If you are building a country cottage or a small country house, then you will need a lot of time and physical effort. But saving energy and time is possible when the necessary construction equipment is at hand. Instruments and mechanized devices greatly simplify the process of preparing materials, and as a result, you can complete construction much faster.

In our article we will talk about concrete mixers. This is a special construction device in which you can prepare different amounts of concrete mixture. We will look at professional and household devices designed for preparing both large and small volumes of concrete. We will tell you about the principles of the design and the rules for choosing a high-quality and durable product. We wish you pleasant reading!

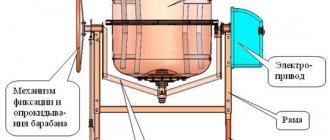

Concrete mixer device

- Drum. A working container into which the components to be mixed are placed. The performance of the machine depends on its size and type.

- Bed. This is a design made of various elements (pipes, profiles) that combines all the parts and components of the machine into one whole. Can be equipped with a chassis for easy movement.

- Kneading parts (blades, augers). They directly affect the components of the solution being prepared.

- Engine (petrol or electric) and transmission. The kneading parts are set in motion.

- Unloading mechanism for removing the prepared mixture.

- A control unit for turning the unit on and off and adjusting the rotation speed of its drum.

Concrete mixer designs

To choose a concrete mixer, you need to familiarize yourself with the basic designs. There are two types of mixers: forced kneading and gravity. Forced ones consist of a stationary container, inside of which mixing blades rotate. Due to the design features, they work only with solutions - without coarse aggregate; they also require more powerful engines, and, accordingly, consume more electricity. All this leads to the fact that they are used mainly by professionals.

Forced type concrete mixer

Gravity concrete mixers are more suitable for developers and household use. This is a barrel-shaped container with blade strips welded inside. This container rotates around its axis and can change its position relative to the horizon. With an inclined tank, the most intense mixing occurs. This design allows you to make both mortar (cement + sand) and concrete (cement + sand + gravel or other coarse aggregate).

Gravity concrete mixer (one of many options)

There are two types of drives - gear and crown drives. Gearboxes are more reliable, but their repair is a very difficult and expensive undertaking. If such a mixer suddenly breaks, it is easier to buy a new one. The crown structure breaks more often, however, replacing the crown is a matter of a couple of hours and a relatively small amount of money (1000-2000 rubles depending on the material of the crown). All this determined the popularity of crown-type gravity concrete mixers.

A geared concrete mixer usually has a characteristic design - the engine is located under the bottom of the tank

Operating principle

The concrete mixer works on its own principle. The design is simple, it includes a drum and a mixing mechanism, which actually stirs the contents of the concrete mixer.

The components of the solution are placed in the drum, which will later become the building mixture. After the tool is started, the blades begin to move and begin to mix the components into a single mixture. Cooking takes from 5 to 15 minutes, depending on the power and speed of operation. As time passes, the concrete mixer stops on its own, and the contents from the drum are dumped out and they begin to work with the resulting mixture.

Main types of concrete mixers

Concrete mixers have evolved over time and are now the main mortar mixing device used in construction and renovation. They are used to form a concrete mixture with a liquid or semi-liquid consistency. Mixing is carried out using axial rotation of the housing with stirrers or stirrers in a stationary housing. For mixing, hand mixers are also used, which are either an attachment for a drill or a stand-alone device, but they are used exclusively for mixing dry materials with a fine fraction. Mixing concrete solution using such a device cannot be realized.

Concrete mixers can be divided into two main categories, namely:

- gravitational;

- forced type.

The main differences (except for the shape of the drum) are the principle of movement when mixing and the capabilities of the device.

Forced type concrete mixer

In forced-type devices, the drum does not rotate when mixing. The main function is performed by stirrers rotating inside the housing. Such devices are usually much larger in size.

A large capacity mixer is capable of processing large volumes of concrete in a short time, which is why forced-type models are usually used for large construction projects. However, since they consume more energy and are much more expensive than gravity ones, it is not advisable to invest in them when planning to build a small building.

How to choose a concrete mixer for your home and garden? Most often, gravity concrete mixers are used in the construction and renovation of a house or cottage, since forced-type devices are advantageous to use only when there is a need to prepare large volumes of mixtures.

How does a gravity concrete mixer work?

The gravity type involves rotation of the entire drum, while agitators fixed in it motionless perform mixing. These devices are usually small in size and do an excellent job of preparing almost all mixtures, including options with a large fraction. A smaller faucet also means less energy consumption.

Geared

The gravity concrete mixer is driven by a motor, and in gear units it is located in a separate housing connected to the tank through a shaft. Such models are quite quiet and highly reliable, although repairs in case of possible breakdown are very expensive.

The motor in geared mortar mixers is connected to the drum through a complex transmission system

Features of gear devices

Gear-type concrete mixers have a separate gearbox installed in a closed housing, which is reliably protected from the ingress of sand, cement or crushed stone. These units are more reliable and create less noise. However, they require more careful operation and compliance with its conditions. If the gearbox does fail, it is quite difficult to repair it. You should not undertake this process on your own. Repairing such a device is almost equal to the cost of a new device.

Crowned

The simplest types of concrete mixers are equipped with a gear, or crown, along the upper edge of the mixing container. This element is directly connected to the engine; when turned on, the teeth drive the drive gear and the drum begins to rotate. Such models cost much less than gearbox ones. Although the crown can quickly fail under heavy use, replacing it is quite inexpensive.

The crown is the toothed ring of the mortar mixer that drives the entire structure

Features of coronal devices

Concrete mixers of the crown type are distinguished by an open mechanism, since the gear stamping is attached around the circumference of the concrete mixer drum. It is susceptible to the effects of building mixtures, wears out during operation, but is not fussy in operation and maintenance. Repairing a crown type mechanism is much easier.

The most popular are crown devices. They have earned their popularity due to their simple and understandable design, which is easy to repair. Despite the fact that gear units are more reliable and durable in operation, they are expensive to repair and it is difficult to find a technician who can do it. You can pick up parts for crowns in specialized stores or order them in online stores, and you can repair them yourself.

prices for concrete mixers which one to choose

For large volumes of construction work, a concrete mixer will optimize the process and reduce labor costs. Even an experienced builder finds it difficult to navigate all the intricacies of the choice, so it is advisable to consider how to purchase a reliable unit that will not incur additional costs.

Selecting drum capacity

To determine the sufficient volume, you should determine the approximate amount of concrete mixture that the unit must produce in one cycle. But, the size of the container should not be equal to this amount. It is recommended to choose those units in which the drum capacity exceeds the volume of the mixture by 10-15%.

You should not load a large amount of the mixture, as the increased load will provoke permanent breakdowns. In private construction, it is optimal to use drums with a capacity of 100-150 liters; reviews of such concrete mixers have been very positive.

If the device is equipped with manual unloading, it must have a “steering wheel” to facilitate drum control

To finally get your bearings on the scope of work, you can consider the following:

- up to 100 l – the weight of the concrete mixer does not exceed 20 kg. The unit is successfully used in the construction of such objects as gazebos, bathhouses, garages, when pouring small areas, paths, etc. These are the types of home concrete mixers that can be found most often;

- up to 150 l - the weight of the unit will be about 40 kg. Such devices are effective when constructing buildings one floor high;

- up to 300 l - the device is effective in the construction of three-story houses. If this type of equipment is required, you should make sure that it has a loading and unloading function. Concrete mixer weight – 50 kg;

- from 300 l – equipment for professional construction.

Housing material

The vast majority of models are made on a steel basis. The master remains to decide what thickness the material has. Concrete, like other solutions, tends to gradually corrode metal. If a durable tool is required, the wall thickness should be 1 mm or more.

Engine selection

It is almost impossible to determine the power of the unit “by eye” to ensure its full functioning. Novice builders mistakenly choose concrete mixers with maximum power. Such a solution does not make practical sense. Operation of the equipment will require high energy costs and threaten to overload the network. It is important to understand the correct ratio between the capacity of the concrete mixer and the power of the motor.

If you approach the choice rationally, you can reduce the amount of financial costs. In practice, for a unit with a tank volume of 130 liters, a power of 700 W is quite sufficient. Such an engine will allow you to carry out the entire range of work - the master will be able to prepare high-quality cement mortar and almost any concrete.

Motor protection

Considering that the equipment is most often operated outdoors, motor protection is of no small importance. The motor can be protected by a metal casing.

Operating mode

All equipment is divided into two categories.

Forced concrete mixers can differ in the vertical and horizontal arrangement of the shafts. High quality concrete mix is ensured by the vertical type model

Models designed for periodic operation (cyclic action):

- similar units are used in the construction of small objects and dispense concrete in portions;

- if the unit is operated without stopping, the resource of key components will quickly be exhausted and the mixer will fail;

- Concrete mixers of periodic operation are optimal for dacha and cottage construction.

Equipment designed for continuous operation:

- devices of this group have a high resource;

- concrete mixers are more technical and are recommended for continuous operation at large facilities, where mixing of the solution is carried out in large quantities, in several shifts.

Principle of concrete mixing

Depending on the construction purposes, you can choose installations with gravity mixing or forced-type concrete mixers.

Units with forced mixing - main characteristics:

- the capacity of the unit is static, kneading is carried out by rotating a screw with blades;

- if the master plans to mix mainly liquid mixtures that will not contain solid particles (mortars for floor screed, plaster mixtures, etc.), this is the most suitable equipment;

- Such models are not capable of working with coarse filler.

Gravity concrete mixers:

- This type of mixing is indicated when working with solutions that contain a large number of solid particles, as well as with lighter varieties. It is better to lean the choice towards this type, since the master will have to work with all types of mortars - heavy ones for the foundation, light ones for screed and plaster;

- the unit is equipped with a rotating drum in which the blades are located;

- For private purposes, it is advisable to purchase equipment with manual loading.

Transmission mechanism and drive type

The gravity-type electric concrete mixer can be geared or crown-type. The latter type of equipment often fails, but can be repaired very quickly, which usually comes down to replacing a single gear.

Forced planetary concrete mixers are distinguished by a high speed of concrete mixing and the quality of the finished mixture, but in private construction their operation is impractical

The crown is a gear that surrounds the mixer drum. The mechanism is not protected from construction debris, which is why it breaks down so often. The material of the crown, which can be steel, cast iron or even plastic, deserves attention.

A universal option is a cast iron mechanism. When purchasing this type, it is recommended to monitor the cleanliness of the transmission mechanism, trying to prevent the ingress of concrete and construction debris.

The gear transmission is more reliable, the mechanism is reliably protected from debris, sand penetration, etc. But if the engine or transmission unit is broken, repair will be difficult due to high financial costs.

Mechanical drive

Mechanical installations are formed almost identically, with one difference - they lack a control panel and an electric drive. The blades or drum are rotated manually using a special lever. This type is very convenient in places where it is impossible to connect to the network, but it requires labor. Craftsmen often make such concrete mixers with their own hands, using metal barrels as a base.

Operating voltage

Units designed for preparing large volumes of solution are most often equipped with a three-phase motor. To power such a device, it is necessary to use a three-phase diesel generator.

If the equipment is required for private construction, it is better to pay attention to models designed for a voltage of 220 V, connected to a household network.

Availability of a steam generator

If the device will be used in winter, it is better to purchase a model equipped with a steam generator. Conventional concrete mixers are used at temperatures not lower than 2°C.

Concrete mixers - which one to choose, prices and manufacturers

When deciding on the selection of a concrete mixer, what price to choose, reviews and practice show that the best equipment is produced in Italy, Germany, and France. Such concrete mixers are available at a higher cost, however, this is fully justified by their long service life.

If construction purposes require the preparation of high-quality plastic concrete, you should pay attention to disc concrete mixers. The preparation of such a mixture is not possible with other types of equipment.

In addition, imported models are well equipped and almost always equipped with wheels, which makes it easier to transport the unit around the site. The market offers a wide range of equipment from a variety of manufacturers.

Limex

In its price segment, this is perhaps one of the best devices. The mechanism is placed as conveniently as possible, the springs do not fail for a long time. In case of drum jamming, motor burnout is prevented thanks to the poly-belt drive function. The unit is easy to repair and maintain; it is easy to replace bearing units.

ALTRAD

Among the advantages of Polish equipment are thick blades that do not bend during operation. However, maintenance can be complicated if the bearing needs to be replaced.

Practice has shown that concrete mixers are characterized by an inconvenient tilt of the drum, and the unit itself often fails. The product is equipped with a toothed belt drive, which causes engine breakdowns, in particular when the drum jams.

GUY Noel

Experts note that models from this manufacturer can be found almost everywhere.

However, they have a number of design flaws:

- inconvenient tilt of the drum;

- low drum wall, which is also inconvenient during operation;

- the width of the blades is 1 mm, which makes them possible to bend;

The manufacturer's warranty is three years, which is a significant advantage. It is impossible to obtain any guarantees for used concrete mixers, so it is better to refuse to purchase them.

If we consider the level of financial costs that can be incurred when purchasing equipment, prices for electric concrete mixers start from 12,500 rubles (100 - 150 l). The price for domestic concrete mixers is about 9,000 rubles.

Concrete mixer review: which one to choose, price, reviews shown in the video:

Books on the topic:

obetone.com

The nuances of choosing a good concrete mixer

What should you look for when choosing a concrete mixer? First of all, on the power of the electric motor : real performance depends on it. On sale you can find Chinese models with 200-liter drums and 600-700 watt motors, which are unable to turn the crown even at half load. Such power will allow you to work with 50-60 liters of solution without overloading and overheating the motor, that is, the actual filling of such a concrete mixer will not exceed 30% - and for high-quality models it reaches 70%.

The crown itself can be stamped or cast; there are also concrete mixers with plastic crowns. The optimal choice is a cast iron crown; it is durable, does not “walk” in the geometry, unlike stamping, and is less noisy. The quietest crowns are made of glass-filled polyamide, but they are also the most demanding in terms of cleanliness and neatness.

The engine itself must be mounted on a solid metal base, otherwise under load its mount will warp and the belt will wear out quickly. The frame also needs strength, especially for large-volume concrete mixers: carefully inspect the welding, choose models with reinforcing gussets at the joints of individual elements.

What is the best volume of pear for a concrete mixer?

The most important structural element of a concrete mixer is the pear. It is in matters of choice that they rely on its volume. The volume should be such that it is convenient to work. That is, you decide in advance on the tasks for which you rent a tool and buy it for specific parameters.

Today there are many options on sale, the tanks of which are determined by the volume from 30 to 300 liters, inclusive. Accordingly, the larger the tank, the harder it is to mix it. Therefore, the motor must be more powerful, the structure more durable, and the price higher.

If we are talking about a gravity concrete mixer, then a tool with a pear volume of 120 to 160 liters will be sufficient for the home. It is worth considering that only half of the volume will be filled with the finished solution. This is due to the fact that the bulb will have to be tilted during operation, so not all of the container will be filled.

Variable Drive Concrete Mixer

Again, look at what kind of solution you will make. If we are talking about a solution that includes crushed stone, then it will be mixed better, since the presence of crushed stone granules will allow the concrete to mix better. The latter will allow you to place a solution with a volume of about 60 percent of the total volume.

Do not forget about the thickness of the walls of the gravity bulb. The thicker they are, the more load the working mechanism can withstand. During operation, you will have to upholster the walls of the pear using a heavy tool. This is because the concrete will stick to the inner surface. Therefore, if the walls are very thin, then after just a few cycles of operation, the volume of the pear will decrease.

Small concrete mixers: up to 100 l

These are the cheapest models that are most often purchased for private use - the construction of small buildings such as bathhouses, summer showers, and toilets.

Concrete mixers with a capacity of up to 150 l

You will have to spend more on such installations than on small ones. It makes sense to buy them only when you need to build a medium-sized house or non-residential building.

Large concrete mixers from 150 l

These models can already be classified as professional and, accordingly, they cost several times more than products with minimal and medium capacity.

What engine parameters should a good concrete mixer have?

The heart of a concrete mixer is its engine. The efficiency of work will depend on its power. It is clear that the more powerful the engine, the better the device will work, but it will also be more expensive. Therefore, it is necessary to decide on important criteria, where a volume of 130 liters will correspond to an engine with a power of 500 watts.

Electric concrete mixer design

If you have a larger volume, you should pay attention to models with a power of 750 W and higher. The larger motor size increases the weight of the device, which complicates the work when moving the mixer around a construction site.

Features of the crown and drive gear of the concrete mixer

It is very important to choose the right concrete mixer design. This is not only the engine, including the bulb, shaft and main gear. You should pay attention only to time-tested manufacturers. It is important that the gear is made of metal. As a last resort, you should choose inexpensive models whose gears are made of cast iron.

There is an option where the gear is plastic, its strength is not enough, so the shaft or the gear itself will quickly fail. As for the shaft, it must also be made of durable metal. This is where the maximum load will be placed during the rotation of the pear. You should not overload the concrete mixer, even if you have a safety margin of 30%.

An important structural element is the crown. This is a kind of gear rack, which is located around the circumference of the entire pear. The rack has teeth that determine the pitch of rotation, speed, and its characteristic strength.

Accordingly, the crown can be made of metal, plastic, polymer, as well as cast iron and other materials. The crown made of steel and cast iron is more durable here. Polymer and plastic options are cheaper, but they are less durable because the teeth wear out quickly.

Gear and drive gear of a concrete mixer

In turn, a crown made of polymer costs about 1000 rubles. It is easy to remove and simply replace, which is done with improvised means. As for a similar product made of steel and cast iron, there may be problems with replacement, and the spare part costs up to 3 times more.

I would like to note that not only do you need to initially choose a more durable crown, but you also need to take care of it throughout the entire service life of the instrument. Firstly, you should not lubricate the teeth with any compounds, since sand will enhance the innate properties, which will increase the abrasion of the material. Secondly, you need to constantly brush the crown, especially after finishing work. Thirdly, try to pour the material into the bulb carefully.

Concrete mixer selection parameters

Drum volume

1. For work with low consumption of mixtures and solutions: up to 100 l;

2. With average flow: from 100 to 150 l;

3. With a consumption greater than average: from 150 to 300 l;

4. With significant consumption: more than 300 l.

Drum wall thickness

Models intended for private construction have a wall thickness of seamless containers of 1.5-2 mm, welded ones - 3-4 mm.

Volume of ready solution

The indicator should be approximately 2/3 of the volume of the concrete mixer drum (partial loading optimizes the operation of the device: improves the quality of the finished mixtures, prevents engine overload).

Number of revolutions per minute

Most consumer-grade models range from 23 to 28 rpm. It should be borne in mind that the higher the indicator, the faster the finished solution sets.

Crown material

Preference should be given to devices with a crown made of polymer materials. The polymer crown is more practical and can be repaired.

Engine power

1. The optimal choice for low-rise construction: power up to 700 W;

2. For large objects: from 1000 W and more.

Voltage

1. For private construction, equipment with a voltage of 220 V is designed;

2. On construction sites that have the ability to connect to a three-phase network, you can use concrete mixers with a voltage of 380 V.

Which concrete mixer crown is more reliable?

If you are rating concrete mixers based on reliability, then, firstly, you need to pay attention to the material from which the crown is made. It is he who is responsible for the service life of the concrete mixer.

Cast iron

Most mid-price concrete mixers are equipped with a cast iron crown. The cast iron crown is easy to manufacture: the cast iron melt is poured into a mold, after solidification the workpiece requires minimal processing. The inexpensive cost of the material and the simple method of manufacturing parts create a relatively low cost of the finished ring and drive gear. This is the main advantage of a cast iron product.

There are several disadvantages:

- Cast iron is a brittle material; under mechanical stress, the part can break;

- With repeated use, the teeth wear out;

- During operation, the heavy cast iron crown makes a lot of noise.

Having compared the pros and cons, we can conclude that a concrete mixer with a cast iron crown is worth buying for occasional use with small and medium loads.

Steel

Steel is a very strong and reliable material that does not wear out as quickly as cast iron and does not burst when dropped or hit. By the way, the steel crown makes much less noise during operation. However, it costs an order of magnitude more than cast iron. This is due to the manufacturing process of the part. First, the hot metal composition is poured into the mold and cooled. After extraction, it is finished using special equipment (grinded and sharpened). In addition, the steel is subjected to hardening. All these processes increase the cost of the part, but at the same time contribute to its strength and reliability.

It is advisable to buy a device with a steel crown for daily long-term construction work carried out both outdoors and indoors.

Plastic

The plastic crown is the cheapest of these. It does not require large financial and production costs during production. Another advantage of the plastic crown is its silent operation and its light weight. The disadvantages include the rapid wear of the teeth, which are worn out by friction with the gear.

You can buy a device of this type for carrying out small work at home. But even in this case, you are not protected from the need to quickly replace the crown.

Polyamide

Polyamide is a modern, durable and lightweight material that began to be used in the manufacture of concrete mixers not so long ago. It is not inferior to steel in terms of strength, and plastic - in lightness. In addition, the material is resistant to high temperatures. Therefore, it is able to withstand heavy loads in the hot summer without deforming or wearing out.

The synthetic material is also resistant to natural factors - it does not rust from water and does not react to the effects of many abrasives. Among the advantages of a polyamide crown: strength; durability; ease; resistance to heat; resistance to electrical breakdown; collapsible design of the ring, simplifying disassembly and repair; quiet work.

Concrete mixers equipped with this type of crown are perfect for daily long-term work, both indoors and outdoors.

Any crown, whether it is made of plastic or steel, is a gear ring fixed around the drum. It sets the drum in motion through a gear that transmits movement from the engine. During frequent use, the ring teeth wear down along with the gear teeth under the influence of friction and vibration. However, these parts can be replaced after they wear out.

The following factors also influence the wear of parts:

- Ambient temperature;

- Water flowing into the drive mechanism during rain;

- Getting sand, water or ready-made change into an unprotected mechanism;

- Incorrect assembly of the device;

- Impacts, mechanical damage, falling of the filled device.

Types of concrete mixers

Forced action concrete mixers

Main areas of application of the equipment:

1. Production of slow-moving and rigid concrete mixtures;

2. Production of solutions based on dense and porous fillers;

3. Production of mixtures for blocks, curb stones, paving slabs and bricks, made by semi-dry vibrocompression and vibrocasting.

Advantages:

- Mixing to high homogeneity in a short period of time;

- Efficient when working with both liquid and fixed mixtures;

- Long service life.

Flaws:

- High level of energy consumption;

- The composition of the prepared mixtures should include components of approximately the same density.

Gravity concrete mixers

Advantages:

- Unpretentiousness at work;

- Versatility of mixed substances;

- Affordable cost;

- Reliability and simplicity of design.

Flaws:

- Long time mixing of substances to obtain a homogeneous mixture.

Geared concrete mixers

Geared concrete mixers can be used to produce a wide range of mixtures with different particle sizes. Most often, the equipment is used in professional activities, but it can also be used in individual construction.

Advantages:

- Rare failure due to the impossibility of contamination of the gearbox during operation, which is due to its location (under the bottom of the drum);

- Low noise level.

Flaws:

- If a device breaks down due to a gearbox failure, its restoration is difficult and expensive.

- They require more careful operation compared to crown equipment.

Concrete mixers

Concrete mixers of this type are most popular in private construction, as well as in small companies performing repair and construction work.

The circumference of the drum is surrounded by a crown - a gear with a large internal diameter, which during the preparation of the solution is subject to heavy loads and contamination, which can cause equipment failure.

The material from which the crown is made is of great importance, affecting the maintainability and service life of the device as a whole.

Types of crowns, their features, advantages and disadvantages:

1. Polyamide is a polymer that can withstand significant mechanical loads and is not subject to harmful environmental influences. During operation the noise level is insignificant. Economical during repairs: the polyamide crown is made, as a rule, of four elements, which simplifies its restoration - it is enough to replace the damaged part;

2. Cast iron - most models are equipped with a cast iron crown. If operating conditions are violated (strong vibration caused by incorrect installation of the concrete mixer; accidental fall or impact with a handy tool), the crown cracks and fails. The gear element cannot be repaired, but it can be replaced with a new one.

3. Steel – this version is the most expensive, which is due to the specifics of the production of the gear element. The steel crown is reliable and durable, but the overly labor-intensive production process limits the production of equipment with a steel crown.

Advantages:

- Low price and quick payback during intensive use;

- Economical - consumes a small amount of electricity;

- Suitable for forming mixtures containing coarse-grained components;

- Convenience of unloading the finished solution and ease of care of the drum after completion of work.

Flaws:

- Low efficiency when forming viscous mixtures;

- Small capacity compared to forced action equipment.

Which company is better to buy a concrete mixer from?

Several Russian brands in our rating prove that domestic production of faucets is in demand in the Russian Federation and beyond. By the way, it is precisely these products that buyers most often prefer because of the acceptable combination of price and quality.

The list of leaders included:

- Vortex - products under this brand have an average price tag and accessibility for customers. There are barrels of both volume and medium capacity. All this comes with a 12 month warranty.

- Lebedyan is a brand of JSC Lebedyansky Plant of Construction and Finishing Machines with a long history, modern equipment and European technologies. Product quality is confirmed by international certificates 9001:2008.

- Prorab is a Russian brand, but production is located in China, which allows us to provide the buyer with inexpensive products. It pleases with good value for money.

- RedVerg is a large supplier of concrete mixers manufactured in China. The high quality of the product is ensured by step-by-step multi-stage control. It has service centers in many large cities to serve customers.

- Kraton - this Russian company has been operating since 1999 and as of 2017 has an assortment of more than 15 models of mixers. They pay special attention to insulation, stability, and drum rotation speed.

Comparison table of characteristics

The table below shows the main characteristics of concrete mixer models. Compare them with each other, and it will be easier for you to choose the required device model.

| Model name | Volume, in l | Voltage, in V | Weight, kg |

| VORTEX BM-180 74/1/4 | 180 | 220 | 47 |

| Parma B-130R-MAXIM | 130 | 220 | 48 |

| ELITECH B120 | 120 | 220 | 45 |

| BISON Master BS-120-600 | 120 | 220 | 52 |

| Zitrek Z200 024-0984 | 200 | 220 | 60 |

| CALIBER BSE-120 | 120 | 220 | 53 |

| Eco CM-192 | 190 | 220 | 72 |

VORTEX BM-180 74/1/4

A concrete mixer from a well-known manufacturer of construction equipment is an excellent option in the professional field. The drum volume is 180 liters, and the volume of the finished solution per batch reaches 130 liters. The model is ideal for a small construction site, but due to its power it is also welcomed by experienced builders of large projects. The crown is made of durable cast iron, operates almost silently, does not fail during operation and does not cause inconvenience to builders. The steering wheel is as comfortable as possible to operate and delivers concrete to the working surface in doses.

| Volume, in l | 180 |

| Weight, kg | 47 |

| Voltage, in V | 220 |

pros

- cast iron crown;

- optimal voltage level;

- almost silent operation;

- 32 revolutions per minute – creating a homogeneous building material;

- full set;

- ease of transportation due to wheels;

- bright color.

Minuses

- not found.

Lebedyan SBR-132

This mixer is designed for preparing a solution with a particle diameter of no more than 40 mm. You can get up to 60 liters of mixture at a time. The finished composition is easily unloaded thanks to the collar and changing the angle of the barrel. The design is stable, the build quality is excellent, in particular, due to reliable connection bolts. The cast iron crown allows you to use the tool frequently and without breakdowns.

Advantages:

- Cheap;

- Thick metal;

- Good mixing plates;

- Tolerates slight overloads;

Flaws:

- No cable to connect;

- The engine casing gets hot;

- Fixed stall on one side only.

Lebedyan RN-200

This device can be used for professional construction: a new production cycle can be started immediately after the end of the previous one. A powerful electric motor promotes thorough mixing of the solution, including large (up to 5 cm) components.

Advantages:

- Cost-effective;

- The control buttons are located on the engine casing;

- The rotation speed of the blades allows you to obtain a solution within 2 minutes.

Flaws:

- High price.

PRORAB ECM 180 A

A universal machine that can be used for preparing mortar, fertilizers and mixtures for animal feeding. A volume of 180 liters is enough to prepare up to 130 liters of mixture. The peculiarity of the device is that the drum tilts at any angle, and if necessary, it can be fixed in a certain position.

Advantages:

- Protective casing on the drive;

- There are wheels.

Flaws:

- The power cord is a bit short;

- At maximum load the engine becomes very hot.

RedVerg RD-CM63 – super lightweight stirrer with steel crown

A miniature model with a 63-liter tank is guaranteed to produce 25-30 liters of solution per batch. Its engine is not particularly powerful (220 W), but when the pear is not fully loaded, it does the job quite well.

Torque is transmitted through the working gear to a stamped steel ring that connects the bowls to each other.

To move around the construction site, there are transport wheels that can easily support the device’s small weight of 29 kg. The solution is unloaded manually using a rotary lever.

Advantages:

- small weight and dimensions;

- steel crown;

- engine overheat protection;

- minimal energy consumption;

- low cost.

Flaws:

- low power of the power plant;

- low solution yield;

- high noise level.

The miniature RedVerg does an excellent job of preparing solutions for small volumes of finishing work. It is also convenient to transport and even carry it onto the floor if you have to do repairs in an apartment building.

RedVerg RD-CM 63

This small Chinese concrete mixer with a capacity of 63 liters is affordable and easy to use. A good option for country house construction.

Advantages:

- Inexpensive;

- The crown is stamped quite well;

- Easy assembly.

Flaws:

- Noisy operation;

- Not a very powerful engine.

Kraton BeeTone 120

A fairly compact concrete mixer with a 120-liter mixer is designed to prepare up to 85 liters of solution at a time. With such a load, the 500-watt motor, in principle, copes normally - unless, of course, you try to first load the mixer completely and then turn on the electric motor.

The tank is traditionally stamped from two halves - at the same time, it is worth noting that the manufacturer used 2.2 mm steel on the lower, most loaded part (which is more than even the more capacious models of many companies), and thinner steel was used on the upper one (1 .8 mm). But not adding normal illustrations of the assembly process to the instructions is a strange decision: one involuntarily recalls Asimov’s old story “Insert cotter pin A into slot B” when you try to understand without illustrations which part should be inserted where.

In general, however, the concrete mixer is not bad - it will work for its price.

Main advantages:

- Good performance

- Durable mixer tank

Minuses:

- Long kneading when fully loaded

Models in the line:

- Kraton BeeTone 120

– 110 l, 500 W - Kraton BeeTone 70

– 63 l, 220 W - Kraton BeeTone 140

– 130 l, 550 W - Kraton BeeTone 180

– 160 l, 650 W - Kraton BeeTone 160

– 150 l, 650 W

Parma B 201 E

A domestically produced machine mixes concrete mortars and painting mixtures. Its main characteristics are operating voltage 220 V, weight 70 kg, drum volume – 200 liters.

Advantages:

- Cast iron crown;

- Push-button control;

- Wheels for transportation;

- Fixing the drum in one position;

Flaws:

- Engine power is less than declared by the manufacturer.

ZITREK ZBR 700/220 B

This unit will be an excellent choice for those people who are going to engage in construction seriously and for a long time. It can mix large batches of concrete mortar, because its drum volume is as much as 500 liters. The entire structure of the machine is treated with a special anti-corrosion mixture, so it is not afraid of bad weather.

Advantages:

- Power 2200 W;

- The crown is made of cast iron;

- High build quality.

Flaws:

- High price.

When planning to purchase a concrete mixer, you should weigh the pros and cons of the purchase. Perhaps, if there is a small amount of work, it will be easier and more profitable to rent this unit.

Caliber BSE 65/220

The compact concrete mixer produces 44 liters of solution in one go. Connects to a 220 V network, which makes it convenient for use in domestic conditions. A good example of a combination of price and quality.

Advantages:

- Build quality;

- Compactness;

- Affordable price.

Flaws:

- No engine cooling;

- The crown is made of metal.