The same thing happens with a household concrete mixer. It is, of course, easy to use; it can be moved directly to the edge of the formwork. But still, there are places where it is impossible to deliver a concrete mixer. In this case, you either pour concrete from it into buckets and manually fill the formwork, or you dump the mixture into a tray, through which it evenly flows to the right places.

Most often, a tray for receiving concrete is made of boards, since the iron structure is very heavy, working with it requires considerable strength and skill. The wooden tray is lightweight, quickly assembled on site, and can be made of any size to fit a specific formwork.

The width of the tray is easy to determine - a shovel should fit in it to help the mixture move off it during pouring. The length of the structure usually does not exceed 3 meters, but there are exceptional cases. Then the tray is made based on the size of a specific object.

To make a tray, take a wide board.

On the one hand, where the concrete will go, it is processed with a plane so that the flowing mixture does not linger on the rough surface. Inexperienced builders cover the board with cellophane film or roofing felt. But you don't need to do this. These materials will rupture when the mixture is first applied. If you have extra galvanized sheet, you can upholster the structure with it from the inside. But if there is no galvanization, then the concrete will move along the planed board.

If the length of one board is not enough, the tray can be extended with a second board, fastening them from below with scraps of plank using self-tapping screws. They also increase the width by screwing a block of the required size to the side of the ribbing.

The height of the side walls will be enough 20 cm. If there is no one board of this width, then you can connect two 10 cm wide. They are connected to each other with self-tapping screws through small pieces of plank.

The next step is to screw the sides with self-tapping screws to the bottom board.

The concrete receiving tray is almost ready.

To prevent the sidewalls from moving apart under the weight of the concrete mixture, they are fastened on top with bars at a short distance.

The concrete tray is ready. Before starting work, it is advisable to moisten its surface with water to reduce the friction force.

Using it, it is convenient to fill formwork even with walls 15 cm thick. The main thing is to direct the mixer feed chute exactly to the center of the tray. If you ordered a mixture with little fluidity, you will have to work with a shovel to help it move. And do not forget to vibrate the concrete well with a deep vibrator, removing air bubbles from it. This will increase its fluidity, the mixture will fill the narrowest niches. Vibrated concrete also has higher strength and water resistance compared to non-vibrated concrete of the same grade.

If you liked the article, share it on social networks.

Building codes require that volumetric concrete structures be poured simultaneously, preferably during daylight hours. One of the components of the rapid pouring of a structure is a concrete tray, which you can quickly and easily make with your own hands.

Concrete tray: where to start assembling?

Volumetric concrete work involves the use of the following machines and equipment: a truck mixer with ready-made concrete or a concrete mixer, a concrete pump or a tray for supplying concrete to the pouring area.

At the same time, a car mixer or a concrete mixer are “constant” quantities, that is, equipment that you cannot do without. An expensive concrete pump to rent (rental costs start from 14,500 rubles per shift) is usually replaced with a disposable wooden tray (in private housing construction), which can be disassembled and the boards used for other purposes.

Recommendations for making a chute for transporting concrete mortar

There are several recommendations that are useful to consider when making a device for concrete mixture with your own hands. Thus, a structure with a narrow shape is more stable and durable when located in a vertical position. Such a gutter, after concrete gets into it, will be able to withstand not only its own weight, but also the mass of the incoming mixture.

In the case of making a very narrow structure for pouring the foundation, it must be strengthened with horizontal struts, which will prevent it from bending during blockage with concrete mortar. If the gutter does not seem strong enough, you can increase its rigidity using angles secured in the transverse direction. In this case, the length of the corners depends on the design features.

Currently, devices with a length of 3 to 15 m can be manufactured for pouring the foundation. They are usually used on large construction sites. In a suburban area, the length of the structure, which should be made by hand, should be from 1.2 to 1.5 m. Depending on the length, the weight of the structure may vary. Ideally, the longer the gutter, the greater its mass should be. This is what will allow the structure to avoid sagging after the concrete mixture gets into it.

Making a filling device with your own hands is an event that does not require special skills or time. But at the same time, it will allow such an important stage of construction as the construction of the foundation to be carried out as quickly and competently as possible. A foundation made using a gutter will last a long time and reliably.

Operating procedure

- Depending on the width of the existing boards, the bottom of the tray box is assembled - 4 (150 mm) or 3 (200 mm) boards in a row are connected into an “end” with an overlay from the same board nailed to the underside of the bottom of the box. For strength and reliability, also on the bottom side of the box with a step of 600-800 mm to the bottom of the box, reinforcing bars 40x40 mm are nailed across;

- The walls of the tray are nailed to the sides of the bottom of the box, and best of all, the walls of the tray are screwed with self-tapping screws, so as to form a U-shaped structure;

- The bottom of the tray is covered with galvanized (roofing) iron, or is not covered if the boards are carefully planed;

- For reliability and strength, the walls of the tray are “bandaged” with 40x40 bars in increments of 0.8-1 meter.

The concrete transport tray itself can be considered ready for use. But there is one caveat. In order for the material to move into the formwork from an automixer or concrete mixer as independently as possible, it must have a slope to the soil surface of 5-15 degrees (for “liquid” concrete) and 20-30 degrees (for thick concrete).

In addition, the concrete tray should not bend under its own weight and the weight of the concrete. This can be achieved in several ways: pin up available materials under the tray (foam blocks, boxes, bricks, etc.) or spend a little time and knock down special triangular trestle supports of different heights from 50x50 mm timber and lay the tray on them as if on a bed.

Also, for the convenience of “turning”, it is advisable to provide two handles in the part of the structure facing the formwork - a 50x50x1000 block nailed to the bottom of the tray, 250-300 mm away from the edge.

Useful practical tips! After you have poured the structure furthest from the mixer, you can cut off part of the tray with a hacksaw and grinder, break the handle for “turning” and continue working without moving the automixer or concrete mixer.

After completion of the work, the tray is disassembled into components that can be used for other construction or repair purposes.

Considering that some companies charge extra for the downtime of an automixer, to speed up the work of delivering concrete to the formwork, use two workers with shovels to stand on either side of the tray and shovel the concrete to the pouring point.

What volume are mixers (concrete mixers)? In the Moscow region, the most common ones are 7 and 9 cubic meters; machines of 4, 5 and 6 cubic meters are less common; in some places there are even very small mixers with a volume of 2.5 cubic meters. Outside the city there are often narrow roads with closed turns, and many places cannot be reached by cars with a capacity of more than 5 cubic meters.

In Moscow, the volume of cars is from 6 cubic meters (and 6-7 cc cars are not kept everywhere). The main reasons why there are no small mixers:

- due to the large volumes of one-time deliveries, it is unprofitable to keep small concrete mixers,

- small mixers are most often not new, have toxic emissions, and with them there is a greater risk of getting fined,

- In addition, with the tightening of fines for overloading in 2015, many factories switched to delivering incomplete vehicles, and a 5-cubic-meter car can only carry 2-3 cubic meters.

Classification of drains

Concrete gutters are divided into two types, differing in shape and method of application:

- Small, representing classic products of a semicircular shape.

- Recessed, which have a quadrangular cross-section and are covered with a decorative lattice on top.

The first type is safe and easy to use, but cannot cope with large flows of water. The second option is more spacious, and thanks to the grille it provides convenient passage for vehicles and avoids falling. Despite the top protection that prevents large debris from getting inside, this tray requires periodic maintenance. To do this, the grille is removed, accumulated dirt and small particles are removed. Ignoring this rule leads to system clogging and reduced functionality.

How to prepare a surface for pouring

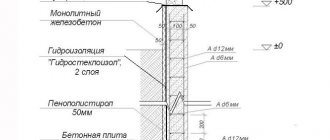

The technological process begins with surface preparation. Excavation work is being carried out, the volume of which depends on the type of future structure. At the next stage, drainage is arranged to remove moisture. This is a two-layer bedding made of sand and crushed stone of medium or fine fraction. The layers are well compacted.

To prevent the solution from spreading, formwork is installed. Use any flat material. To make tracks with a curved profile, plastic sheets are used. The structure is installed along the edges of the site, trenches, and secured with bars driven into the ground. The formwork determines the contours of the future product.

At the stage of preparation for pouring, waterproofing is arranged. It is necessary so that moisture from the soil does not penetrate into the concrete, and liquid from the solution does not go into the ground. Use plastic film, roofing felt or waterproofing material.

Next, they begin laying the reinforcement, which gives the structure strength. A metal mesh made of wire with a diameter of 6 mm or more is used. The size of welded cells is not less than 100×100 mm. Lay sheets overlapping. Instead of mesh, they are reinforced with rods with a cross-section of 8 mm or more, which are connected to each other.

Pouring Tools and Equipment

To pour into the formwork, make a wooden trough through which the mixture is directed. If the construction is large-scale and the mixer cannot get closer to the pouring site, concrete pumps are used.

The solution is prepared by hand using a concrete mixer. It takes about 4 hours of work to prepare 1 m³ of mixture - the time depends on the equipment parameters. With such productivity, you can pour a floor or foundation without any problems.

Other equipment may be needed for the job - it all depends on the technology used and the volume of construction. You may need a concrete delivery wheelbarrow or bucket. Air bubbles must be removed from the poured solution. This is done manually with a piece of reinforcement or a special vibrator.

Some features

Maintaining uniformity of concrete transportation directly depends on the shape of the gutter. A narrow and high chute makes it possible for individual particles to come closer together during the movement of the mixture. In addition, it is necessary to ensure that the concrete mass does not overflow over the sides of the device during feeding.

- A narrow-shaped accessory has one advantage, which is that it is the most durable and stable in a vertical position. This is very important, since its design must withstand not only its own weight, but also the load from the entire concrete mass.

- The very narrow element must be reinforced with horizontal bracing to prevent it from buckling in the event of a blockage.

- To increase rigidity, it is reinforced with corners in the transverse direction. The length in each specific case may be different and depends on the type of future structure.

- On an industrial scale, when creating a foundation, systems with a length of 3-15 meters can be used.

It should be remembered that the longer the gutter, the greater its mass should be in order to prevent it from bending during the supply of concrete solution. The connection of such products is determined by the peculiarities of pouring the concrete mass, more precisely, by whether the gutter is supposed to rotate in a certain direction or not.

In order for the movement to be circular, it is necessary to connect its parts with a rotating head. If there is no need to rotate the gutter in a horizontal plane, it is quite enough to use hinges that allow you to adjust the angle of inclination.

Recommendations for filling at different times of the year

The filling technology has its own characteristics depending on the region of residence and the time of work.

Pouring walls with concrete mixture and other structures in summer

In summer, at low humidity and high temperature, the solution hardens quickly. A good organization of work and a sufficient number of people are required. If concrete will be delivered, order it from where delivery takes the least time. It is necessary to organize quick unloading - the quality of the product depends on the speed of filling. When preparing by hand, there must be enough workers to ensure the process is continuous.

In this case, water is used to adjust mobility, but not more than 12 liters per 1 m³. The poured surface, formwork and reinforcement are moistened, but there should not be excess water.

Do not pour directly over the waterproofing - pour 10 cm of sand on it. They don’t delay leveling - they start as soon as the shine of the water on the surface disappears. After finishing, cover with moistened burlap and film. Constantly spray with water until the cement sets completely.

Pouring concrete mortar in the cool season

Weather conditions - low temperatures and humid air - slow down the hardening of the mixture. You will need to wait longer to start grouting the surface. This does not affect the quality, but the speed of work is reduced.

Waterproofing film is used if the project requires it. To quickly set the solution, it is abandoned, especially on surfaces located at an angle. Moisturizing is carried out moderately.

Recommendations for working in the cold season

Quicklime is added to the solution intended for screeding - it accelerates hardening. Its amount in relation to cement is 0.5-2%. As a result, the material's resistance to destructive stress increases. It occurs when a solution freezes and then thaws. Lime is aggressive towards metal, so plastic mesh is used to reinforce the screed.

Before pouring the structure, make sure that the pillow is not frozen. The work site is heated with special equipment, regardless of what object is being poured and where it is located. The finished product is covered with a film and additionally with heat-insulating material on top. In private construction, straw and sawdust are used in a 10 cm layer.

It is prohibited to pour a solution without a frost-resistant additive at high negative temperatures. This especially applies to pouring a heated floor, over a wooden base or into formwork.

Making a gutter

The technology for making a concrete gutter with your own hands is not a particularly complicated process. The principle of its creation is exactly the same as when erecting formwork on a foundation.

Scheme of pouring a strip foundation.

- It is necessary to take an edged board measuring 25x150 mm and put together a “U-shaped” structure from it, the sides of which should be high enough so that the concrete mass does not stagnate.

- To make concrete flow easily, the inner surface of the gutter is lined with tin, linoleum or ordinary polyethylene, which will reduce the adhesion of the material.

- After the foundation gutter is made, it is installed in the desired location and supported by 4 support points. A good option would be to use gas silicate blocks for such purposes, which will prevent the structure from destruction.

In some cases, concrete is unloaded using a mixer into a special bunker and only then used for its intended purpose.

It is very important to remember that in open long structures the concrete mass loses a certain amount of moisture, which contributes to the disruption of its homogeneity. That is why such gutters are the worst way to supply material and are used only in private construction.

To construct a structure (foundation) on an industrial scale, gutters are used, which are designed in such a way that constant mixing of concrete is ensured at the lower end of the structure. This is achieved by passing the concrete mass through a special funnel-shaped trunk pipe.

How to pour concrete mixture technologically correctly

To produce a high-quality concrete structure, it is important to choose the right technology and stick to it.

For floors

To install a concrete floor in an apartment, beat off the old screed with a hammer drill. Clean the surface and begin pouring.

In a private house, the floor is laid on an earthen base.

- mark the floor level;

- level the soil surface, add more if necessary;

- lay waterproofing;

- insulated in a suitable way;

- reinforced if increased loads are provided;

- create formwork from beacons, dividing the area into separate sections - maps.

Concrete is prepared from cement, sand and crushed stone in a ratio of 1:2:4. Concrete is placed from the corner that is furthest from the door. The solution is poured into the card, leveled with a shovel, pierced many times with a rod, and stretched over the entire area.

Better compaction is carried out with a vibrator. When cement laitance comes to the surface, stop shrinkage and move on to the next card.

After completion of the work, the filling is left for 4 days. Spray with water daily to prevent cracks from appearing. Then cover with film and leave for 3-4 weeks until completely set. Periodically moisten with water.

A screed is made over the frozen surface: liquid cement mortar or self-leveling mixture is applied. Allow to stand for 2-3 days, spraying with water daily.

For the foundation

The technology for pouring any foundation is the same. After the preparatory work, a concrete composition is mixed or ordered. When the volume is large, it is better to buy with delivery - this is the only way to create a monolithic base.

If the mixer can approach the object, one of the workers holds and directs the trench, and 2 more people straighten the solution in the trench. They start pouring from the corners, then fill the space around the entire perimeter.

Compaction is carried out using a vibrator or improvised means. The concrete is leveled in the filled trench until it hardens.

The construction of a columnar foundation has some features. This is not a continuous ribbon, but pillars connected by a grillage.

First, holes are made for the supports and reinforced, releasing rods 20 cm above the level of the pillar. Filled with concrete. Then they make the formwork for the grillage, which connects the pillars, lay the reinforcement, and pour it.

Into the formwork

If the solution is delivered by a mixer, it is poured immediately to a given height over the entire area. When using a concrete mixer or manual preparation, it is not always possible to prepare enough mixture to cover the entire volume of the structure.

Therefore, there are technological methods for laying the foundation in parts.

There are 2 options. In the first case, the formwork is filled in layers, but not too thin. In the second method, the space is filled along the entire height with separate blocks, forming a beveled sidewall to reliably connect the individual parts. If the break in work is more than a day, wait until the previously poured solution dries. Before new concreting, it is necessary to wipe the joints with a brush and rinse with water.

Air is removed from the freshly poured mixture using a vibrator or rod. They hit the formwork with a heavy hammer - the concrete settles and compacts. Then the surface is leveled.

In water

In industrial construction, 2 methods of pouring concrete into water are used: pile and caisson. When building a private house, 2 options are also used. The first one is similar to a coffered one. A concrete mixture is made, poured into bags and lowered into a pit above the water level. The bags sit for a month until the composition hardens. Then the formwork is erected and poured according to the generally accepted method.

The capillary version is more complex. A liquid solution without crushed stone is prepared, which is fed into the pit with a prepared cushion.

The work is performed using the following technology:

- Metal pipes with a cross section of 40-100 mm are installed in the trench at an equal distance. A layer of crushed stone is poured above the groundwater level.

- A liquid cement mixture is poured into the pipes, which flows out of them and fills the space between the crushed stone. The pipes are gradually raised so that the solution disperses evenly throughout the entire volume of the structure.

Device requirements

Formwork diagram for the foundation.

In order for the supply of concrete mass during the construction of the foundation to be as uniform and homogeneous as possible, the gutters must meet certain requirements that apply to them:

The slope of the gutter must remain unchanged throughout the entire period of work during the construction of the foundation of the house. If this condition is not met and the angle of inclination, for example, decreases, then the speed of passage of the concrete mass will also decrease.

This, in turn, would lead to a buildup of solution and blockage of a certain area of the gutter. With an increase in the angle of inclination, and therefore the speed of passage of the mass, the concrete surface will be divided into separate parts, which is completely inconsistent with the existing technology. The foundation will be of poor quality.

The angle of inclination of the gutter relative to the horizon must have a certain size, an increase in which will lead to the concrete mass being divided into parts. The reason for the change in the size of the angle of inclination may be the consistency of the concrete and the degree of its delivery distance.

Solutions of a more liquid consistency, supplied over a short distance, allow gentle slopes; for longer distances, steeper gutters are appropriate.

Forms for filling

Industrial molds are used to make tiles, facade stones, and paving stones.

They are expensive, so for their own needs they make homemade ones from flexible plastic. The durability of the molds is affected by the type of material and thickness.

If large products are cast (piles, curbs, pillars), wooden formwork from boards and plywood is knocked down. Before use, the wood is well moistened with water. If you need many small products of the same type, this method is also used.

In some cases, the mold is made in the ground. Sand is poured into the holes, heavily moistened, and filled with concrete. The surface is leveled, covered with film, and moistened with water until completely set.

Stencils for stone or tiles can be created from any materials, even from children's molds or dishes. To cast the ring, take old tires that are suitable in size.

For disposable forms, foam is used. A blank is cut out of it and filled with concrete. To remove the product, the mold will have to be broken. But the most unimaginable configurations are created from the material.