Markings and characteristics of concrete

Concrete is a very common material in construction. Therefore, the choice of concrete mixture is an important task for designers. Modern GOST (25192-2012, 7473-2010) obliges manufacturers to indicate the relevant material characteristics:

- M – brand;

- B – class;

- P – mobility;

- F – frost resistance;

- W – waterproof.

However, the main emphasis is on brand and class. The numbers following the abbreviation M indicate the cement content in the mixture. Thus, brands M50-100 include less daylight component than M500-600. Accordingly, the class of concrete is determined.

The indicator indicates the compressive strength of the material and is based on the amount of cement in the concrete mixture. For example, M150 is class B10, but class B45 corresponds to the M600 brand.

Recommended mixture composition for foundation

For the construction of the foundation, a concrete mixture of the highest quality is used, since the durability of the garage structure depends on the foundation. When choosing components, you need to be guided by simple but important rules:

- The base requires the best cement: without debris, lumps and unnecessary impurities. It is also not recommended to purchase material long before construction. If storage conditions are not observed, it quickly deteriorates. The best time to purchase is considered to be 1-2 weeks before the start of construction.

- Sand is recommended to be used with a minimum moisture content. Before mixing concrete, the raw materials can be dried or the amount of water intended for the solution can be reduced. However, such calculations should be trusted to a professional.

- Crushed stone or gravel for the foundation is not required to be large, no more than 2 centimeters in diameter.

Important! To create high-quality concrete, it is necessary to maintain proportions and take into account the influence of external data. It is recommended to entrust such a troublesome task to specialists.

Determining the right brand

When choosing which foundation is best suited for a particular garage, you need to take into account the characteristics of the future structure. It is recommended to consider the following parameters:

- Material for the construction of walls and roof of the future garage. The more weightless it is, the less strength the concrete mixture is required. However, for bricks or cinder blocks it is recommended to use a grade of at least M300.

- The dimensions of the future garage also determine the force of pressure on the foundation. Therefore, it is definitely recommended to take into account the height of the ceilings and the total area of the building. An increase in dimensions also leads to the need to increase the strength of concrete.

- If you are planning a garage with a basement, exceptional care is required when choosing a brand. For such a structure, concrete with a high level of water resistance is needed.

Also one of the parameters is the time of pouring the garage foundation. If the base is poured at a time from the base to the top of the base and is not protected from the effects of precipitation, then it is recommended to choose a brand with the largest amount of cement. For example, M350. Not less.

Cost of concrete for the foundation - order or prepare it yourself?

Before starting concrete, and indeed all construction work, the developer is primarily interested in the cost of materials, delivery, and installation. That is, a more accurate estimate is necessary.

This fully applies to the implementation of zero-cycle work; the cost of concrete for the foundation is one of the fundamental factors.

What should you consider?

First of all, it is necessary to calculate the volume of the proposed foundation; this can be done using the simplest mathematical formulas known from a school mathematics course, so we will not dwell on this issue.

The only thing worth considering is the correction factor, which takes into account possible leaks of the concrete mixture and its shrinkage. Based on practical data, the volume obtained by calculation must be multiplied by 2.

Then it is worth considering two options for preparing the mixture, which will significantly affect the cost of one cube of concrete for the foundation. We are talking about independent preparation and delivery of the finished mixture to the site. That is why we will consider the nuances that affect the price of the concrete mixture in both of these cases.

Making your own concrete

For many, this option is more profitable in many ways. Let's look at all the nuances more carefully. Let’s make a reservation right away that it makes no sense to indicate the specific cost of each factor, because there are regional differences, and the cost of materials is constantly changing.

Therefore, it is only possible to determine how much a cube of concrete for a foundation costs approximately; the main task is to learn to correctly take into account all the factors that influence the total cost:

- The cost of the initial components of the concrete mixture makes a significant contribution to the price of the finished material. It should be noted that depending on the brand of cement and the required strength of concrete, the ratio of the main components will depend. On average, the preparation of a concrete mixture M250-300 from cement grade M500 (the most used option in private construction) is carried out at a ratio of 1/3/5 (volume fraction of cement, sand and crushed stone). That is, even for a small house in the middle zone (the volume of the strip foundation is 25-27 cubic meters) you will need at least 3 cubic meters of cement, 9 m3 of sand and 15 cubic meters. meters of crushed stone.

- Based on this data, you should immediately take into account the cost of delivery of each of these materials. According to the most conservative estimates, there is a need to hire transport with a significant carrying capacity at least 3 times (for the delivery of each type of material). In this case, the cost increases in direct proportion to the distance.

- The next thing to consider when calculating the cost of 1 cubic meter of concrete for the foundation is the need to store all the material, which requires the construction of at least temporary storage facilities.

- Preparing the concrete mixture manually can reduce the cost of building a foundation. But, at the same time, this will require the involvement of additional assistants. In addition, this will significantly increase the time required to complete the work, which will entail additional costs.

- The presence of a concrete mixer can speed up and simplify the construction of the foundation, but it most likely will not be possible to fill such a volume (25-27 cubic meters) in one day. It is also worth taking into account the cost of electricity.

The advantages of preparing concrete yourself are some savings on the cost of the material. At the same time, there is another side to the coin. Increased labor costs, decreased speed of foundation construction, which negatively affects the solidity of the structure.

At the same time, there is a need for the construction of additional structures necessary for the accumulation of basic materials, and this leads to the need to increase the construction site.

Ready mix concrete

Now let’s look at how much it costs to order ready-made concrete. It’s worth noting right away that when delivering concrete mixtures using mixers (special vehicles) with a large carrying capacity, it is necessary to have good access roads to the construction site.

The average cost of concrete mixture delivered by special transport is 3.5-5.5 thousand rubles per cubic meter.

This run-up is determined by the following factors:

- The grade of concrete plays the most important role. For most private buildings you will need a mixture of M300-400, the price of which will be about 4 thousand rubles.

- The presence of anti-frost additives, which are necessary when performing work in the spring or autumn, when frosts are possible, which can significantly affect the quality of the foundation.

- The type of crushed stone used is also important. Concrete made from granite materials will cost much more.

In addition, the required moisture absorption of the mixture will also affect how much a concrete mixer for a foundation costs. This is especially important for construction in areas with high groundwater levels.

Advantages of purchasing ready-mixed concrete

There are several main factors that make it preferable to purchase concrete mix with delivery to the site:

- There is no need to work with several suppliers, as in the case of purchasing individual components for concrete.

- Refusal to build sheds or warehouses for storing materials.

- Reducing labor costs for concreting the foundation.

- Possibility to order concrete of the required grade with certain characteristics. Having a certificate for the mixture will guarantee its quality. When preparing concrete yourself, it is almost impossible to meet technological requirements.

- The ability to pour the entire foundation structure for a country house in just one day, which improves the quality of the building’s foundation.

And this is far from a complete list of all the advantages. And even the cost of the finished concrete mixture is offset by the economic benefits obtained from these advantages.

Possibility of savings

When calculating how much a concrete machine for a foundation costs, take into account the fact that it is possible to save significantly provided that the technological process is properly organized:

- Order concrete delivery for the date when all formwork structures are assembled. Partial pouring of the foundation is justified only if technologically necessary.

- Consider and prepare access roads for the mixer in such a way that you can quickly move it. In this case, it is desirable to ensure the possibility of gravity supply of concrete to the entire volume of the foundation. Ordering a machine with a concrete pump may increase the cost of the work.

- Try to use the services of volumetric mixers; delivery by one vehicle with a volume of 9 cubic meters will cost less than two trips of vehicles with a smaller carrying capacity. In some cases, it makes economic sense to order a large mixer even with an underload.

- Organize the work so as not to delay the car unnecessarily, this will all affect the overall cost.

Which method to choose is, of course, up to the developer. But, if there are normal access roads to the construction site, then it is much more profitable to order ready-mixed concrete of the required quality with delivery.

www.bobrovka.ru

Methods for preparing the solution

There are several methods for mixing concrete for a garage foundation. However, no matter what method it is decided to use, it is imperative to observe the proportions of the relevant materials. On average, the concrete mixture should have the formula: for 10 kilograms of cement, about 30 kilograms of sand and 45 kilograms of crushed stone are required. It is recommended to take half the total weight of the components.

Manual

When mixing the components by hand, you will need a shovel and a large tin container with sides. To begin with, the dry raw materials are mixed, forming a slide with a notch in the middle. Next, observing the proportions, water is gradually poured in and the ingredients are thoroughly mixed. The concrete must be homogeneous, without lumps or debris.

It is also recommended to monitor the consistency: the solution should not easily flow out of the shovel, but a constant shape upon contact with the tool is also a bad sign.

Mechanized

A mechanical concrete mixer will help make the process of preparing a concrete solution for the garage foundation easier. The design is quite easy to use and contains the following components:

- the basis of the structure on which the remaining parts are installed;

- tilt axis for securing the mixing container at the desired angle;

- a propeller with blades that ensures mixing of the solution components;

- small engine;

- hole for disposal of ready-mixed concrete.

When building a garage, you can use a gravity or forced construction. These units differ in their operating methods, but are generally similar in the results achieved. However, due to good transportability and small dimensions, the first one is in high demand.

Important! Depending on the concrete mixer you select, the order in which components are added and operating safety precautions will change.

Factory production

There is not always a specialist nearby who can advise something or take control of the construction. Then factory-made concrete will come to the aid of people who are not sure of the correct proportions of the components. The solution can be ordered by specifying the parameters of the future garage.

Professionals will calculate the required strength, respectively, the brand, and send it to the site in a concrete mixer. The cost is calculated in cubic meters.

Concrete for foundations in Moscow and the Moscow region

The foundation is the most important part of the structure, its basis and support for the entire structure. The best material for its manufacture is concrete. It is strong, waterproof, durable, frost-resistant. In addition, it is able to effectively support the weight of other structural elements of the building. The durability of a structure can only be ensured by a reliable, strong foundation. Therefore, you cannot save on it. Concrete work accounts for up to 20% of construction costs. And saving even one cube can lead to large material costs in the future. The only proven way to significantly reduce costs without compromising construction is to buy a concrete mixture for the foundation in. For more than 10 years, we have been supplying construction mixtures of the highest quality to construction sites in Moscow and the Moscow region.

Foundation concrete is a particularly durable artificial stone material. A hardened mixture of Portland cement, sand, gravel aggregate and water. The cost of concrete for the foundation per 1 cubic meter (1 m3), as well as its quality, depend on the proportions of the ingredients. The more cement it contains, the larger the filler fraction, the better and more expensive the material. For pouring the foundation for a residential, public or industrial building, mixtures of grades no lower than M300 are best suited. Call the number to find out how much it costs to order a concrete solution for the foundation with delivery to the construction site using our company’s own transport. It is more convenient and cheaper than hiring a car yourself.

www.transbeton.ru

Basic requirements when pouring

Before starting work, you should examine the soil and, based on the analysis, decide on the type of foundation. If the construction is done with your own hands, it is recommended to give preference to a strip foundation.

When pouring, certain requirements must be met:

- To increase the service life of a structure, excellent waterproofing is required.

- It is recommended to pour the garage foundation in the warm season, with minimal air humidity.

- To avoid problems with the proportions of the solution components, the initial mixture must be dry.

The foundation is the main component in the construction of any garage. Therefore, it is extremely important to comply with the appropriate GOST standards and proportions. This affects the timing and safety of operation.

What concrete is best to use when pouring a foundation?

The process of mixing concrete for a foundation is not difficult. If the amount of mortar that needs to be prepared is small, then you can mix it without even using certain construction equipment. To do this, you only need a small container in which the solution will be mixed, as well as a stirring device (often a regular drill with changing attachments).

If you need to mix a large amount of concrete solution, then for these purposes it is necessary to prepare a large vessel, which can be used for mixing during cooking.

Very often such a device is an ordinary bayonet or shovel. The advantage of such a shovel is that you can prepare a high-quality concrete mixture without purchasing expensive specialized devices.

The only disadvantage of manually preparing a concrete mixture is rapid fatigue, because it is not so easy to mix a heavy solution with a shovel. Moreover, for high-quality preparation of this mixture, it is necessary to select the appropriate components suitable for the concrete solution.

Concrete mortar is a commercial mortar mixture that acts as a binder among other materials, as well as a major component in some building applications.

The construction concrete mixture consists of four main components, which are arranged in appropriate percentages:

- cement;

- crushed stone;

- sand;

- water.

There are other mixtures that are based on the same admixtures, for example, expanded clay concrete. Expanded clay concrete is a mixture of cement, water, expanded clay and sand. It is not difficult to guess that this mixture is distinguished by the absence of crushed stone in its composition.

In order to calculate the amount of water in a concrete mixture, you need to take into account some parameters of the initial components of concrete:

- Humidity of crushed stone.

- Sand moisture.

- Brand of cement.

- The amount of prepared concrete mixture.

It is worth mentioning in advance that when pouring the foundation with concrete mortar, it is necessary to use a grade of mixture M-300 or M-200.

To prepare a concrete solution, you need to use the following types of components:

- Water.

- Cement.

- Gravel or crushed stone.

- Cement.

- Sand.

If we take everything in 10 kilogram form, then the proportions of these components are as follows:

- you need to take 10 kilograms of cement

- sand - 30 kilograms,

- crushed stones or gravel about 40-60 kilograms.

In order to obtain high-quality concrete grade 300, you need to use approximately half of the total volume of solution used as water. If you adhere to these calculations, you will get a completely high-quality concrete solution for pouring the foundation.

If you couldn’t get the water level right, then in any case you can add it slightly and make the solution a little thinner.

In order to correctly calculate the volume of concrete solution required, you need to know the parameters of the trench for the foundation, as well as the required height of the upward indentation from the ground. It is worth noting that the calculation of a cubic meter of concrete solution must be done separately, by tape.

In other words, if the length of the trench is 10 meters, the height is 1 meter, and the width is 0.5 meters, then with simple mathematical calculations it can be calculated that the volume of the mixture will be approximately 5 cubic meters of concrete.

In addition, for different purposes, the methods of making a concrete mixture are different. For a pile foundation, use a grade of concrete not lower than M-400, and for a conventional columnar foundation, a grade of concrete M-200 will be sufficient.

Composition of concrete mixture for foundation

If the construction of the foundation takes place on a monolithic basis and a type of concrete composition, then for such purposes a special type of concrete mixture is often used, which involves the use of expanded clay or crushed stone.

Crushed stone, as a heat-retaining substance, allows you to make the walls of the house quite warm, and due to the porosity of the material, excellent sound insulation of the walls is ensured. The preparation of a solution with crushed stone components differs both in its composition and structural components.

Their ratios should be approximately the following; for 1 bucket of cement use:

- 3 buckets of crushed stone,

- 2 buckets of sand,

- 2 buckets of water.

If the prepared solution is dry, it may be slightly diluted with water.

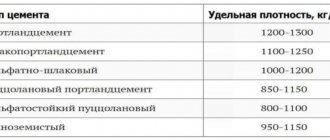

Marking: class and characteristics

As mentioned above, each type of construction work uses its own type and marking of concrete mortar. Today, there are a lot of different ways to produce one or another concrete solution for various construction structures and works, and this point especially concerns the pouring and installation of the foundation of a particular construction project.

Among other things, when talking about concrete mixture, it is worth mentioning its classification.

Concrete mortars are divided into grades of a certain qualitative ratio of all building components that are included in the mortar.

Thus, the following markings of concrete solutions are subdivided:

- Concrete grade M-200;

- Concrete grade M-300;

- Concrete grade M-350;

- Concrete grade M-400;

- Concrete grade M-500.

It is worth noting that the classification of concrete directly depends on the brand of cement and its proportion in the solution.