- home

- /

- Finishing and installation

- /

- Interior decoration

- /

- Floor screed

Floor screed is a mandatory element of construction work in country houses, and is also used in many cases in the process of major renovations of objects. A high-quality floor not only ensures long-term use, but also does not create problems in the future with the placement of furniture. The quality of floors is based on the arrangement of the screed. As part of our construction services, our company screeds floors in houses built using aerated concrete blocks. We can guarantee the quality of work regardless of the size of the interior and the architectural complexity of the facility.

Peculiarities

A screed is a coating applied to the base before laying finishing materials (tiles, laminate, parquet, etc.). In some cases, the screed remains a finishing coating, but this is typical only for industrial enterprises, while this practice is not used in residential construction.

The main purpose of the screed is to level the floor, obtain the required height, and also increase the thermal insulation properties. Especially often, insulating screed is used on the first floors of private houses. Often, heated floors are installed directly into the screed.

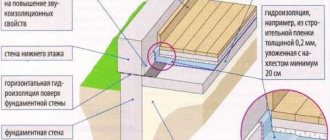

Ground floor floor: requirements

In order to properly arrange the ceiling on the ground floor, you need to know about the requirements that it must meet:

- The material must be strong, reliable and durable.

- The ceiling must adequately withstand climatic, technological and temperature influences.

- The structure must withstand permanent and temporary loads from load-bearing walls and foundation.

- The base must be quite rigid, with regard to the permissible performance of the structure for deflection.

- The design should not create bridges of sound and cold;

- The material must have thermal insulation properties.

Types of screeds

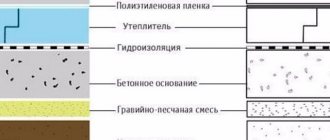

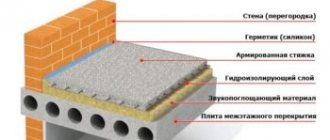

For screeding floors in block houses, several types of classifications are used, based on different principles. First of all, the classification is based on the materials used. Modern floor screed can be made of concrete or gypsum compounds, as well as asphalt or cement. Secondly, the classification of screeds is based on the type of adhesion to the surface:

- The non-floating screed ensures a tight fit to the base. Its use is justified in cases where existing conditions do not require work to enhance the waterproofing of premises.

- The floating screed is separated from the base by a waterproofing agent. Its use is typical for modern households, including cottages, where additional thermal insulation and noise protection are provided.

- Moisture-proofing screed is used in basements that require reliable protection against water penetration.

Another classification of screeds is the design features:

- Monolithic screed is made using concrete or other materials with similar characteristics.

- A prefabricated screed is a combination of several materials, including slats, glass wool, and so on. The selection of materials used is based on the materials of the floor base.

Leveling the floor with a gas block. Experiment.

Good day, dear masters.

The purpose of the experiment: on your own, without experience, to raise and level the floors using D500 gas blocks, 75 and 50 mm thick, then lay the finishing coating (laminate/tile), without overloading the floor slab.

Given: corner two-room apartment in Brezhnevka project II-68-3 with uneven floors with an area of 41.4 sq.m. Floor slabs PK 61-12-8 6 m long acted as floors. The unevenness of the slabs is from 2 to 7 cm per 6 m. There were also multiple holes in the slabs for anchoring and the wiring of the neighbors below was scattered. On these slabs, creaky wooden floors lay freely and shook.

What I did: I dismantled the old wooden floors, and then measured the height from the floor slabs, which turned out to be 6-14 cm below the floor level in the vestibule. The task arose to increase the height by installing a new screed. I thought about installing the same floor on the joists, but I couldn’t find even, dry lumber. I also refused to use expanded clay floors, because I heard that expanded clay sags on thick layers. I was afraid to deal with wet processes, because there was a risk of flooding the neighbors, and the weight was heavy.

As a result: I glued 75 and 50 mm gas blocks D500 to the floor slab on a layer from 0.5 to 25 mm, using a 3 in 1 Eunice mixture, which works up to 30 mm. The result is a flat plane, with holes of 0.5-2mm at 2.5m

On such a plane I placed sheets of superfloor for testing, without gluing or screwing with screws. There is a third layer of gypsum fiber on them, and then a substrate and laminate.

The result is a hard and light floor, but in places where there are differences the gvl moves a little. The cost of the floor at the current stage is 1600 rubles / sq.m. for the material only, weight - 120 kg per sq.m. at a height of 14 cm. There are no knocks, but just in case I plan to remove these 0.5 - 2mm irregularities in order to completely eliminate movement. Tell me how best to do this? The following options have matured in my head: 1) pour in river sand and stretch the uneven areas under the rule. 2) prime the gas block, dilute the same Yunis or Knauf Fugen thinner and stretch it under the rule 3) prime the gas block, apply fugen cakes in the holes and put superfloor on top 4) prime the gas block, pour 5mm self-leveling compound

In the bathroom I left a concrete tray from a shovel sanitary unit. There will be tiles and no gas blocks. I also installed a gas block in the kitchen. There I want to lay the tiles directly on the superfloor, having previously applied a coating waterproofing material to it. 5) Is it possible to glue tiles directly onto a layer of coating waterproofing?

There is very little information on the Internet on this method of installing floors. The positive and negative aspects of the decision are not covered. I noticed the following advantages:

- with such a thickness (14 cm), the screed turns out to be light - 120 kg per sq.m. With a smaller thickness it is even easier.

- can be done on weekends, in parts

- eliminates the possibility of flooding neighbors

- All material can be brought by car

- does not slip through

- warm floor

Minuses:

- Press the aerated blocks for a long time onto the mortar layer in one level, leaning on the beacons

- Probably the gas block absorbs moisture (I haven’t noticed it yet)

- there is still an error. Subsequent leveling is required.

- vibration isolation?….the neighbor didn’t seem to come yet…. I welcome informed criticism of my experiment, and also ask you to share your advice and experience.

Classic screed

All described types of screeds belong to the classic, that is, “wet” types, which require a lot of work and serious financial costs. In addition, the arrangement of such a screed is very labor-intensive and requires the involvement of a large number of people.

Each of the materials used to create a “wet” screed has its own disadvantages. For example, when using concrete, you have to wait a long time for it to harden, and asphalt screed is not able to withstand water. Magnesium screeds also do not perform well in damp conditions.

An alternative to the classic screed can be a dry technology that involves backfilling the base. This technology is distinguished primarily by the absence of the need to work with aqueous solutions and wait for drying.

Working with gas silicate blocks

The porous structure of aerated silicate products makes it necessary to take into account its properties when working with aerated concrete blocks in order to prevent deviations from construction technology and ensure the design durability and reliability of the structure. The presence of air pores ensures easy delivery of products to the construction site and directly to the masonry site, as well as a quick increase in the height of the walls due to the large size of the products and the tongue-and-groove system, which automatically aligns the rows relative to each other.

Tongue and tongue system

But due to the low weight of the porous block, it puts little pressure on the mortar, creating poor adhesion between the mixture and the brick. Therefore, it is recommended to limit the use of cement-sand mortar as much as possible, and to work with a special construction adhesive, the thickness of the seam is minimal with high adhesion to any surface.

In individual construction, such characteristics of aerated concrete as the size of products and the density of building materials are mainly valued. The use of an adhesive composition in combination with large product sizes and a small number of adhesive seams does not allow the formation of “cold bridges” that will inevitably appear when working with cement.

Laying aerated concrete bricks

Thermal insulation properties are another undoubted advantage of gas silicate bricks. The air in the pores of the blocks does not allow heat to pass through itself well, and it remains indoors, while cold air does not penetrate into the house from the outside. Therefore, additional insulation for the building is not required, with the exception of insulation of the foundation and roof.

The waterproofing characteristics of aerated concrete are not high enough to do without layers of waterproofing, so protection from moisture is necessary not only for the foundation and roof, but also for the walls, both inside and outside. Usually this is a layer of plaster with preliminary impregnation with bitumen, primer and other moisture-proofing agents. In this case, the thickness of the wall does not matter, since moisture will penetrate the entire width of the blocks.

Waterproofing walls made of aerated concrete

Independent masonry of walls made of gas silicate blocks will cost much less than construction work with traditional materials - brick, concrete or wood. The price is determined by the low cost of natural components for the production of gas silicate, cheap production technologies, and the low cost of transporting large volumes of building materials with low weight. The use of conventional tools without the use of automation and special equipment, as well as the high speed of masonry, makes the work inexpensive.

Cutting gas blocks

The use of gas blocks is a masonry of gas silicate blocks not only in the private sector, but also on an industrial scale, limited only by the number of floors of buildings. Optimally selected block sizes, multiples of the size of a standard brick, make it possible to complete repair and construction work of any volume in a short time. In addition, you can order blocks of non-standard sizes from the manufacturer, which will speed up the laying or ensure the speedy construction of geometrically complex architectural objects.

The surface of walls made of gas silicate is almost perfectly flat, so the savings from minimizing finishing work are obvious.

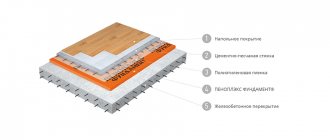

Semi-dry screed

Today, the most modern is semi-dry technology, which is based on the use of polypropylene fiber. The main difference between this technology and “wet” technology is the ability to prepare the solution directly at the site of screed installation. In addition, it is possible to introduce additives with antifreeze properties into the composition of such solutions, which is important for basements in houses in a significant part of the territory of Russia. Fiber fiber is not subject to combustion, which is also an important advantage. The use of semi-dry screed in houses made of aerated concrete is allowed in cases where wires or pipes of communication systems are located above the floor.

When using this method of screed manufacturing, the time required for preparatory work is significantly reduced, and the surface is strong and reliable. When using semi-dry screeds, only environmentally friendly materials are used, which is especially important for residential premises.

How much does it cost to build a house from gas silicate blocks? A house that grew fat during construction

| Cost of a house in the “thermal circuit” option | 1.95 million rubles. (17.7 thousand per sq. m) |

| Cost of a house with rough finishing without networks | 2.9 million rubles. |

| External dimensions of the house | 10.5×8.5 m |

| Room area | 110 sq. m |

| Duration of construction | 1 year |

| Purpose of the house | Permanent residence |

| Used materials | Substandard twin blocks from Teplit 300 mm D500, metal tiles with velvet coating |

| Heating system | Gas boiler, heated floors, radiators |

| Foundation type | Bored piles with grillage |

| Contractor organization | MasterStroy |

Our services

In each specific case, our company’s specialists are ready to determine the optimal solution for installing a floor screed in a house made of aerated concrete and carry out all the work as quickly and efficiently as possible, ensuring the final result in the optimal time frame. We take care of all the preparatory work, offering the customer a ready-made, high-quality surface.

Contact our company for comprehensive services for the construction and interior finishing of aerated concrete houses, as well as professional production of screeds using advanced technologies.

Aerated concrete - material features

Foam concrete, gas silicate and aerated concrete belong to the category of cellular concrete - a separate type of building material containing a large number of air chambers in its structure (from 70 to 90%). The advantage of this material is its high thermal insulation properties, the disadvantage is low strength depending on the concentration of air cells. In this regard, before constructing an aerated concrete house, careful calculations are carried out.

The main features of aerated concrete include the following:

- When building a house over 1 floor, it is necessary to make serious calculations.

- It is important to exclude all factors leading to shrinkage of the house, otherwise the formation of cracks in the structure of the blocks cannot be avoided. Therefore, they are especially careful when arranging the pit and foundation.

- Aerated concrete has thermal insulation properties, but retains heat poorly.

- It is important to perform high-quality interior and exterior finishing. It is worth remembering that walls made of aerated concrete do not hold fasteners well.

- Particular attention is paid to the choice of floor material, which should not be too heavy.

MZLF device

To understand how to build a foundation, you need to know what it consists of. The first element is a sand cushion. It levels out soil vibrations and strengthens the structure.

The second part is the concrete strip itself, reinforced with reinforcement. Also important components are waterproofing, drainage and insulation.

Construction stages

1. Planning. First of all, a calculation is made of the total weight of the structure, including the useful mass and the frame of the aerated concrete building itself. A drawing of the structure is being prepared, and soil characteristics are being studied. After this, a diagram of the base is drawn with all the corners, load-bearing walls and internal partitions.

2. Preparation of the land plot. It all starts with clearing the area of debris and vegetation. Trees and shrubs are removed along with the root system. If reinforcement with piles and grillage is planned, you need to dig a control hole 1-1.5 meters deep to study the soil layer.

Making your own floor

Today I easily covered the floor in my room with polystyrene foam. And for dessert, I almost completely installed a heating system from batteries - soldering pipes is a pleasure. The move has been delayed because I want to do the water supply first (1-2 days)

If I'm not mistaken, what you have on the floor is not polystyrene foam, but extruded polystyrene foam? Will you be laying pipes on it and pouring screed? Why do you need radiators if you are using underfloor heating? Are you afraid of freezing? A friend of mine in Chelyabinsk built a house with warm water floors, without radiators; just to be on the safe side, he added circuits to the walls, but turned them on only once, for testing. Three winters only on heated floors is normal, not cold, and in the Urals it is cooler than in the Civil Code.

Many thanks to Lyudmila from the forum for providing me with the concrete mixer - I couldn’t have done anything without it

A few communications at the boiler.

And secondly, I don’t like the use of tees and extension cords in the room, so I replaced the single sockets in my apartment with blocks of sockets. There are blocks of 3 sockets in the living room, and blocks of 2 sockets in the bedroom and kitchen. As a result, there is not a single tee or extension cord.

Hall 3 blocks of 3 sockets, bedroom - 2 of 2, kitchen - 3 of 2 and in the hallway 1 block of 2 sockets + floor heating thermostat in the bathroom and toilet.

The wires must be corrugated

Any wires in a screed must be laid in corrugation - firstly, they can simply break during shrinkage, and secondly, if there is a leak, there is a high probability of breakdown!

The corrugation costs three and a half kopecks, but it saves you from a lot!

The tie will be thicker by the corrugation, or the cable length will increase. I believe that the temperature of the wire along the drum is 70 degrees, and I’m unlikely to keep it at that temperature; it will be too hot. Now the temperature of the batteries is +40 degrees - in the house in Tashkent, and this is with the heated floors turned off. The cross-section is 2.5 cores, so it won’t break. I have all double sockets - each socket has 2 sockets. I think 4 sockets are enough for a room.

Of course, this decision was made against the rules of the PES - be careful.

Heating radiators in a house made of gas blocks

Why radiators if there is a heated floor? By the way, pipes, etc. are laid in increments of 230-300 mm and 100-150 mm along the edge. The screed plate must be at least 50 mm. The comb with taps is called a manifold and regulates the flow rate of the coolant in the pipeline, and not the temperature; as a result, the floor will warm up unevenly. To avoid this, use the coolant adjustment in the boiler (yours has such a function). There is a laminate on which it is written that it is suitable for water-heated floors, use only this one. The heated floor can be turned on a month after laying the screed, with the exception of the heating mode to prevent the screed from freezing, but without experience it is better not to experiment with this. They gave you a sensible note about the corrugation: it can tear 2.5 mm2, besides, if you have to change the wire, you won’t have to spoil the finish.

Well, that's it, I've moved, now I'm moving on to the next room - the processes are the same - warm floors, screed, putty, painting, wallpaper, laminate.

Well, yes, it was a temporary floor under the legs of the bed; the foam would not have held up. .

I poured the screed, despite the cold weather on the street. I calculated that for a room of 9 square meters you need 4 batches of a concrete mixer, it takes 2 bags of cement and 7 wheelbarrows of coarse sand. I make the screed in a ratio of 1 to 5 For one shovel of cement - 5 shovels of sand. Whatever strangely, it turns out very durable. I use Portland cement grade 500 from Novorossiysk. I came up with an original idea for attaching the beacons in height - using aerated concrete, I cut cubes 4 cm thick using a hacksaw according to a pattern from a board, then I glue the stands with dragon glue to the foam plastic, and then I screw the beacons on with self-tapping screws - everything is very quickly and practical compared to alabaster.

Damper tape for floors

Somehow the damper tape is not visible. I hope you didn't forget to add it?

I decided not to lay it down - the screed is quite soft - 1 to 5 interfered, and the rooms are small. I'll lay it in the guest room.

I started preparing the heated floor in the living room. The weather is rubbish - it’s unclear how to deal with such wind and rain.

Isn't the step too big? "Zebra" won't work?

In the penultimate photo, the pipes seem to be walled up in the wall. The screed must be “floating”; it can break the pipe if it is jammed in the wall or somewhere else. Concrete will expand at the rate of 0.5 mm/m. By the way, the damper tape is again not visible. I wouldn't risk it without the tape, especially since it costs pennies. In addition, it prevents the heat from the screed from “floating” through the bottom of the wall to the street. And also, do not tightly tie the TP pipes to the welded mesh.

Well, I finished all the little things with the heated floor - beacons, wiring, damper tape. Tomorrow morning, if there are no natural disasters, I’ll try to fill it, I’m tired of jumping through pipes

Hooray! Filled it up. There were 5 and a half batches. . And I wasn’t very tired, apparently because I started working in the morning, whereas before I always finished everything in the evening in the dark.

Laying technology errors

Violations of gas silicate wall masonry include:

- The absence of a waterproofing layer between the gas silicate and the base of the foundation or the installation of such a layer with glue rather than cement mortar.

- Laying a row without offset.

- Lack of reinforcement when connecting partitions and load-bearing walls.

- The process of laying blocks using regular glue in winter.

- Filling of window and door openings without additional reinforcement. For strength, it is customary to use steel corners measuring 80 by 80 or larger, but so that they exceed the length of the structure by 90 cm.

- Insufficient filling of the seams with glue and its uneven distribution throughout the block.

So, gas silicate blocks are a modern high-quality building material. It is equally suitable for private homes or large buildings. Construction from them is faster in terms of time and allows you to erect a building even with your own hands, provided you follow the instructions for the work order.

Screeding floors in aerated concrete houses

Floor screed is a mandatory element of construction work in country houses, and is also used in many cases in the process of major renovations of objects. A high-quality floor not only ensures long-term use, but also does not create problems in the future with the placement of furniture. The quality of floors is based on the arrangement of the screed. As part of our construction services, our company screeds floors in houses built using aerated concrete blocks. We can guarantee the quality of work regardless of the size of the interior and the architectural complexity of the facility.