Repair and decoration

04/17/2018 Anastasia Prozheva

To maintain order even in a small area, concrete is constantly required: pour fence posts, mix mortar for masonry, pour the foundation for a gazebo, shed, shed, pour slabs for a path...you never know how much housework to do. Stirring in the trough is long and physically difficult. That’s why many people think about purchasing a concrete mixer. And if there is a serious construction project ahead, and there is nothing to think about, this tool is simply necessary. One has only to say that a solution well prepared in a concrete mixer is 50% stronger than one made by hand (with the same composition of components). There is only one thing left: choose a concrete mixer.

What operating principle should you use for a stirrer?

How to choose a concrete mixer based on its operating principle? It is worth noting that absolutely all models can work either according to the principle of gravity or in a forced way.

The gravity method of operation consists of mixing the mixture by lifting the solution on the blades and throwing it down. That is, these blades are fixedly fixed in the drum, and the drum itself moves.

Devices with a gravity operating principle are capable of mixing no more than 75% of the total volume of the drum. Accordingly, the drum cannot be lifted vertically.

- Home Appliances

How to pester your neighbor: choosing a hammer drill for your home

The forced principle of operation involves the rotation of the blades inside the drum (as in a food processor). At the same time, the mixture is mixed very efficiently. On average, devices with a forced operating principle are capable of mixing 75 - 90% of the total volume of the mixer. But the cost of such units is much more expensive than gravity ones.

Which is better to take a stirrer, with a gravitational or forced method of operation? For household work, gravity units are quite suitable, since there is no particular need to mix large volumes at once (except for pouring the foundation). Among the domestic ones, you can take the Whirlwind BM-230 , which is capable of mixing up to a maximum of 165 liters of mixture out of 230 liters of total volume. Devices with a forced method of mixing the mixture are best used for construction teams of masons, where a large volume of mortar is needed in a minimum amount of time. It is also worth considering that the price for such models starts from 50,000 rubles.

Device types

Gravity mixing concrete mixers are divided into gear and crown mixers according to the type of device and the method of transmitting rotational motion from the engine to the drum.

- Geared concrete mixers are characterized by a high degree of protection of the gearbox from sand, water, and construction debris. Therefore, such devices are considered the most reliable and durable. But if a breakdown does occur and the gearbox fails, repairing the mechanism is extremely difficult, almost impossible.

- Concrete mixers are more popular among users. The crown is a gear that encircles the drum along its outer diameter. It is thanks to the crown that the drum rotates. Since it is located outside the machine, the crown structure is in no way protected from falling construction debris, dirt, dust, and solid particles. That is why the crown wears out quite quickly and fails. However, its replacement or repair is not as difficult as in the case of geared concrete mixers. For this reason, this type of concrete mixer device is in particular demand. To extend the life of the crown and simplify machine maintenance, you should pay attention to the material from which the crown is made. It can be polyurethane, steel or cast iron. Cast iron crowns are considered the most reliable and durable. That's why they cost more. Polyurethane crowns are not so durable, but they are cheap, which makes it possible to frequently change them as they wear out.

Concrete mixer volume

The choice of concrete mixer for this parameter directly depends on the intended work, as well as the number of people in the team. The more workers there are, the faster the next portion of the solution will be needed. Below is the ratio of the volume of the mixer to the number of workers in the team:

- Up to 100 l: 1-2 workers,

- 100-150 l: 2-3 workers,

- 150-180 l: 4-5 workers.

These indicators are average, and much depends on specific working conditions. Here we note that size affects the weight of the device. You should not take a stirrer that is too large unless necessary, as it will be difficult to drag around the object.

Equipment operating rules

A concrete mixer for a home not only does all the dirty and hard work on a construction site, but also requires special care and compliance with rules during operation.

So, here are the basic rules for working with a concrete mixer of any model:

- maintaining cleanliness on the work site;

- protection from moisture and water;

- protection from children;

- during non-working hours, the concrete mixer should be stored in a dry place;

- the device should not be overloaded, it is better to read the instructions and mix a small amount of components;

- during operation, it is better to remove all jewelry;

- It is good to use safety glasses when working;

- Do not come close to the device when it is in working condition;

- Correct care involves timely cleaning of the drum (before the solution sets) and proper maintenance.

Drum speed

For models with a power from 500 to 1000 W, the rotation speed of the drum is practically irrelevant. But for more powerful devices, the drum rotation speed must be at least 30 rpm so that the mixture is mixed well. In principle, the higher the speed, the faster the solution will be mixed and, accordingly, less electricity will be consumed. Unfortunately, this indicator is rarely written in the characteristics of the product in the product card of online stores, so this parameter should be clarified directly with the seller.

The best crown concrete mixers 2020

Parma B-121E

Budget concrete mixer for home repairs. Its volume is 120 liters, and it can stir up to 65 liters of the finished mixture, that is, about 55% of the tank volume. There is a good quality cast iron crown here. Its service life is on average 3 - 4 years, depending on the frequency of use.

The mixer can be called relatively light, its weight is 53 kg. The power of the device is small, but in principle it corresponds to the volume of the drum. If you need a small, reliable stirrer, then this model is just what you need.

Zitrek Z200 024-0984

This is a more serious and larger unit. The motor power here is 800 W. The total volume of the drum is 200 l. In one pass, the concrete mixer is capable of mixing up to 150 liters of concrete mixture, which is about 75% of the total volume of the tank - this is quite a large figure for crown units.

Users note that even when loading 2/3 of the barrel, the engine practically does not heat up. This device weighs 63 kg, so you will need a second person to move it. Overall, this is a good stirrer for the money for home repairs.

Whirlwind BM-200

This 200-liter concrete mixer from a domestic manufacturer is capable of mixing up to 140 liters of ready-made mortar. Note that even when fully loaded, its rotation speed does not drop and is 29.5 rpm.

The power of the concrete mixer is 900 W. It is also worth noting that a durable cast iron crown is installed here. According to user reviews, the device mixes the mixture well and does not make much noise. The weight of the device is 56 kg.

Concrete mixer designs

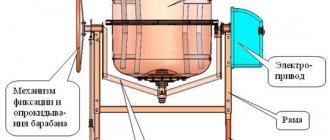

Gravity concrete mixers equipped with a rotating container are more often used.

. In practice, they are pear-shaped devices equipped with a tipping loading mechanism. The blades, due to the work of which mixing occurs, are located on the walls of the container. The quality of the consistency and the speed of its mixing depend on the rotation speed of the container, the number of blades and the angle of inclination of the bowl. The main advantages of a gravity concrete mixer with a rotating container are reliability of installation, simplicity of design, rapid unloading of the device, low energy load and the ability to incorporate large aggregates.

Build continuous gravity mixers

They consist of a cylindrical drum supported by 2 bands on support rollers. To prevent the drum from moving horizontally, one of the tires rests against the support rollers with its outer surfaces. The rollers themselves are mounted on an iron frame, which is installed, in turn, on a concrete foundation. From the electric motor (through the ring gear and gearbox), rotation is transmitted to the drum. Inside it, 30 bucket-type blades are installed along a helical strip. They lift the elements of the solution and ensure their free fall.

The gravity concrete mixer is loaded by rotating the drum through the loading funnel. At the same time, the blades capture the concrete mixture, lift it up and throw it down. As the solution falls, it moves to the discharge end of the drum along its axis. Thorough mixing of the consistency components is ensured by the special arrangement of the blades. There is a special tray at the end of the drum to unload the consistency. Water is supplied to the drum through pipes, and a special water meter monitors the dose.

Concrete mixers with forced mixing of continuous action

They are most often used in stationary and mobile concrete plants. Their body is welded from sheet steel and lined on the inside with a lining made of armor plates or sheet steel with increased wear resistance to ensure long-term operation. The housing is installed on the frame and locked at the top with a lid.

Two shafts with mixing blades attached to them are installed inside the housing. When starting, the shafts begin to rotate towards each other. In order for the mixture to move in the appropriate direction, the blades are installed along an interrupted helical strip. This design of the construction mixer ensures intensive mixing and movement of the consistency to the discharge hole due to the presence of counter flows. The productivity of a concrete mixer with forced mixing is adjusted by rotating the blades from 0 to 90 degrees relative to the shaft axis.

The drive of the shafts of such a concrete mixer is carried out from an electric motor through an open gear transmission, a gearbox and a belt drive. The loading funnel is installed in the front part of the construction mixer. The dry mixture continuously flows into it. At the other end of the concrete mixer there is a pipeline supplying water to the device. The finished solution is transferred to a special storage tank or specifically to a vehicle. During interruptions in supply, the storage tank makes it possible to collect the concrete mixture, ensuring very fast loading of vehicles and preventing downtime of the concrete mixer. In order for the finished mixture to be of the highest quality, it is necessary to accurately calculate the ratio of the components supplied to the device.

Repetitive concrete mixers, forced, with a fixed container.

The main function of devices of this type is to produce mobile, molding, hard concrete and lightweight concrete with special additives. Currently, two subtypes of such concrete mixers are more common, equipped with:

- cylindrical body with a vertical shaft. trough-shaped body with a horizontal shaft.

Their main advantage is the creation of a solution of the highest properties. In addition, builders value them for their versatility, which allows them to produce mortars of varying mobility and density.

Concrete mixers are forced, repeatable, with horizontal shafts.

The container of such concrete mixers is made in the form of a trough. The blades that mix the solution are placed on horizontal shafts. This design ensures thorough mixing of the solution. The main disadvantage of these devices is:

- difficulty in repairing the mixing part; large mass of the mixer relative to the working size of the container; introduction of only small and medium-sized aggregates; long unloading of finished material.

Concrete mixers are forced, repeatable, with vertical shafts.

The mixing container of such mixers is made in the form of a cylindrical bowl, additionally equipped with a selection cylinder inside. This inner cylinder prevents the consistency from accumulating in the center of the device. The mixing part is constructed of 4 racks on which mixing and sampling blades are attached.

This type of concrete mixer is considered more suitable. At the same time, the solution it creates is of the highest quality, which is why this technique is quite popular in the construction environment. With the help of these devices it is possible to make solid molding compounds as well as fixed and moving concrete. The disadvantages of forced concrete mixers in this category include the very high power of the electric motor and the inability to use components for consistency of different densities.

Repetitive planetary concrete mixers

They belong to forced concrete mixers and have the following advantages:

- the highest mixing quality with relatively low time costs; cleaning the walls of the container using selected scrapers; the ability to use components of different densities and at the same time obtain high-quality finished material.

But despite all their advantages, planetary concrete mixers are quite expensive and technically complex (complicated gearbox, high drive power, need for constant maintenance). Yet, they have the highest performance and make a mixture of excellent properties.

Rating of geared concrete mixers 2020

Stroymash SBR-132N

This is one of the most inexpensive geared concrete mixers for home use. With a drum volume of 132 liters, it is capable of mixing up to 64 liters of mixture - this is a small figure for a gear mixer, but at such a low price this is normal. The motor power is 600 W.

This model is the younger brother of the SBR-350N device, with the ability to prepare a ready-made mixture up to 175 liters and operate on a voltage of 380 V. If you need it for small home repairs, then take the SBR-132N, and if for a construction crew, it is better to take the SBR-350N.

Profmash B-130R

Many people buy this concrete mixer if it needs to be rolled with mortar from the place of mixing to the place of pouring. Thanks to a well-thought-out balanced design, stable wheels and comfortable handles, it is convenient to roll it at a distance of up to 50 m from the kneading site (rolling over longer distances greatly tires your arms and back). In one go, the unit is capable of mixing up to 70 liters of solution. Moreover, it prepares the maximum volume of solution in just 2 minutes.

The manufacturer claims that the service life of the concrete mixer is about 20,000 cycles (meaning on/off for one batch). In this case, the device can (more precisely, it is recommended by the manufacturer) to mix crushed stone with a size of no more than 40 mm (although at a construction site it was necessary to mix crushed stone of a larger fraction). The power of the device is 850 W, and its weight is 48 kg.

Caiman M134

Professional concrete mixer for home and commercial construction. It has the best power/solution volume ratio: with its 300 W, it is capable of making up to 100 liters of concrete in one go. Electricity consumption is almost half that of competitors with the same tank volume.

The engine speed is 2750 rpm. In this case, the mixer itself rotates at a speed of 21 rpm. The tank has good steel up to 1.5 mm thick, which, even with intensive use, does not corrode for a long time (although, of course, it will rust over the years). For ease of filling, the tank can be rotated around its axis. The cost of the device is certainly quite high, but the build quality and performance compensate for all costs.

What else do you need for home renovation:

- Doing repairs while at home: the best cordless screwdrivers 2020

- Retirement brushes: which electric spray gun is best to buy for your home?