Vibration of concrete mixture as a way to ensure uniformity and density

Vibration of the concrete mixture (compaction) helps ensure density and uniformity of the composition. This is very important, since the prepared and transported mixture is loose - the filler in it is non-uniformly distributed, and there are also free air bubbles in the structure.

How vibration occurs

Vibrating concrete is a popular operation in monolithic masonry. It involves liquefaction of the mixture due to vibrations of the aggregate particles inside. Concrete, which has good mobility after vibration, easily fills all the corners of the formwork and the areas between the reinforcement rods.

Vibrations of the mixture are provided by different types of vibrators:

- The internal ones are immersed in concrete and transmit vibrations through the body;

- Surface - installed on top of concrete and vibration is transmitted through the working platform;

- External - fixed to the formwork.

Each of the designs has its own zone of efficiency - surface vibrators can work the mixture up to 300 mm, internal vibrators up to 600 mm, and external vibrators up to 400 mm.

Technical nuances

Vibration of concrete can be used to compact mixtures with mobility in the range of 60-80 mm. If you vibrate more rolling stock, they will separate.

It is very important to choose the right time for concrete vibration - surface vibrators can work up to 1 minute, deep vibrators - about 30 seconds, and external

– from 1 to 1.5 minutes. There are certain signs by which you can visually determine the end time of the process. Thus, vibration should be stopped if the mixture has stopped settling and has acquired a homogeneous appearance. It also stops if the surface becomes horizontal or cement laitance appears on the concrete.

The process of vibrating the mixture requires rearranging equipment over the entire prepared surface. If an internal vibrator is used in the work, then it is moved to a distance equal to 1.5 radii of action from the previous point. When working layer-by-layer, the tool is immersed into the underlying layer by 50-80 mm so that the existing joint between the layers is completely worked out - this ensures the solidity of the concrete structure. If a surface vibrator is used, then it is rearranged so that the working surface overlaps 100 mm of the adjacent area just worked.

Source: https://betonkharkov.com.ua/news/vibrirovanie-betonnoy-smesi-osobennosti-protsessa

Organization of work

The main task when concreting the foundation of a residential building is competent planning of work, scheduling the arrival of vehicles with concrete mortar and the distribution of workers on the site.

The main task when concreting the foundation of a residential building is competent planning of work, scheduling the arrival of vehicles with concrete mortar and the distribution of workers on the site.

For example, for large volumes of work, it is recommended to use concrete pumps with an established unloading scheme - they drive up one by one to the hose, and there is no need to strengthen the construction site for vehicles in advance.

Three people are expected for each concrete mixer truck: two take the solution, and the third compacts the concrete mixture with a vibrator.

It is also necessary to provide in advance the availability of all the tools necessary for pouring a concrete foundation, since this process does not involve interruptions in work to search for the missing ones. It is also recommended to think about the availability of spare parts for the tool.

If you are pouring a pile foundation, we advise you to pump out the water accumulated in the trenches in advance; to do this, prepare a pump and hoses in advance.

Be sure to use a deep vibrator, because even the most liquid concrete will not be completely compacted, and voids may appear in it when moisture evaporates.

How to vibrate concrete correctly

Vibrating concrete is one of the effective methods of compacting concrete mortar during the period of pouring it into the formwork of structures.

The main characteristics of concrete, such as uniformity of structure, strength, durability, are laid down at the stage of concrete work.

One of the technological factors influencing the further operational characteristics of structures is the mandatory vibration of the composition during the formation or construction of a reinforced concrete monolith.

Mechanism of vibration compaction of concrete mixture

Why vibrate concrete? We will try to answer these other questions related to laying concrete in formwork in detail in this article.

Concrete is an artificial material that, at the preparation stage, appears as a composition consisting of binder, coarse or fine aggregate and water.

As a result of chemical reactions between binders (cement) and water, cement stone is formed, filling the free space between sand and crushed stone.

The technology of concrete production and its laying is significantly influenced by the amount of binder components and water, which determine workability.

In addition, physical and mechanical characteristics, such as: strength, frost resistance, water resistance directly depend on the homogeneity of the solution, which in turn depends on the uniform distribution of the mixture components in the structure of the material.

During transportation and subsequent pouring into formwork, a violation of the water-cement ratio of the composition and airing may occur, which significantly affects the quality of the work. Therefore, if you do not vibrate it, air bubbles and residual moisture, which are not removed from the solution by vibration, will contribute to the appearance of cracks during the operation of the structure.

Non-vibrated material

The order of laying mixtures

Vibration of concrete SNiP 3.03.01-87 regulates the procedure and standards for laying mortars.

The main provisions of this document are as follows:

- Before starting work, the reinforcement frame and formwork should be cleaned of rust, dirt, oil stains, etc.

- The compositions must be poured in such a way that stratification of the solution does not occur, which may occur in the case of an abnormal drop height. The optimal delivery height for heavy concrete should be no more than 2.0 m.

- Mortars must be laid in successive horizontal layers in the same direction in all layers.

- When compacting, the thickness of the layer should not exceed 125% of the length of the tool club.

- The compaction coefficient during vibration must have a value not lower than K ³ 0.98.

- Laying each subsequent layer is allowed only after the previous one has completed vibrating, without allowing the previous layer to set (maximum 2 hours).

- If laying in several stages is planned, then the break point of the monolithic structure must be equipped with a working seam perpendicular to the axis of the structure.

- Resumption of work in this area is possible only after the previous layer reaches a strength of 1.5 MPa or higher (approximately 8 hours).

Types and methods of compacting concrete compositions

The vibration compaction process involves the transmission of mechanical vibrations.

In this case, due to vibration, the original structure is destroyed and a transition of the solution into a liquefied, plastic state is observed.

Vibrating concrete

There are different rules and recommendations for proper installation of cement mortar. They improve the quality and durability of concrete structures. When concrete is vibrated, an auxiliary process is carried out, which allows the required fluidity and compaction of the pour to be achieved. Vibration removes air bubbles from the cement, thereby increasing its density and uniformity.

Process Benefits

The compaction process in concrete has a number of advantages:

- Vibration reduces the porosity of concrete stone. As is known, voids in liquid pulp account for 1-2%. If they are not removed, they will fill with air and the cement will lose strength and water resistance. Vibration effects can solve this problem. High-frequency mechanical vibrations with low amplitude increase the mobility of the liquid pulp, which causes the outflow of air bubbles.

- Vibration vibrations make it possible to increase the viscosity of the sand concrete mass and prevent delamination. Thus, the finished concrete stone will be more uniform. In addition, oscillatory movements increase the fluidity of the liquid mass, which allows it to more evenly fill the formwork shape. Vibrating concrete allows you to obtain a ready-made product that is resistant to cracking, mechanical stress, seasonal temperature fluctuations and other negative environmental factors, with an increased service life.

Signs of sufficient compaction of the concrete mass

One of the signs is the absence of bubbles in the concrete mixture.

Compaction work with concrete can be carried out in two ways: manually and mechanically. However, it is difficult to achieve good results with manual compaction. Vibration is also not always possible to obtain the required homogeneity.

On the one hand, the mixture may not be completely compacted, and on the other hand, it may delaminate due to excessive vibration. This can be avoided by achieving sufficient rigidity of the composition and selecting the optimal particle size distribution of the fractions.

These options vary depending on the vibration device selected.

The degree of compaction can be correctly determined using several parameters:

- there is no settling of liquid conglomerate;

- laitance with sand floats to the surface;

- there are no air bubbles;

- After removing the vibrator nozzle, the surface of the conglomerate quickly closes.

Vibration rules

The process of applying oscillatory pulses has clear rules that must be followed in order to achieve a good result.

- It is recommended to immerse the oscillating device to 80% of its length. This allows you to qualitatively mix the lower and upper layers of the conglomerate.

- The entire concrete composition must be subjected to vibration. The area of action of the tool should be located so that the wave from its operation covers the entire solution.

- Contact of the pins with the reinforcement should be avoided. It is recommended to place the vibrator at some distance so that the space around the metal element is not free.

- It is not recommended to insert the vibrator close to the edge, to joints and corners.

- There should be no crater left after removing the mechanism.

Types of vibration equipment

Deep vibrator for compacting concrete mixtures.

The classification of vibration machines consists of three types.

- Surface compression devices transmit vibrations from the top layer of liquid pulp. These include metal vibrating plates, vibrating slats, weights connected to the vibrator. These mechanisms are placed on the surface of the mortar being compacted. Equipment is used at construction sites, during road construction, to compress reinforced concrete structures up to 2 dm thick, but with a large area. Weights are designed for use on moving platforms to compact cement simultaneously from above and below. Among the surface compression tools there are vibrating attachments and vibration smoothing mechanisms. With their help, additional compaction is carried out. To vibrate concrete, attachments and cassette installations are used.

- Depth compactors are completely immersed in the mold. These include vibration exciters. These mechanisms are used on construction sites in the manufacture of massive products. This category of devices includes vibration void formers.

- Volumetric tamper vibrators transmit oscillatory movements to the entire mold containing the solution. This device is called a vibrating plate. Vibrating platforms are divided into several types: with horizontal and vertical vibrations, with moving frames and blocks. Such vibration equipment is intended for compacting a variety of loose and non-cohesive soils, paving slabs, as well as for repair work on the road surface.

Formwork vibrators

Formwork vibrators are usually rigidly attached to the formwork or mold and cause the entire mold to vibrate. Vibrations are transmitted to the concrete through the form. The use of formwork vibrators gives satisfactory results when concreting heavily reinforced parts or small and narrow parts. A formwork vibrator consumes more energy than a deep vibrator, since part of it is absorbed by the formwork. In addition, the formwork or mold must be strong and rigid enough to withstand the effects of vibration.

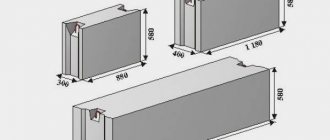

Electric motors with unbalance, pneumatic hammers or electromagnetic pulsators are used as formwork vibrators. A formwork vibrator is used to produce precast concrete elements.

To obtain uniform compaction with external vibrators, it is necessary to lay the concrete mixture in layers no more than a few centimeters thick. Formwork vibrators often cause air pockets to form, especially in the upper part of the layer. It is recommended to compact the top 60 cm of concrete manually or using an internal vibrator, if space allows.

Portable electric and pneumatic hammers are also sometimes used to compact through the formwork by placing them at specific points in the formwork. This method is especially useful when certain areas of the concrete structure are inaccessible to internal vibrators.

One of the types of formwork vibrators are vibrating tables, which have the advantage that they impart the same vibrations to the entire form. They can be either pneumatic or electric driven and are widely used in the manufacture of concrete products. In other types of vibrating tables, concrete is compacted not by an oscillating motion, but by a series of successive blows. This compaction method gives quite satisfactory results.

Compacting concrete by vibration

Source: https://stroy-svoimi-rukami.ru/fundament/beton/64/

In what ways is concrete vibrated?

Concrete is vibrated using construction vibrators, which differ in their design and methods of functioning. Vibration can be transmitted to concrete mortar in three ways:

- surface - the vibrator acts only on the surface of the mixture, spreading vibration inside; it can be used if concrete is poured in layers of no more than 0.3 m;

- external - the vibrator works with the formwork, the waves spread evenly throughout the entire volume, it is important that the formwork meets all the requirements, otherwise vibration can have a destructive effect on it;

- deep - the vibrator is lowered into deep layers of concrete and vibration waves are created by the tip.

What technology is used to compact concrete?

With any vibration, the work associated with compacting the concrete mixture proceeds in the same order. They begin to be made only after complete filling has occurred.

The vibrator must not be used to touch the reinforcement frame of the foundation, otherwise the contact of the reinforcement with the concrete will be destroyed, which will lead to a deterioration in the strength of the structure.

The time of the vibration process depends on the consistency of the concrete solution. If it is viscous, it is vibrated longer until it becomes completely compacted. To compact one area located within the radius of influence of the vibrator, you need to spend from 15 to 40 seconds. You can determine that vibration has been carried out to a sufficient extent by the following signs:

- no further shrinkage;

- absence of bubbles on the surface;

- appearance of laitance.

If the mixture is poorly compacted, then air remains in it, which significantly reduces the strength indicator, but if the impact of the vibrator was too long, then the solution begins to delaminate - all the heavy particles settle down, and the cement laitance rises to the upper layers. Therefore, it is important to correctly calculate the vibration time in each specific case.

The radius of operation of the vibrator depends on how much power it has, this can be seen in the places where air is released. It is recommended to compact concrete sequentially from one area to another.

You can purchase high-quality concrete of various brands from the company RegionStroyBeton . We sell products at competitive prices and deliver them within strictly specified time frames. In order to get detailed advice, you can contact our specialist at the contacts listed on the website, or leave a request.

Source: https://regionstroibeton.ru/stati/vibrirovanie-betona.html

Mobility, consistency of concrete for pouring

Be sure to pay attention to the category of its mobility when ordering a concrete mixture. If you don’t know the details, without prior preparation, the choice may be limited to the question: Do you want thick concrete or liquid concrete? You should know that concrete mixtures according to their mobility class are divided into five categories: from P1 to P5. The most mobile, that is, the most liquid types, are designated categories P4 and P5, they are delivered using a concrete pump, all the rest can only be delivered by a dump truck with a concrete mixer truck.

The mobility of a concrete solution can be increased by adding water to it, maintaining a certain concentration.

Check the mobility of the concrete mixture using a cone. It’s quite simple to create: a steel sheet is rolled into a cone and handles are welded to it for ease of operation. The height of the cone and the hole at its base should be 30 cm, the hole at the top should be 10 cm. Concrete must be poured into the cone and compacted with improvised means. The excess above the cone is cut off, then carefully, using the handles, the cone is removed.

After the cone is removed, the shape of the concrete figure and its deformation are immediately checked. If the form sinks down (loses height) within 1-4 centimeters, this is the lowest category of mobility - P1. From 5 to 9 cm - P2, from 10 to 15 cm - P3, from 16 to 20 cm - P4, if the cone-shaped concrete shape has settled by more than 20 centimeters - this is the highest category of mobility - P5.

Please note that when conducting such an experiment, it is necessary to move away from operating engines and mechanisms that create vibration - in this case, the solution may show higher mobility.

How to vibrate concrete and why you need to do it

Experienced specialists know why vibration of concrete mortar is required and what positive effect it gives. But many newcomers to the construction industry have doubts about the advisability of labor-intensive work. They wonder whether it is necessary to vibrate concrete when pouring foundations, walls, and other structures. You will find answers to these questions in our article.

Why do you need to vibrate concrete?

The concrete solution is poured into a mold to create a foundation in a liquid state. It may seem that it will fill all the voids, forming a monolithic structure. In fact, air bubbles will definitely remain in this mass. They will subsequently become containers for moisture, which will destroy the structure. To prevent this from happening, vibration is used. In the process of creating mechanical vibrations in the solution, air comes to the surface, the porosity of concrete is significantly reduced, and the risk of premature damage is eliminated.

Vibration of concrete provides other important effects:

- improves solution viscosity;

- eliminates pulp delamination;

- increases the fluidity of the mass.

In the process of mechanical action, the adhesion of the components of the solution improves, it becomes more viscous and dense. Vibration does not allow parts of the mass to peel off, ensuring its uniformity throughout the entire volume. During vibrations, the consistency of the concrete liquefies. This allows him to fill the form efficiently and eliminates the appearance of voids.

The main result of such work is a high-quality, reliable structure that will maintain its integrity for many years, regardless of conditions.

By the way, in one of our articles we told you what grade of concrete is needed for the foundation. Check out this article to make the right choice.

Types of vibration of concrete solution

Experts use three options for vibrating the concrete mass. The choice of method depends on the type of structure and the tool used in the work. Compaction of concrete by vibration can be:

- superficial;

- external;

- deep.

In creating a monolithic concrete slab, a surface technique is usually used. The method involves the creation of mechanical vibrations at a depth of up to 30 cm. In order to obtain a high-quality slab of large thickness, layer-by-layer pouring is used with processing of each of them.

It is difficult to vibrate concrete in formwork using the traditional method. In such cases, it is advisable to use the external option. It is not the concrete mass that is subject to vibration, but the walls of the formwork over the entire area. It is important to carry out such work carefully, eliminating the risk of compromising the integrity of the formwork.

The use of powerful vibrators allows for high-quality deep processing of the entire mass of the solution. This method can be used in the creation of any concrete structures and structures.

Vibration procedure

You need to know how to vibrate concrete correctly in order to achieve a good result and provide the mass with the required quality. The general rules for conducting this process apply equally to all methods.

It is important to take into account that when pouring pulp into formwork, a vibrator is not used to distribute and lay the mass. The device is used only after filling has been completed. Do not touch the reinforcement parts with the tip, this will disrupt the adhesion of the solution and the rods. If you decide to buy ready-made concrete, it is advisable that the material be delivered by special transport. Renting a concrete pump will simplify the pouring process.

The time it takes to vibrate depends on the structure of the solution. On average, the area in the vibrator's action zone is processed for about a minute. You can determine the end time of the process by certain criteria:

- bubbles do not come to the surface;

- shrinkage has stopped;

- appearance of laitance.

As soon as the shrinkage of concrete during vibration has stopped, a massive release of air bubbles is not observed, the process must be stopped. Otherwise, the mass may begin to separate. This will negatively affect the strength of the structure.

If you need to buy concrete with delivery in Moscow and the Moscow region, please contact.

Source: https://betonmosobl.ru/nashi-stati/kak-vibrirovat-beton-i-dlya-chego-eto-nuzhno-delat/

| After pouring reinforced concrete structures, such as a foundation, the concrete mixture must be compacted, because its particles are not located in the most optimal way and there are air bubbles between them. Voids in the thickness of concrete do not make it stronger, and the structure of uncompacted concrete itself is more porous and “loose”, and then more susceptible to moisture and more fragile. To increase the strength of concrete, all air bubbles must be removed from it and the concrete mixture must be compacted as much as possible. Vibration is used for this. If you pour sugar into an ordinary three-liter jar so that it takes up the entire volume, and then shake it (that is, create vibration), then the sugar will take up a slightly smaller volume than before - it will become denser. Individual grains of sugar begin to move under the influence of vibration until they occupy all possible voids. Exactly the same process occurs in concrete when vibrating. Methods of vibrating concreteTo compact concrete using vibration, special construction vibrators are used, which differ in design and method of operation. There are three ways to transmit vibration to concrete:

|

Violation of frame and formwork

During the process of pouring the foundation during the construction of a residential building, other problems may arise, one of which is the displacement of individual parts of the formwork or reinforcement.

Displacement and deformation of individual parts of the formwork occurs from improper installation of the mounting reinforcement, but it holds the formwork walls and protects them from swaying to the sides, as well as subsidence downwards. Be careful - the concrete mixture has a very high density and can deform the formwork or reinforcement structure in height, squeezing it out from the bottom up.

Pay special attention to any rust on the reinforcement cage of your structure. Immediately before pouring the foundation, rust must be removed by any possible means, including manual cleaning with a wire brush, grinder, etc., and also treated with special anti-corrosion agents. This question is very important, because with rust-covered reinforcement, the concrete mixture may have poor adhesion to the metal, and voids may appear inside the foundation, and possibly cracks.

Be sure to pay attention to the correct installation of formwork when pouring a concrete foundation. Since the installation of various types of formwork is carried out according to the same principle, namely with the help of fasteners, it is this that must be checked before pouring the concrete solution. The fasteners must be installed in such a way that the formwork does not come apart during operation.

Check the surface roughness of the formwork, the presence of nails and protruding fasteners: irregularities may set when the concrete mixture hardens, which will subsequently make dismantling the formwork difficult.

It is also recommended to cover the entire surface area of reusable formwork with specialized products based on natural or synthetic oils; these products will help with stripping at the end of the work, that is, dismantling parts of the reusable formwork. Some experts also use various films, but this is most often unnecessary, and the concrete can tear the film with crushed stone during pouring.

When using disposable formwork, for example, from boards, no additional means other than spraying with water are required.