- Application of screenings in concrete preparation

- Advantages and disadvantages compared to sand

- Concrete from screenings and sand: selecting proportions

- Features of mortar made from granite screenings

- Making concrete: mixing technology

- Advice from professionals

Screened concrete is widely used in construction due to its low cost of components and acceptable quality. Let's look at the proportions and technology for preparing such a solution.

The use of concrete mortar prepared using crushed stone screenings is a common practice in construction. Such a solution has a low cost, and the quality of the monolith obtained after hardening of the concrete mass is sufficient to solve most problems. Let's figure out what the proportions of components for concrete mortar from screenings are, and also consider the technology for preparing this composition.

Application of screenings in concrete preparation

During the preparation of crushed stone, particles of various diameters are formed. After passing them through sieves, various fractions of crushed stone and screenings are formed - the smallest particles that cannot be included in any of the fractions. Although screenings cannot be used together with crushed stone, they are quite capable of replacing sand in the preparation of many brands of concrete mortar.

The use of dropouts appears economically attractive. However, from time to time on construction forums one comes across complaints about the poor quality of the resulting concrete monolith. Therefore, before starting construction work, many builders wonder whether it is worth saving, or whether it is better to use sand and not worry about the quality of the finished concrete.

Experts say that in some cases, using screenings instead of sand is not only possible, but even preferable. Such solutions are made not only in individual construction, but also in centralized production in concrete plants.

Complaints about poor quality are usually due to one of three reasons:

- Deliberately high expectations.

- Error when choosing brand of screening. Here the reason may be incorrectly selected material, particle size or low quality filler (large proportion of clay and dust particles in the composition).

- Violation of solution preparation technology.

We provide a table of the suitability of various brands of screenings for the preparation of different types of concrete solutions. With its help, you will easily understand in which cases you can take screenings, and in which it is better to leave the sand:

This table is of a advisory nature. Data may vary slightly depending on region. For example, screenings of diorite, for which low suitability for concrete production is indicated, has quite appropriate strength characteristics. It was given this rating due to its high price in many areas of our country.

Characteristics of concrete made from screenings

Concrete screenings are the most affordable building material, which is formed directly after careful processing of ready-made concrete into crumbs.

This screening is used for the production of concrete and various reinforced concrete products. In addition, it is actively used in construction and for the production of asphalt. Concrete made from screenings is much stronger, which is why it is often used instead of sand.

The final product acquires the required strength and good density. The resulting material is quite economical, so its use significantly reduces construction costs. It does not in any way affect the existing characteristics of the final structure, which makes it simply irreplaceable in many areas of construction.

If the ratio of cement and screenings used is chosen correctly, then a final product with very high strength can be obtained. The main use of screenings is to completely replace sand or use it as a partial substitute.

During production, it is worth paying attention to all components and their quality. To produce a high-quality solution, the diameter of the clean screenings used must be 1.5-4 mm. Screenings with smaller particles are completely unsuitable for making concrete.

Particular attention should be paid to the quality of the material used, because the screenings should not contain any impurities at all.

It is very important to choose the right brand of cement for preparing a high-quality mortar, because cement is the main component of any concrete.

When constructing a solid monolithic foundation, cement is often used, which is characterized by good resistance to frost, water resistance, high density and fairly rapid hardening.

Return to contents

Advantages and disadvantages compared to sand

Screening has a number of advantages compared to sand. These features make it an excellent choice as a filler for preparing concrete mass:

- Screenings are a by-product of making crushed stone or dismantling old concrete structures. This makes it a significantly cheaper material compared to sand. The use of cheaper filler allows you to reduce the cost of each cubic meter of solution, which provides significant cost savings for large-scale work.

- The screening is durable, fills all the voids in the formwork well, and is practically not afraid of temperature changes. This has a positive effect on the durability of the concrete monolith and increases the service life of the finished product.

- There are no clay or organic impurities in the screenings prepared using the technology. The content of dust particles depends on the variety, but is usually also lower than in sand. In addition, it is easier to wash the screenings to remove dust.

The formation of the screening price is greatly influenced by the cost of transportation. Depending on the distance from the quarry to the construction site, as well as the thoughtfulness of logistics solutions, the cost of even high-quality varieties of this filler can be very low.

At the same time, the screening of some rocks (for example, granite, diabase, etc.) has a number of specific features. First of all, granite, depending on the deposit, may have quite noticeable background radioactivity. In order for a material to meet safety requirements and be suitable for use in residential construction, its radioactivity should not exceed 370 Bq/kg.

The second feature is differences in hydrophilicity associated with the acidity of the rock. Thus, rocks with an acidic environment (for example, granite) are well saturated with water and give the concrete mass a dense, homogeneous structure. In rocks with an alkaline reaction environment (limestone, diabase) a hydrophobic effect is observed. Therefore, plasticizers will have to be added to the concrete solution.

DIY solution

The solution can be easily prepared with your own hands. To do this, you will need a concrete mixer, and if it is not available, any construction container in which the mixing will be done. The required proportions of dry ingredients are poured into the mixer or container:

Next, they are mixed until a homogeneous mass is obtained. Lastly, water is introduced in small portions. In this case, the mixture must be constantly stirred. You need to make a homogeneous mass and moisture - then the solution is ready and can be used for work. It should be noted that the mass must be used within two hours after preparation, otherwise loss of its properties cannot be avoided.

If moisture evaporates during operation, it is necessary to add as much water to the mixture as necessary for the desired consistency. It should be noted that if any of the components is wet, then when manufacturing the building material it is necessary to reduce the amount of water.

Calculation and improvement of qualities

To improve the quality, it is necessary to sift the sand. It is worth paying attention to the fact that the composition of concrete of various grades greatly influences its shrinkage after pouring. Therefore, before determining how much composition will be needed and starting to calculate its quantity, it is necessary to decide on the brand of material. The higher the shrinkage factor, the more it will be needed to complete the job.

How much concrete is needed, for example, to pour a foundation? To calculate, you need to multiply the length by the width and multiply the resulting result by the height of the future foundation. Next, the resulting indicator is multiplied by the shrinkage coefficient. And after that, multiply by 1.05 again. This must be done in order to establish the volume that will be occupied by the fittings.

The traditional composition of concrete, in addition to cement, includes a certain amount of sand and crushed stone.

The use of screenings as a filler - a by-product of grinding various rocks - reduces cement consumption and makes it possible to obtain a material with high performance indicators.

The variety of types and options of source rocks and degree of grinding makes screening a material capable of forming many types of concrete. The compositions obtained by combining different types of screenings and cement differ in qualities due to the properties of the initial material of the screenings.

Concrete from screenings and sand: selecting proportions

The ratio of components used to prepare the concrete mass significantly affects its strength, durability and performance characteristics. The classic recipe involves the use of cement powder, sand and crushed stone. Screenings (depending on the grain size) are used both to replace sand and to replace crushed stone.

To calculate the optimal ratios for a solution in which screenings partially replace coarse and partially fine filler, use the table below:

The table is compiled based on the use of M400 cement. The weight of cement powder is taken as a unit, and the weight of the main components is obtained by multiplying the given mass fractions by the weight of cement. For example, to prepare 1 cubic meter. M200 concrete, you will need:

- Cement M400 – 286 kg.

- Crushed stone - 286 kg x 3.9 = 1115.4 kg.

- Sand - 286 kg x 1.7 = 486.2 kg.

- Dropout – 286 kg x 2 = 572 kg.

All component weights are based on dry conditions. The weight of water is obtained by multiplying the total mass of dry matter by 0.2. For our example, you will need 2459.6 kg x 0.2 = 491.92 kg (or l.) of water.

For ease of use, the obtained values are rounded to whole values and converted into buckets.

Mortar without sand: we use only screenings

For the production of fine-grained varieties of concrete mass, it is possible to completely replace both sand and crushed stone with screenings. The solution, therefore, consists of only two dry components: cement powder and screenings. The proportions for this case are shown in the table:

The calculation principle is similar to the previous one: we take the mass of cement, multiply it by the fraction of screenings in the selected type of cement mass, and get the mass of dry components. So, for the M300 variety you will need (per 1 cubic meter) 382 kg of M400 cement and 382 kg x 4.5 = 1719 kg of screenings. As in the previous case, the mass of water is 20% (0.2) of the mass of dry components.

How to make concrete using granite screenings?

- home

- Screening with delivery

- How to make concrete using granite screenings?

The proportions of the concrete mixture are always determined by GOST. But, you must admit, it is difficult to adhere to production standards at home (at the dacha, for example). That is why there are so many new recipes from amateur builders. Through trial and error, they come to the optimal proportions for independent production.

How is granot screening used in concrete?

It either replaces sand completely or, which happens more often and is considered more reasonable, is used as an additional component.

What kind of cement should I use?

To obtain a high-quality, durable result, you need excellent quality cement. Brand – not lower than M400. This cement promotes better adhesion of aggregates to each other and has better binding characteristics. You can also use various seals.

In what proportions should I mix the concrete mixture?

If you added 1 part of cement, 3 – sand, 4 – crushed stone, you should subtract one part of sand and crushed stone and add 2 parts of granite screenings.

Our company offers to buy granite screenings with delivery throughout St. Petersburg and the Leningrad region on favorable terms. We deliver to the site using our own transport. Cooperating with us is convenient, profitable and economical!

Useful information for the customer

Prices for screenings with delivery in our company

- Granite screenings from 150 rub/m3

BUY ELIMINATION ON-LINE

www.inert-materials.ru

Features of mortar made from granite screenings

Granite screening is obtained by crushing granite layers. In this case, the screening particles have high hardness and are practically not afraid of mechanical deformation or temperature changes.

Granite chips have uneven edges, which has a positive effect on the ability to bond with cement into a durable monolith. The particle diameter is usually 2-5 mm. A characteristic feature of granite screenings is their beautiful natural color (pink, greenish, gray). Concrete mass prepared with the addition of granite screenings is well suited for the manufacture of paving slabs and other decorative structures.

The dismantling of concrete structures that have outlived their allotted time is also accompanied by the formation of screenings. Both pure concrete screening and material with the addition of brick chips obtained during the dismantling of old masonry are distinguished. With the low cost of such screening, its properties are less stable: they largely depend on the quality of the original concrete monolith, as well as the degree of development of the processes of its natural destruction.

The characteristics of a particular batch of concrete chips may differ from the values stated by the manufacturer. Therefore, it is permissible to use a solution based on concrete screenings for the manufacture of products that do not bear significant loads: paths in parks, floors in technical rooms, garden structures, etc.

What is sand and what is screening?

Sand

is a sedimentary rock consisting of quartz grains (most often). The grain size is no more than 5 millimeters. Sand is mined in quarries or on river banks, and natural or artificial washing with water allows dust particles and foreign inclusions (for example, clay) to be removed from it. Experts distinguish several types of sand - according to the degree of purification, the size of the grains, and the rock material.

Sand is used for the production of concrete and products made from it:

- blocks;

- well rings;

- tubing;

- reinforced concrete trusses, etc.

In addition, sand is used in the production of paving slabs, in the construction of embankments, in the construction of roads, bridges, hydraulic structures, for sandblasting and much more. Dyed sand has found application in landscape design.

Dropout

, like sand, has grain sizes of no more than 5 millimeters (in most cases), however, it is not a sedimentary rock, but a product of crushing factories in stone quarries. In professional language, screening is called “crushed stone of fraction 0-5”. This is the main difference between dropouts and sand. Here, perhaps, it is worth making a retreat and explaining something. At the quarry, after crushing the stone, it is sorted; for this purpose, units called “screens” are used. They are vibrating inclined grates along which large pieces of stone are rolled onto a conveyor, and small pieces fall into cells and are poured into heaps. Everything that falls into cells measuring 5 by 5 millimeters is screening.

The fundamental difference between sand and screenings is the presence of a large number of very small particles in the latter. Therefore, there is always a cloud of dust in the sorting areas during work. Screenings are in demand in the production of asphalt concrete, mortars and landscape design. It can be used in the production of paving slabs and some grades of concrete, but most often in these cases sand is still used. The most valuable screening is granite (due to the strength of the material). Other types - for example, screenings from porphyrite - are of less importance.

Making concrete: mixing technology

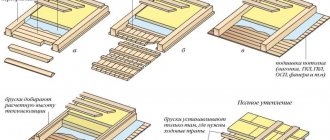

Mixing large batches is carried out using concrete mixers, since it is difficult to mix the solution by hand. In addition, with such mixing it is almost impossible to guarantee the homogeneity of the mass. Here is the algorithm:

- Cement and screenings are measured according to previously made calculations. Each component is sieved to ensure that the material is free of stones, debris and other unwanted contaminants.

- Dry materials in specified proportions are loaded into a concrete mixer and mixed thoroughly.

- Water is added in small portions and mixed thoroughly. Excess water will cause cracks to appear on the monolith, so there is no need to rush to add it.

Concrete proportions: calculation of components, diagrams (video)

Concrete is a flexible, widespread building material that is characterized by high strength after hardening. It is a universal building material and is used in all areas of construction.

The characteristics of the soil, the weight of the structure, the type of the basement of the structure are factors that influence the choice of cement.

The composition of the concrete mixture is determined by 4 main components: sand, water and gravel, crushed stone, screenings or, less commonly, scrap brick, expanded clay. To obtain high-quality building materials, it is necessary to use the same high-quality components, strictly adhere to production technology and, most importantly, know what proportions of concrete need to be observed.

Concrete is an indispensable building material

The question of what proportions of the concrete mixture must be observed is of interest to all private developers who decide to independently prepare concrete for the construction of the foundation for their house. In order to mix a high-quality concrete mixture with the desired composition and properties, first of all, it is necessary to correctly develop its composition, then maintain all the proportions of the mixture components and, finally, make concrete.

Ready-mixed concrete, which consists of a binder (cement), water and various fillers (crushed stone, gravel, clean sand, etc.), and in some cases plasticizers and other special additives that improve some characteristics of the finished mortars, is the most common construction material a material practically used in the construction of all types of monolithic foundations. Therefore, it is very important to know how to make concrete if you decide to do individual construction.

Return to contents

Main components of concrete mixture

The functionality assigned to the foundation or other structure depends on the proportions of the components included in the concrete mixture.

It is important to know how to make the concrete needed for your purposes. Strict proportions of concrete mortar for the foundation must be strictly observed, because they are the key to the durability and reliability of building structures. First of all, special attention is paid to the quality of each component used.

Cement marking scheme.

The dimensions of clean sand used for preparing concrete mortars should be from 1.2 mm to 3.4 mm. Material with smaller particles is not suitable for preparing concrete. Particular attention must be paid to the cleanliness of the material; sand should not contain clay and silt.

Coarse and fine crushed stone or gravel must also be clean; a small clay content is allowed. The main particle sizes of gravel, like crushed stone, can range from 10 to 80 mm.

One of the most important tasks in the production of concrete is the correct choice of the appropriate grade of cement. Cement is the most important component of concrete. When constructing monolithic foundations, Portland cement is most often used, which is characterized by high frost resistance, density, rapid hardening and water resistance. Portland slag cement is used mainly for the construction of various types of foundations, although compared to Portland cement it gains strength much more slowly, especially at low temperatures above zero.

The composition of concrete includes: cement, sand, crushed stone and a certain amount of water; in addition, it may also contain some additives - hydrostabilizers, plasticizers.

Cement comes in different grades. For each of them there is an individual proportion in the production of concrete mortar. Therefore, first of all, the cement of the required brand is selected, and only after that it will be possible to determine its consumption.

The use of screenings helps to achieve the highest strength of concrete foundations. That is why many developers use screenings when preparing concrete mortar. Most often it is used as a replacement for sand or as an additional component, which is completely justified and very rational. However, not all owners of construction sites know what proportions of concrete mixture with screenings must be observed when producing high-quality mortar. In reality, everything is quite simple. Subtract 1 part of crushed stone and sand from the mixture and add no more than 2 parts of screenings instead.

Many private developers are also interested in the possibility of preparing concrete from a sand-gravel mixture and the most acceptable proportion of the composition containing such components. At home, you can prepare a solution using a ratio of 1:8. In this case, the proportions of sand-gravel mixture and cement for construction consist of 1 part cement and 8 parts high-quality sand-gravel mixture. This ratio has long been verified by many professional specialists and is the most optimal.

Return to contents

Calculation of concrete mixture proportions for foundations

Depending on the composition of minerals, they are distinguished: Portland cement, aluminous cement, magnesia cement, mixed cements, acid-resistant cement,

The exact proportions of the concrete mixture for the foundation are calculated using the basic formula. Take any brand of cement, clean sand and high-quality crushed stone in a ratio of 1:3:5. In accordance with this formula, for 10 kg of cement blank you need to take 30 kg of sifted sand and about 50 kg of small crushed stone. When selecting the composition of a concrete mixture, you first need to determine one more important parameter - the water-cement ratio. The strength of concrete depends entirely on maintaining the exact proportions of cement and water. Water must be added until a pliable mass is formed. The most important thing is not to forget that the amount of clean water added in excess often leads to a decrease in the strength of hardened concrete.

Calculation of the proportion of concrete mixture for a foundation using crushed stone is carried out taking into account many important factors:

- fractions of pure sand and crushed stone;

- sand and crushed stone size module;

- quality of components and their density;

- waterproof;

- resistance to severe frosts;

- mobility.

Most often, ready-mixed concrete is made using cement grades M400 and M500. High-quality crushed stone, sand and various additives, mainly anti-frost, are added to the mixture.

Using different numbers of components at different costs can result in the same design grade of concrete. To obtain a higher grade of concrete mortar, you need to increase the cement consumption.

Concrete of lower grades, for example M100 and M150, belongs to the group of lightweight concrete. Therefore, it is most often used in the preparatory stages of the construction of concrete structures.

To obtain a building mixture, it is necessary to thoroughly mix the components in the given proportions. The sand is poured onto a flat, clean surface, cement is added and everything is thoroughly mixed. All components are thoroughly mixed until a homogeneous dry composition is obtained, to which the required amount of water is added and everything is thoroughly mixed.

It is quite difficult to obtain the optimal composition of a concrete mixture that has the necessary characteristics and qualities at home, since it is very difficult to select the optimal proportions at home without the help of modern equipment. Therefore, it is much easier and more expedient to order the composition with delivery from the factory directly to your site.

Try to prepare the amount of mortar that you can use in 1 day of construction, because... Within 24 hours, the concrete will gain some strength and will become impossible to use anywhere else.

moidomkarkas.ru

Advice from professionals

To give you a better idea of the technology for preparing mortar from cement powder and screenings, we have prepared several useful videos. These videos also contain useful tips from experienced builders on preparing concrete mortar from waste material:

With the correct selection of proportions and the use of high-quality components, a concrete solution mixed using screenings will not be inferior to a traditional cement-sand-crushed stone mixture. At the same time, significant cost savings are achieved, which makes the use of screening in construction a justified solution. Good luck with your work!

Types of dropouts

Screenings are rocks that have been crushed and sorted by size. The concept of “screenings” also includes secondary processed building materials. It is popular due to its low price and availability. At the same time, this is an environmentally friendly raw material, harmless to human health, regardless of the size of the fraction. When compared with sand, it has the following advantages:

- homogeneous composition that does not contain clay or organic matter;

- durable, safe and resistant to sub-zero temperatures;

- crushing waste in some situations replaces sand;

- concrete from screenings, made without the addition of crushed stone, is cheaper, but has similar parameters;

- Suitable not only for producing concrete, but also as an independent bulk material.

Screenings are classified by size and source material. The following sizes are common: 0.1 – 10 mm. In application, fractions of 1.5 – 4 mm are more common than others. The smallest elements are separated by washing out - they are laid out on a flat, solid plane and watered with water under pressure. The smallest particles are washed out of the total mass with a stream of water. What remains is suitable for further purposes.

If desired, concrete is made from screenings. The resulting solution is suitable for many tasks: construction of houses, reinforced concrete structures, construction of highways, and so on. Screening filler comes in several types: granite, concrete, concrete and brick.

Granite

It has become most widespread, primarily due to its high performance properties. Granite mortar from screenings allows you to make concrete of a high strength class. It is made from granite particles ranging in size from 0.1 to 1 cm. This screening is characterized by gray or red color.

Positive qualities of granite screenings:

- affordable price. Thanks to the affordable cost, the overall price of the project is reduced. A similar, but crushed stone composition will cost more;

- screenings from granite can be used instead of sand in concrete, both partially and completely;

- visual characteristics. Red particles are often used to make decorative concrete elements, such as columns, tiles and much more;

- increases the performance parameters of the finished product. If the proportions are correctly observed, the density of the concrete increases, and with it the load-bearing capacity of the finished structure.

Different kinds

Granite crushed stone is obtained by curing the residues of rock crushing on special sieves.

Granite is a crumb whose size varies approximately between 0-10 mm. This may have a reddish and gray color. Various shades of red make it possible to use granite in the production of products, paving slabs, and in gardening.

Concrete is the most affordable material that is obtained after recycling concrete. This material contains the smallest fraction of secondary crushed stone, from 1 to 10 mm, which is obtained during the crushing of products. Concrete is used in the production of reinforced concrete products, in the field of road construction, and in landscaping. In the production of products, concrete is widely used in industrial construction, in the production of asphalt and wall materials.

Concrete with brick is a mixture made from products of processing or destruction of brick and concrete. Processed products involve breaking bricks with some concrete, cement and other building materials. You can purchase cement in Dnepropetrovsk using the website sellstroy.dp.ua.

The solution is much stronger.

In a solution based on granite, the final material acquires the necessary strength and density. This material is cheaper than that made from crushed stone, and its use significantly reduces construction costs. But the main thing can be considered that concrete produced from cement and granite is not able to influence the operational characteristics of the resulting structure or structure, which makes this material indispensable in many areas of construction.

With proper preparation of the mixture, you can ensure the high strength of the final product. In this case, it is important to use screenings in the correct proportion. The main use of granite is to replace sand or use it as a partial substitute. The last option is usually used more often.