More and more new technologies are emerging, construction is developing rapidly, but the good old familiar brick does not give up its position. New brick houses are still being built. The point is not only that it is a reliable material, a good heat and sound insulator. If you make jointing on the front side of the walls of such houses, no additional facing materials are needed. Internal walls and partitions in structures built using new technologies also often remain brick.

Carefully executed brickwork does not require additional cladding.

Compared to the size of the objects being built, the size of one individual brick is small, so a fairly accurate calculation of their number is necessary. Of course, the extra building material purchased may come in handy in the future. And if not? And is it worth spending money right now, when it can be spent on other, more pressing needs? It is impossible to make this kind of calculation without knowing exactly the number of bricks in a cube (cubic meter) of masonry.

Only by owning this data, knowing the volume of work, can you decide on the amount of materials to be stored and avoid wasteful expenses.

Varieties and parameters

Private houses, garages and other structures are created using bricks. It can withstand cold, is resistant to moisture, has energy-saving properties, and can last for a long time.

But since it is not cheap, it is not recommended to be too careless about the choice. Data on the total volume in all walls is required. Thanks to the presence of all the necessary indicators, it is possible to determine the most accurate number of products suitable for specific construction work. The quality of work has a huge impact on the final result. After all, if violations occur due to a lack of material, then the house will not last long and everything will have to be redone.

Stones come in different sizes and shapes. It is very important that the weight is supported by the vehicle hired for transportation. The mass of silicate brick is much greater than that of red brick. Therefore, different vehicles will be needed for transportation.

The required consumption can be determined after selecting the type of material. If you know its parameters, you will be able to calculate how many bricks are in a cubic meter.

Today, the construction of buildings is carried out using materials of various types. Each option has the following differences:

- Single products are ceramic bricks. Their color is red or yellow, and their parameters are 250x120x65m3. Thanks to this material, the appearance of the walls is improved. After taking into account the parameters, we begin to determine all other data that will be required in the construction planning process. Thanks to this indicator, you can calculate the amount of red brick in 1m3. Since the volume indicator is 1950 cm3, 513 elements of this type will be needed.

- The difference between one-and-a-half bricks is that its height is greater. These are white silicate products. They are bought if you need to quickly build a building. The work will go faster, but the walls will not look very nice. Therefore, after construction, they are faced with different materials. The dimensions of a white brick in a cube are 250x120x88mm. Therefore, its volume is 2640 cm3, from which we can conclude that there are 379 products of silicate masonry in 1m3.

- Double bricks are purchased for construction if there is not much time to complete the plan, and the work needs to be completed urgently. Each such element has dimensions of 250x120x128, and a volume of 4140 cm3. This means that a cubic meter can accommodate 255 elements of this type.

Thanks to correct calculations, you can avoid additional visits to construction warehouses and contacts with suppliers.

Conversion of cubic meters to square meters

The volume of material is not the footage. Volume is used to calculate the price for the material and its delivery (weight, dimensions, etc.). Before starting serious repairs, it is necessary to know exactly the number of lamellas m2. We described in detail how to correctly calculate the required amount of finishing for a living room in the corresponding article (hyperlink).

However, to recalculate the amount of m3 to m2, additional calculations must be made.

Let's say you need to cover a room with a 0.025 m board (2.5 cm is the standard for covering the walls of an apartment building).

We calculate the area that can be covered with 1 m3 of such lining: 1/0.025 = 40 m2.

Find out the area of the wall that needs to be covered. For example, two opposite walls 2.5x4 m have an area of 20 m2.

Now we determine the volume of lining for purchase at the warehouse: 20:40 = 0.5 m3

If necessary, we can convert this value into the number of linings in pieces. To do this, the required volume of the lining must be divided by the volume of one board: 0.5 / 0.0072 = 69.4.

Round up to 70 (1 for margin).

So, to cover two walls with dimensions of 2.5x4, you need 70 lining boards of size (150x25x2000), or 0.5 m3.

What indicators need to be taken into account

The volume of bricks is measured in cubic meters. This is due to the way finished products are stored and released. To find out how many pcs. in 1 m3 of masonry, do not forget that the bricks are connected with cement mortar.

The thickness of the seams determines how much material will have to be used for construction.

If you make masonry with such a gap, you can get strong walls that will last for many years and withstand the influence of external factors.

If the thickness of the seams is reduced, the walls will not be as reliable and over time the building may become deformed.

The regulatory documents indicate that vertical masonry joints should be 10 mm, and horizontal joints should be 12 mm. Possible errors that are permissible for buildings of a certain type are not taken into account.

If you need to determine the quantity in 1m3 of masonry with a margin, first of all you need to decide on the exact dimensions of the products. All parameters are standard and regulated by regulatory documentation. There are different types of bricks, each with its own size, allowing you to know the quantity in one cube. Most often, walls are laid using single and one-and-a-half bricks. But sometimes they resort to double products. Having decided on the option, it is necessary for each of them to calculate the amount of facing bricks in the cube.

We do the calculation manually

When purchasing, it is important how many cubes there are in a pallet of bricks. If the approximate data does not interest you, then you can make the calculation yourself. To do this, take one block of baked clay, measure its length, width, thickness and multiply by each other. Then you need to multiply the quantitative indicator of the pallet by the volumetric weight of one.

In order to find out the number of clay products in 1 cube, you need to divide 1 by the volumetric weight of one. Let's look at the example of a brick measuring 250x120x65 and how much there is in a cube.

- 0.25*0.12*0.065=0.00195 - volumetric weight of one clay product.

- 1 m3/0.00195 = 512.82.

In the same way, one-and-a-half brick pieces in a cube are determined.

An example of how to calculate a material

When it becomes necessary to find out how much a cube of brickwork costs, its quantity is first calculated, because billing is done by the piece. To obtain accurate data, you need to alternately add the thickness of the cement mortar to the length and height of the block. For example: 0.25+0.15 and 0.088+0.015, the results must be multiplied by each other and by the thickness. The total number of blocks, taking into account the thickness of the seams, is obtained by dividing 1 by the cubic capacity of the product.

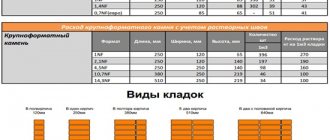

| Unit | Brick size | Excluding mortar joints, pcs. | Including mortar joints, pcs. |

| 1 m³ of masonry | Single | 512 | 394 |

| Thickened | 378 | 302 | |

| Double | 242 | 200 | |

| 1 m² of masonry with 0.5 bricks (masonry thickness 12 cm) | Single | 61 | 51 |

| Thickened | 45 | 39 | |

| Double | 30 | 26 | |

| 1 m² of masonry in 1 brick (masonry thickness 25 cm) | Single | 128 | 102 |

| Thickened | 95 | 78 | |

| Double | 60 | 52 | |

| 1 m² of masonry with 1.5 bricks (masonry thickness 38 cm) | Single | 189 | 153 |

| Thickened | 140 | 117 | |

| Double | 90 | 78 | |

| 1 m² of masonry in 2 bricks (masonry thickness 51 cm) | Single | 256 | 204 |

| Thickened | 190 | 156 | |

| Double | 120 | 104 | |

| 1 m² of masonry in 2.5 bricks (masonry thickness 64 cm) | Single | 317 | 255 |

| Thickened | 235 | 195 | |

| Double | 150 | 130 |

Attention! If you think that mortar joints are so insignificant that they can be neglected in the calculation process, then you are mistaken. As practice shows, it is the fastening solution that accounts for about 0.3 of the total volume. Don't make a common mistake when counting.

How to count one and a half bricks

The amount of one-and-a-half in a cube of masonry is also determined. To determine how much sand-lime brick is in a cube, the dimensions 250x120x88 are multiplied. As in previous calculations, we convert a cubic meter into mm, divide the result by the volume of brick, and get the number of one-and-a-half pieces in a cube of masonry.

Types of building material

How much a cube of brick costs depends on its type. If we talk about production technology, it can be ceramic or silicate. According to its content - facing, solid, hollow. The most commonly used products are ceramic type. They are made directly from varieties of clay by repeated firing. If you are interested in the weight of a pallet, you should understand that the indicator depends on the characteristics of the products on it. For example, facing ones are the heaviest, solid ones are a little lighter, but hollow ones weigh almost 2 times less.

The next step in popularity is the silicate block. Its production is carried out in autoclaves under the influence of high pressure and water vapor. 92-94% of the material consists of sand, the rest is impurities. Its weight is significantly different from the red blocks described above; the minimum is 3.7 kg. The capacity of a cubic meter of silicate products also depends on a number of their parameters.

Stone size with joint thickness

The table of brick consumption per 1 m3 of masonry takes into account the parameters of the seams that are located between the elements:

- Find out the parameters of each product.

- Determine the sum of height and length together with the size of the seams. It is necessary to consider the options in different positions. There is no need to change the width.

- Convert m3 to cm or mm (in units used to measure the volume of a stone with a seam).

- The number is then divided by the resulting volume indicators.

This will help you calculate how many bricks are in 1m3 of masonry.

Weight of sand-lime brick in 1m3

The maximum weight has silicate brick, which is made from quartz sand, lime and water purified from harmful impurities. This material has a good level of sound insulation and a long service life. The products in question are usually used for laying load-bearing walls and finishing facades. A solid brick weighs at least 3.7 kilograms, while a hollow brick weighs only 3.2 kilograms. The mass of ordinary solid materials is as follows:

- single – 1600-1700 kg/m3;

- one and a half – 1400-1500 kg/m3;

- double – 1300 kg/m3.

If we consider the mass of silicate slotted brick, it is as follows: for single 1400-1500 kg/m3, for double – 1100-1200 kg/m3.

The weight of a brick per cubic meter can be calculated independently, knowing the mass of an individual product and the quantity per given volume. For example, in a cubic meter of solid sand-lime brick there are 500 pieces (notional quantity), and the average weight of the product is 4 kilograms. In this case, the density indicator will be 500 × 4 = 2000 kg/m3.

Pallet location

It is clear how to calculate how much masonry is in a cube, taking into account the seams, and the volume of bricks in m3, but in order to avoid excessive overload, it is worth finding out how many products will fit in them and what is the maximum permissible weight. To determine this indicator, pay attention to:

- Material from which the bricks are made: silicate, ceramic.

- Stone sizes approved by state standards.

- The shape of each element: with or without voids inside. In the second option, voids are contained in an amount of no more than 13%. They are used for laying out walls of various types. The weight of one such ceramic product is 3.3-4.7 kg, and silicate - 3.7-6 kg. In hollow ones, voids represent 13-45% of the total structure. Such bricks contain air layers, due to which their ability to transfer heat is reduced. Ceramic hollow stones weigh up to 5 kg, and silicate ones - a little more. Therefore, the shape and material of each product plays a role.

To determine how many kilograms a pallet filled with one-and-a-half bricks will weigh, take the weight of one stone and multiply by the total quantity.

According to GOST, the pallet should weigh no more than 850 kg. If it is a Euro pallet, then 1.5 tons is allowed.

To the general calculations, you need to add the weight of the wooden pallet itself, which is 30-40 kg. Pallets are used to bring materials to the required location. They are made of wood or metal. They can also combine several options. To determine the amount of stone in pallets, you must first find out the standard dimensions of the products.

Typically, manufacturers provide information in the accompanying documentation about the maximum number of products that can be placed on a pallet. To calculate how many elements can be placed on it, you need to divide the maximum number allowed by the manufacturer and divide by the weight of the brick.

If the bricks are laid in an overlap or in a herringbone pattern, then it will not be possible to find out the exact data.

To make the material easier to count and transport, it is preferred to lay it in the shape of a cube. For stability, the structure is tied with fastening tape. How many stones will fit depends on their size.

Most often, about four hundred pieces can be placed on a pallet, the total weight of which is up to 1.5 tons. It is not advisable to exceed the permissible limit.

Where to find standards

As mentioned above, you can get approximate information about the amount of material used in special tables. They are often used by developers who do not want to do calculations manually. According to the information given there, for 1 m3 of masonry in 2 blocks it takes:

- single - 204 pcs.;

- one-and-a-half - 156 pcs.;

- double - 104 pcs.

If the laying is carried out in 2.5, then the indicators increase, these are 255, 195 and 130 pieces.

You can use tabular data, but you must not forget about the architectural features of the future structure, which are also reflected in quantitative indicators. Even if you are 100% sure of the accuracy of the calculations, you need to take it with a margin, but a small one, within 10%. It happens that a clay block may break or be used up more than planned.

So how much is a linear meter?

Such a simple question - how much is a linear meter - sometimes baffles a person who is not experienced in construction or does not work in trade. Meanwhile, the answer is extremely simple: a linear meter is a universal unit for measuring goods . But not the length of the object in its pure sense.

In this case, purely mathematically, the linear meter remains equal to 100 cm or 1000 mm. Unclear? Let's look at it with an example.

Let's say we buy some long material (for curtains or an ordinary board). The price tag indicates the cost per m.p. Naturally, we have the right to contact the seller with a question: how much is 1 linear meter? If the seller answers with the above definition, that’s good; if not, you need to know the answer to the question in advance.

So, 1 m.p. corresponds to a section (piece) of material (wall, kitchen). But it expresses the length of an object regardless of its width. It is already included in the price. Let's explain with an example. We buy tulle for a window measuring 2000×2000 mm. The material is available in 2 and 3 meter widths. If we want to save money, we buy 2 m.p. fabrics two meters wide. If we want to fold the tulle beautifully, we take the same 2 m.p. three meters wide. But the price of a second piece of the same length will be more expensive, because the width is already initially tied to the cost. Conveniently, it turns out that a linear meter is a universal measure of a product; we know exactly how much of it we need to take.

Let's watch a short video that shows the connection of this length measure to the kitchen (more precisely, its choice), and then we will point out some pitfalls that can greatly ruin the life of any buyer:

Outwardly everything is fine. But sellers are sometimes cunning (online stores are especially guilty of omissions).

- It’s good when the material is 1, 2, 3 meters wide. What if 0.8-0.9 m? We sometimes don’t pay attention to such little things and buy things at a loss, but this is not good.

- When purchasing a built-in kitchen or wall unit, the stated price per m.p. in practice it can be much higher. Because it is taken from the price list, i.e. at a minimum (according to the standard version). But in addition to vertical and horizontal partitions, furniture also needs fittings, for which a bill (and a considerable one) can be issued separately.

- You need to be especially careful about the abbreviation “m.p.” at the stage of cottage construction. Don’t hesitate to ask the foreman what kind of work is included in this very “meter”.

As you can see, not everything is so simple with the answer to the question - how much is 1 linear meter?

Popular articles

How to correctly submit water meter readings

All about toilet sizes

Calculation of dew point in construction

Review of gas meter SGMN-1-G6

How to choose water meters

Electric welded steel pipe weight calculation, tables, calculator

Cellular polycarbonate: standard sheet sizes

Is it possible to verify water meters without removing