Monolithic works

- !Attention! Prices from FACTORY! When ordering from 100 m3 – DISCOUNT

- When calculating the price of concrete with delivery, you can receive a bonus of up to 12,000 rubles. Call!

- FACTORY prices are 12-15% lower than market prices. We are profitable!

- Quality guarantee and full package of documents! We are the best!

since 2007 year, using its own specialists (as a General Contractor), provides a full range of additional services related to monolithic construction in Moscow and the Moscow region.

The benefits of ordering monolithic work from a concrete manufacturer are obvious! Our specialists have priority round-the-clock support from the company’s factories, this applies to laboratory services, shipment and delivery of solutions using our own vehicles (including concrete pumps), and most importantly, our prices for the materials used (such as concrete mixtures) will always be noticeably lower than competitors! It is important that one organization will bear full responsibility for the entire range of work, from the production of concrete mixtures to the delivery of a monolithic structure!

The main technological stages of production of monolithic works:

• Coordination of design documentation and cost estimates;

• Installation of formwork (panel, tunnel);

• Installation of a frame made of reinforcement (reinforcement);

• Work on pouring concrete mortar (maintenance of concrete after work);

• Warming up the concrete and structure (in winter);

• Removal of formwork structures (stripping, stripping).

Cost of monolithic works and their types:

* Prices for services are valid from March 1 , 2018 .

| Mechanized soil development (with loading) | 400 rub./m3 |

| Excavation of soil manually (without securing the pit) | 600 rub./m3 |

| Excavation of soil manually (with fastening of a pit, up to 3 meters deep) | 700 rub./m3 |

| Installation of crushed stone and sand bases manually (with compaction and watering) | 800 rub./m3 |

| Construction of a monolithic concrete foundation for columns with a volume of up to 3 cubic meters. (with installation of formwork) | RUB 2,900/m3 |

| Construction of concrete pillar foundations (with installation of formwork) | RUB 2,800/m3 |

| Construction of flat reinforced concrete foundation slabs (with installation of formwork and reinforcement) | 2,700 rub./m3 |

| Construction of strip foundations (with installation of formwork) | 2,600 rub./m3 |

| Construction of retaining walls and concrete basement walls (with installation of formwork) | RUB 2,650/m3 |

| Construction of reinforced concrete columns up to 4 meters high, with a perimeter of up to 3 meters (with installation of formwork and reinforcement) | RUB 2,900/m3 |

| Construction of reinforced concrete partitions up to 3 meters high, up to 200 mm thick. (with installation of formwork and reinforcement) | 2,700 rub./m3 |

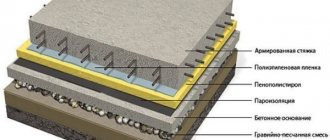

| Installation of reinforced concrete floors up to 200 mm thick. (with formwork and reinforcement) | 2,700 rub./m3 |

| Concrete preparation device (without mesh reinforcement) | 1,800 rub./m3 |

| Concrete preparation device (with reinforcement with road mesh in one layer) | 2,000 rub./m3 |

| Monolithic works in a complex for the installation of a foundation slab | 4000 rub./m3 |

| Installation of monolithic floors in a complex (industrial) | RUB 3,700/m3 |

| Construction of strip monolithic foundations (complex) | 4,900 rub./m3 |

| Installation of monolithic grillages (complex) | 5,300 rub./m3 |

| Installation of bored piles (complex) | 7,500 rub./m3 |

| Construction of monolithic columns, beams, lintels (complex) | 7,700 rub./m3 |

| Construction of monolithic walls (complex) | 6,500 rub./m3 |

| Construction of monolithic stairs and flights (complex) | 9,700 rub./m3 |

| ** All materials for the work are certified! | |

| *** The company’s guarantee for all types of construction work and materials is 5 years! |

The whole range of services comes from the concrete manufacturer!

Source: https://beton-moscow24.ru/raboty

Cost of pouring concrete by hand

In the case when it is customary to fill it yourself, it is necessary to accurately calculate the volume of concrete. Otherwise, it is difficult to achieve reliability and durability from future construction. A minor error can ultimately lead to disastrous consequences: in the best case, the price of the future building will increase, in the worst case, the safety of the resulting house will be called into question.

First, let's find out how much it will cost to pour a cube of concrete

First you need to remember - the higher the grade of concrete used, the correspondingly higher the price per cubic meter.

So, for example, the lowest grade M100 - M150, in which gravel is chosen as a filler, will cost 3,500 rubles. If you choose granite as a filler, the price will rise by 200 rubles.

For those who need a foundation with the best strength indicators, it is better to choose concrete grades M300 - M350. For the Moscow region, the price today is 3,500 rubles. with gravel as a filler, and 3,700 rubles. with granite.

Concrete grades M400-450-500-550 and M600 are used only with granite as a filler, the price tag starts from 3800 rubles. and up to 4500 rub. In the process of choosing the components of your foundation, you must remember that the price also increases depending on the size of the aggregate fractions. There are small and large fractions, with and without additives (anti-frost).

Designations of concrete grades

The B6.5 digital indicator indicates that the foundation used, after hardening, is capable of withstanding loads of up to 6.5 MPa. It is quite logical that the higher this figure, the higher the price tag for concrete.

Other important markings on concrete:

- Fee , these letters indicate that the concrete mass includes frost-resistant components, the values after the letter can be 50, 100..., and up to 300.

- W , waterproof.

- P indicates the volume of additives and water; the most popular are P3-P4 among concrete mixtures for foundations.

How much does it cost to pour a cube of concrete?

At the very beginning, it is necessary to determine the price of components for the production of 1 cube of concrete.

The prices shown are taken from different regions of the country:

- Sand – 500r/m3;

- Bags of cement (50kg). Taking into account that the density is 1400 cu/m3, the total amount is 4200r/m3.

- Crushed stone 800rum/m3

With a ratio of 1:3:5 (cement, sand, crushed stone), 1 cubic meter of concrete is:

- 0.1 m3 of cement – 466 rubles.

- 0.3 m3 of sand – 166 rubles.

- 0.6 m3 crushed stone – 444 rub.

- 0.06 m3 of water.

Ultimately, this concrete mass will cost 1076 rubles. for every 1m3 of concrete. Of course, you can simply order concrete, but here the price will double, since delivery will not be cheap.

How much does it cost to pour a cube of concrete by hand?

We decided on the price of the components above, now let’s figure out how much it will cost to pour a cube of concrete manually. In this part of the article we will talk not about financial costs, but about physical costs, because Before pouring a cube of concrete, it must first be mixed.

Doing it manually will be slow and difficult, which is why it is better to choose this method if:

- it is necessary to fill a small area;

- you have serious intentions to save money (or simply don’t have any).

The sequence of actions is as follows:

- First of all, the trough must be placed so that each of the components of the concrete mixture is located as close as possible, otherwise it will simply be difficult to carry them in buckets. It is advisable to have a water hose on hand.

- Do not pour water into the trough first, and in general it is better to add it in small portions, because in this case, the kneading process will be most simplified. Stir the mixture until a homogeneous mass is obtained.

- As soon as the consistency of the solution begins to resemble sour cream , you can begin to add gravel (granite) to it in portions. You shouldn’t dump out the entire volume of filler at once; it’s easier to mix the concrete in parts rather than the whole trough at once.

Of course, to save on delivery (and it’s not cheap) and simplify manual labor, you can use a concrete mixer. Its only drawback is that the components for the mixture must be immersed in it with your own hands, but the beauty is that there is no need for painstaking work with a shovel.

There are 5 types of concrete mixers common in Russia. It is noteworthy that the technological process differs from manual kneading in the sequence of loading the components; each type of mixer has its own.

Calculation of the cost of 1 cube of concrete for the foundation

Cement consumption per cube of concrete

To obtain a high-quality concrete composition of the required grade, it is necessary to carefully observe the proportions when mixing it. It is important to maintain the accuracy of placing each component, so for cement in a concrete solution the accuracy of the error should be no more than one kg, while crushed stone can be added with an accuracy of up to 5 kg.

If the proportions are followed properly, the resulting concrete mixture will not differ in quality from purchased concrete. High-quality concrete is characterized by mobility, strength, and low rigidity.

During the calculation process, it is necessary to determine the required grade of concrete. The brand of cement you choose will help determine this. Here you need to know it exactly - because... The exact grade of concrete for the foundation can significantly save money.

It is necessary to select a brand of concrete based on the following conditions:

- the type of base adjacent to the foundation, the presence of underground structures;

- if possible, accurately calculated load on the future foundation or from rough calculations;

- soil characteristics.

Taking into account the future load, which depends on the future structure, you can choose the brand:

- M200 is sufficient for a prefabricated panel structure;

- M250 is suitable for the construction of a timber/log bathhouse;

- M300 for buildings made of foam concrete;

- M350 for low-rise brick houses;

- M400 is considered to be a “last resort”; it is chosen for the construction of a multi-story brick building on it.

So, to obtain 1 cube of concrete M100, you will need grade 300 cement. The total mass of cement is from 160 to 170 kg.

If you still choose grade 400 cement, then to produce one cube you will need from 180 to 195 kg. cement.

Experts in the manufacture and pouring of concrete recommend measuring each component in fractions. Those. if you need to use 600 cement, then you will need to make a solution in the proportion of 1/3, 1 part (1 kg) of cement, and 3 parts (3 kg) of sand.

Source: https://poznaibeton.ru/beton/zalivka-betona-vruchnuyu.html

A special technology is used when pouring concrete in winter.

The main condition is to prevent the concrete from hardening before pouring into the formwork and the crystallization of water inside the mixture. To do this, components are added to the concrete mixture that increase the frost resistance of the material. As a rule, these components are hydrochloric or acidic in nature.

Another way to ensure successful pouring of concrete at low temperatures is to artificially heat the poured structure: you can make a tent around it - a greenhouse made of film and turn on the heating device.

If we pour concrete into formwork with reinforcement (i.e. we are making a reinforced concrete product), we can run a low-power current through the reinforcement.

Prices, price list, prices for concrete work, construction of foundations, floors (2012)

One of the most important stages in the construction of buildings, without which the construction process is practically impossible, is concrete work . It is concrete, used both in the foundation and walls or other parts of buildings, due to its extremely durable characteristics, that plays the role of the main support of the entire building.

This process takes a considerable amount of time, requiring the expenditure of a large amount of resources, including the labor of workers. concrete work seriously means jeopardizing the successful completion of the entire construction.

For this reason, choosing a company that will carry out such work is a task no less important than the work itself. It is no secret that not every company providing construction services has professional specialists capable of high-quality work with concrete.

This is the reason to seek help from a Russian Professional Construction Company, since we have extensive experience in such work, and the use of only high-quality materials and highly qualified professionals makes it possible to guarantee that the resulting building will be reliable and durable.

Assurances that the construction of floors, foundations, concrete paths and the like do not require any special knowledge do not have the slightest basis, since this requires taking into account the specifics of many factors that inevitably arise during construction. Therefore, even such a simple, at first glance, process as installing a blind area should be done only by competent specialists.

The specialists who work in our company have extensive experience in carrying out work of this type. In addition, they have at their disposal all the necessary tools and modern equipment, which is a guarantee of high quality concrete work of any level of complexity.

We are able to guarantee the construction of truly permanent buildings, characterized by a high degree of reliability, not to mention excellent performance characteristics.

In turn, the prices for concrete work indicated on our website will allow you to make the most optimal choice when ordering the appropriate services.

You can view our latest projects here.

Prices for concrete work

Name Units of measurement Price, rub.

| Manual mixing of concrete | m3 | 1000 |

| Installation of a monolithic ceiling for a cottage and other buildings (overlap height - up to 3.0 m) | m3 | 2600-3900 |

| Construction of a monolithic foundation for a cottage, fence, etc. (double formwork, concrete up to 0.4 m thick) | m3 | 3200-3500 |

| Construction of a monolithic foundation for a cottage, fence, etc. (double formwork, concrete thickness from 0.4 to 0.7 m) | m3 | 3400-3600 |

| Installation of a monolithic concrete foundation for columns, with installation of formwork up to 3 m | m3 | 3400-3600 |

| Construction of monolithic foundation flat slabs with the manufacture of reinforcement frames and installation of formwork | m3 | 3300-4300 |

| Construction of small monolithic reinforced concrete grillages and foundation pads with laying and viscous reinforcement, assembly and disassembly of formwork and manual preparation of concrete | m3 | 3800-4500 |

| Construction of strip foundations and basement walls made of concrete blocks with the preparation of mortar and assembly and disassembly of formwork | m3 | 3800-4650 |

| Construction of a strip foundation: laying depth of 0.5 m under a sand cushion (backfill) | m3 | 3900-4400 |

| Construction of monolithic platforms for various purposes (entrance platforms, blind areas, paths) concrete thickness up to 0.2 m | m3 | 2500-3000 |

| Construction of monolithic reinforced concrete stair steps and landings with the manufacture of reinforcement frames and installation and dismantling of formwork | m3 | 2500-9800 |

| Construction of a monolithic staircase “in concrete” (without finishing) | m3 | 2800-3000 |

| Construction of monolithic retaining walls | m3 | 1700-4300 |

| Construction of a concrete balcony | m3 | 2100-2800 |

| Construction of monolithic bowls for swimming pools and small plunge pools (wall thickness up to 0.2 m) | m3 | 2800-3400 |

| Construction of monolithic bowls for swimming pools and small plunge pools (wall thickness from 0.2 to 0.4 m) | m3 | 2400-6500 |

| Strengthening foundations and other building structures using concrete pouring method | m3 | 3000-3600 |

| Concrete floors 200 mm sanded with trowels and sanders | m3 | 1200-1500 |

| Concrete floors 200 mm with topping (with a reinforced top layer) | m3 | 1500-1800 |

| Epoxy floors (including 200 mm concrete preparation) | m3 | 1800-2000 |

| Polyurethane floors (including concrete preparation 200 mm) | m3 | 2000-25000 |

| Installation of reinforced concrete jumpers | PC | 600-800 |

| Construction of reinforced concrete partitions up to 3 m high, 200 mm thick with installation of formwork and reinforcement | m3 | 3000-3750 |

| Installation of reinforced concrete floors 200mm thick with installation of formwork and reinforcement | m3 | 2800-4650 |

| Construction of monolithic reinforced concrete glass-type foundations (for columns) with the manufacture of reinforcement frames and installation and dismantling of formwork | m3 | 3500-4890 |

| Concrete preparation device 100mm thick without mesh reinforcement | m2 | 180-240 |

| Reinforcement of concrete bases with mesh in 1 layer | m2 | 130-150 |

| Construction of pile reinforced concrete foundations d = up to 300 mm with the installation of asbestos-cement pipes, with the production of a reinforcement frame | mp | 2400-3000 |

| Construction of monolithic reinforced concrete beams, crossbars, load-bearing columns with the production of reinforcement frames and installation and dismantling of formwork | m3 | 2500-6900 |

| Construction of monolithic reinforced concrete walls of the basement and plinth with the manufacture of reinforcement frames and installation and dismantling of formwork | m3 | 3000-5600 |

| Crushed stone and sand preparation | m2 | 80-100 |

| Crushed stone and sand preparation | m3 | 550-700 |

| Excavation work, soil development | m3 | 600-1000 |

Recommendations from professionals

Duration of foundation construction:

Depending on the complexity, it takes from several weeks to several months to build. It is better to start the foundation at the end of April, beginning of May, when the soil warms up. It must be completed before the first frost sets in.

Further, experts recommend giving the foundation time to settle until next spring so that it can fully gain strength and go through all temperature conditions during seasonal weather changes. If there are no defects in the spring, then you can confidently continue building the house.

If defects are found, then it is necessary to find out the cause of their occurrence. (Is this type of foundation suitable for this soil? Is the manufacturing technology broken? Etc.) Usually, as a result of identifying the cause of the defect, its repairability is determined. While there is no home on the foundation, there are many opportunities to renovate it.

In the worst case, it is possible to dismantle this foundation and build a new one. And if the house is already standing, then this greatly reduces the choice of technical options for repairing the foundation and increases the cost of this work.

And the option of building a new foundation, in this case, turns into building a new house and this is very expensive. Therefore, experts recommend taking your time and setting aside one year for the construction of the foundation.

Construction of concrete paths and platforms with exposed aggregate texture.

Placing coarse aggregate - gravel or small stones - in the surface layer of concrete provides a beautiful and practical finish. Spread the moistened aggregate evenly over the freshly laid mixture and tamp it firmly with a wooden block so that its grains are flush with the surface.

Place a board across the formwork and level the surface with all your weight. When all the water has evaporated from the surface, use a watering can and brush to wash off a thin layer of concrete so that the grains begin to protrude slightly above the surface. Cover the concrete for 24 hours and then lightly wash the surface again to remove any remaining coating or sediment from the grains.

Cover the concrete again and leave it to harden.

Source: https://rpsk-msk.ru/betonnye-raboty

Monolithic technology

This method has appeared in our days and has become more often used, as it makes it possible to erect a structure in a short time. Let's look at how to make a poured concrete house yourself. Wall formwork is installed on the foundation, reinforcement and concrete are laid. After the composition has hardened, the mold is removed.

This method assumes that the walls of the building are cast or that the monolithic frame has walls made of a hollow block. If cast technology is used during construction, then the foundation is made around the perimeter of the entire house, but at the same time leaving space for doors (interior, entrance) and for window openings.

After the foundation for the house is ready, the sheathing is attached to the frame reinforcement in the corners (joints of the walls) using knitting wire. Next, everything is filled with solution.

The article discusses how to build a concrete house with your own hands, but if you don’t have the skills in this matter, then turn to specialists for help.

How much does it cost to pour 1 cubic meter of concrete - what is taken into account when calculating?

To accurately calculate the cost of filling 1 cubic meter. m of concrete, you need to take into account the type, class of material, type of concrete work, the need for reinforcement, installation of formwork and prices for renting a mixer machine.

Pricing policies vary from company to company, up to a difference of 1,500 rubles. per 1 m3 when performing one volume of work. However, you need to make a choice not only based on cost, but also on the quality of work.

Concrete composition

The websites of building materials suppliers often display calculators that separately calculate the cost of material, reinforcement, transportation and construction work. However, there is no computer program for calculating the price of a set of works.

To obtain the necessary data, you can use a calculator program.

It is impossible to give exact prices for concrete, since the cost varies depending on the following factors:

- Selected filler. If the mixture of cement and sand includes gravel, then the payment ranges from 3.5 to 4 thousand rubles; when granite is added, prices increase by 200 rubles. per one cubic meter. It must be taken into account that more expensive material increases strength, which is important in the construction of industrial, multi-story buildings.

- The presence of additives that can be used to fill in winter or increase water resistance. Introducing additional material into the mixture to ensure good hydration at lower temperatures greatly increases financial costs.

- Class of large aggregates. The fee per square meter does not change significantly.

The approximate market value of various grades of concrete, depending on quality, is presented in the table:

| Brand | Cost, rub. |

| M100 | 2900 |

| M150 | 3250 |

| M200 | 3450 |

| M250 | 3600 |

| M300 | 3700 |

| M350 | 3800 |

| M400 | 3900 |

| M450 | 4000 |

| M550 | 4150 |

If you mix the solution yourself, then this will cost much less money.

You can mix the concrete yourself by hand, then you can reduce costs and further save on supplies by refusing to rent a mixer machine. The approximate price of materials, which may vary depending on the region, is presented in the table below:

| Composition component | Required quantity to produce 1m3 of concrete, m3 | Cost, rub |

| Sand | 0,3 | 166 |

| Cement | 0,1 | 466 |

| Crushed stone | 0,6 | 444 |

| Water | 0,06 | — |

| Final material | 1 | 1076 |

How is the total cost calculated?

The customer's costs may also be affected by the weather in which the work is carried out.

The price of pouring the finished material depends on the following parameters:

- quality of work done;

- pouring method (manually or using a mixer);

- finding a manufacturing company;

- weather.

The pricing policy will vary depending on the type of service: building stairs, pouring floors in a multi-story building, in a garage, constructing formwork and columns.

If the work only requires laying the foundation, then the approximate price for 1m3 will be 5-6 thousand rubles; if it is necessary to arrange floors, prices increase by 500-1000 rubles.

Depending on the chosen company, payment for 1 square method may vary by 1000-1500 rubles. in different directions.

Work carried out

When ordering ready-mixed concrete, it is necessary to take into account that the dimensions of most mixer machines are designed to transport at least 20 m3. If you purchase a smaller volume of material, you will still have to overpay.

Approximate prices for the main construction areas related to concrete laying are presented in the table:

| Concrete works | Approximate price for 1 m3/1 m2 |

| Pouring, laying by machine | 640 |

| Concrete pouring, laying by hand | 2500 |

| Grinding | 200 |

| Arrangement of the foundation of a private house with a concrete thickness of less than 0.5 m | 2500 |

| Pouring a flight of stairs | 2500 |

| Installation of formwork | 1000 |

| Concreting terraces | 1500 |

| Concrete balcony | 2000 |

| Concrete floors in an apartment with a grinding machine | 1200 |

| Reinforced concrete floor | 1600 |

| Reinforcement | 800 |

Additionally, delivery to the construction site is added, the approximate cost of which ranges from 3000 to 4800 per m3. Workers charge up to 15 thousand rubles for pouring for 8 hours of work. Before accepting an order for work, the company providing the services must agree on the price for lifting concrete to a height if required by the project.

Source: https://ZnayBeton.ru/rabota-s-betonom/vazhnye-momenty/skolko-stoit-zalit-1-kub.html

Start of construction

If they are not going to do this work themselves, then they turn to specialized companies that have not only the necessary tools, but also equipment. Otherwise, you don’t have to purchase them, but simply rent them, and the same can be done with the construction equipment necessary for the work.

To begin with, they draw up a house project on their own, but if they don’t know how to make the calculations, then they turn to specialists who will prepare it. It indicates: the thickness of the walls, their strength indicator, the load-bearing capacity of the entire structure, etc.

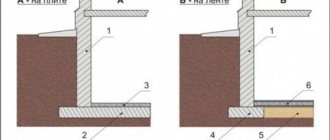

Determined by the type of foundation. If the building has a basement, then the foundation for the house should be strip, and the interfloor ceilings should be made of monolithic slabs. Mostly concrete houses have a well-waterproofed pile-strip foundation.

Due to the fact that walls made of monolithic concrete are quite heavy, they are deepened to the level of soil freezing, and the formwork is reinforced, while the base is poured in such a way that it is elevated 0.5 m from the ground.

Price list for monolithic work – We carry out monolithic work in Moscow and the region

* Approved prices for 2020 (updated 05/05/2019)

| Mechanized soil development (with loading) | 380 RUR/m3 |

| Excavation of soil manually (without securing the pit) | 580 rub./m3 |

| Excavation of soil manually (with fastening of a pit, up to 3 meters deep) | 680 rub./m3 |

| Installation of crushed stone and sand bases manually (with compaction and watering) | 750 rub./m3 |

| Construction of a monolithic concrete foundation for columns with a volume of up to 3 cubic meters. (with installation of formwork) | RUB 2,800/m3 |

| Construction of concrete pillar foundations (with installation of formwork) | 2,700 rub./m3 |

| Construction of flat reinforced concrete foundation slabs (with installation of formwork and reinforcement) | 2,600 rub./m3 |

| Construction of strip foundations (with installation of formwork) | 2,500 rub./m3 |

| Construction of retaining walls and concrete basement walls (with installation of formwork) | RUB 2,550/m3 |

| Construction of reinforced concrete columns up to 4 meters high, with a perimeter of up to 3 meters (with installation of formwork and reinforcement) | RUB 2,800/m3 |

| Construction of reinforced concrete partitions up to 3 meters high, up to 200 mm thick. (with installation of formwork and reinforcement) | 2,600 rub./m3 |

| Installation of reinforced concrete floors up to 200 mm thick. (with formwork and reinforcement) | 2,600 rub./m3 |

| Concrete preparation device (without mesh reinforcement) | 1,700 rub./m3 |

| Concrete preparation device (with reinforcement with road mesh in one layer) | 1,900 rub./m3 |

| Monolithic works in a complex for the installation of a foundation slab | RUB 3,750/m3 |

| Installation of monolithic floors in a complex (industrial) | RUB 3,450/m3 |

| Construction of strip monolithic foundations (complex) | 4,750 rub./m3 |

| Installation of monolithic grillages (complex) | RUB 5,150/m3 |

| Installation of bored, secant and drilled tangential piles (complex) | 7,250 rub./m3 |

| Construction of monolithic columns, beams, lintels (complex) | 7,450 rub./m3 |

| Construction of monolithic walls (complex) | 6,250 rub./m3 |

| Construction of monolithic stairs and flights (complex) | 9,450 rub./m3 |

| * All materials are certified! | |

| ** Company guarantee for all types of work and building materials - 5 years | |

| *** The cost of work in the table is indicated for 1 cubic meter (m3) |

If in classical construction technologies the volumes of concreting do not exceed 50%, then with monolithic construction of a building they increase to 80%. The supplier's price list allows you to roughly estimate the construction budget in Moscow. The nuances of pricing concrete work are discussed below.

How are prices for monolithic work determined?

Monolithic construction technology consists of a sequence of operations:

- formwork

- reinforcement and anchoring

- laying the mixture and maintaining concrete

At temperatures below +5 degrees, the construction cost increases sharply, since for normal hydration of the cement stone the mixture and formwork are heated, and no reagents are introduced into them.

Installation of formwork for columns and floors is much more complicated than installation of panels for pouring foundations and walls. Therefore, the cost of elements increases by 20–50%. The complex configuration of the building and the abundance of internal interfloor communications also increases the developer’s expenditure of funds.

The price of ready-mixed concrete depends on the brand and type of filler; special compositions (heat-resistant, waterproof, hydraulic) are even more expensive. To lift the mixture to a height, concrete pumps are used, the rental of which is also included in the estimate. It is unrealistic to haul large volumes of this structural material in buckets; when working from buckets, the lifespan of concrete should be taken into account.

Welded reinforcement mesh/frames are laid faster than wire rods on site. To provide a protective layer for floating slabs, three times more polymer spacers are consumed than for MZLF frames.

Price for concreting

The main operations of concrete work for monolithic construction will cost the customer the following amount (in rubles):

- footing – 2500 rub. per cube

- screed – 500 rub. per square

- installation and dismantling of panels – 400 rub. per square

- laying concrete – 1350 rub. per cube

- knitting frames/nets – 1700 rub. per ton of reinforcement

- foundation – 4500 rub. per cube

- columns – 5000 rub. per cube

- walls – 4500 rub. per cube

- stairs – 8000 rub. per cube

- ceilings – 7000 rub. per cube

- built-up waterproofing – 350 – 500 rub. per square (1 – 2 layers)

- coating waterproofing – 180 RUR. per square

- insulation – 350 rub. per square

- porch – 400 rub. per square

- blind area – 550 rub. per square

- terrace – 1000 rub. per cube

- grillage – 3000 – 4000 rub. per cube (beams, slabs, respectively)

It is very difficult to accurately order volumes of ready-mixed concrete using a mixer. When manually mixing the missing amount, you should focus on 1000 rubles/m3.

Call or email today to receive a more detailed estimate from our staff.

Source: https://atlantstr.ru/prajs-na-monolitnye-raboty/

Prices for monolithic works

The final price for all types of work is determined only after drawing up an estimate.

| Mechanized soil development (with loading) | from 300 rub./m3 |

| Excavation of soil manually (without securing the pit) | from 480 rub./m3 |

| Excavation of soil manually (with fastening of a pit, up to 3 meters deep) | from 580 rub./m3 |

| Installation of crushed stone and sand bases manually (with compaction and watering) | from 650 rub./m3 |

| Construction of a monolithic concrete foundation for columns with a volume of up to 3 cubic meters. (with installation of formwork) | from 2,500 rub./m3 |

| Construction of concrete pillar foundations (with installation of formwork) | from 2,400 rub./m3 |

| Construction of flat reinforced concrete foundation slabs (with installation of formwork and reinforcement) | from 2,300 rub./m3 |

| Construction of strip foundations (with installation of formwork) | from 2,200 rub./m3 |

| Construction of retaining walls and concrete basement walls (with installation of formwork) | from 2,250 rub./m3 |

| Construction of reinforced concrete columns up to 4 meters high, with a perimeter of up to 3 meters (with installation of formwork and reinforcement) | from 2,500 rub./m3 |

| Construction of reinforced concrete partitions up to 3 meters high, up to 200 mm thick. (with installation of formwork and reinforcement) | from 2,300 rub./m3 |

| Installation of reinforced concrete floors up to 200 mm thick. (with formwork and reinforcement) | from 2,300 rub./m3 |

| Concrete preparation device (without mesh reinforcement) | from 1,500 rub./m3 |

| Concrete preparation device (with reinforcement with road mesh in one layer) | from 1,700 rub./m3 |

| Monolithic works in a complex for the installation of a foundation slab | from 3,350 rub./m3 |

| Installation of monolithic floors in a complex (industrial) | from 3,150 rub./m3 |

| Construction of strip monolithic foundations (complex) | from 4,350 rub./m3 |

| Installation of monolithic grillages (complex) | from 4,750 rub./m3 |

| Installation of bored piles (complex) | from 6,550 rub./m3 |

| Construction of monolithic columns, beams, lintels (complex) | from 6,750 rub./m3 |

| Construction of monolithic walls (complex) | from 5,650 rub./m3 |

| Construction of monolithic stairs and flights (complex) | from 8,450 rub./m3 |

| * All materials are certified! | |

| ** Company guarantee for all types of work and building materials! |

If in classical construction technologies the volumes of concreting do not exceed 50%, then with monolithic construction of a building they increase to 80%. The price list of the service provider SK-Service allows you to roughly estimate the construction budget in Moscow. The nuances of pricing work are discussed below.