House made of aerated concrete blocks lined with bricks

Designing the construction of any building begins with the selection of materials for it. Lightweight concrete is increasingly being used. When the issue has been resolved, and aerated concrete blocks have been chosen as the basis for the construction of walls, the characteristics and their main technical parameters must be clarified in advance. Let's look at this in more detail.

Main parameters of aerated concrete products

The main parameters of aerated concrete blocks are determined by the properties of the materials from which they are made, as well as by production technology.

Production of aerated concrete products

The main components in the production of aerated concrete are:

- Cement;

- Sand;

- Lime;

- Water;

- The gas-forming agent is aluminum powder or a paste made on its basis.

Technical characteristics of aerated concrete blocks depend on the properties of the constituent materials

The result of the chemical reaction is the formation of a large number of voids - pores - in the material. This structure largely determines the main technical characteristics of aerated concrete blocks. The type of aerated concrete based on the method of hardening depends on further processing technology.

There are gas blocks:

- Not autoclaved;

- Autoclave curing.

Characteristics of aerated concrete processed in an autoclave and a non-autoclaved block

Non-autoclave hardening implies natural drying of products.

With this option, what happens:

- Significant reduction in production costs;

- Aerated concrete blocks: characteristics and geometric parameters will be slightly worse than when processed in autoclaves.

Note! Basically, the thermal conductivity of a gas block increases due to the uneven distribution of pores in the material. It is economically beneficial to use such products in the construction of temporary or utility buildings.

Autoclave processing of products involves creating special conditions for the hardening of aerated concrete:

- presence of saturated steam at high temperature;

- high pressure in the autoclave.

Autoclaved concrete is different:

- greater thermal insulation due to the uniform formation of cells inside the material;

- correctness and accuracy of geometric dimensions;

- stable mechanical and physical properties.

The cellular structure determines the main technical characteristics of aerated concrete blocks

After autoclave treatment, the moisture content in aerated concrete blocks is about 30% by weight of the dry mixture.

Types and sizes

Aerated concrete products are produced in the form of:

- blocks;

- slabs

Blocks can be:

- rectangular smooth;

- rectangular with grooves and pockets;

- U-shaped;

- Non-standard shape.

The variety of shapes of aerated concrete blocks also differs in a large number of their sizes

Aerated concrete blocks - technical characteristics

Basic technical data of aerated concrete blocks

The production of these materials is standardized by GOST 31360-2007 “Non-reinforced wall products made of autoclaved cellular concrete. Technical conditions". It applies to aerated concrete blocks without reinforcement, which are used for the construction of load-bearing and self-supporting external walls under dry, normal or wet operating conditions in the absence of aggressive environments.

If the air humidity in the premises is less than 75%, then internal walls and partitions are also made of aerated concrete.

Aerated concrete block and its characteristics

Depending on the thermophysical and physical-mechanical properties, aerated concrete products are characterized by:

- Medium density;

- Compressive strength;

- Thermal conductivity;

- Shrinkage during drying;

- Frost resistance;

- Vapor permeability.

According to its intended purpose, aerated concrete is classified as:

- Structural;

- Structural and thermal insulation;

- Thermal insulation.

The first two options of aerated concrete blocks are used for the construction of load-bearing and non-load-bearing wall structures, the last - as thermal insulation of buildings and structures.

House made of structural blocks

Average density and strength of aerated concrete blocks

Due to their porous structure, aerated concrete products have low weight and low density. Based on the average density of concrete, it is assigned a certain grade.

The density of aerated concrete corresponds to its purpose:

- Structural – a grade higher than D700 is used;

- Purpose - structural and thermal insulation - the density of aerated concrete blocks is not higher than grade D700;

- Thermal insulating aerated concrete – grade lower than D

The compressive strength class of concrete can be:

- For structural – B3.5 and higher;

- For structural and thermal insulation – B1.5 and higher;

- For thermal insulation - above B0.35.

The cellular structure of aerated concrete gives it a high degree of water absorption, which greatly affects the strength characteristics of aerated concrete.

The strength of aerated concrete blocks depends on the degree of their humidity

Aerated concrete blocks are used in the construction of buildings and structures no more than four floors high. The compressive strength of this material is quite limited. In addition, the front surfaces of products crumble very easily, and aerated concrete’s resistance to mechanical damage is very low.

The strength of aerated concrete blocks is directly dependent on the brand of aerated concrete.

Aerated concrete d 500 - strength characteristics: one cube can withstand a load of 500 kg.

Characteristics of aerated concrete d500 - block with grooves

Characteristics of aerated concrete D600 in terms of compressive strength: from 2.5 MPa to 4.5 MPa. The design strength of aerated concrete is taken to be its strength at a product moisture level of 10%. The average masonry density required to calculate the loads on the wall structure also takes into account the thickness and density of the material for the seams.

Aerated concrete density 600 and D300

Thermal conductivity of aerated concrete

The thermal insulation parameters of aerated concrete, like any cellular concrete, are determined in a dry state.

They depend on:

- Density or volumetric mass of concrete;

- Porosity of the material;

- Humidity levels;

- Mineral components of the composition.

Thermal characteristics of aerated concrete depending on its density

As a rule, calculated thermal conductivity coefficients according to GOST do not take into account the characteristics of mineral components from different regions where they are mined. As a result, most products made from aerated concrete have significantly lower thermal conductivity than required by standards. Therefore, the thermal insulation of buildings and structures made of cellular blocks is usually provided with a margin.

The average value for thermal conductivity according to GOST can be seen in this table.

Coefficients of aerated concrete materials for thermal conductivity and vapor permeability

For example, aerated concrete blocks d600 - thermal conductivity characteristics: 0.14 W/(mS) - 0.15 W/(mS).

After 2-3 years of operation, aerated concrete dries to an “operational” humidity level, at which the real thermal conductivity of aerated concrete blocks is determined. Its value will be higher than when the mixture is dry.

The operating humidity of aerated concrete is approximately 4-5% and depends on:

- Structural features of the walls;

- The conditions under which the building is operated;

- Orientations depending on the cardinal directions.

Many other factors also influence its value.

Thermal conductivity coefficients at equilibrium humidity of aerated concrete

The heat-insulating option has the highest heat transfer resistance of aerated concrete compared to the structural and structural-thermal insulation types.

The unique thermal characteristics of aerated concrete are ensured by its cellular structure

In a dry state, the specific heat capacity of aerated concrete is approximately 0.84 kJ/kg.oC. With a humidity level of 4% to 5%, it will be from 1.0 kJ/kg.oC to 1.1 kJ/kg.oC.

Aerated concrete - thermal characteristics in relation to other wall materials

The thermal conductivity of aerated concrete depends on the degree of its humidity.

Increase in thermal conductivity of aerated concrete grades D400 and D350 depending on humidity

The high degree of thermal insulation of the aerated concrete blocks themselves will only be maintained if the wall structures are laid correctly:

- A significant amount of heat can be lost through interblock seams if they are performed incorrectly.

- Laying blocks on cement-sand mortars leads to an increase in thermal conductivity of the entire wall structure in general.

- Therefore, it is better to use special adhesive compositions for aerated concrete for seams.

Special adhesive for laying aerated concrete materials

They make it possible to reduce the thickness of the masonry layer, which significantly reduces the heat loss of wall structures. So, with a glue joint size of 1.5 mm and up to 2.0 mm, sufficient uniformity in thermal insulation of the entire wall as a whole is ensured. This makes it possible to construct a single-layer wall structure without additional insulation.

Thermal conductivity increases with seam thickness:

- At 10 mm and up to 12 mm - by approximately 20%;

- More than 20 mm – by 30%.

Thin-seam masonry made of aerated concrete wall blocks

Due to the fact that the thermal characteristics of aerated concrete are quite high, it can be used as insulation instead of mineral wool, foam plastic, etc.

Vapor permeability of aerated concrete structures

Good vapor permeability of gas blocks allows you to create:

- Favorable indoor microclimate.

- Condensation does not collect on the walls.

- Normal moisture balance.

Aerated concrete - technical characteristics of vapor permeability in comparison with other materials

When using aerated concrete blocks in rooms with a high degree of humidity, a mandatory vapor barrier layer is required.

It is necessary to prevent the penetration of water vapor into the material of external wall blocks in:

- Bathrooms and shower rooms;

- Kitchen areas;

- Saunas and steam rooms;

- Baths;

- Drying rooms.

Vapor barrier can be done using:

- Laying tiles on the inner surface of wall blocks with sealing the seams with a waterproof fugue;

- Installation of a vapor barrier layer made of special materials.

Protection of aerated concrete blocks with tiles.

The higher the vapor permeability of the wall structure, the faster the humidity characteristics of aerated concrete blocks will reach operational parameters.

Drying diagram of aerated concrete in wall structures

If the outside of aerated concrete walls are covered with bricks without a ventilation gap, then the drying of the aerated concrete blocks will occur slowly, since the degree of vapor permeability of the resulting system is very low. If you install a ventilated façade or finish it with plaster, the walls will dry much faster.

Facing aerated concrete products with facing bricks

Sound insulation of aerated concrete products

The technical characteristics of aerated concrete as a soundproofing material are quite high. Additional internal and external wall decoration significantly improves these properties.

So the sound insulation characteristics of aerated concrete D500 are:

- With a wall structure thickness of 100 mm and double-sided finishing with putty - 39 dB.

- If the wall thickness is 150 mm under the same conditions - 41 dB.

Even one-sided cladding of wall blocks increases the sound insulation of the entire structure by 5 - 20 dB.

Frost resistance

The frost resistance of aerated concrete largely depends on its humidity. If aerated concrete with a density of 500 has a moisture level of more than 40% of the total volume or 80% of the total mass, then this value is critical.

When exposed to negative ambient temperatures, the material loses its physical and mechanical properties and begins to deteriorate. If the density of aerated concrete products is 400 kg/m3, then the critical moisture content will be 45 - 50% of the total volume, 100 - 120% of the weight.

House made of aerated concrete - construction in winter

When carrying out construction work, it is necessary to carefully protect the blocks from waterlogging.

The frost resistance class of aerated concrete depends on the number of cycles of freezing and thawing of products, as a result of which concrete loses no more than 15% in compressive strength and no more than 5% in weight.

Frost resistance classes for aerated concrete products:

- _F15;

- _F25;

- _F35;

- _F50;

- _F75;

- _F

According to the frost resistance grade, aerated concrete blocks must be no lower than:

- F25 – for blocks that are used in external wall structures;

- F15 – all other blocks are made of aerated concrete.

Thickness of partition walls

This parameter is selected taking into account certain factors, the load-bearing capacity is calculated and the height of the partition is taken into account.

When choosing blocks for such walls, you should pay close attention to the height value:

- if it does not exceed the three-meter mark, then the optimal wall thickness is 10 cm;

- when the height increases to five meters, it is recommended to use blocks whose thickness is 20 cm.

If there is a need to obtain accurate information without performing calculations, you can use standard values, which take into account connections with the upper floors and the lengths of the walls being erected. Particular attention is paid to the following tips:

- when determining the operational load on the internal wall, it becomes possible to select optimal materials;

- for load-bearing partitions, it is recommended to use D 500 or D 600 blocks, the length of which reaches 62.5 cm, the width varies from 7.5 to 20 cm;

- the installation of conventional partitions involves the use of blocks with a density index of D 350 - 400, which makes it possible to improve standard sound insulation parameters;

- The sound insulation indicator fully depends on the thickness of the block and its density. The higher it is, the better soundproofing properties the material has.

Related article: How to lay natural stone on a wall

If the length of the partition is eight meters or more, and its height is four meters or more, then in order to increase the strength of the entire structure, the frame base is reinforced with a reinforced concrete reinforcing belt. In addition, the required strength of the partition can be achieved by using the adhesive composition used for laying.

Shrinkage of aerated concrete products

During drying of aerated concrete products, their shrinkage should be no more than 0.5 mm. This value applies to structural and thermal insulating aerated concrete, as well as structural concrete. For thermal insulation materials, the degree of shrinkage is not established.

When the moisture content of the material decreases from 35% to 5%, the shrinkage characteristics of D600 aerated concrete are approximately 0.12% or 0.12 mm/m.

Note! When humidity decreases below the 2% mark, the shrinkage of aerated concrete blocks increases significantly. This point must be taken into account when constructing technological structures for chimneys made of aerated concrete products.

The main advantages and significant disadvantages of aerated concrete products

The porous structure of aerated concrete is the basis of many of its advantages. However, it is also often a big disadvantage of products made from it.

The main advantages of aerated concrete

We can name the main advantages of using aerated concrete blocks:

- A light weight;

- Cost-effective – no large consumption of adhesive and plaster compositions is required due to clear geometric dimensions;

- High thermal insulation properties;

- Environmental cleanliness;

- Ease of processing materials;

- Easy installation of blocks due to their weight and flat surface;

- Durability of structures;

- Low price of materials;

- Fire safety;

- Wide range of block shapes and sizes.

Light weight aerated concrete blocks

Due to the low weight of aerated concrete blocks, the following is ensured:

- Convenience of loading and unloading operations;

- Lower transportation costs;

- Easy to install - no special equipment required;

- The overall weight of the building is reduced, as well as the load on the foundation.

Since aerated concrete blocks have precise geometric dimensions, they can be laid with special glue. In this case, the masonry of the walls is more finely jointed than when using cement-sand mortar. As a result, the load on the base of the structure is reduced.

Structural and thermal insulating aerated concrete

Environmental friendliness of aerated concrete materials

Aerated concrete can definitely be called a very environmentally friendly material, since:

- For its production, only natural, natural ingredients are used.

- No environmentally harmful technological processes are used in its production.

- During operation there are no emissions hazardous to human health or the environment.

- The natural radioactivity level of 54 Bq/kg is much lower than the permissible value of 370 Bq/kg.

Aerated concrete belongs to class 1 in terms of environmental safety.

Aerated concrete blocks - comparative characteristics of radioactivity

Resistance to external influences

Since aerated concrete contains mineral components, it is highly resistant to many external influences.

Key points worth highlighting:

- Not subject to rotting.

- The material is not susceptible to fungal attack.

- Resistance to many aggressive environments - aerated concrete is chemically inert.

- It is fire resistant and is classified as a non-combustible material.

- Tolerates temperature changes well.

All products made from aerated concrete are included in the group of non-combustible materials, which is confirmed by GOST 30244.

Aerated concrete d500 fire safety characteristics:

- With a wall structure thickness of 100 mm – EI 120;

- If the wall size is 150 mm - R 120, EI

A wall made of aerated concrete blocks after a fire - photo

The degree of fire resistance REI 240 is the ability to withstand open fire for 4 hours without losing the basic physical and mechanical properties of aerated concrete. This characteristic is the highest among other structural materials.

Working with aerated concrete blocks

Processing and installation of aerated concrete blocks are quite simple processes; it is quite possible to do it yourself, without the use of special tools and equipment. Aerated concrete products are easy to saw, sand, and simply drill holes in them.

Due to their light weight, correct shape, and the presence of grooves, the blocks are installed:

- Quite quickly, since everything is done manually, without construction equipment.

- Very accurate - the presence of a special locking system allows even a non-professional to install them.

If aerated concrete blocks have a tongue-and-groove system, the assembly of wall structures is quite easy. The manufacturer's instructions will help you do everything correctly.

Service life of aerated concrete buildings

Aerated concrete structures can last quite a long time - 50-60 years. But for this it is necessary to properly and reliably protect aerated concrete blocks from interaction with moisture, and also to exclude the possibility of mechanical damage to the surface of the walls.

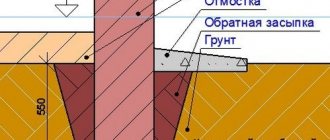

- A reliable waterproofing layer between the base of the foundation and the bottom row of aerated concrete blocks is required.

- The outer side of external walls needs high-quality protection in the form of plastering or cladding.

The multilayer structure of the wall structure is a reliable protection of gas blocks from external contact with moisture and from mechanical influences

The main disadvantages of aerated concrete

A significant disadvantage is the high ability of aerated blocks to absorb moisture. The structure of open and interconnected pores accumulates moisture well. Over time, this leads to the destruction of the material.

When reinforcing structures made of aerated concrete, mandatory protection of metal reinforcement from corrosion is required. Due to its porous structure and rather low degree of alkalinity, it weakly protects the metal. Rod reinforcement, metal reinforcing mesh, metal connecting elements must be covered with a layer of aerated concrete or adhesive mortar.

There are not many reputable aerated concrete manufacturers in Europe and they are all responsible for the quality of their products. But in Russia it is quite possible to organize “handicraft” production of this material, the quality of which often leaves much to be desired. However, more and more enterprises are appearing, the quality of their products is confirmed by certificates, including international ones.

This means that the likelihood of choosing aerated concrete blocks that meet all the required technical parameters is becoming greater. Additional information about the main characteristics of aerated concrete can be obtained by watching the video in this article: “Aerated concrete - properties and characteristics.”

Splitter for fences

A variety of textures and colors allow you to make a unique and unusual fence from a splitter block, suitable for any style of landscape design. The resistance of products to temperature changes and high humidity, ease of installation and low cost are qualities that attract many developers.

In order for the fencing of their splitters to serve for a long time and reliably, you should follow some installation rules:

- For a block fence, a shallow-depth strip foundation is made. Its width should be slightly larger than the thickness of the block.

- The support pillars are installed in increments of 3.0-3.5 m. The frame or core of the support must be linked to the foundation reinforcement. And to connect with the filling, you need to make reinforcement outlets or anchors.

- The top of the base must be covered with waterproofing.

- Laying is carried out in the usual way using cement mortar or glue for external use. During the work, the horizontal and vertical surface is constantly checked. The rows are also reinforced with meshes and linked to the racks. For strength, reinforcement is also applied to vertical columns.

- After finishing the masonry, the voids can be filled with cement mortar and the upper part of the fence can be covered with a parapet.

A fence built from splitter stones looks very similar to a fence made from natural stones. Thanks to a wide range of colors, you can choose the one closest to any natural material. And, using splitters with a double-sided torn surface, you get a fence with the same finish on the outside and inside.

- Wall kit