A basement is a place that can simultaneously serve as a storage room for winter supplies and a warehouse for unnecessary things. As a rule, the arrangement of a full-fledged and functional basement must begin simultaneously with the construction of the house, i.e. from the moment the foundation was erected. Of course, the foundation for a house with a basement will be more expensive than a simple one, but the costs of its construction will pay off very quickly: the room under the floor will act as a “thermos”, improving thermal insulation and reducing heating costs.

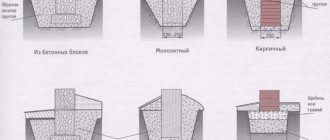

Basement foundation power circuits.

At first glance, the construction of such a structure is fraught with great difficulties, but with the right skills it can be done with your own hands.

The main thing is to decide on the type of foundation and make the correct calculations. According to experts, the best foundation option for a house in this case is a strip foundation. Unlike columnar or slab, it does not require a high base and a large sample. The vertical segments of the strip base will serve as both the foundation of the building and the walls of the basement.

What type of foundation to choose and why

If you decide to build a basement below the ground, then you should take into account the depth of groundwater and the type of soil. If these characteristics allow you to go deeper into the ground, then the foundation for a house with a basement can be made in two versions: a monolithic reinforced concrete slab or a strip foundation. In the first case, you can fill the required area with concrete directly on the site or use ready-made factory slabs. If you choose to build a strip foundation, then it can also be made in different ways: prefabricated and monolithic. The choice of foundation type depends on careful calculations of the foundation. If the soil is rocky or semi-rocky, then any of the foundation construction options can be used. Such soil will withstand any load. If the groundwater level is high, then you need to choose a reinforced concrete slab as the foundation for the house.

There is a well-known technique that allows you to build a house with a basement even with a high groundwater level. To do this, select soil up to the water line, and when the foundation and walls of the lower floor are built, this soil is poured around the future house, the visual perception of which in this case will be most advantageous.

Rules for the manufacture of reinforcement for the base

When starting to build a foundation with a basement on your own, you should make certain calculations based on the height of the future structure. In this case, you can start from the following rule: the height of the basement should not be less than the height of the tallest member of the family. Also, the calculation of the foundation itself cannot be ignored. And if there is no point in calculating its load-bearing capacity, then it is necessary to calculate compression and tension. Otherwise, the force of soil pressure, which will act on the monolithic foundation, without encountering resistance from the empty basement room, will simply split the concrete into pieces.

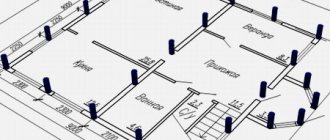

Scheme of foundation types for basement-free houses

With a planned basement height of 1.7-1.9 m, the base can be reinforced according to the following scheme:

- 2 meshes are made from reinforcement with a diameter of 12 mm with a vertical and horizontal pitch of about 40 cm;

- the meshes are transversely fastened together with reinforcement of the same diameter in a checkerboard pattern through 2 cells;

- when laying reinforcement, the distance from the edge of the wall should be at least 5 cm.

The use of such reinforcement will reliably strengthen the monolithic foundation and prevent the destruction of concrete walls.

Construction of a slab foundation

This is the most advantageous type of foundation. It can support a building of any weight. First, the soil that is located at the installation site of the slab is selected half a meter below the planned installation depth and replaced with sand, which is spilled with water and thoroughly compacted. Then the crushed stone is poured. The layer of sand and gravel (crushed stone) should be at least 15-20 cm.

This “cushion” is poured with a layer of concrete 4-5 cm thick. After that, waterproofing is laid (most often roofing material or waterproofing film is used) and a concrete layer of the same thickness is poured again. After that, the reinforcement is laid, and a thermal insulation layer can be made. Then concrete is poured again, the layer thickness should be 20-25 cm.

This type of foundation is called floating. So, during seasonal movements of the soil, the concrete foundation rises and falls along with the house. Currently, it is used in the vast majority of cases in the construction of houses with a basement. The top of the slab can be leveled under the basement floors using a cement-sand mortar screed. In order to avoid the accumulation of radon in the lower room of the house, plastic pipes are built into the “cushion” of sand and crushed stone, which will serve to remove underground gas to the roof. The basement walls are built on the slab and covered with a double waterproofing layer. Mandatory reinforcement of the walls in connection with the slab is carried out.

Features of the construction of the basement

A strip foundation, built taking into account all the requirements and in compliance with technology, becomes a high-strength structure that can withstand fairly heavy loads. To build a basement in a building erected on such a foundation, it is necessary to take into account not only the characteristics of the soil itself, but also the level at which the groundwater is located.

The basement is convenient to use for economic purposes

Before starting to build a house with a basement, erecting it on a strip foundation, it is necessary to determine at the project development stage what the dimensions of the basement will be.

Properly making a basement in a house means providing the entire structure with additional heat. The basement plays the role of a kind of thermos, significantly increasing its functionality.

The size of the basement determines whether it is necessary to remove all the soil from the area under the house. The construction of a basement under the entire house requires additional reinforcement of the structure, since the foundation strip will act as the walls of the basement.

During construction, it will be necessary to comply with a specially developed technology, in accordance with which the following is carried out:

- floor reinforcement;

- ventilation device;

- changing the foundation belts.

The basement in a country house with a strip foundation carries a certain load. Products are usually stored here, and therefore increased attention is paid to the arrangement of effective ventilation.

Installation of a strip foundation for a house with a basement

The foundation for a house with a basement will be little different from the foundation for a house with a basement

- Block strip foundation. This foundation for a house with a basement is built from piece factory products - reinforced concrete blocks. Its advantages: simplicity and speed of assembly. This type of foundation for a house is built only on dense soils with deep water.

- Monolithic strip foundation. Its structure is similar to the usual one. The difference is that first the “cushion” is poured out, as is the case with a slab foundation. Next, the formwork is constructed, the reinforcing layer is laid and concrete is poured. Most often, this type of foundation for a house is built to build a basement.

Installation of formwork and pouring concrete mixture

External insulation of the foundation with a basement.

To build formwork with your own hands, you will need boards with a thickness of at least 25 mm. It is desirable that the side of the boards directed inside the formwork for a monolithic foundation be as smooth as possible. This will reduce the absorbency of the wood and improve the quality of the future base. You can make the boards smooth by treating them with a plane.

It is necessary to construct shields from the boards, the height of which will be slightly higher than the height of the base walls. Then the formwork is installed around the entire perimeter of the future house and secured with the help of spacers and slopes. A layer of crushed stone is poured into the bottom of the trench, on top of which roofing felt or any other waterproofing material is laid out.

The reinforcement is placed in the trench prepared for pouring the concrete solution. In this case, the upper part of the reinforcement frame should not reach the upper end of the base by more than 2-2.5 cm. Otherwise, the reinforcement protruding from the foundation may interfere with the laying of walls.

After installing the frame, the concrete solution is poured. Concrete can be purchased at a factory or made by yourself. As a rule, a monolithic strip foundation is made of M200 concrete. To prepare it you will need 5 parts of crushed stone, 1 part of M500 cement, 3 parts of river sand and 0.8 parts of water. If necessary, the amount of one or another component can be increased.

Diagram of the installation of blind areas and waterproofing of the basement.

A base of this type is poured in layers. This requires mandatory compaction of each layer. The uniformity of concrete pouring, on which the quality of the foundation with a cellar completely depends, is determined by the beacons. As beacons, you can use nails driven into the formwork at a distance of 1 m from each other at the level of pouring the concrete solution. The upper edge of the base is leveled with a trowel.

Concrete hardens within 2-3 weeks depending on the time of year and weather conditions. After this, you can remove the formwork, waterproof the base, if this is planned during the work, and fill the monolithic foundation from the outside with earth.

Private house within the city

Arranging a basement in a private house is more relevant in rural areas. As a rule, heating of such houses is carried out using solid fuel (wood and coal). The presence of a basement allows you to organize a boiler room directly in the basement.

This version of the boiler room is considered quite convenient and practical. Firstly, the absence of a boiler in a living space contributes to its safety. Imagine that a heating boiler that runs using coal or wood will be located in the kitchen. This will result in the walls and ceiling of the kitchen becoming contaminated with fumes. This will lead to inevitable repairs after a fairly short lifespan of the kitchen. In addition, the constant smell of smoke in a living space does not make such a room very comfortable.

If the house is located within the city, then the need for organizing such heating disappears by itself. Such houses are connected to the city gas network. Thus, there is no need for a basement to install a boiler room. But, another problem appears.

Brickwork

Where to put canned food and vegetables prepared for the winter? Having a basement automatically solves this problem. The basement is not cold in winter and not hot in summer. This creates an ideal atmosphere for storing food for the winter.

In the absence of a basement, it becomes necessary to build a special separate room in which vegetables and engineering equipment can be stored. According to statistics, the cost of building a separate room is three times higher than organizing a basement. It follows from this that the presence of a basement in a residential building is simply necessary.

Start of preparatory work

Before you begin all the necessary work, you should plan the foundation of the house that you will create. Then make a list of all the necessary materials, calculate them

optimal quantity. It's always better to take a reserve. Then carry out the marking, which is done according to the site plan. Be careful and careful, because if you make mistakes, the walls of the house may be installed incorrectly, and subsequently, in the worst case, destroyed. Marking is carried out in two stages:

- First you need to drive pegs into the ground where the corners and main floors will later be;

- then you should pull the thread diagonally to determine the symmetry of the sides.