What is a base?

Everyone knows that houses have a basement, but what is it? If we turn to SNiPs, we will find that there is no clear technical definition.

But there is a description in which the base is defined as the lower part of the external walls of the building, located directly on the foundation. At the same time, building regulations stipulate that it is this element of buildings that is subject to the most significant physical, mechanical and temperature influences.

On a note! The basement floor is defined by the building regulations as a floor with a floor level below the ground level by no more than ½ the height of the room. And this is the fundamental difference between a basement and a basement, where the floor level is below the ground level by more than half the height of the room.

Why does the plinth experience the greatest level of impact? This is due to the location of this structural element and its dimensions.

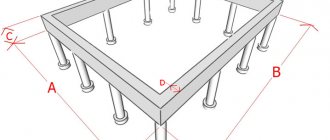

Design section of the basement wall

Functions

If we relate to construction “geography”, then the plinth is a vertical element of the building, which begins where the foundation ends and ends where the wall of the living space begins.

The main function of the base is protective. It lies in the fact that it takes on all natural influences, including precipitation and temperature changes.

In order for the barrier to be sufficiently reliable, the height of the base above the ground must be at least 0.5 m. If this size is reduced, the material of the load-bearing walls will be regularly exposed to the destructive effects of high humidity as a result of precipitation or capillary soil moisture. The strength and performance characteristics of building materials in such a situation are significantly reduced.

The remaining functions that the base performs are also quite important:

- On a building-wide scale, it distributes the vertical load from the weight of ground structures across the foundation area.

- Often allows you to create a clearer horizontal surface of the base for laying wall material.

- Raises the first floor to the required, safe and comfortable level.

- Increases the height of the basement, making the room more interesting in terms of operational characteristics.

Moreover, it is a connecting or transitional section between the foundation and the load-bearing part of the main structure. And if we take into account not only practical aspects, then sometimes, being quite attractive from an aesthetic point of view, the base shapes the overall appearance of the building.

The photo shows the consequences of exposure to moisture on the unprotected base of the building

Kinds

It is customary to divide the base according to its location relative to the main wall into the following types:

- Sunken . The outer wall of the plinth is shifted inward by 50 - 80 mm. It is an interesting and non-standard architectural solution. It is highly practical and reliable, as it is partially protected from rain moisture by the “canopy” of the wall.

The falling base looks very impressive

- Equal level . The simplest and most common construction option. The walls of the plinth and load-bearing walls in this case have the same thickness. Requires a more careful construction of the waterproofing barrier.

The flush-to-wall option significantly reduces the efficiency of the plinth design

- Speaker . With this option, the plinth wall is slightly thicker than the main walls of the building. The price of a device of this design is higher than in previous versions, since it requires a larger volume of building materials. Gives the appearance of the house some “solidity”.

Protruding plinth with metal casting device

Selection rules

The type of base is determined at the design stage, and is not chosen at random. To avoid unnecessary expenses and use all the functionality of the base, you should consider a few simple rules.

For simplicity, let’s summarize the general patterns in a table:

| Type of base | Type of building, purpose of the premises | Achieved effect |

| Sunken | Utility premises | Savings in material costs |

| Equal level | Not recommended for device | Water protection is reduced and requires additional measures for thermal insulation |

| Speaker | Thin-walled buildings or houses with a residential basement | Thermal insulation of basements |

Materials

Knowing which plinth to build, you should decide what to build it from.

In view of the rather significant functional load of the basement element of the building, several types of building materials and corresponding construction technologies are possible for use:

- Brick. Due to its moisture-resistant properties, clay brick is more acceptable in this case. The method is characterized by the simplicity of the device.

- Natural stone. A very durable option, but costly in terms of labor resources and will require additional thermal insulation.

- The block is concrete. Its impressive dimensions significantly reduce construction time, but special equipment will be required.

- Concrete monolith. Various non-standard shapes are possible. Suitable for DIY construction.

The choice of material is also carried out at the design stage, taking into account the weight of the building and horizontal loads associated with the type of soil. In this case, the average annual precipitation and groundwater level are taken into account.

A monolithic reinforced concrete plinth has no restrictions and can be installed under almost any conditions.

Ready concrete basement for further insulation work

Laying depth of a columnar brick foundation

Columnar foundations, like strip foundations, can be shallow or made to a depth below the soil freezing mark in accordance with the data of regulatory documents on construction climatology and soil conditions at the construction site. Depression below the freezing depth is usually provided for when constructing foundations on weak heaving soils that can be subject to significant deformations as a result of freezing and thawing of the groundwater that impregnates them, resulting either from the infiltration of surface storm drains or from water-saturated layers at the construction site. You can see approximate freezing depths in the table below:

| Regions | Average depth of soil freezing, cm |

| Vorkuta, Surgut, Nizhnevartovsk, Salekhard | 240 |

| Omsk, Novosibirsk | 220 |

| Tobolsk, Petropavlovsk | 210 |

| Kurgan, Kostanay | 200 |

| Ekaterinburg, Chelyabinsk, Perm | 190 |

| Syktyvkar, Ufa, Aktyubinsk, Orenburg | 180 |

| Kirov, Izhevsk, Kazan, Ulyanovsk | 170 |

| Samara, Uralsk | 160 |

| Vologda, Kostroma, Penza, Saratov | 150 |

| Voronezh, Tver, Moscow, St. Petersburg, Novgorod, Ryazan, Tambov, Tula, Yaroslavl | 140 |

| Volgograd, Kursk, Smolensk | 120 |

| Pskov, Astrakhan | 110 |

| Belgorod, Kursk, Kaliningrad | 100 |

| Rostov | 90 |

| Krasnodar | 80 |

| Nalchik, Stavropol | 60 |

When using tabular data, you need to remember that the freezing depth is given under the condition that there is no snow cover on the surface of the earth. If in winter the ground is covered with even a not too thick layer of snow, then the freezing depth is noticeably reduced, which makes it possible to construct foundations with less depth. Columnar foundations have good load-bearing capacity. Thus, in an article on the construction of foundations from asbestos-cement pipes, the load-bearing capacity was given as 800 kg per column of a pipe with a diameter of 200 mm. As you understand, a brick column, having a superior cross-sectional area and significant load-bearing capacity, will be able to support a fairly decent load. Moreover, the weight of the log house or frame walls of the bathhouse is not so great and to support them, a columnar foundation made of brick will be quite enough.

Pouring technology

Let's look in detail at the measures that will have to be carried out if a monolithic concrete base is used for the device. The most common question that arises when building a foundation for a basement is why can’t the basement be poured at the same time as the foundation?

The answer is a hydrobarrier. Underground walls (foundation) should be separated from the ground part by a layer of waterproofing to avoid the influence of increased humidity in the ground and on the surface on the main walls of the building. But more on this a little later, but now the standard instructions for constructing a concrete plinth.

Formwork installation

Any monolithic pouring requires formwork, a reinforced concrete base is no exception. Before installing the panels, you should make sure that the base has gained full strength. Moisture-resistant plywood can be used as the material for the panels.

Formwork for a monolithic base with reinforcement inside

If you choose another material at hand, make sure that its inner surface has no flaws or protrusions.

Next, the algorithm of actions is as follows:

- The formwork panels are carefully fixed with construction timber using self-tapping screws.

- The formwork must be installed strictly according to the level, which should be controlled during the installation process.

- The shields fit tightly to each other to avoid the formation of any gaps.

- If a material that absorbs moisture is used, the inner surface should be lined with plastic film.

Important! All formwork elements must be connected in such a way that after the concrete has set, they can be freely dismantled without causing damage to the concrete block.

Reinforcement

Monolithic concrete should be reinforced with internal metal reinforcement. The parts of the structure are assembled outside the formwork on site, and then placed inside the trench and tied into a single reinforcing belt.

Depending on the size of the plinth, the following restrictions apply:

- for reinforcement, hot-rolled periodic profile reinforcement of grades A500C or AIII is used;

- the horizontal reinforcement bar must have a diameter of at least 12 mm;

- vertical rods - with a diameter of 8 mm;

- It is preferable to tie the rods together with construction wire;

- the bundle forms a cell with a size of at least 150 * 150 mm, on average a cell with a size of 200 * 200 mm is used;

- corners are formed by bending one rod, and not by tying two;

- in places where unidirectional rods join, the length of the overlap must be no less than 40 times the diameter of the rod used.

Important! The metal should not touch the edges of the structure; the minimum distance from the rod to the pouring boundary is 50 mm.

Schematic illustration of building basement reinforcement

Ventilation

When building a basement, ventilation openings are required. Ventilation is designed to ensure a normal level of air circulation in the basement under conditions of temperature changes and high humidity.

Normal air exchange will avoid the formation of condensation, which, when penetrating into concrete, can deteriorate its strength characteristics over time and lead to a reduction in the service life of the building.

In general, the vent system is designed to:

- formation of a comfortable level of air humidity;

- preventing the formation of mold or mildew indoors;

- maintaining the strength of the monolith.

The air exchange system can be formed in 2 ways:

- Natural. During the construction stage, holes - vents - are installed in the basement wall. The exchange of air in this case occurs due to the temperature difference inside and outside the house. The number of vents, their sizes and location are calculated by specialists at the design stage.

- Forced. Air duct lines are laid with the top point of the pipe above the roof level and fans connected to power from the electrical network are installed. In this case, the channels pass through the main walls of the building.

Important! A system based on natural air movement due to temperature differences is more effective in small rooms.

Modern forced ventilation systems look very aesthetically pleasing

Pouring concrete

The solution is poured after the air duct system is installed and the reinforcing frame is laid. As a rule, designers lay M200 grade concrete for the basement. In practice, M300 grade solution is usually used for filling. This is done not because builders do not trust design organizations, but for other reasons.

By using a brand higher than prescribed, you are guaranteed to receive a safety margin.

It is needed in order to compensate for the decrease in the performance characteristics of ready-made concrete, which can occur as a result of:

- low-quality cement used during mixing;

- delivery time exceeded as a result of unsuccessful logistics;

- other force majeure circumstances.

If you mix the mortar yourself, then you can use materials for mortar grade M200, that is, M400 cement with a production date no earlier than six months before use.

When purchasing mortar from an unverified supplier, it is better to increase the grade of concrete for a safety margin.

Which brick is better for the foundation?

If you decide to build a columnar foundation made of brick, then you should know that not every brick is suitable for this. For example, lightweight hollow bricks or silicate bricks are completely unsuitable for this. The brick for the foundation should be solid red fired. Such bricks have high strength, low moisture permeability and, with proper waterproofing, can serve for decades without deterioration. One of the main characteristics of solid ceramic bricks from which the foundation will be built is its frost resistance, expressed in the number of freezing and thawing cycles. The higher the number, the more years a brick foundation will last without visible signs of destruction. This figure should be specified when purchasing. So, if frost resistance is 35, then the foundation built from it is guaranteed to last at least 35 years. To build a brick foundation for a light bathhouse, it will be enough to choose a brick of the M-100 brand, which has a load-bearing capacity of 100 kg per 1 sq.cm.

Solid ceramic bricks of standard sizes 120x65x250 are quite suitable.

Base protection

When installing a monolithic base, it is mandatory to carry out measures for heat and waterproofing of this part of the structure. A little earlier we already mentioned that waterproofing the base is mandatory. You can learn more about this and how to insulate the base by watching the video in this article.

Insulation from destructive moisture

Concrete is a very durable material, but only if certain conditions are met. The porous structure of the material has a very serious drawback - concrete perfectly absorbs water, which over time can destroy everything.

It is for this reason that waterproofing is mandatory, and in both planes:

- Vertical to establish a barrier between concrete and moisture in the air.

- The horizontal one is laid to prevent saturation of the basement walls with capillary moisture.

On a note! Vertical waterproofing is carried out inside and outside the building.

Different types of waterproofing materials can be used.

In summary, all insulation used for this purpose can be divided into 3 main types:

- Coating. Various types of mastic. Bitumen, polymer-bitumen and cement-polymer compositions are available for sale. Recommended for use inside and outside the building. They are applied with a roller or brush, sometimes by spraying, in several layers. An excellent waterproofing effect is achieved.

Waterproofing based on mastic

- Penetrating. Deep penetration primers. They are sold both in the form of solutions and as a dry mixture, which must be dissolved before use. Penetrating into the concrete, they create additional crystal lattices, further strengthening the cement mass and creating a barrier impenetrable to moisture.

Penetrating compounds are applied by brush or roller

- Roll (sheet) . Essentially mastic applied to a flexible, durable material. The sheets are laid overlapping, the seams are soldered with liquid composite compounds. As a rule, for the best effect, 2 layers of perpendicular orientation are laid.

Pasting the foundation and plinth with rolled material starts from the bottom edge of the foundation

Important! No matter how firmly you lay the waterproofing material or how many layers you apply, if the site does not have a drainage system, the base will “sweat.”

Thermal insulation

The base is an element of the building in which, in the event of insufficient thermal insulation, the greatest energy loss will occur. Simply put, you will be heating the street.

To the question, where is it better to install thermal insulation inside or outside, there is a rather funny answer: when you are cold, do you swallow or put on a fur coat?

So: how to insulate the concrete base of a house - some practical tips:

- Thermal insulation materials that have poor moisture resistance should not be used. For example, mineral wool is not suitable for the base; it is better to use penoplex, which will also serve as additional waterproofing.

- Thermal insulation should be carried out as part of the insulation of the foundation. If repair work is being carried out, the foundation should be dug out to the ground and all the thermal insulation should be re-installed.

- Unevenness, potholes or growths from the concrete base mass should be removed. In unsealed holes, the dew point will shift and condensation will accumulate under the insulation.

- Layers of horizontal roll thermal insulation are laid in the direction from bottom to top with obligatory overlap.

- If you plan to use cold bitumen-based mastic to solder a seam or insulate a joint, then carefully read the instructions. Some formulations contain substances that are aggressive to thermal insulation materials.

Layout of insulation in the section of the building

Decoration

Successful cladding of the plinth can radically change the overall appearance of the building. The cladding of a monolithic concrete plinth is mandatory for the construction for the same reasons: concrete does not like water.

Decorative material can be attached:

- on a concrete base using an adhesive composition,

- on a frame made of metal guides.

The frame method is more convenient for installing a layer of thermal insulation and technologically simpler when lining the base with slab material.

The most popular materials for finishing plinths are:

- Natural stone. The material is highly durable, but no less expensive. For cladding, you should contact specialists; the material is difficult to cut.

For cladding, you can use natural stone of inexpensive species.

- Porcelain stoneware or concrete plinth tiles have sufficient strength, a variety of textures and a wide color palette.

Concrete tiles for cladding with imitation masonry

- Plaster. Decorative compounds are used, working with which requires certain skills.

Decorative finishing with plaster

- Plastic. A budget option, very easy to work with, and has a wide selection of materials in color and texture.

Plastic panels for cladding the plinth

Materials and tools

To install the base you will need the following materials and tools:

- Cement.

- The sand is dry.

- Small crushed stone.

- Nails.

- Wooden slats.

- Hammer.

- Shovel.

- Electric drill, if available.

- Soft wire.

- Reinforcing bars.

- Sackcloth.

- Capacious container for mixing concrete mortar.

- Hydraulic level.

- Any herbicide.

- Bitumen.

- Rule.

- Master OK.

Cement is required to construct the plinth.

In order to perform reinforcement, it is necessary to stock up on reinforcing bars for spacers in advance and secure the latter with soft wire.

Next, the upper sections of the formwork should be secured with ties. Reinforcing bars can also be hung on the ties themselves. If the pieces of reinforcement are quite short, then they must be overlapped and then tied together using pieces of ordinary wire.

After this procedure, the plinth sheathing is completely prepared for concrete mortar to be poured onto it. It is quite firmly connected to the base of the foundation itself and is a fairly rigid structure.

Basement at the cemetery

Having nothing to do with capital construction, this structure is also called a basement. At the same time, a concrete base in a cemetery not only serves to strengthen the monument during installation, but can also limit the territory of the site.

Work on the construction of this structure is being carried out using the following technology:

- A shallow pit is dug, the bottom of which is compacted.

- Formwork is installed around the perimeter.

- If necessary, the platform is reinforced with metal mesh.

- The solution is tapped and vibrated, releasing air.

- To dry, the base is covered with plastic film.

- The concrete should be moistened within 7 days.

The service life of the structure depends on the quality of the solution. In this case, concrete grade M300 or more is used for pouring. At the mixing stage, plasticizers are introduced into the solution.

Be sure to treat the base with penetrating waterproofing. If possible, it is recommended to cover the concrete with porcelain stoneware or natural stone.

Cemetery plinth lined with granite

Features of the construction of columnar foundations

If you have read the article How to build a columnar foundation with your own hands, then you already know that the foundation should not be left unloaded for a long period, since soil processes can lead to its deformation. So, if you started building a brick columnar foundation in the summer, do not leave it unloaded during the winter. Try to calculate the duration of construction so that the construction of the main structures above zero is completed within one season. If this is not done, then in the spring you may find a change in the elevations of your columnar foundations and their position in space. Simply put, they can be limed due to soil heaving, as well as the peculiarities of the hydrogeological conditions of the construction site.