Brick is a universal building material with high strength and durability. Its history goes back more than 4000 years. During the development of brick making, its appearance, shapes, and sizes have changed, and today there are more than 15,000 combinations of textures and colors of this material on the construction market. All its types are divided into several conditional categories that determine composition, structure, purpose, color.

Standard brick dimensions

The key factor in standardizing the size of brick products is the following aspect ratio of 1:1/2:4. Such proportions are considered optimal for laying building materials with alternating longitudinal and transverse positions.

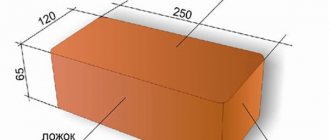

In private construction, single products are in demand; the consumption of building materials per cubic meter of masonry is 513 units of products. In accordance with government regulations in force in Russia, the size of a standard single brick in millimeters is:

- 250 length;

- 120 width;

- 65 height.

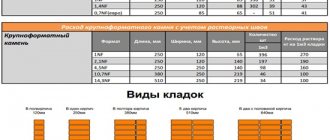

In addition to single blocks, the construction market offers other types of standard sizes:

- one and a half;

- double.

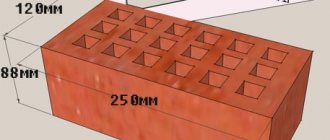

One and a half building material was put into production during the industrialization of the country, in order to speed up the pace of construction. The standard consumption of building materials is 318 products per cubic meter. A characteristic feature of a one-and-a-half block is the increased height of the product; GOST establishes the following standard brick sizes (in millimeters):

- length - 250;

- width -120;

- height – 88.

A double brick with the same 250 millimeters in length and 120 millimeters in width has a height of 138 millimeters. Given their impressive dimensions, to reduce the weight of the product, double blocks are usually made in a hollow shape. Double products are widely used in various fields of construction. Building materials with increased height are used for the construction of both industrial and civil facilities.

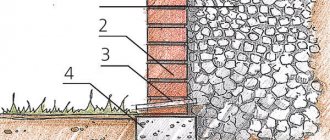

Rules for calculating the amount of material for silicate masonry

Before building a brick wall, it is necessary to make preliminary calculations to determine the thickness of the masonry. Also at this stage they are determined using thermal insulation materials. Once a project for the construction of a building and structure has been drawn up, it will be possible to calculate the required amount of material for masonry.

Divide the perimeter of the wall by the length of the brick element, taking into account the width of the masonry joints. The result will be the amount required to lay one row of the wall.

To calculate the number of rows, you need to divide the height of the wall by the height of the brick element, taking into account the masonry joints. Masonry joints should not exceed 13 mm.

If there are openings on the wall, then their area must be subtracted from the total area of the wall.

To calculate how much is needed for one wall, you need to multiply the resulting number in the horizontal row by the resulting number of bricks in height.

Permissible errors

Building materials are produced in strict accordance with production technology.

Brick block blanks, which are fired in kilns during the production process, are manufactured with an increase in geometric parameters by 8%. As a result of heat treatment, the product is reduced and brought to standard parameters. GOST allows a slight deviation in the geometric dimensions of finished products, namely, in length no more than 4 millimeters, width and height no more than 3 millimeters. The standard also allows for slight curvature along the spoon (no more than 4 mm) and along the bed (no more than 3 mm).

Production of sand-lime brick

The ingredients for making silicate block are lime and quartz sand, so it

turns out white. The mixed ingredients are formed under pressure and sent to an autoclave, where for a certain amount of time the workpiece is exposed to hot steam at a temperature of 200 degrees and a pressure of 10 atmospheres.

It is also possible to add dye if it is necessary to make a product of a certain color.

Types of brick products and their standard sizes

The dimensions of brick products depend not only on the standard size, but also on the type of building material. The main types in demand in the construction of residential buildings and the construction of industrial buildings are:

- Red brick;

- silicate;

- facing.

Red building blocks and their features

Red brick is a universal-purpose building material used for the construction of foundations, external enclosing structures and partitions in the house, and fences.

Red brick products are made from clay briquettes, which are pressed by firing. The dimensions and technical characteristics of the product are regulated by GOST 530-2007 and are (in millimeters):

- standard format – 250x120x65;

- thickened format – 250x120x88;

- double format – 250x120x138.

In addition to the popular standard sizes by GOST, less popular formats are also provided:

- 0.7 NF with parameters 250x85x65 mm;

- 1.3 NF with parameters 288x138x65 mm.

Building materials of the “European format” are used for decorative finishing of windows and other structural elements of the facade.

Sand-lime brick

Silicate brick blocks are a building material made on the basis of silicate, intended for the construction of load-bearing external walls and partitions in the house. The modular dimensions of white brick are 250x120x65 and 250x120x88 millimeters.

Silicate building blocks are produced in two types:

- full-bodied;

- hollow.

The void volumes of the silicate block, as well as the overall dimensions, are adjustable

state standards. Hollow silicate blocks are divided based on the volume fraction, diameter and number of blind voids having a cylindrical shape.

The following types of hollow sesquisilicates are distinguished:

- three hollow – the proportion of voids is 15% of the volume of the product, the diameter of blind holes is 52 mm;

- eleven are hollow – the proportion of voids in the total volume is 25%, diameter – from 27 to 32 mm;

- fourteen hollow - the proportion of voids varies from 28 to 31%, the diameter can be from 27 to 32 mm.

Facing brick

For facing facades, standard size facing bricks are used, which corresponds to the traditional counterpart.

The construction market offers several types of cladding products:

- clinker;

- ceramic;

- hyperpressed;

- silicate.

Clinker building blocks are used for finishing facades, for erecting decorative pillars, decorating window openings, and using this type of material to build arched windows. The material is characterized by a dense, smooth structure, excellent sound-insulating and frost-resistant qualities, is resistant to moisture, and retains heat well. Clinker can be colored and glazed, glossy and matte. Windows and facade walls faced with clinker blocks retain an attractive appearance for a long time.

Clinker facing

Ceramic facing products can withstand up to one hundred changes in natural seasons; the material is not afraid of sudden temperature changes. Brick retains its original qualities and appearance over a long period of use.

Ceramic veneer

Hyper-pressed material is made from a lime-cement mixture using the method of semi-dry hyper-pressing, followed by steam treatment. The material is used for decorative finishing of facades; it is used to highlight windows and doors. There are several types of facing material:

- smooth;

- spoon;

- figured;

- angular.

The standard dimensions of smooth and figured hyperpressed bricks are 250x120x65 mm. Standard spoon bricks have parameters of 250x85x65 mm, corner and narrow spoon bricks – 250x60x56 mm.

Hyperpressed facing

Sand-lime facing brick is an environmentally friendly frost-resistant material. Facing sand-lime brick amazes with its variety of colors; it differs from its ceramic counterpart in its uniform color tone over the entire area of the product. Silicate facade material is not used for cladding areas in contact with the ground.

Technical characteristics and classification of sand-lime brick

The solid silicate block has the following technical characteristics:

- thermal conductivity – 0.98 W/m*K;

- average density – 1840–1933 kg/m3;

- ultimate strength – 100–150 kg/sq.cm;

- water absorption – 12%.

Weight:

- maximum weight of products – 4300 g;

- a hollow single element is 3000 g, a hollow one-and-a-half element is 4000 g;

- the weight of a full-bodied single is 3500 g;

- weight of a full-bodied one and a half - 4900 g.

Classification by structure:

- hollow. The structure of such material implies the presence of through holes of different shapes - round, oval or rectangular;

- full-bodied. There are no pores or holes in the structure of such a material;

- porous-full.

Variety by area of application:

- decorative or facing. The purpose of this material is surface cladding. Brick is used as decoration for building facades. Its distinctive feature is the presence of even smooth edges, the absence of nicks, cracks and chips;

- special purpose or construction. Used for the construction of partitions and walls. A distinctive feature of this material: unpresentable appearance, minor defects may be observed. It is used for laying walls and partitions, which will later be plastered or covered.

Non-standard dimensions

However, in the segment of facing building materials you can find products of non-standard dimensions. Custom-sized products are produced non-industrially, in organic batches. An atypical building material is used for restoration work, the introduction of original design ideas, and to emphasize the window opening. The dimensions of non-standard single material for finishing facades can be (in millimeters):

- 210x100x50;

- 210x100x60;

- 240x115x52.

European standards

In the European Union there are other standards that do not comply with GOST 530-2007. Thus, the most popular series in the countries of the European Union are the following series of building materials:

- DF – geometric parameters of the product 240x115x52;

- 2DF – 240x115x113;

- WDF – 210x100x65;

- RF – 240x115x61;

- NF – 240x115x71;

- WF – 210x100x50.

Advantages and disadvantages

Hollow silicate, like any other material, has its disadvantages, namely:

- poor waterproofing properties. This material cannot be used for the construction of baths and saunas;

- cannot tolerate high temperatures. Cannot be used for laying stoves and fireplaces.

The advantages of hollow blocks include:

- high density;

- soundproofing;

- thermal insulation;

- aesthetics;

- relatively low cost;

- environmental cleanliness.

Features of production and operation of the product

The product is made from natural materials. The process begins with mixing water with lime and sand, after which the resulting composition is formed using the autoclave method, at a temperature of 170 - 200 ° C and an atmospheric pressure of up to 10 atm. The result of this is steaming of the product, and after cooling it gains the required level of strength. Thanks to silicate processing, it is possible to obtain products of the following brands: M-125, M-150, M-200 It is necessary to take into account the characteristics of the product in order to use it only in those conditions that correspond to its technical capabilities. For example, brick has excellent vapor permeability and excellent water absorption. Consequently, despite its resistance to temperature changes, it has a low level of frost resistance, not exceeding 25 changes. It is characteristic that brick can be used simultaneously as a facing and main building material. An undoubted advantage is the low cost of white sand-lime brick, which allows it to be actively used during the construction of various objects.

More to read:

What should be the minimum wall thickness in a brick house?

How to insulate the walls inside a brick house with your own hands?