or in combination with regular ceramic tiles.

Depending on the type of 3D effect, tiles are made in several types:

- Ceramic with a print applied to the surface. Thanks to the high clarity of the image and the brightness of the colors, a volume effect is obtained.

- Glass stereo tiles made using a special technology by applying an image to the back of tempered glass. It looks good not only in the bathroom, but also in the kitchen in combination with lighting.

- Relief tiles are a material that has volume not only visually, but also to the touch. It can imitate any coating. It is even used for finishing living rooms in an apartment.

According to the specifics of applying the print, tiles also have different types. Thus, the image can be applied by sublimation, that is, the design is prepared in advance on photographic paper, and then fixed on the tile under high pressure.

Creating a permanent image using the decal method involves removing the desired picture from paper and transferring it to the tile. Thus, under the influence of high temperature and pressure, the pattern penetrates into the structure of the material, and is subsequently covered with a protective layer.

The most used method of applying an image to a tile is UV printing, when the design is applied directly to the surface of the tile and dried using a special technology. This results in a coating that is resistant to various influences.

How to choose tiles

3D tiles, the range of this material in construction stores is huge, you need to carefully approach the process of choosing 3D tiles. You should definitely study the criteria by which suitable tiles are selected:

- Any finishing material should decorate the bathroom.

- 3D tiles should be purchased in such a way as to hide as much as possible all the shortcomings of the bathroom.

- The coating should be easy to clean regularly.

- The quality indicators of the material must be high so that the cladding lasts for a long time without loss of appearance and technical data.

- For a cramped room, it is not recommended to buy too bright tiles with a lot of accentuating details. Otherwise, this will provoke an even greater visual decrease in space.

- 3D tiles in themselves are a decoration of the space, so you need to approach the choice of decor with restraint so as not to overdo it and not end up with an overly cluttered interior.

- A large bathroom is a space for creativity, so you can decorate it according to your wishes and taste. Even bright design ideas will do.

Tile laying technology

3D tiles in the design of a bathroom differ from those used when installing ceramic tiles, but you can do the work yourself, without the involvement of professionals.

To decorate the room yourself, you will need to perfectly level the base surface, make sure that it is dry and not crumbling, and prepare the tiles. After this, you need to mix the adhesive composition. Typically, such mixtures are sold in dry form and contain gypsum, silicone and cement.

If 3D floor tiles are laid on a heated floor system, then a heat-resistant type of mixture is used.

If it is planned to install additional lighting in the bathroom, then the electrical wiring is created at the stage of design and preparation of the room. To do this, you need to strengthen the guides made of polycarbonate, plexiglass or PET and install them on the surface. Subsequently, tiles are attached to them, maintaining gaps of 3–4 mm, which are necessary to preserve the pattern on the surface.

If lighting is not needed, then the material can be mounted directly on the wall, but there is also a gap left here, which is filled with colorless sealant. The grout is applied very carefully with a spatula so as not to damage the tile coating. Remains of the mixture can be easily removed with a damp cloth.

Recommendation: When laying 3D tiles on the floor, use a self-leveling mixture, which allows you to remove even the slightest differences in the surface.

Tile care

3D tiles, like any finishing material used on walls and floors, require maintenance.

- Dirt is removed with a damp sponge and the surface of the material is wiped dry with a soft cloth.

- The problem can only be caused by hard water, which, as a rule, leaves a residue on the coating. To avoid such developments, it is necessary to add softening substances to the water when washing the tiles.

- During operation, tiles must be handled very carefully, since even the slightest scratch or chip on the finishing material can ruin the appearance of the entire bathroom.

- In addition, as a result of deformation, the material may lose its glossy shine.

Let's sum it up

3D tiles are a modern finishing material, suitable not only for decorating bathrooms, but also for kitchens. With its help, you can create a real work of art and complement the space with unique designs that are so realistic that it is sometimes difficult to believe that the effect is achieved simply by installing ordinary tiles.

Business idea to open a hotel with a stable income

The hotel business is considered a fairly stable and very profitable activity. You can open a hotel complex that generates high income in any region of the country. Thanks to the rapid growth of the tourism business in the country and the increasing influx of foreign tourists, the demand for high-class establishments is increasing. This is why opening a hotel is profitable. But to implement the project it will be necessary

…

237

for men