One unit of measurement

Brick is one of the most popular building materials. It is often used for the construction of a wide variety of residential and commercial buildings. And to make it convenient to deliver piece goods to customers, manufacturers use special packaging - a metal-reinforced wooden pallet.

It has special fastenings for special equipment, which help to remove and load a large number of bricks at once in one step. Pallets for bricks are made of different designs, the type of which is indicated by one letter:

- “ O ” is a rectangular platform with supports.

- “ P ” – standard pallet.

- “ K ” – a pallet with hooks that make it easier to grip.

- “ D ” – wooden shield.

- “ M ” is a metal product.

POD - a wooden pallet on supports Source palletlps.com

There are combined designs. When selling a large batch of bricks and transporting it, “POD” (a wooden pallet on supports) and “POM” (a flat panel on supports) are most often used. The type of placement of piece material on them is selected taking into account the transport by which the brick will be transported to the site.

The “herringbone” and masonry with dressing have proven themselves well. Choosing the second method allows you to fill the tray very quickly. The bricks are stacked on edge. For fixation, each new row is bandaged, and then the finished block is packed in film. This greatly simplifies the loading and unloading of building material and significantly reduces the percentage of its damage.

Laying method “on edge” Source depositphotos.com

Before this, transportation by shaft was used. The brick was manually thrown into the back of the car, and then unloaded as well. This took a lot of time. It was faster when the brick simply fell to the ground. The percentage of spoilage here often reached 60%. And this is very unprofitable.

The use of pallets minimized the percentage of spoilage. There is no longer a need to attract loaders and pay for their work. Pallets turned out to be convenient both during loading and unloading, and during transportation and storage. If you know in advance how a pallet of bricks is filled, how many bricks fit on one panel, it’s easy to independently calculate, buy, deliver and unload the most consumable wall material on site.

When choosing the herringbone laying method, the bricks are laid at an angle of 45 degrees. The assembly turns out to be strong, it is of higher quality, but it is difficult to assemble. If you do something wrong, the slide will quickly disperse and crumble.

Herringbone laying method Source loader22.rf

See also: Catalog of companies with their own production that specialize in the construction of brick houses.

When a pallet of bricks is assembled in a herringbone pattern, more blocks are placed on the board. Since the structure has good stability, there is no need to install additional blocks. There is no need to tie up each row and then pack the bale in film. And this also helps you save.

Number of bricks on a pallet

It is regulated by regulations. It is important that the weight of the platform matches the weight of the batch of building material. The standard version has dimensions of 1030x520 mm. It is designed for a maximum weight of 750 kg. If you know the number of bricks in a pallet, it’s easy to place an order, place the required batch, and then accept it, check it with the order and get a 100% result without writing off damage.

The seller indicates the number of bricks on the price tag Source sogonkom.com

How many bricks will fit on a wooden pallet?

In order to answer this question, you must first provide a few facts:

- Pallets come in sizes 52 by 103 cm and 77 by 103 cm.

- The standard size of a single brick is 250*120*65 mm, and a one-and-a-half brick is 250*120*88 mm.

- The brick can be laid either on a spoon or on a bed.

- The installation height is allowed no more than 1 meter.

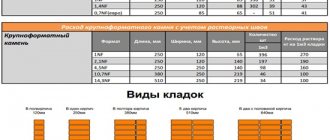

Accordingly, you can calculate from the table how many and what kind of bricks will fit on the two most common types of pallets.

Table of the number of bricks in a pallet

| Pallet | Laying (single/one-and-a-half bricks) | |

| On the largest face of the brick (bed) | On the edge (spoon) | |

| 52*103 | 16/16 | 32/20 |

| Total per pallet | 240/176 | 256/160 |

| 77*103 | 24 /24 | 48/24 |

| Total per pallet | 360/264 | 384/192 |

To carry out the calculation, we take the average size of the pallet, in which case the number of bricks will be as follows:

— one pallet can accommodate 275 pieces of smooth brick, its standard size is 25x12x6.5 centimeters;

— 307 pieces of torn bricks will fit on a medium-sized pallet. Its standard size is 25x9x6.5 centimeters.

- also on an average pallet you can lay 357 pieces of torn bricks with two torn edges, its dimensions are similar to the previous type.

- when laying a base brick with one torn edge and dimensions 25x6x6.5 on a pallet, 480 pieces will fit.

Prices for bricklaying: technology, types, approximate calculations

Calculation of boards and timber in one cubic meter - formulas, calculation examples, tables

Transportation Features

Bulk transport is still used when transporting wall building materials. In this situation, experts advise immediately including the percentage of losses in the estimate. In order not to overpay, it is worth taking a closer look at alternative transportation methods. Packing in pallets provokes extra expenses, but they are not commensurate with paying for broken bricks.

Loading and unloading is fraught with certain difficulties. It is important to stack bricks correctly on pallets, to immediately prevent the risks of skewing of folded structures and falling of finished products. To do this, tiebacks and rafters are used. It is important to choose the right type of transport for transporting pallets. Road and rail transportation are considered optimal. Pallets can be placed quite stable on platforms. You can use machinery for loading and unloading and completely eliminate manual labor. Understanding how many bricks are in a pallet (red bricks separately, yellow bricks separately) makes it possible to save and order exactly as many blocks as needed for the construction of a specific residential building.

Bricks collected on pallets are easier to transport Source zabor.bz

Number of bricks per cube

Let's move on to analyzing the topic of how many bricks are in 1 m³ of masonry. Here the calculations are practically the same, only based not on area, but on volume. Therefore, you must first calculate the volume of the brick block itself. Let's just label them:

- single – 0.00195 m³;

- one and a half – 0.00264;

- double – 0.00414.

Determining the number of bricks is now easy:

- single – 1:0.00195=513 pieces;

- one and a half – 1:0.00264=379;

- double – 1:0.00414=242.

These figures do not take into account the thickness of masonry joints. Now with them. The number of rows was calculated in the previous section. If the masonry is carried out using the spoon technology, then the number of seams: vertical 7, horizontal 14. To find the volume of masonry mortar, you need to:

1x1x0.012x14=0.168 m³, where units are the lengths of the sides of the cube, 0.012 is the thickness of the horizontal seam, 14 is the number of seams.

1x1x0.01x7=0.07 – volume of vertical seams.

Total value: 0.168+0.07=0.238 m³.

We determine the volume of bricks without the volume of masonry mortar: 1-0.238 = 0.762 m³. All that remains is to divide the resulting value by the volume of each type of stone.

- 0.762:0.00195=391 pcs. – single;

- 0.762:0.0264=289 – one and a half;

- 0.762:0.00414=185 – double.

It is clear that the shape of the external and internal load-bearing walls and partitions does not resemble a cube. Therefore, the type of masonry is included in the calculations. This changes the end result. The table below shows the relationship between the type of brick block and the thickness of the wall to obtain the number of brick products.

Where to get containers

Having decided to buy a packaged batch, you need to decide where to find pallets. The easiest way is to order them along with the building material. Many manufacturers today include the price of containers in the cost of a batch of blocks. Practice shows that this is beneficial for those who build a lot and constantly buy bricks. Unloaded pallets can be reused. And now you can save money here.

You can look for used pallets. This product is available. Separate purchase of new brick pallets is also available.

Briefly about the main thing

The number of bricks in one pallet may vary. It all depends on the size of the blocks, their weight, the material from which they are made, as well as the size of the pallet itself.

The standard one is considered to be 1030 mm long and 520 mm wide. It is better to choose this kind of container when calculating the purchase estimate. It can accommodate up to 420 pieces of single brick, up to 309 pieces of one-and-a-half blocks, up to 200 double blocks, up to 300 facing products.

Ratings 0

How many bricks are in a pallet?

First you need to consider the dimensions of the pallet, the usual type is 52 * 103 centimeters, and the maximum has a width of 77 centimeters and a length of 103. After this, you need to find out the parameters of the brick, the standard indicators of the element are 250 millimeters in length and 120 millimeters in width. But the thickness depends on the type of brick, a single element is 65 millimeters, a one-and-a-half element is 88 millimeters, and a double element is 103.

Now you can calculate the number of elements in the first row on the pallet; to do this, you need to divide the area of the pallet by the area of one brick. This number is multiplied by the number of rows. In this way, the amount of material in one pallet can be calculated.

In order not to carry out calculations, you can use ready-made data for 75 and 150 grades of brick, which is placed on a standard pallet.

Construction brick:

- single – 420 pcs.;

- one and a half – 390 pcs.;

- double – 200 pcs.;

- standard – 300 pcs.

Quantity of non-standard facing bricks: 360 pieces

According to GOST, a pallet with red brick should weigh no more than 850 kilograms, but not everyone adheres to this figure. Some manufacturers can use containers that can transport up to 3 tons of material. Bricks can be laid in rows or at an angle; the weight of the pallet with the material depends on this. To calculate the weight of a pallet with bricks, it is necessary to add the total mass of all elements to the mass of the carriage. To do this, you need to find out the mass of one brick and multiply this figure by the amount of material placed in the pallet.