There is probably no older and more reliable building material than ordinary red brick. Over the course of several hundred years, the clay brick block has de facto turned into a material with enormous potential and capabilities.

In fact, this is the only building block made of minerals, which, like wood, you need to be able to work with your hands, so brick, no matter what it is made of and what size, will remain the number one building material for a very long time.

Types of bricks

Today, there are about a dozen different types of bricks, they differ in the raw materials used and composition, have different strength and resistance to the external environment, but they are all united by one rule - the size of the brick, adopted by the standard, most closely corresponds to the grip of the fingers of an adult’s palm. It’s hard to take more with one hand, less - the laying speed drops sharply.

The most popular types of material used in home and low-rise construction:

- Ceramic red brick;

- Clinker blocks;

- Hyperpressed brick;

- Silicate blocks and bricks;

For your information! For each of them, a brick size standard has been developed, which takes into account production technology, raw materials and the load-bearing capacity of the material, which is sometimes confused with contact strength.

All of the listed types of building blocks are used for the construction of masonry walls using a binder mortar. The main feature of this building material is that all wall brick blocks, without exception, are subject to requirements for three main characteristics:

- The brand of brick that determines its strength. This allows you to compare and determine the load-bearing capacity of brick buildings made of different materials. The standard strength value for ordinary brick is in the range of 125-180 units;

- Frost resistance shows the number of cyclic frosts that a specific ceramic material can withstand before completely losing its load-bearing capacity. For middle and northern latitudes, brick blocks with MP3 = 35 or more are used;

- Thermal conductivity is one of the most important characteristics. For ordinary ceramic bricks of standard sizes, without voids, this value is 0.72 W/m∙C.

In addition to the most important indicators, density, water absorption and multiplicity of shape are also used to describe the capabilities of the material. The last coefficient determines how many times a particular brick is larger in volume than a standard-sized stone. This indicator allows you to easily, almost immediately, recalculate how many bricks are in a pallet when purchasing material or, what is more practical, when determining the work performed by a mason - how many bricks are in a cube.

Fireclay brick parameters

For the construction of stoves and fireplaces in the area of contact with fire, special fire-resistant bricks are used. In its production, a special type of clay is used - fireclay. That’s why such a brick is also called fireclay. The production process is the same as for building red bricks - molding, drying, firing in a kiln. But, due to the special properties of fireclay, the resulting building material can easily withstand prolonged contact with open fire. There are two brands of general-purpose refractory bricks used in everyday life: ShA and ShB. ShA can withstand temperatures up to 1690°C, ShB - up to 1650°C, all other parameters are identical. Therefore, their scope of application is the same - this is the molding of fireboxes for fireplaces and stoves.

Some types of fire bricks: sizes may vary, but they are all standardized

Encode the size of the refractory brick in the number that appears after the abbreviation:

- ШБ-5, ША 5 - 230*114*65 mm;

- ShB-6, ShA 6, ShA 14 - 230*114*40 mm (flying blade);

- ШБ-8, ША 8 - 250*125*65 mm;

- ШБ-9, ША 9 - 300*150-65 mm;

Most often they use ShA 8 or ShB 8. They are the same in length and thickness as the ceramic red brick from which the rest of the stove is made. There is also a wedge-shaped refractory brick - for forming firebox arches and smooth curves in the horizontal plane.

There are two types of wedge refractory bricks:

- end - for forming curves in the horizontal plane ША, ШБ 22 - 230 * 114 * 65/55 mm;

- ША, ШБ 23 - 230*114*65/45 mm;

- ША, ШБ 48 - 250*124*65/45 mm;

Types of wedge fireclay bricks: edge and end wedge

- ША, ШБ 44 - 230*114*65/55 mm;

These are not all the sizes and types of fireclay bricks. You will find more in GOST 8691-73.

Red ceramic brick

According to statistics from companies involved in the production and sale of brick building materials, 65% of block ceramic materials on the market are red ceramic bricks, 13% are silicate blocks, the remaining percentage are clinker and hyper-pressed materials.

By region, such a distribution can fluctuate greatly, since production is strongly tied to the raw material base. Today, a deposit of high-quality brick clay is becoming as rare as, for example, a source of mineral water.

Red brick is available in several versions:

- Ordinary brick block;

- Porous and hollow bricks;

- Facing brick.

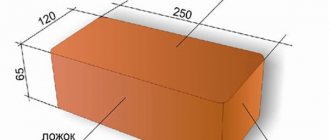

In addition, brick ceramics are produced in several sizes. A standard size brick of 250x120x65 mm is called single, one-and-a-half is available with a height of 88 mm, but there are also larger blocks. For example, according to GOST 530–2007, lightweight bricks of increased dimensions 250x120x138 mm are produced under the name ceramic stone.

For your information! Due to the large number of voids, such a block has 30% less thermal conductivity and weight. Accordingly, a wall with a thickness of 640 mm will retain heat as well as standard brickwork, three bricks thick.

Ceramic briquette

Recently, in order to save money, ceramic bricks have also found their use in construction.

Tutego pros and cons. It is also called a double stone and is very different from its single counterpart, which is red in color. This is especially noticeable in height, which is several times greater.

Dimensions of a single ceramic brick – 250x120x65 mm;

Single

The dimensions of the double ceramic briquette are 250x120x138 mm.

Double

Recently, builders began to actively purchase one-and-a-half ceramic briquettes. Their size is 25x12x8.8 cm.

One and a half

It immediately becomes clear that the cost of ceramic bricks is directly proportional to the dimensions: single red bricks measuring 250x120x65 mm are especially popular among builders.

Full-bodied red ceramic briquettes are considered the most versatile. It is actively used for finishing the ground floor and for the construction of load-bearing structures.

It is distinguished by its excellent resistance to sub-zero temperatures and its low thermal conductivity. The percentage of moisture absorption is 14% - this will be enough to use it in regions with frequent rain.

Most construction companies opt for ceramic briquettes, the cost of which is relatively low. The reason for this choice is quite obvious:

- red ceramic briquettes are considered a classic building material that is used for the construction of residential buildings.

Construction of houses

The material has undergone many tests.

The history of its use goes back many decades, during which time it has established itself in the modern construction market. environmentally friendly material. Ceramic briquettes are made from environmentally friendly ingredients.

As a rule, no chemical impurities are added to the composition. durable. The material in question is extremely difficult to destroy. According to this indicator, it is identical to natural stone; it can be rationally used for the construction of multi-story structures.

high resistance to moisture. In addition, the material dries as quickly as possible, while it creates an optimal climate in the room. does not absorb moisture. This figure is no more than six percent.

not susceptible to negative environmental factors. resistant to fire. It can hardly be called a combustible material.

resistant to sub-zero temperatures and practically does not allow any extraneous sounds to pass through. thanks to it, the warmth in the room will remain even without the use of additional insulation. optimal cost. This building material is durable.

Hollow, enlarged and ordinary ceramic stone

Ordinary bricks have the highest strength, ranging from 200-300 units. they do not have specially made voids, although the proportion of internal pores can reach 8%. The weight of a standard size brick is 4.1 kg. Of all ceramic materials, this one has the highest thermal conductivity - 0.72 W/m∙C, therefore it is used only for arranging load-bearing structures and walls.

Hollow bricks are made with special voids, the volume of which can be up to 50%. The weight of a single block is 3.4 kg, but the thermal conductivity is reduced to 0.5 W/m∙C. Strength reaches 200 units, so this material can be used for masonry of residential buildings.

One- and two-story buildings are built from brick with a maximum void content of up to 45%; it can be easily distinguished by the row arrangement of holes. For high-rise buildings, a material with 22% voids is used; they are usually made in the form of squares and are located in the body of the stone in a checkerboard pattern.

Often, red ceramic brick is stereotypically perceived only as an ordinary, very durable and fairly cold wall material. Actually this is not true. The industry produces porous brick stones made from fired clay of increased size. For example, a ceramic block of brand 4.5 NF RAUF has dimensions 250x250x138 mm, weight 7 kg and thermal conductivity 0.22 W/m∙C. One such block replaces four hollow stones.

A 10.8 NF block measuring 380x253x219 mm can replace ten standard red brick stones. Weighing 14 kg, the material has a thermal conductivity of 0.15 W/m∙C.

Unfortunately, both options, due to the high percentage of voids, have a strength of only 35-60 units. and can only be used for single-story construction.

Product classifications, their dimensions and scope of application

Now let’s talk in detail about the dimensions of building bricks and their existing types.

Ceramic brick and stone

Let's start with the most popular material - ceramic products. They are manufactured in accordance with GOST 530-2012, which we will rely on when considering classifications.

The standard sizes of ceramic bricks are as follows:

- A single product has dimensions of 250*120*65, it is marked 1NF. The weight of a standard brick is about 4 kg.

Single brick size

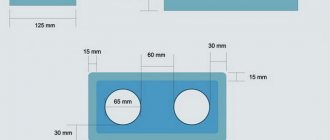

- One-and-a-half, or thickened brick is characterized by a size of 250 * 120 * 88, its marking is 1.4NF;

Dimensions of one-and-a-half working bricks

- There are double products - they differ in thickness, which is 138 mm;

The size of one double brick is more than twice the size of a single brick

- The dimensions of a single euro brick are 250*88*65 mm.

Euro ordinary brick, sizes

- It is also worth noting the presence in the range of ceramic products of stone, which is characterized by a thickness exceeding 14 cm. This is a large-format material with the obligatory presence of voids. Large bricks are actively used in the construction of lightweight walls.

Hollow brick, thickness 380 mm

If we talk about porous facing brick, its dimensions can reach (in the standard version) 11.3 NF, that is, 398 * 253 * 219 mm. Also produced: 10.3 NF - 380*253*219, 4.5 NF - 250*120*188 mm and many others.

Large brick, dimensions

- There is also a so-called modular brick, the dimensions of which can be equal to 288 * 138 * 65 (for single products). The one and a half product differs in height, which is 88 mm.

What other classifications exist:

- Ceramic bricks can be faced or ordinary. A stone with a groove or ridge is used only as an ordinary product.

- Bricks can be solid or have voids. The stone cannot be full-bodied due to its large format.

- The voids can be located either parallel or vertical to the bed. Their number and shape may vary.

- Bricks are also distinguished according to their strength grade, which determines the scope of use of the products.

The dimensions of a standard ordinary brick can be as follows: 250 * (120, 80, 65) * (65, 88, 55); 288 * (138) * (65, 88).

On a note! The size of the finishing brick and working brick, as well as the stone itself, may differ from the above. By agreement with the buyer, it is also possible to produce non-standard bricks that differ in length, height or width.

Now let's talk a little more about facing bricks:

- The surface of the products can be either smooth or textured.

- The assortment also includes surfaces textured by torquetting, glazing, and engobing. The surface imitating stone looks quite advantageous. For example, glazing has a glossy surface, which can noticeably highlight the structure. Often such products are combined with other materials during construction, and they are used to create mosaic designs on masonry.

- The color of the bricks can be different; they can be characterized by a natural color or be painted.

- The dimensions of the facing brick are similar to the dimensions indicated above.

Facing brick

It is worth highlighting clinker brick separately. It is also made from clay. But the clay used is special - refractory, and specialized additives increase the strength characteristics. Moreover, firing is carried out at a very high temperature.

Clinker products are characterized by the highest density, strength and durability. It is also worth noting their low hygroscopicity.

The palette of shades is quite wide. The surface can not only be painted, but also have a texture.

Clinker brick, photo

What sizes of clinker bricks can be found on the building materials market? The most diverse! There is also a so-called crossbar - a long brick reaching 528 mm.

Cladding with brick-transom (Long)

In addition to the above classifications, products are also divided depending on manufacturing technology, quality of preparation of raw materials and, as a consequence, appearance and scope of application.

- Red brick is the most durable and high quality. A bright, saturated color, as well as a ringing sound when dropped, indicate full firing. Such products can be used in almost any work.

Red brick

- Iron ore is a burnt brick. It has a dark red color. Such products are characterized by extremely low water absorption, which partly determines their scope of use. This could be, for example, laying a pipe above the roof. The material is also used in the construction of basements and basement walls. The size of the burnt brick meets the same standards.

Zheleznyak

- You can often find bricks on sale that are relatively pale in color. This indicates poor firing. Such products are the least durable, hygroscopic, and particularly fragile. Of course, you can build from them, but you should take into account the above-mentioned weaknesses. The price for this material is more budgetary.

Insufficiently fired brick

- Backfill brick has high performance, but at the same time, external characteristics leave much to be desired (uneven edges, broken corners). The cost of such products is much lower, which increases the demand for them. They cannot be used for exterior finishing, but for rough masonry they are quite possible.

Backfill brick

- Stove and refractory bricks are used in the construction and finishing of stoves, fireplaces and other structures that require high heat resistance of materials. Such products, as a rule, are made from fireclay, and, in the case of fireclay bricks, with the addition of fireclay in an amount of at least 50%.

Kiln brick

The photo below shows shaped products that have an unusual shape, different from a regular parallelepiped. They are used for laying out various architectural elements of a building: basement ebbs, cornices, belts, columns.

Shaped products

Silicate products

Structurally, there are also solid and hollow products here:

- Solid brick is relatively durable, but its thermal efficiency is somewhat reduced. The weight of building bricks that do not have voids is slightly higher than that of clay bricks - about 3.7 kg for a single brick, and 5 kg for a one and a half brick. Such products are usually used in the construction of walls, including load-bearing walls, partitions, and other structures that are subject to significant loads.

Solid silicate brick

- Hollow is exactly the opposite: it has a lower thermal conductivity coefficient, and the strength characteristics and weight are also reduced.

Hollow silicate brick

There can be a different number of voids. Their shape can also be different.

The most common options are the following:

- Three-hollow brick is characterized by a voidness of approximately 30%;

3-hollow product

- 14-hollow products have a hollowness of 14-15%;

Ahead are products with 14 voids

- 11-hollow products have a hollowness of about 23%.

Silicate brick with eleven voids

On a note! The voids in sand-lime bricks must be non-through. This requirement is dictated by GOST. But the number of voids can be changed by agreement with the buyer.

If we talk about the purpose, then sand-lime brick can be facing or ordinary:

- Ordinary products are used in the construction of walls or partitions - that is, when performing the main masonry. Finishing of such products is necessary.

- But the facing brick does not need finishing. Special requirements apply to appearance. The surface of such material can be not only smooth, but also have the texture of crushed stone.

Facing colored sand-lime brick

There should be 2 decorative surfaces - bonded and spooned. However, by agreement with the developer, this requirement may not be fulfilled.

Regarding sizes:

- The dimensions of a single product are, as in the case of ceramic bricks, 250*120*65;

- One and a half - 250*120*88 mm;

- The silicate stone is 138 mm thick;

- And the block is characterized by a poke equal to 13 cm (or more);

- Euro silicate brick has a size of 250 * (60, 85) * 65 mm.

Brick with textured front surface

A little about decorative and textured products:

- They are characterized by the presence of a decorative coating on the surface of the brick. This can be glazing, application of polymer materials, paints.

- Chip bricks have a textured surface.

- The range also includes rusticated bricks with a surface reminiscent of natural stone.

Sand-lime facing brick

Concrete brick made by hyperpressing method

Now about hyper-pressed products. Their classification is almost identical. This type of brick is produced in accordance with GOST 6133-99.

Products can be:

- hollow or solid;

- privates and officers;

- The assortment also includes bricks of regular and shaped shapes;

- the texture can be: corrugated, chipped, polished, smooth.

Facing hyperpressed brick

Colored hyperpressed brick

Figured brick

And now a little more about decorative products. As already mentioned, their sizes and shapes can be different. Such bricks are used for cladding, creating and executing architectural forms, and in other cases.

Here are the sizes of some of them:

- The narrow product has dimensions of 250*60*56 mm;

- Spoon – 250*85*65 mm;

- It is not uncommon to produce decorative items with a length of 23 cm. The thickness is maintained (6.5 cm), and the width can be different: 50, 100, 56, 107 mm.

- Shaped bricks, for the most part, have the same standard dimensions at one end - that is, 250 * 120 * 65. Moreover, it has a certain figured shape, different from a rectangular parallelepiped.

Some sizes of decorative finishing bricks produced by the hyper-pressing method

Often developers ask the question: “How to calculate the volume of a single brick based on its dimensions?” In fact, there is nothing complicated in the calculations. You can do it in a couple of simple steps.

The instructions are as follows:

- The standard size of our product is 250*120*65 mm;

- To calculate the volume, we just need to multiply these data, because volume is the product of length, width and height;

- 0.25*0.12*0.65=0.0195 m3.

- Simply put, 1 m3 of single brick contains about 512 pieces of products.

Note! The above calculations do not mean at all that 512 products are needed to lay 1 m3 of wall. When calculating masonry, it is necessary to take into account the thickness of the mortar layer and some other factors.

Hyper-pressed brick has one significant advantage: it can be made by hand, and a large amount of expensive equipment is not required. And the video in this article will briefly tell you about some of the methods for making products of various types.

Raw brick: briefly about the material

Features of the products are as follows:

- The peculiarity of the composition is due to the straw content;

- Such products are not fired, which dramatically increases the hygroscopicity of the material;

- That is why raw brick is most suitable for use in regions characterized by a dry climate, where the amount of precipitation is minimal;

- The popularity of use is due to the extremely low cost of the material;

- Over time, the raw brick recipe has been significantly improved. Liquid glass, manure, cement, lime and other ingredients are added to the mixture. They are able to improve strength and other performance characteristics, and the plasticity of the mixture also increases;

- As has already become obvious, this material is not entirely suitable for our region. In Russia, it is used, as a rule, when lining a furnace with metal in order to maintain temperature;

- Raw brick can be easily made at home, and no special skills are required.

Raw brick

Facing material

Unlike ordinary and hollow bricks, for facing stone, what is primarily important is a beautiful, uniform pattern of the front surface and precise adherence to dimensions.

Brick can be produced in ordinary and lightweight versions. The strength of ceramic facing material reaches 125-175 units, which makes it possible to use it for finishing high-rise buildings. The thermal conductivity of ceramic cladding is at the level of 0.2-0.5 W/m∙C.

A facing block with a painted and textured surface is also produced, this means that the color of the front surface can be artificially painted in standard colors, and sharp edges and corners can be rounded.

Some of the facing stone is produced in shaped designs, in a variety of shapes and sizes, for example, in the form of triangles or semicircles.

Materials for making bricks

Initially, the blocks were made from clay, which was then fired. Over time, the composition gradually changed, various materials were added, including straw, and the amount of water and drying time were increased. The use of plinth - fired blanks characterized by increased strength - made it possible to erect high-rise buildings.

Tools for making bricks.

At the moment, clay is still used to make bricks; additives, sand, and lime are also used. There are only two main varieties:

- Silicate. It is made from lime, sand and a small amount of binders. Color - gray-white. During production it is treated with steam under pressure. Disadvantages of silicate blocks: they are not fireproof bricks and cannot withstand moisture. For these reasons, this material is mainly used for the construction of partitions and walls.

- Red, or ceramic. It is made from practically the same clay, the concentration of impurities is low. Processing: fired by fire. It is used almost everywhere, as it does not require special operating conditions. Withstands temperatures up to 1.8 thousand degrees.

Red brick is available in two types:

- Refractory. It is made from the most durable types of clay and differs in the method of hardening. Unlike other species, it can tolerate high temperatures and can be used in places where high temperatures are constantly observed.

- Simple. Resistant to temperature changes. Typically used for laying fireplaces and stoves.

In addition, blocks may have voids. The porous structure allows for better heat retention and reduced weight of the structure. Depending on the method of use, there are ordinary bricks, intended for the construction of walls, and facing bricks, for facade decoration.

Hyper-pressed, clinker and silicate material

Despite all the positive characteristics, the red clay brick block remains not strong enough to finish the basement sections of walls, porch groups or road paving facades. For these purposes, clinker bricks with a strength of 400-500 units are used. and frost resistance of 50-100 units.

The clinker block is produced by high-temperature firing of special mixtures of limestone, marl and red clay. The thermal conductivity of clinker is 7-8 times higher than that of hollow clinker and twice that of ordinary material, so it is used primarily for exterior decoration of buildings. A very durable and wear-resistant material, it can be used to build fortresses and mansions with equal success.

What is hyper-pressed brick material

The production of hyper-pressed material is very similar to the technological process of forming stressed concrete. The raw materials for hyperbrick are limestone and marl, purified and crushed to dust. A plasticizer is added to the mixture - 0.5%, pigment - 2% and high-quality cement - 10%. The mixture is mixed and the mold is filled, after which a monolithic, homogeneous material reminiscent of natural stone is formed under pressure at high temperature.

10-15 hours are allotted for tempering and drying the stone; another 5-6 days after the end of the shrinkage processes, the brick can be used for construction work. The shine of the micrograin is visible on the fracture. When laying hyper-pressed stone, the solution penetrates into the thickness of the material 2-3 times deeper, thereby ensuring very strong adhesion and adhesion.

According to its characteristics, hyperbrick is very similar to facing stone, and has high strength in the range of 150-300 units. and a wide selection of dyes make it an ideal choice for finishing porch paving and stair coverings.

Hyper-pressed stone should not be confused with vibro-pressed blocks and tiles. The latter is a conventional concrete casting compacted on a vibrating table.

Clinker brick

Clinker brick is another special type of ceramic brick. In its manufacture, a special type of clay is used - refractory shale. The molded blocks are fired at a very high temperature - 1200°C. As a result of this processing, the clay acquires the properties of ceramics, the color ranging from dark red to rich brown.

Clinker brick has very high strength and abrasion resistance. You can use it to pave roads or decorate porches. And they will serve for centuries. The surface of the clinker is flat, smooth, shiny. This allows it to be used also as a finishing brick - for finishing facades, laying pillars, etc.

Types and sizes of clinker bricks from one of the companies

The shape and size of clinker bricks can be very different - there are a lot of them, since there are not only standard ones - in the form of a parallelepiped, but also with beveled at different angles, rounded edges.

The best posts

- How to make a plasterboard box in the bathroom - step-by-step instructions

- Painting drywall - step-by-step instructions

- Drywall figures or how to make the interior stylish and fashionable

- Socket boxes for drywall: correct selection and installation

- Wiring under drywall: lay it out correctly

- Grouting drywall joints: materials and techniques for performing the work

- How to join drywall in corners and the process of building a decorative niche

- Installing spotlights in drywall: advice from experienced specialists

Related article: How and how to seal gaps between boards in a wooden floor

Sand-lime brick

The main components in the production of silicate blocks are sand and lime. The mixture is pressed and steamed in an autoclave at elevated temperature and pressure. The result is a brick of standard 250x120x65 mm or one-and-a-half sizes 250x120x88 mm. The weight of a single stone is 3.3-3.45 kg, which is less than that of an ordinary ceramic stone.

The strength of a high-quality silicate block is 150 units, which allows it to be successfully used for the construction of low-rise and auxiliary buildings. The old Soviet silicate was the main brick for rural construction and the construction of “Khrushchev” buildings.

Instead of the previous gray tones, the modern silicate block is painted in warm yellows, browns, reddish pinks and greens.

Today, silicate brick blocks are produced in both regular and hollow versions. For example, a lightweight brick with 30% void volume weighs 2.5 kg with a strength of 140 units. and thermal conductivity of 0.44 W/m∙C. The main advantage of silicate is its low production cost due to the use of widely available materials. In addition, silicate mass is perfectly cut, drilled and processed with ordinary metalwork tools, while for cutting ceramic and especially clinker bricks, circular saws with CBN grain are used.

The downside is low frost resistance and the ability to be destroyed by carbon monoxide.

Single

Construction companies and manufacturers of relevant materials, as a result of long negotiations, reached a compromise regarding the typical size for the material discussed in the article.

A single brick has standard dimensions: length - 250, width - 120 and height 65 mm.

These parameters are considered optimal because this material is the easiest to alternate placement of bricks. This is done longitudinally and transversely relative to the masonry axis.

For more details about the dimensions of a single brick, watch the video: