Aerated concrete blocks, due to their high technical characteristics, are widely used both in individual construction and in the construction of commercial and industrial buildings. These products are made with minimal variation in geometric parameters: therefore, the masonry seam is very thin. Reinforcement, which must be done every 3-4 rows of masonry using reinforcing mesh, unjustifiably increases the thickness of the masonry joint, which negatively affects the heat-saving properties of the structure. Therefore, reinforcing bars are placed in grooves, for the manufacture of which you will need a wall chaser for aerated concrete.

You cannot do without such a device when arranging internal hidden electrical wiring, as well as when making grooves for pipelines and laying other communication networks (Internet, television cable, wired telephone, etc.).

Types of wall chasers for aerated concrete

Aerated concrete belongs to cellular concrete, its density is 4–5 times less than that of ordinary concrete. Therefore, for its processing and gating, you can use not very powerful tools (and even manual ones with success).

All devices for making grooves are divided into electric and manual. Now on sale you can find a huge variety of different electric wall chasers (single, double, multi-disc, milling) at prices ranging from 4,000 to 40,000 rubles from different manufacturers. Almost any model is suitable for cutting grooves in aerated concrete.

However, given that aerated concrete blocks are quite easy to process, many builders have come to the conclusion that a manual wall chaser for aerated concrete is quite suitable for making grooves. Manufacturers of hand tools: Petrotech, Aeroc, H+H, Remocolor, KSMI. The price for these products is quite affordable and ranges from 450 to 850 rubles. There are two types of furrow machines for working with aerated concrete:

- Hand-held devices designed for making grooves on horizontal surfaces. They have a shorter and curved handle and are designed for cutting grooves for laying reinforcing rods.

- Products designed for cutting grooves on vertical wall surfaces. These devices have a longer and straighter handle.

On a note! The division of manual wall chasers is very arbitrary; everyone chooses their own convenient tool to use.

Both types of manual wall chasers have common advantages:

- low price;

- light weight;

- simplicity of design and reliability in operation;

- minimal dust formation and noise during work;

- durability;

- energy independence (that is, they are not afraid of power outages: and this is very important in suburban construction).

Homemade wall chaser for aerated concrete

Having some plumbing skills, you can make a wall chaser for aerated concrete with your own hands without much difficulty and with little investment.

Manual wall chaser

The simplest device can be made from a piece of ordinary metal fastening perforated tape. Using a hacksaw for metal, we cut a strip 40÷45 cm long, bend it in half, form a scraper at the bend (we choose the configuration and dimensions depending on the desired width of the groove), connect the two free ends together and wrap them with several layers of electrical tape (that is, we get something like a handle), saw off the excess. We get a cheap, but quite practical wall chaser for aerated concrete blocks. Having pressed our device along the aerated concrete several times (usually no more than 4÷5), we get a neat furrow. If desired, you can make a handle, for example, from a wooden block.

Another option for making a manual wall chaser for aerated concrete with your own hands:

- We use a wood crown saw as the cutting element. Bend it using pliers into a triangle shape with rounded corners.

- A piece of water pipe is suitable for the handle. From one end, using a hacksaw, we make a cut with a depth equal to the width of the cutting blade.

- We insert the cutting workpiece into the cut, drill a hole in the pipe and the workpiece and screw a self-tapping screw into it.

On a note! Since it is quite simple to make a wall chaser for making grooves in aerated concrete, everyone can choose the design of the cutting element and the length of the handle independently.

Hidden and exposed wiring

Hidden wiring is an option when wires are hidden in the walls, ceiling and floor. Grooves are made in the walls, cables are laid in them and covered with plaster. Corrugated wiring in floors is filled with concrete screed. On ceilings, corrugated cables are covered with suspended ceilings, plastic panels and other hanging materials.

The main purpose of hidden wiring is visual perception and additional decorative options.

Open wiring is an option when corrugated cables are laid outside the walls in special cable channels. Cables along the floor and ceiling are laid in plinths. In appearance, such wiring does not look very nice, my subjective opinion.

And it is more susceptible to mechanical damage, for example, if it is accidentally hit by moving furniture. The advantage of open wiring is quick replacement and simple repairs.

Using corrugation

Corrugation is an additional cable protection and is used in electrical wiring quite often. But is its use always justified? Let's figure it out. Many electricians insist on the widespread use of corrugation in order to increase the amount of work and the overall cost. But let's approach this issue logically.

Think about it, if you use a good VVGng-Ls cable, which is hidden in an aerated concrete groove and plastered, does it need corrugation? From a fire safety point of view, corrugation is not needed in this case, but it can be justified if the cable is replaced when it is pulled out of the groove with wire. But it is far from certain that this will work out.

Corrugation must be used if part of the cable is laid in a concrete screed.

The use of corrugation is mandatory for open wiring, and especially when using flammable facing materials such as plastic and wood.

Installation of distribution boxes and sockets

Distribution boxes, like sockets, can be recessed into the thickness of aerated concrete, or they can completely protrude on the surface. The recessed version in aerated concrete is more preferable, as it is both more fireproof and more practical.

A large hole in aerated concrete for a socket or distribution box can be made using a screwdriver with a crown. The circles are drilled out and the inside is chopped off with a hammer.

Seal of grooves with wire

Once the cable is securely fastened, you can begin termination. To do this, mix a small amount of gypsum putty. Let me remind you: to prepare the putty solution, add a small amount of the dry mixture to the water and stir thoroughly. You shouldn’t do the opposite - add water to the dry mixture: nothing good will come of it - you’ll only ruin the putty.

Using a small spatula, apply the prepared solution onto the groove with the wire. Apply the solution horizontally, then level it vertically.

We learn to take care of our tools - we wash out the container in which the putty was located and the spatula with which the work was carried out.

Basic Rules

Strict adherence to safety measures, which includes the following rules:

Scheme of correct and incorrect wall scraping

- work can only be carried out with working power tools;

- Before gating, it is necessary to check the treated surfaces for the presence of connected electrical wiring;

- availability of protective devices for the respiratory system, eyes and hands - glasses, respirator and gloves;

- stable support when working at upper levels.

The parameters for laying the grooves require maintaining the following parameters:

- the width and depth of the grooves laid should not exceed 25 mm;

- channels in the walls are laid only in the vertical or horizontal direction;

- the length of one groove should be no more than 3 m;

- You can cut a wall at a distance of at least 150 mm from walls, doors, windows and at least 400 mm from gas pipelines;

- aerated concrete is a fragile material, it is advisable to strengthen it with reinforcement every 2 rows (and in the case of laying large blocks - each row).

Preparing for work:

- Careful design and marking of treated surfaces.

- Isolation of other rooms from dust, which will be released abundantly during work.

- Availability of a specific electrical wiring project in the house.

- Preparing a set of necessary tools and accessories.

After studying the safety measures, the rules for repairs or construction, you can sit down to do the calculations. It is necessary to take into account that you need to purchase aerated concrete 10-15% more than the calculated quantity, taking into account its cutting during laying and possible damage. Before deciding to purchase tools, you need to familiarize yourself with the features of working with aerated concrete.

Aerated concrete can be tapped manually or mechanically.

Shooting brick walls

If we are talking about laying wiring in a house where finishing work has not yet been carried out, then usually grooves are not made on brick walls. A flat cable with conductors of the required cross-section is fixed over the wall, which is then covered with plaster. Usually it has a thickness of at least 3 cm, which is more than enough for laying 3*2.5 or 3*4 cables. Large ones are rarely used anyway.

It’s easier to make fines in brick

If for some reason you are not satisfied with this option or want to lay cables in a corrugated hose, gating the walls for wiring is done in exactly the same way, using the same tools as for concrete. The only difference is that cutting brick is easier and faster.

Types of wall chasers for aerated concrete

Aerated concrete belongs to cellular concrete, its density is 4–5 times less than that of ordinary concrete. Therefore, for its processing and gating, you can use not very powerful tools (and even manual ones with success).

All devices for making grooves are divided into electric and manual. Now on sale you can find a huge variety of different electric wall chasers (single, double, multi-disc, milling) at prices ranging from 4,000 to 40,000 rubles from different manufacturers. Almost any model is suitable for cutting grooves in aerated concrete.

However, given that aerated concrete blocks are quite easy to process, many builders have come to the conclusion that a manual wall chaser for aerated concrete is quite suitable for making grooves. Manufacturers of hand tools: Petrotech, Aeroc, H+H, Remocolor, KSMI. The price for these products is quite affordable and ranges from 450 to 850 rubles. There are two types of furrow machines for working with aerated concrete:

- Hand-held devices designed for making grooves on horizontal surfaces. They have a shorter and curved handle and are designed for cutting grooves for laying reinforcing rods.

- Products designed for cutting grooves on vertical wall surfaces. These devices have a longer and straighter handle.

On a note! The division of manual wall chasers is very arbitrary; everyone chooses their own convenient tool to use.

Both types of manual wall chasers have common advantages:

- low price;

- light weight;

- simplicity of design and reliability in operation;

- minimal dust formation and noise during work;

- durability;

- energy independence (that is, they are not afraid of power outages: and this is very important in suburban construction).

Methods for cutting grooves for wiring

Today, professional electricians use two main methods for cutting grooves:

- Using a special tool - a wall chaser. The method is good for cutting speed, relatively little dust emission, and uniform depth of the resulting furrow. The disadvantage is the rather high cost, and often purchasing such a tool to make just one furrow is simply an irrational waste of money.

- Using a grinder – “grinder”. The main advantage of the method is the availability of the tool. Indeed, almost every craftsman has a grinder, and accordingly, he can make a groove for an electrical cable quite quickly. As for the disadvantages: firstly, the unevenness of the cut - it is impossible to make a cut with the same depth of cut along the entire length; secondly, when cutting concrete, a huge amount of concrete dust is released, which clogs not only the furniture, but also the ears, nose... quite unpleasant, I tell you.

The question is: is it possible to make a wall without a grinder and a rather expensive wall chaser? Of course available! Below we will take a look at this method.

Equipment for gating aerated concrete

The peculiarity of aerated concrete is that this material has a porous structure. Thanks to this, it is quite lightweight and any processing of it, including gating walls for wiring and other communications, does not cause difficulties. After gating the aerated block structure, the groove simply needs to be covered with mortar. This method allows you to completely hide wiring and other communications into the wall.

Due to the porous structure of the material, gating of aerated concrete walls can be done using almost any available means:

- chisel and hammer;

- hammer drill with a special attachment;

- grinder on which discs for concrete are installed, etc.

However, all of the tools listed above in relation to wall gating have a number of significant disadvantages:

- high dust formation. When finishing new buildings this is acceptable, but when renovating residential premises this is a very serious problem;

- noisy work process;

- strong vibration and shock effects on the wall, which can lead to cracks and chips;

- large expenditures of time and labor resources;

- visible unevenness of both the groove itself and its walls.

Those who are going to use improvised means in order to save money should know that the Hilti wall chaser for aerated concrete is quite inexpensive, but at the same time it works “without noise and dust.” Solving the problems that improvised tools create, in the form of chips, cracks and dust, may require much more money, not to mention effort and time.

Working with an electric wall chaser on aerated concrete

Wall chasers for aerated concrete can be of two types: manual and electric. Electric tools will do the job much faster and require less effort, but are much more expensive. Therefore, they purchase it more often for professional work. To groove walls for wiring and other communications in the process of renovating a house, hand tools are usually used. It is more difficult to drill a wall with such a device, but it costs many times less.

Electric wall chaser

The electric tool can work both on aerated concrete and on harder materials: reinforced concrete, brick, etc.

The Hilti electric wall chaser resembles a grinder in appearance and operating principle. The only difference is that two diamond discs are installed on the tool for gating on aerated concrete or reinforced concrete.

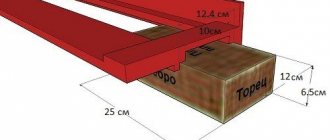

The distance at which one disc is set from the other determines the width of the furrow. For example, to lay wiring in a casing, a groove of 2 cm is enough; for water pipes it should be wider.

The depth of the groove depends on how deep the disks go into the wall. The deeper the discs go, the deeper the furrow becomes.

Another feature of the electric furrower is the ability to connect a dust extractor to it. This tool allows you to eliminate dust formation when cutting aerated concrete or reinforced concrete.

When choosing between manual and electrical equipment, you need to pay attention to the noise level. Diamond blades for reinforced concrete, in combination with an electric motor, make quite a bit of noise during the process of cutting walls for wiring. Therefore, using it during renovations in a residential building is harmful to the neighbors’ nerves.

What components does an electric wall chaser consist of?

Given the high dust and noise generation, all work on an electrical device must be carried out in special clothing, including goggles and a respirator.

In addition to devices for slitting hilti, which resemble a “grinder,” there are also more serious units used in industry for cutting stone.

When choosing an electric tool, pay attention to the following parameters:

- the minimum and maximum distance at which disks can be installed on the axle;

- what diameter disk can be installed on the tool. The maximum depth of the furrow depends on this;

- a method for adjusting the distance at which the disk stands from the disk;

- number of engine revolutions.

You should not try to save on electrical equipment and accessories. It is better to purchase such devices from licensed stores.

Diamond blades, although they have high performance characteristics, still wear out from time to time. The better quality drive you installed, the longer it will serve you.

Manual wall chaser

For home construction and renovation, it is more profitable to purchase a manual wall chaser. Although such a device requires more time and effort than an electric one, it costs many times less. In addition, the hand tool does not create any noise or dust during operation and does a good job of tapping walls for wiring.

A manual wall chaser is only suitable for aerated concrete. It is not possible to apply it to harder building materials.

The device of a manual furrow maker is absolutely elementary. This is a piece of pipe with two firmly fixed (welded) handles for pressing and a cutting element, which is a metal arc. In more expensive models it may have a diamond tip.

A manual furrower can be of two types:

- for gating walls for wiring (for vertical surfaces);

- for horizontal surfaces.

These two tools have no fundamental differences. The only difference is the curvature of the base tube itself and the angle at which the handles are attached. Such differences make it possible to optimize physical effort when working on horizontal and vertical surfaces.

Working with a manual wall chaser on aerated concrete

Work with a manual furrow maker is carried out as follows:

- We draw the markings of the future groove to ensure its evenness.

- We apply the cutting element to the beginning of the line.

- With our left hand we grasp the handle located further from the cutting element.

- With our right hand we grasp the handle located above the cutting device.

- We press the handle with our right hand, and with our left hand we slowly pull the furrow maker along the drawn line.

How to use a manual wall chaser on aerated concrete? (video)

Is it possible to ditch load-bearing walls?

In theory, when repairing electrical wiring in an apartment, it is necessary to order a project. When developing it, the presence and location of load-bearing walls, and the possibility of laying grooves in them are taken into account. As a result, a plan is issued that shows exactly where and what needs to be laid, what width and depth each groove should be. All that remains is to do everything exactly.

According to the finished project, it is safe to do wall grooves for wiring

If you are worried about damaging the load-bearing walls during work, submit a request for permission to the Criminal Code. They should pull up the paperwork and see how much safety margin there is in your home. Most likely, permission will be given.

But few people do this. Basically, they draw a plan (if they do), then they transfer it to the walls, and work begins. If gating walls for wiring is carried out in this order, do not make grooves more than 20 mm deep and wide in the load-bearing walls and simply hope that they will not damage anything.

Do-it-yourself wall chaser

Making a wall chaser for aerated concrete with your own hands is not so difficult, but it is not always rational.

Manual

As for making a hand furrower, it is a very simple task if you know how to use welding. To do this you will need a pipe and a little imagination.

- Take a metal pipe with a diameter of 0.5 inches.

- Cut a piece 80-100 cm long.

- We bend one edge into a semicircle. This semicircle will serve as a pulling handle.

- Stepping back 3-4 cm from the second edge, we weld a second handle, bent from the remains of the same pipe.

- Cut a ring 1-2 cm long from the pipe and sharpen it.

- We weld or screw to the straight end of the pipe.

Scoring Tools

To groove walls made of aerated concrete blocks, a wall chaser for foam and aerated concrete is selected. It is convenient because its design provides a special outlet tube that allows you to collect dust. They also use a grinder with a circular attachment, but with this method there will be much more dust. You can reduce the amount of dirt by wetting the surface with plain water, but this will complicate the work. It is worth saying that even if you choose a special tool, you will not be able to avoid dust and dirt. After gating, you will have to use a construction or regular vacuum cleaner.

Chiping gas silicate walls with a tool

Considering that aerated concrete is a fairly easy-to-process material, you can make a channel in it using mechanical tools. A mechanical wall chaser is a pipe with a handle and a protrusion at the other end. There are two types of such tools:

- with a shaped handle - they are designed for scoring on a horizontal surface, most often used to create recesses for reinforcement when laying walls;

- with a less protruding handle - used for working on a built wall to make a channel for electrical wires and pipes.

Both of these tools are inexpensive and can be purchased at almost any hardware store.

How to make grooves in wood

In principle, you can work with all the tools described above, except for a hammer drill. The main difference is that chisels are used instead of chisels, but the very essence of the work remains the same. First, two parallel cuts are made, and the wood between them is removed with a chisel. But besides these tools there are several more specific ones:

- A circular saw. With a sufficient level of proficiency with this tool, a groove in a wooden wall can be made only with a circular saw - in two or three passes, gradually expanding the cut to the required size.

- Fraser. You can also make a neat groove using a hand router. To do this, you can attach a flat plank to the wall as a guide and, running along it, make a recess, which is then expanded to the required size. (You can read about working with a hand router here.) There is even a special cutter (pictured on the left), but you can also use a regular one to form a groove or side cutter (on the right, but it’s not very convenient to work in this case).

Mills for grooves in wooden walls

So there are more opportunities for chiselling in wood. In this case, if you have one of these tools, it is better to work with it - they are designed for wood and are the most convenient.

Sockets and switches

In order to make a socket for a socket, switch or junction box, the following factors must be taken into account:

- first a hole is made in the center, the diameter should not be more than 1 cm;

- the crown indicates the outline of the future box;

- then a hole of the required depth is made.

When planning sockets, it is worth considering the convenience of connecting electrical appliances, safety, as well as the possibility of their placement. When the cable channels are ready and the electrical wires are laid, all that remains is to hide them.

It is quite natural that installation of socket boxes in walls made of aerated concrete is much easier than in other building materials - such as concrete or brick. You can make grooves in such walls with any available tool, but you will do everything much more carefully if you do not forget about the markings and general construction principles.

Wall chipping using accessible methods

Preparatory work

The first thing you need to do is make sure that there is no hidden wiring already located along the gating route you have chosen.

At a minimum, you can damage the working wiring, or at a maximum, harm your health by hitting live wires with a tool.

If nothing interferes with the groove, make markings on the wall. It is better to cover the exit from the room with a damp cloth or film to prevent dust from spreading throughout the apartment.