How to make a concrete blind area - step-by-step instructions, from preparing the solution to pouring concrete

A reliable, time-tested way to protect the foundation from the effects of surface water is to install a concrete blind area around the house.

The undoubted advantage of a concrete blind area is its low cost and ease of manufacture. 100% protection from moisture, which is provided by a concrete blind area with a complete coating, cannot be guaranteed by any material (without arranging a multi-tiered “pie”). The condition of the foundation directly affects the position of the entire structure. Therefore, the foundation needs major protection.

This is precisely the main task of the blind area - protecting the foundation and base of the house. In addition to the barrier, it performs several other functions. For example, it allows you to organize more convenient movement along the blind area and gives the building a finished appearance.

Do-it-yourself concrete blind area around the house

Let's take a step-by-step look at how to properly make a blind area around a concrete house with your own hands. We propose to divide all the stages of arrangement into theoretical and applied.

- In the first part, we will look at what you need to know and prepare before getting started.

- In the second - how to prepare the bed and properly pour the concrete blind area.

Types of blind area waterproofing

The type of blind area waterproofing should be selected based on the design features of the building. So if it is located at the level of the base, then the waterproofing should also be at the same level. If the blind area has a slope, then the membrane is laid in a cascade manner, with protrusions. If the house has a basement, then waterproofing the blind area with rolled materials is carried out in 2 stages - one layer at the basement level and the second at the plinth level.

Clay

The most budget option for waterproofing a blind area. The process begins by removing the top layer of soil and then filling the area with clay, compacting it and sloping it away from the house. The top is covered with crushed stone.

Roll

The installation of a blind area with geotextiles and waterproofing with rolled materials is most often relevant for a building with a basement. First, the clay is compacted, then rolled materials coated with mastic are installed overlapping the walls. All this is rolled with a roller and covered with soil.

Painting room

This type of blind area waterproofing is quite popular. To do this, the concrete surface is treated with a primer and, after drying, with bitumen mastic. The thickness of each layer should be no more than 2 mm, so the waterproofing process is carried out in several stages.

Concrete

Waterproofing under a concrete blind area is done as follows:

- a ditch is being dug;

formwork is installed to form a slope away from the house;

concrete reinforced with mesh is poured;

After drying, the tile covering is laid.

With insulation

Waterproofing the blind area with insulation allows you to retain heat in the basement, increases the service life of the building and reduces the depth of soil freezing. Relevant only for buildings with a ground floor or basement. Insulation work can be carried out using the following materials:

- extruded polystyrene foam – has water-repellent properties and reliably protects against moisture;

polyurethane foam is a frost-resistant material with excellent thermal insulation;

polystyrene foam – has low water absorption and is resistant to mold and temperature.

Properly done waterproofing of a concrete blind area will increase the strength of the structure and give the architectural structure a finished look. Such important work must be carried out by an experienced specialist. If you have decided to do everything yourself, then it would be useful to use the following tips:

- at the stage of creating a blind area, moisture-proof components must be added to the concrete;

the blind area without waterproofing or with it is done immediately after the construction of the house is completed;

maintain the same slope along the entire perimeter;

if the blind area is made with insulation, then the material for this should be taken with high density.

Requirements for the blind area and rules for its construction

- The width of the concrete blind area

, according to SNiP 2.02.01-83, should be 200 mm. more than the overhang of roofing material. If there is a drain, its parameters are also taken into account. The same SNiP regulates the width depending on the type of soil. The traditional (optimal) width of the blind area can be considered 1 meter. This width provides freedom of movement and acts as a path around the house;

- length

. Since the foundation needs protection along the entire perimeter of the house, it is logical that the blind area should also completely surround the building. The only exception may be the installation site of a concrete porch;

- depth or level of penetration of the blind area

should not exceed half of the calculated depth of soil freezing characteristic of a particular region. This parameter can be viewed in the table or you can request information from the architecture department at the location of the object.The ability of a concrete blind area to move with the soil gives it its functions. Otherwise, its role will be reduced to draining water, which is not enough to protect the foundation.

Note. The depth of freezing is affected by the presence of communications in the ground.

- thickness of the concrete blind area

. The minimum thickness of the surface layer is 70-100 mm. If increased operational load is planned, for example, vehicle movement, the thickness can reach up to 150 mm;

- slope of the blind area

. SNiP III-10-75 recommends what the slope should be - from 10 to 100 mm per 1 meter of width (i.e. 1-10%). The angle of inclination is directed in the direction opposite to the foundation of the house. Slope requirements depend on regional rainfall levels and soil type. In practice, the slope is taken to be 20-30 mm per 1 m (2-3 degrees). If you do more, then in case of icing, it will be difficult to move along such a blind area;

- border

_ In the case of a blind area, the border is a decorative element and the decision to install it is made based on the preferences of the home owner and his financial capabilities. However, if bushes are planted in the immediate vicinity of the blind area - “root aggressors” (raspberries, blackberries) or trees that have a powerful superficial root system (poplar, sycamore), then installing a limiter is mandatory;

- plinth height

. The standards establish a minimum plinth height of 500 mm for a hard type blind area and a minimum of 300 mm for a soft type. Let us remind you that the blind area around a concrete house is of the rigid type;

- height of the blind area from ground level

. It is desirable that the blind area be 50 mm higher above the ground level. This recommendation is due to the fact that water should not accumulate on the edge of the blind area and turn into puddles. In winter, this is fraught with freezing and, accordingly, destruction of the structure.

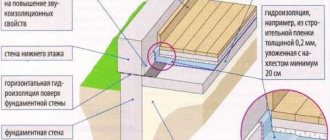

- The design of the concrete blind area

has a specific design diagram, which is shown in the drawing below.

Armed with the above data, you can proceed directly to the installation of a concrete foundation blind area.

Features of blind area waterproofing

When waterproofing a blind area, you must consider the following recommendations:

- When making a protective “tape” around a building, it is best to use solutions that include waterproofing substances.

- Rolled materials can only be used if the differences in base height do not exceed 2 mm.

- If it often rains heavily in your region, then after constructing the foundation, dig a gutter around its perimeter that will drain the water.

- It is not recommended to use scrap as a filler for the base, since this material will contract and expand with temperature changes.

- The depth of the blind area may vary depending on the groundwater level, the amount of precipitation and climatic conditions, and the presence of sewage systems.

There is also a painting waterproofing of the blind area, which is performed by applying bitumen mastic.

How to make a concrete blind area around a house

- concrete for blind area. Grade is an indicator of the quality of concrete; its value ranges from 100 to 1000. It indicates the proportion of cement content in concrete. The concrete class ranges from B3.5 to B8 and indicates the strength of concrete. Thus, class B 15 indicates that a concrete cube measuring 15x15x15 cm is capable of withstanding a pressure of 15 MPa.

What brand of concrete is needed for the blind area? To prepare the solution, use cement grade M 200 (class B15).

The parameters (properties) of concrete depending on the brand are shown in the table.

- sand. Which one do you need? River or quarry sand is suitable for making the bottom layer of the pillow. The main thing is that it does not contain large impurities that can damage geotextiles;

- crushed stone (gravel). Crushed stone of fraction 10-20 is suitable for the blind area;

- clay or geotexil for hydraulic locking. In practice, this layer is absent in the base cushion, because concrete drains water well;

- cement for ironing.

Composition of concrete mortar for blind area

If it is not possible to use ready-made concrete, you can mix it yourself. To do this you need to prepare:

- cement for blind area. You should know that the grade of concrete is determined by the grade of cement and its specific gravity as a percentage of the components of the solution. For the blind area, cement M400 Portland cement is used. The cement must be fresh; with each month of storage it loses 5% of its properties. It’s easy to check the freshness; just squeeze a little cement in your fist; if it shrinks into a lump, its shelf life is running out; if it crumbles freely, you can work with it;

- sand. To prepare concrete, you need to take concrete that has been sifted and washed to remove impurities and soil;

- crushed stone It is advisable to use crushed stone of a fraction of 5-10 mm. At the same time, crushed stone is better than, for example, small pebbles;

- water. Should be at room temperature;

- additives. They are needed to give concrete frost-resistant properties. Liquid glass is often used as an additive.

How to make a concrete blind area around a house?

The longevity of a building depends on the condition of the foundation, the health of which is determined by the reliable and efficient removal of surface water from the house at all times. This task is performed by the blind area, which primarily has a protective function. One of the most common and accessible is the technology of arranging a concrete blind area around a building. Its correct design, created with your own hands, will effectively perform its functions for many years.

The cost of waterproofing a blind area

The cost of waterproofing your blind area depends on several factors:

- total area of the blind area;

waterproofing technology;

the need for preparatory and related work;

type of material chosen for waterproofing;

deadlines for completing the work.

The table below shows the basic prices for the service; an accurate calculation can be made by a specialist after inspecting the property or a personal meeting with the client. The estimate will be based on the type of waterproofing chosen for the blind area of the house.

What does it represent?

The blind area is an external basement waterproof concrete structure in the form of a continuous path along the perimeter of the building, sloping from the wall towards the surrounding topography of the local area. Its arrangement involves a tight but movable connection to the base of the house.

The structure is a layered “pie” consisting of materials that together keep the foundation dry. The basis of such protection is in proportion: a compacted, even underlying layer of sand (crushed stone, clay), waterproofing and a coating - concrete, which ensures the waterproofness of the structure.

Waterproofing materials

When organizing waterproofing near the walls of a house, they use various

materials.

Any blind area resembles a layer cake

, where several layers alternate.

Typically, to ensure waterproofing

properties, the following are used:

- Rolled materials

, for example, roofing felt, hydroglass insulation.

They are cut into pieces and rolled out with an overlap along the entire perimeter

of the trench; - Tar

, bitumen mastic are materials for gluing layers, as well as for coating the foundation; - Inexpensive rolled materials: geotextiles

,

rubemast

,

polypropylene

. Most often they are used to organize roofs, but they can also be laid in a blind area; - Solid materials

: concrete, asphalt, hydraulic cement, etc.; - Protective compounds

absorbed into concrete. They penetrate into its pores and create a crystal lattice that does not allow moisture to pass through; - Polymer compositions

suitable for waterproofing purposes.

When using joint sealing products, you must first

clean the surface from dirt.

Functions performed

A properly equipped blind area ensures the longevity of the structure, preventing the destruction of the foundation and structures of the house by moisture from precipitation and melt water. A blind area without concrete, created with your own hands, is a temporary measure that does not solve the entire complex of problems of such a design.

The main function of a proper blind area is to drain and transport water a sufficient distance from the foundation towards the lowest place on the site or into a storm drain.

In addition to the function of a horizontal hydrobarrier, the blind area (especially insulated) reduces the freezing of the soil around the house, which reduces the likelihood of it swelling (rising), and also reduces the thermal conductivity of the building. A blind area without concrete does not prevent periodic moisture of the soil close to the foundation and, as a result, the harmful effects that hard plant roots can cause to it. The protective device also gives the building an aesthetically complete appearance and can be used as a pedestrian path.

Requirements for the blind area and design rules

The encircling protective structure must have the same width, the value of which is 20–30 cm greater than the overhang of the roof eaves beyond the wall of the building. It is generally accepted that it is about 1 m (or more on subsiding soils). The blind area is buried to no more than half the depth of soil freezing in the area. The thickness of the concrete coating is selected within the range of 7 - 10 cm (up to 15 cm if used as a path).

The recommended slope of the coating is 92 - 94 degrees relative to the wall of the building (or 10 - 100 mm per 1 meter of blind area width). The height of the base above the blind area at the junction of the structure is set to 50 cm. Its outer lower edge should be raised approximately 50 mm above ground level, which prevents the accumulation of water at the edge. The technology for creating a structure assumes the possibility of its integral movement following soil deformations relative to the foundation, which provides a wall expansion joint.

What is it for?

All blind areas for a private house are two-layer structures. The lower part of the structure consists of gravel or sand. The material for the top layer is chosen by the owner himself, based on his preferences. The only requirement that is placed on it is to be waterproof and durable.

High-quality blind area in a private house is part of the general measures that are included in the drainage and waterproofing system.

We list the main functions of the protective structure:

- It prevents water from the atmosphere from penetrating under the foundation of the building: once on the blind area, it flows into the drainage system;

- An insulated structure does not allow the soil underneath to freeze, so the effects of frost heaving are eliminated;

- It looks like a decorative element: if its decoration is correctly combined with the appearance of the walls and base, then the house takes on a harmonious appearance.

You may be interested in: All stages in the design and construction of a canopy in the courtyard of a private house

The blind area is a necessary element of any foundation. The exception is pile and pile-screw foundations. In these cases, it is a decorative element.

How to make a blind area?

Markings are made on the area, the fertile layer of soil is removed. An underlying layer of sand (clay) is laid. Geotextiles (for example, roofing felt) are laid. The formwork is formed taking into account expansion joints. The area filled with concrete is reinforced. Concrete for the blind area is prepared in the correct proportion and poured into the formwork. The coating surface is drawn out with the selected slope along the edge of the formwork and leveled. The concrete is given time to dry.

Preparation of tools and materials

For excavation work you will need shovels, a pick, twine, tape measure, rammer, and pegs. The required volume of geotextile (waterproof film) for the water seal should be calculated. The required quantity and proportions of components for mixing concrete (washed sand, water, gravel, crushed stone of fractions 5 - 10 mm, cement) or a ready-mixed concrete (for example, grade M400 and higher) are required. Tools also include a mixer (container) for forming the solution, shovels, buckets, carts (stretchers), and a measuring bucket. The laying of the underlying layer must be provided with sufficient sand (clay).

The formwork is formed from boards, but a hacksaw, level, nails, and hammer are also useful. Reinforcement is performed with steel mesh (steel wire), which should be delivered. You will need a welding machine and a tool for cutting pieces of reinforcement. A long rule, trowel, and spatulas will help in laying and leveling concrete. The construction of seams will require polyurethane sealant.

A trench is marked around the house with pegs and string. The level at which the blind area adjoins the plinth is marked with beacons in 1.5 m increments. A layer of fertile soil is removed around the building, taking into account the layout of the surrounding surface. The bottom of the trench is compacted and leveled with the already formed slope (herbicides can be added). The depth of the passage can be 500 mm (on heaving soils).

Creation and compaction of a sand cushion

The bottom of the trench is lined with sand, the surface of which is also profiled with a slope. The material is abundantly moistened and compacted. The operation should be repeated at least twice. The thickness of the layer can be up to 20 cm. Its surface is carefully leveled.

Waterproofing

Its device involves laying two layers of waterproofing (for example, roofing felt) on a sand substrate, which are slightly folded onto the wall to create an expansion joint. At the joints the material is overlapped. Next, the geotextile is covered with a thinner layer of sand, and then gravel (about 10 cm thick) with a slope of the top layer and compacted. It is advisable to place a drainage system close to such a water seal.

Creating formwork

A removable wooden form encloses the concrete pouring area. It is reinforced with strong pegs from the outside. The form provides for transverse expansion joints (every 2 - 2.5 m), which are installed, including diagonally, at the corners of the formwork. Their tightness is formed by wooden blocks placed on edge (butyl rubber tapes), impregnated with waste oil and coated with bitumen.

How to protect the blind area from destruction?

The width and density of wall expansion joints and expansion joints filled with waterproofing should be controlled, and they should be repaired in a timely manner. For the latter, it is better to use vinyl tapes up to 15 mm thick rather than wood. On heaving soils, the blind area is not connected to the base of the house, and a storm drain and drainage system are created around the building, the structure of which effectively drains water into the external system.

The tightness of the concrete surface is increased by treating it with a deep penetration primer, a water repellent, a solution of liquid glass and cement. Additionally, the blind area around the building is decorated with stone, tiles (paving, clinker, etc.), and pebbles. Concrete acts as a solution.

Repair of concrete blind area

Most often, the installation of an expansion joint fails, which over time loses its tightness due to expansion. A common reason is a broken technology for forming the correct concrete solution and temperature and humidity conditions for strength development. A slight increase is “treated” with sealants and foam fillers. The wide gap is widened and filled with sand-cement mortar with fine crushed stone, maintaining the isolation of the blind area from the base.

Then the dry surface is primed. The same is done with cracks in the surface of sections of the blind area: small ones are spilled with liquid sand-cement mortar, large ones are opened deeper in the form of a cone and filled with bitumen mastic, covered with sand. Significant damage (splits) are concreted with a new mixture in the mode of long-term post-wetting and covering with film.

Is the blind area crumbling? Use modern concrete impregnations!

In order to protect the foundation of the house from the penetration of atmospheric moisture, a blind area must be made around each building. Various materials are used for its manufacture, but concrete is most often chosen for this purpose.

Concrete, being an artificial stone, has sufficient strength to last for several decades. But anyone, even a not very experienced builder, knows that concrete structures located in the open air are quickly covered with cracks, sinkholes and other defects. The culprit of these processes is water - the most terrible enemy of concrete structures. Penetrating into the pores of concrete, it freezes and contributes to the formation of micro-fractures in the material, which subsequently turn into serious defects.

And, if water quickly drains from concrete walls, then the blind area, which has a slight slope and is almost horizontal, is exposed to moisture much longer and therefore needs protection.

It is advisable to carry out protective measures immediately after installing the blind area, but even if quite a lot of time has passed and it has begun to crumble, it is not too late to use the achievements of modern science and restore its integrity and functionality. For this purpose, special substances called “concrete impregnations” are used.

Order waterproofing of the blind area

You can order waterproofing of the blind area using rolled materials or any other materials by phone or through the online form on our website. We guarantee a prompt response to your request and high-quality performance of work of any complexity.

During construction it is necessary

will take care of the safety of the foundation and basement.

Typically, any construction begins with studying the properties

of the soil and moisture levels.

But after its completion, if the blind area is not implemented, rainwater will begin to flow down the walls of the house, and the level

ground soil and the house will begin to sag, possibly flooding the basement.

It is to protect the structure that they organize not just a blind area of the house, but use special

waterproofing materials.

Impregnations for concrete, their types and purpose

There are two types of means to improve the properties of concrete. These are additives and impregnations .

But, if additives are used to introduce into the concrete mixture during its preparation, then impregnations are applied after the concrete has acquired the necessary strength. They are used not only to protect new concrete structures, but also to restore the properties of those in service.

All impregnations for concrete are divided into two large types:

- made on the basis of inorganic compounds;

- made on the basis of organic compounds.

The effect of inorganic mixtures on concrete is based on their ability to react with soluble external molecular compounds of the structure, turning them inert to other reactions. Thus, the top layer of concrete becomes immune to external factors.

Organic impregnations are liquid mixtures based on acrylic, polyurethane, and epoxy resins. When in contact with concrete, they fill all, even the smallest, pores of the outer layer of concrete, providing it with the ability to resist aggressive environmental factors and repel water. They give the material additional strength and prevent the formation of cement dust.

The following classification of impregnations for concrete is based on their division according to purpose:

- Colored impregnations - used at the final stage of processing the concrete surface. If you want the blind area to fit perfectly into the overall exterior of the building, then you should think about giving it a color that is in harmony with the appearance of the house. In previous years, this was done by painting the blind area with paints and varnishes, but such a coating is extremely short-lived and requires constant restoration. It turned out to be much more effective to use colored impregnating compounds, which, penetrating 2–3 mm into the thickness of the blind area, create a durable colored layer. But color impregnation alone is not enough; you will also have to cover the blind area with a layer of a water-repellent mixture.

- Dust-removing impregnations - mainly used for treating dust-producing concrete floors with intensive use. It is not necessary to cover the blind area with such a composition, because it should not be subjected to large mechanical loads. But if you consider that the same impregnation will give it moisture resistance, then you can achieve two goals in one application.

- Protective impregnations - their main task is to give the top layer of concrete water-repellent properties. They fill all the smallest pores, making the concrete almost hydrophobic. Their use helps prevent the occurrence of cracks, chips and efflorescence of the blind area surface. After their use, concrete becomes immune to the effects of fungus, mold, harmful substances and UV radiation. Thus, these mixtures are an almost universal protective agent, which cannot but affect their cost.

- Strengthening impregnations - when exposed to them, the top layer of concrete is subject to modification, increasing its strength. Substances penetrate concrete to a depth of 5 mm.

Rules for using impregnations

Better results when using impregnating compounds can be achieved if you treat a new concrete surface. But this method is also suitable for old structures. The only condition for its use is the need to repair the surface of the structure in use:

- it must be cleaned of dirt and dust;

- cracks and chips need to be repaired;

- It is advisable to dry grind the concrete using special grinding machines (if possible).

There is no point in applying impregnation to an uneven, flaky surface. New structures are treated no earlier than 15 days after they are poured.

The remaining rules are the same for both new and old blind areas:

- The impregnating composition must be applied at temperatures from +5 to +40 degrees. Carrying out work outside this temperature range is fraught with deterioration in the properties of both the impregnation and the treated surface.

- Impregnation must be applied to a dry surface of the blind area; work should not be carried out during fog or rain.

- The blind area should be treated using personal protective equipment for the skin, eyes and respiratory system.

- Impregnation is applied in several layers, and a certain time must pass between their application. Typically, the second layer of impregnation is applied approximately 1 hour after the first, when the surface becomes sticky, and the third - 2 hours after the second. But these are general recommendations; the instructions for each composition contain more specific instructions. The time for complete drying of the impregnation is approximately 12 - 14 hours.

- To apply impregnations, you need to use brushes and rollers made from materials that are resistant to solvents.

Waterproofing materials

When choosing the type of waterproofing for the blind area around the house, the material for the work must take into account the design features of the element. Sealing of the plane can be achieved by using:

- Bitumen mastics. They are optimally suited for creating a protective surface on the foundation of a building, and are used for pouring bulk blind areas.

- Roll materials. The film for waterproofing the blind area must be applied when installing it on the wall. It is recommended to combine rolled materials with the application of mastic to the surface to enhance the tightness of the coating.

- Hydrocement (asphalt concrete). Solid slabs of the blind area will create a reliable water barrier against water flows.

- Penetrating compounds (polymers). They are used for surfaces with a porous structure, providing deep impregnation with protective compounds. They are resistant to ultraviolet radiation and sudden temperature changes. Vapor permeability properties protect the surfaces of the material from the formation of mold and mildew.

The process of working with bituminous materials requires special care. The composition should be heated in a deep cauldron, avoiding liquid getting into the fire while wearing special protective clothing. Personal and fire safety rules must absolutely not be ignored. Initially, a low grade of bitumen is melted, completing the process with a higher grade. Violation of the rules will lead to strong foaming.

Painting options for liquid waterproofing are distinguished by the availability of material and ease of installation. The primer layer can be made using bitumen mastic. Next, a polymer, bitumen, or mixed type of composition is applied. If necessary, it is recommended to level and clean the surface to ensure the required degree of surface adhesion.

Treatment involves applying 2-3 layers of paint waterproofing. After the work is completed, the surface is checked for defects. Cracks and areas of swelling of the layer are cleaned and re-treated with the composition.

It is advisable to waterproof the blind area with rolled materials for soft-type construction options. The optimal coating is polyvinyl chloride films. The area where the foundation adjoins the plinth can be treated using bitumen or polymer materials.

Ironing. What is this? What is it for?

The ironing process completes the arrangement of the concrete blind area. This procedure is performed to strengthen the surface. That is, to make it strong and solid. And also in order to increase its waterproofing. After completing this activity, the water easily moves away from the walls of the house. Concrete is a durable material, but it also needs additional protection from moisture.

If water, precipitation or mechanical stress influence the blind area, the structure may collapse. In this case, the material will begin to crumble, break, separate into layers, and peel off. Atmospheric precipitation - strong wind, sun rays, rain. They negatively affect the building.

Changes in weather also have a negative impact on the design. For example, when after a hot sunny day cold weather sets in with continuous rain. These factors further destroy the blind area.

Despite the fact that the name of the process is “Ironization of the blind area,” iron is not involved in the procedure. Ironing is performed with an original composition - SPEKTRIN, Lithurin, PENTRA, etc.

Such cements may contain:

- Hard mineral corundum;

- Liquid glass;

- Granite and quartz fillers;

- Sodium aluminate.

Each of these fillers affects the cement and adds its own properties to the ironing composition.

During this procedure, cement should be applied to the wet concrete surface after pouring in an even, thin layer and leveled. It should take up to two hours after the initial concrete pouring. By following these recommendations, strong adhesion of concrete to cement is guaranteed.

Ironing is also done using the “wet method” - 8-10 hours after pouring the concrete. The desired type of composition, as well as important components, are mixed with water and applied in an even layer. Preferably in two layers! This creates a film coating.

Types of waterproofing

When creating a waterproofing area around the perimeter of the entire house, they use different

materials.

The type of

depends on the number of layers and materials .

types

are usually organized :

- Simple bulk type

. Suitable for houses with organized water drainage from the roof, as well as in climates with rare precipitation; - Bulk

with

an additional

waterproofing layer.

A little more difficult

to install, more suitable for houses with basements; - : easy

to install and

durable

protection even from the heaviest rain showers; - Prefabricated blind area

from ready-made slabs.

The characteristics are similar to concrete, but it looks more aesthetically pleasing

.

When creating a blind area it is necessary

remember that it frames the entire house, so it must

be consistent

in style with the decoration of the external facades and complement it.

Often or others similar

Attention!

When choosing the type of blind area,

you need

to focus on the ground floor and their position relative to the ground level.

The blind area is raised and bent

onto the wall if the ground floor

is above

ground level.

Ironing methods

Ironing methods are divided into three types:

- Dry method;

- Wet method;

- Polymer tile method.

Ironing a blind area with your own hands using any of the above methods does not cause any difficulty. The article outlines tips for creating a shallow foundation, installing waterproofing and insulating the blind area.

Dry ironing

Dry ironing is used when little time has passed since cementing the blind area (literally an hour, maximum two). The blind area should still be a little damp, which will create favorable conditions for successful ironing. To do this you need:

- Carefully and evenly “spray” cement over the surface of the blind area in a layer of 2 millimeters. To spread the cement this way, you may need a sieve. The sieve is lightly tapped, which leads to a uniform spread of cement over the blind area.

- We take a hand grater and the whole work is finally leveled.

- We wait a little for the cement to become stronger: the surface will adhere to the dry cement mixture, forming a strong material.

Wet ironing

Wet ironing involves the use of liquid - liquid cement. Hence the name of the method. It is recommended to mix the solution in a one to one ratio (sand to cement). You will also need lime paste in an amount of one to ten of the total mass of cement in the solution.

The prepared solution, from all of the above, is spread with light movements over the entire surface of the blind area. It should be noted that, in contrast to the dry method, wet ironing can be carried out only after two weeks from the completion of cementation, since only after this amount of time the blind area can be finally stabilized. But if you start earlier, the structure will not hold up and will crack.

Polymer ironing

Using polymer tiles and polyurethane, you can do everything that is described in the dry method. Concrete impregnation can be from different manufacturers. The most popular brands: Lithurin, SPEKTRIN, PENTRA. They can be found in the relevant store.

As already noted, everything needs to be done as with dry ironing, but it is better to use a metal grater - it is more convenient. This method is considered the highest quality, it is universal: it can be used at any time of the year, without taking into account sudden drops or increases in temperature.