Scope of application

Repair and restoration work on concrete. Specially designed for repairing parts of building structures that have damage caused by metal corrosion. In addition, for the quick repair of individual, small-sized damage to the concrete surface and restoration of broken edges. Additionally, with the help of the product it is possible to produce accurate, lightweight and high-strength figured copies: balusters, cornices and other profile surfaces, such as reliefs. The product Funcosil Epoxi-Saniermörtel is also used for repair and restoration work on natural stone.

Step-by-step instructions for pouring methyl methacrylic and cement-acrylic floors

The installation processes for methyl methacrylic and cement-acrylic self-leveling floors in a garage are similar and consist of the following steps.

- Thorough preparation of the surface for laying the mixture, including leveling and removing all contaminants.

- Preparation of mortar for filling the floor. In this case, the required additional components, such as a color additive, can be added to the mixture.

- Applying the mixture to the base surface. Pouring should be done as quickly as possible, since the MMA solution hardens quite quickly. In the case of a large garage, it is better to divide the space for filling into sectors in order to level the coating if necessary.

- The floor surface covered with methyl methacrylic mixture is immediately leveled to avoid the formation of bulges and depressions.

After completing the application of the solution, the coating is left to dry. The curing time is indicated in the attached manual. The minimum period that passes before the final readiness of different types of self-leveling floors for full operation is seven days. You can walk on the surface of the poured floor no earlier than 24 hours after applying the coating.

The choice of a specific type of floor is made by the garage owner in accordance with his own preferences and financial capabilities. The most important criteria for high-quality installation are thorough preparatory work and ensuring proper conditions, that is, humidity and temperature conditions. Compliance with the technology and the features and nuances specified in the manual for installing a self-leveling floor in a garage ensures not just an aesthetic appearance, but a long-term service life of the floor covering.

Application

Both components of Funcosil Epoxi-Saniermörtel are supplied in adjusted proportions in special packaging. The mixture is carried out according to with Leaflet DBV » Application of reaction resins in concrete structures - part 3.2″ The hardener (component B) is added without residue to the resin (component A). For small quantities (approx. 10 l), use a mixer on the counterflow principle. As a drive, use a drill with a maximum speed of 400 rpm. Mixing time – from 2 minutes. The greater the mass of the components being mixed and/or their viscosity, the slower the mixing process. Poor mixing quality leads to the formation of bubbles and subsidence at the locations of incompletely reacted components. Especially with different viscosities of the components, it is necessary to clean off and mix again until a completely homogeneous mixture is obtained, any under-mixed particles of components remaining on the edges and bottom of the mixing vessel, as well as on the mixing tool. Finally, the finished mixture is poured into another vessel and mixed again. After this, the mixture is ready for use. When mixing, use the appropriate mixers (eg Beba forced-action mixer). Poor mixing leads to the formation of bubbles and contributes to the formation of soft, incompletely reacted areas. The finished solution must be applied to the surface before its pot life expires, compacted and smoothed well. Pre-wet the smoothing tool with solvent V 101, while avoiding the formation of smudges and puddles. If a subsequent application of Ausbesserungsmörtel fein is planned, the surface of Saniermörtel EP 2K must be roughened using stiff brushes. Protect the formwork by covering it with a separating film (for example, polyethylene).

Working with epoxy resin

Hello, friends. Before creating the Solar Ocean series, I had the opportunity to work with different types of epoxy resin. Perhaps the experience I gained will be useful to you.

Selection of material: There are various types of resins, conditionally divided into two groups: technical and decorative. When starting a task, choose the appropriate type of resin. There is no need to fill the tabletop with technical ED-20 or use jewelry grades for boats and modeling. The correct choice of material at the preparatory stage will eliminate many problems during the final processing of the product.

Epoxy resin ED-20 is a cheap and accessible material. The name of the resin indicates the composition (epoxy-diane), the number 20 indicates the content of epoxy groups in the resin molecule. The lower the number, the higher the resistance of the resin to temperature influences, i.e. heat resistance ED-8 > heat resistance ED-16.

ED-20 is the most popular Russian-made resin, most often sold in kits with PEPA hardener (300 grams of resin and 30 grams of hardener). The kit is ready for use (the proportion for the mixture corresponds to the packaging: 10 parts resin / 1 part hardener). The resin is transparent, slightly yellowish, and when a hardener is added, it acquires a rich shade from amber to cinnamon color. The main inconvenience when working with ED-20 is its high viscosity, which prevents the release of air bubbles from the finished mixture. At room temperature, the mixture resembles honey, but when heated, the viscosity of the material decreases significantly, approaching the viscosity of sunflower oil, which allows air bubbles to easily rise to the surface.

You can increase the temperature of the mixture in several ways: 1. Water bath. Place the container with the prepared mixture in a tank of hot water. 2. Heating the mixture in the oven. 3. Warming up the applied layer with a hair dryer or gas burner. 4. Use of an aerosol corrector that dilutes the top layer of the poured mixture (recommended when pouring large volumes of resin to avoid overheating and premature polymerization / rejection of the poured layer).

An increase in the temperature of the poured mixture affects the polymerization process, significantly reducing the lifetime of the mixed composition. If the resin is overheated, the material can not only harden before casting, but also foam, become cloudy, and change color. To save time and money, do a few test pours before starting to work with unfamiliar material.

ED-20 is a technical resin suitable for gluing parts, priming surfaces, and repairs. However, this type of mixture is not intended for work with high (artistic, decorative) quality coatings. When working with ED-20, a number of disadvantages are inevitable: the lack of absolute transparency and color purity of the finished product, the need to purify the mixture from air, and grinding the finished surface.

Before pouring: 1. Place cling film or oilcloth under the mold (the paper or cardboard will be saturated with resin and stain the work surface). 2. Dry the base of the future product well. 3. Degrease (ordinary white spirit or acetone will do) and prime the surface intended for pouring. To do this, carefully coat the top layer with the prepared mixture (primer is especially necessary when pouring a wood base: impregnation of the material eliminates the escape of air that fills the material in microcracks and kinks. 4. When preparing the mixture, mix the components thoroughly. It is best to use two containers: half the time mix the components in one container, then pour and mix in another (when mixing in one container, the original composition will always remain near the walls and bottom.) 5. Add the hardener gradually, in a thin stream, mix the resin carefully, avoiding the penetration of air bubbles into the mixture. Homogeneity of the resin - a prerequisite for a good result, the absence of streaks and waves on the surface of the product.

When installing formwork, be sure to seal all connection lines of the outer perimeter: 1. Plasticine can be used to seal formwork for small products. 2. You can use wax (drop each joint or melt the wax in a metal bowl and coat the seams with a brush). 3. You can use a mounting gun with hot glue. 4. Or silicone sealant - the most reliable method for filling large volumes.

When installing the formwork, do not forget about the separator (a layer that prevents the adhesion of the resin and formwork). The best option is polyethylene (for small-scale work, the formwork can be covered with tape) or wax. Use any option of your choice, selecting a separator for a specific brand of resin or using the most common and cheapest option - technical petroleum jelly. Be sure to check the sealing of the formwork (for example, using a flashlight). The smallest hole will be enough for the resin to leave the mold and end up everywhere. After filling the form, protect the filling from random debris (cover with plywood, canvas, cardboard). Even the smallest dust, lint, hair and pet hair will ruin the workpiece and require sanding.

When using lightweight fillers (such as petals), pour the first layer of resin thinly to secure the individual elements before adding the bulk, otherwise loose parts will rise to the surface of the mixture.

About polymerization: The polymerization process heats the mixture and the resin expands. When the reaction with the hardener is completed, the resin “stands up”, gradually cooling, which causes the compression process to occur. The compression ratio depends on many factors: the resin used, hardener, plasticizers, environmental characteristics and temperature conditions in the working room. When working with multiple layers, add resin to the live mixture (a mixture at the gelatinization stage with the possibility of diffusion of the poured and added composition). If topping up is on a hardened surface, be sure to clean the top layer before adding a new one. If an amine film appears - polymerization products that appear on the surface of the mixture when the resin hardens under conditions of low temperature, high air humidity, exposure to water vapor or carbon dioxide - the film should be removed. Rinse the surface of the product thoroughly with plain water, dry it, and sand it if necessary. During the polymerization process, the mixture releases toxic volatile substances, so it is best to leave the poured mold for a day in a ventilated room with a set temperature of +25 to +30 degrees.

ED-20 has a significant compression ratio; during polymerization of the resin one can observe (depending on the area of the base and the thickness of the poured layer): deformation of the product, rupture of small parts along the connecting seam line, significant bending/delamination of the base. To reduce defects, modify the mixture with a plasticizer, select the optimal type of hardener, dry thoroughly and prime the base of the future product.

During the experiment, a task arose: to fill a wooden surface with ED-20 resin in such a way as to completely avoid curvature of the base, assuming that the compression coefficient is a negligibly small value if the casting technology is followed. Then the cause of deformation may be excess moisture in the material. Once cured, the resin will form a film that is impervious to water, causing the wood to begin to split on the exposed, “soft” side. To test the version, the dried board was covered on one side with a layer of plaster that absorbs moisture, which was then painted with acrylic (as a hydrophobic separator between the plaster and the resin). After a week, the treated board completely retained its original shape. A mixture of ED-20 and PEPA hardener was applied to the acrylic (in a ratio of 10:1, with a layer thickness of 5 mm). After two days, the curvature of the base reached 6 mm per 40 cm in length.

About grinding: Grinding is a necessary step when finishing a product. Some resins do not require finishing, but even a perfect casting requires alignment of the bonding edge created when the resin contacts the formwork. Grinding is performed with an orbital sander (in extreme cases, you can use a drill with a grinding attachment, but carefully monitor the deviation of the axis of rotation). Start sanding with sandpaper with a grit of 600, gradually lowering the grain size: 600 - 1200 - 2500. When using sandpaper, wet the surface of the resin. The resin effectively “washes” the sandpaper, the water removes the removed material and smoothes the surface being treated. After sanding, use a hard foam pad with abrasive ointment; final polishing is done with a soft foam pad with polish. It is not recommended to use felt tips - the fibrous material leaves raised indentations on the surface of the resin.

When working, be sure to follow safety rules: avoid skin contact with the resin, use gloves and a respirator, work in a room with good ventilation. When polishing the product, be sure to protect your respiratory tract: the resin is inert and cannot be eliminated from the body.

About hardeners: There are two types of hardeners. Cold (polymerization occurs at room temperature) and hot (polymerization occurs at temperatures from +50 degrees). Only cold hardeners are discussed below.

PEPA (polyethylene polyamine) is a technical hardener developed in the USSR in the second half of the last century. The hardener has a whole range of disadvantages, however, it is still popular today, primarily due to its extreme availability and low cost.

The main disadvantages of PEPA: 1. Coloring of the resin. PEPA is a rich copper-colored liquid. 2. Low quality of the original product. About 70% of the hardener consists of impurities that do not react and remain in the product. 3. Toxicity. 4. Uneven reaction when interacting with resin. When working with large volumes, the mixture may boil. 5. Not suitable for work in conditions of high humidity / low temperature (minimum temperature: +15 degrees). Advantages: 1. Extremely cheap. 2. Forgiving about precise dosage. 4. High curing ability.

TETA (tetraethylenepentamine) is a hardener that differs from PEPA in better distillation (mass fraction of the active substance is at least 96%) and high requirements for working conditions.

Disadvantages of TETA: 1. Minimum ambient temperature for reaction in the mixture: +25 degrees. At room temperature the mixture will remain sticky (removable by heat treatment). 2. Strict adherence to the technological process, precise adherence to proportions, and very thorough mixing are necessary. 3. Toxicity. 4. Not suitable for work in conditions of high humidity. Advantages: 1. Transparency. The hardener is almost completely colorless. 2. If used successfully, the product will receive high strength and uniformity of composition (compared to PEPA).

Etal-45 is a continuation of the line of amine hardeners, but, unlike PEPA and TETA, Etal-45 has practically no disadvantages.

Advantages: 1. When added to the mixture, it also acts as a plasticizer (the proportion in the mixture is 2:1 / resin: hardener). 2. Non-toxic. 3. Suitable for work in high humidity conditions. 4. Permissible ambient temperature: from -7 to +45 degrees. There is only one drawback: thick, dark brown color.

None of the mentioned hardeners were suitable for the production of Aurelia. The first two are due to their technical profile, the last is due to their coloring properties. After experiments with ED-20, Etal Optic resin was tested.

Resin characteristics: 1. Low viscosity (air will leave the mixture quickly and easily). 2. Transparency. 3. The use of the same hardener (10:4 / resin:hardener) plasticizes the resin well.

This resin was perfect for making “Aurelia”, but to obtain the effect of waves, a different material was required (see “Making sea waves”. Unfortunately, experiments with Etal Optic did not provide such a range of impressions as working with ED-20. The only useful note : when painting resin, pay attention to the density of the resulting mixture and the viscosity of the components, and do not use water-based paints.Epoxy and water do not mix, upon contact the resin loses transparency, becomes cloudy, and acquires a whitish tint.

About organics: When pouring organics (flowers, leaves, buds), be sure to dry / stabilize the material. Water getting into the epoxy resin can completely ruin the job. To stabilize, use wax, spray varnish or glycerin. If using glycerin, mix equal parts glycerin and water, then immerse the flower in the liquid and leave in a cool place for several weeks (depending on the size of the plant). During the stabilization process, the water will evaporate, the glycerin will fill the tissues, and the flowers will retain their elasticity, shape and color.

About silicone: After completing work on the sculptural part, a silicone matrix is removed from the plaster cast. When working with silicone, there is one rule: follow the proportions and mix the mixture thoroughly. If you follow the technology exactly, you cannot spoil the shape.

Before you begin: 1. Select silicone of the correct hardness. The Shore A scale is used to indicate the hardness of silicone products. The scale ranges from 0 to 100, the higher the number, the harder the material. A material hardness of 30 is equivalent to a hard eraser. 2. Prepare your work area. As with epoxy resin, silicone is extremely fluid and requires careful sealing of the formwork. 3. Degrease/dry the master mold. 4. Pour silicone onto the surface with minimal adhesion; if necessary, use release mixtures or materials. 5. The thinner the layer of silicone poured, the longer it will take to complete the reaction. A volumetric fill and a layer of a millimeter can harden within a day of each other. The final reaction time of the mixture is up to 48 hours. 6 Use the material effectively. When pouring complex forms, it is much more profitable to fill the formwork to a certain height, then surround the protruding elements with a new perimeter and add the useful volume of the form.

Making sea waves, coloring resin, working using the Resin Art technique.

Before starting work: To work in the Resin Art technique, you cannot use any resin, even the best, flowable, distilled one. A resin that gives an impeccable result when filling areas or volumetric surfaces with a single color or gradient coloring is not suitable for this work. What is required here is a resin with a certain viscosity, combining, if you like, the fluidity of technical resins and the purity of jewelry mixtures. This feature is necessary for two reasons: - To prevent arbitrary mixing of layers of different colors. — For controlled manipulation of the painted surface. Use brands specifically designed for this technique.

Once again, using resins intended for jewelry making, flooring, or countertops will not guarantee a predictable result. This is a fact that has been repeatedly tested in our own experience with various brands of resins and dyes (from powder pigments and acrylic paints to specialized dyes for epoxy resin).

Workplace: Cover the workspace with film, put on gloves, prepare a hair dryer, containers for mixing resin, and pigment.

Prepare the base: It is not recommended to use canvas or similar material for the base. The base must be rigid, otherwise the material will sag. Cover the back of the base with masking tape. During operation, the resin forms smudges; after the mixture hardens, tape will help you easily clean the material. Formwork is not required when working with this technique. When forming a pattern, the painted plane periodically tilts in the desired direction, the layers move on the surface, any obstacles will only limit the free flow of paint. In addition, the absence of formwork will save the work from forming the outer edge. After the mixture hardens, the surface immediately has a clean, smooth, glossy appearance. Working without sanding is a big plus. Think over the design in advance and prepare the required number of containers for each paint. It’s convenient to do this: mix the total volume of components A / B in one container, then divide the finished mixture into separate containers (try to calculate in advance how much resin will be needed for each color), then color the resin and start pouring.

Process: Having learned to work with the original mixture, you can move on to complex modified compositions that form a whimsical pattern of granular, cellular color zones. To obtain such cells you can use:

Natural Layer Blending: Fill the base color with the bottom layer, then add a thin release layer of clear resin, then add a layer of secondary color on top. Use of modifiers (for example, Resi Blast): The modifier is added both to the finished colored resin before pouring and to the surface of the product with the plane laid out. Can be used when working with the “dirty pouring” technique (mixing colors in one container immediately before pouring). Some modifiers actively interact with the resin, leaving depressions and pits on the product. Adding alcohol to the resin (alcohol purity must be >90%). The technique is used both for “dirty pouring” and when working using the traditional method. Alcohol is added to the mixture of resin and dye, the cells appear gradually as the layers are distributed on the plane. There is no need to add alcohol to each color - dilute the base color to interact with the other colors. After the reaction is completed, no traces, streaks or stains remain on the hard surface, the alcohol completely evaporates. Using Silicone: It is advisable to use pure silicone oil. As a last resort, you can spray silicone spray into a container (not onto the finished mixture), then mix the liquid sediment with the paint. Then proceed as when working with any modifier. Also, to create the effect of depth, you can sequentially paint and pour several layers of resin, giving each level the necessary properties. Finally, in case of accidental marking (for example, you checked the hardness of the layer and left a fingerprint on the surface): simply heat the damaged area, the resin will liquefy and the surface will become smooth again.

The total time spent working on “Aurelia” was two weeks. Taking into account test fills and checking materials - almost two months. The main experience: learn from the mistakes of others (if you read the entire text, that’s what you do). But if you do make a mistake, analyze the situation and remember the lesson. Only perseverance and work lead to success.

Preparing the leveler

Leveler Streamline EP 2321 consists of two components that need to be mixed, adhering to the weight ratio. Add Part A to a clean container, then add the required amount of Part B and mix thoroughly with a low speed mixer.

The speed of work and the quality of the result will depend on the quality of mixing the components.

The prepared mixture is suitable for use for no more than 30 minutes, and its temperature should not be lower than + 10 ºС.

Before carrying out work, carefully calculate the amount of material required, taking into account the speed of work, the thickness of the layer, and the number of workers on the site. It is not recommended to store the prepared mixture in a container for more than 5 minutes.

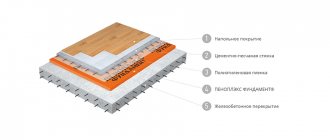

Base requirements

A colorless epoxy composition or leveler is applied to the original concrete base as a leveling screed.

The concrete base must be strong; before carrying out all necessary work, it is necessary to remove dust from the concrete floor.

The coating of the concrete substrate must be free of traces of oil, paint, putty and other materials that reduce adhesion. There should also be no flaking elements on the surface.

If the leveler will be used on a relatively weak base, then it is recommended to treat it with a special strengthening primer.

A cement-sand screed coated twice with a primer will serve as an excellent base for the epoxy composition Streamline EP 2321.

When installing floors on surfaces with high humidity, it is recommended to additionally install high-quality waterproofing.

Polymerization of the leveler proceeds several times faster (depending on the thickness of the applied layer) than the hardening of the cement-sand screed.