One of the most universal types of foundation is a pile foundation. It is suitable for any climatic conditions and various types of soil. That is, it can be used in almost all cases, regardless of the conditions of future operation of the structure.

But it is necessary to understand that the floor of the lower floor of the building will likely be quite cold, which is due to the significant air space underneath. That is why insulation of a pile foundation will significantly improve the properties of a house, making it more suitable for various household needs.

Technology of work: execution of the blind area

View gallery

If you are faced with the question of how to insulate the pile foundation of a wooden house, then you should familiarize yourself with the technology. It involves working on the blind area. Many people perform it after insulation work, but experts recommend starting manipulations from the blind area. In this case, you can lay insulation that will adhere to the insulation of the blind area, and not to the ground.

The blind area is performed using the following technology. You will have to dig a trench around the perimeter of the house, the width of which is a meter. It is necessary to go deeper by 40 cm. Sand is poured onto the bottom of the trench, the layer thickness should be 20 cm. The sand is well compacted. Afterwards, a 5-centimeter layer of crushed stone is poured, which is well leveled and compacted. Next, you need to lay a waterproofing film, the sheets of which are laid with an overlap.

The next layer will be thermal insulation material. Extruded polystyrene foam is excellent for these purposes. A drainage pipe must be laid along the edge of the blind area. At this point, the work on the blind area is completed. If the foundation is insulated from the outside, and the area has heaving soil, then at the junction of the base and the blind area the trench must be filled with expanded clay. This way you can prevent the base from breaking due to soil heaving.

What materials can be used

Airgel insulation

- Most often, insulation of a pile-screw foundation is carried out using polystyrene foam. The material is inexpensive, very light, and has a number of remarkable characteristics. Insulation is carried out as follows: the sheets are glued to the foundation along the perimeter. Bitumen mastic is used as glue. The foam is pressed tightly, trying not to leave gaps or cracks. If they do form, they are filled with ordinary foam for wall insulation.

- No less effective than insulating a screw foundation is penoplex. And in some properties it even surpasses polystyrene foam. This heat insulator is durable, resistant to moisture, and easy to install. Attached to the grillage using special glue.

- Foam glass, extruded polystyrene foam and airgel. Their advantages are that during application there is no need to do additional waterproofing. These materials themselves have excellent waterproof qualities.

Installation of sheathing

View gallery

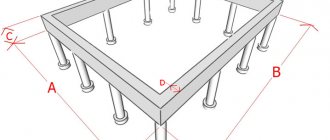

If you, like many home craftsmen, are faced with the question of how to insulate the pile foundation of a wooden house, then you must decide how to install the sheathing. It is necessary, because insulation and finishing will be attached to it. The frame consists of several belts of boards that are installed around the perimeter of the base. The boards are attached to the outermost piles. If they are metal, then horizontal strips can be welded to them and holes can be drilled. This way you can secure the boards with bolts.

If you don’t want to get involved with welding, you can secure the sheathing with clamps. Another option is to fix it to the walls of the house. In order to make the structure more rigid, vertical jumpers are placed between the boards, which are fastened with self-tapping screws.

Carrying out insulation

View gallery

When insulating the pile foundation of a wooden house from the outside, different materials can be used. If it is extruded polystyrene foam, it is attached to the sheathing with dowel umbrellas. In this case, cold bridges must be eliminated by filling the space with polyurethane foam. It is better to install the insulation from the inside so that there are no problems with the lining of the base.

Polystyrene foam is also used quite often as insulation. It is less durable, but has similar characteristics to extruded polystyrene foam. If your budget allows, you can use spray polyurethane foam. When installing the sheathing, the boards should be located as close to each other as possible. Thermal panels are attached to the sheathing with dowels or special fasteners, which are supplied in the kit.

If the house has a wooden grillage, then before insulating the foundation it should be treated with a protective impregnation. The rest of the wooden elements, including the sheathing, are also coated with this composition. As soon as the insulation is in place, it is necessary to fill the blind area with concrete. After this, work stops until the concrete hardens.

Design features for use on permafrost, sand, swamp, etc.

For long-term operation of a pile foundation on screw piles, it is necessary to protect their screw part from corrosion. Of the applied protective coatings, only hot zinc coating can withstand the conditions of twisting into permafrost. It is applied by repeatedly dipping a cleaned screw pile into a bath of molten zinc. This procedure is not cheap and the pile also costs a lot.

An alternative was a cast screw part. It is designed specifically for use in permafrost zones. Such tips are cast from steel, for example, St. 25-35L. The casting wall has a thickness of up to 15 mm. The spiral is called a “screw” and is located along the entire length of the conical part of the tip. Available for pipes from 57 to 108 mm, i.e. for piles twisted by hand. The pile shaft fits tightly onto the supporting part and is welded with a circular seam directly at the construction site. The blade width is 20 mm, which provides good load capacity with many turns.

For swampy areas, a cast single-thread tip is used. Casting ensures the uniformity of the geometry of the cast blade and cone and the absence of welds. The thickness of the blade is 10 – 13 mm, which is difficult to achieve for welded structures. The corrosion life of metal of this thickness is more than 100 years. The manufacturing cost is significantly lower than welded tips

Carrying out cladding

View gallery

At the final stage it will be necessary to cover the base. This is usually done using siding. The instructions for its installation are as follows. Along the perimeter of the house, it is necessary to fix the starting profile to the sheathing. It is located vertically, so it must be installed using a building level.

The lower part of the panels is inserted into the starting profile, and the upper part is attached to the sheathing. In this case, it is necessary to use self-tapping screws. At the final stage, additional elements are installed, namely corners and ebbs. When covering the sheathing, it is necessary to provide vents that will be needed to ventilate the underground space.

Base insulation

View gallery

Insulating the base of a pile foundation allows you to make the interior space more comfortable. First you need to build a base, and then begin insulation using any of the existing methods. The construction of the plinth is allowed in certain ways. You can lay a wall that will cover a row of screw piles. The height of the wall should be equal to the length of the line from the blind area to the lower belt of the house.

You can arrange a pick-up, which is a fake plinth. It will be built on a frame base and will have an external cladding. If you chose the first method, then the masonry must be done in half a brick. The products will be red ceramic, as they are most resistant to high humidity.

First, you must prepare the foundation, for which you dig a trench around the perimeter of the building. The depth and width will be 0.3 and 0.25 m, respectively. The bottom is well leveled and filled with coarse sand. The layer thickness should be 10 cm. After this, the sand mixture is compacted and moistened.

A reinforcement frame of longitudinal and transverse rods is laid on such a base, after which the concrete mixture is poured. After the concrete mortar has hardened and gained strength, you can begin building a brick wall.

What is a screw pile and its purpose?

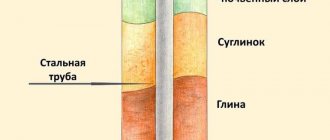

A screw pile is usually called a special type of pile, consisting of two fundamentally different parts: the pile shaft and the bladed spiral part.

The blade part is usually a single-thread auger device, to which a force is transmitted through the pile shaft to rotate this part. It loosens the soil and moves deeper into the soil. In this case, the pile shaft, when immersed, compacts the loosened soil. The vertical load of such a pile is supported by one blade. If you do not allow it to rotate around its axis, the magnitude of the indentation load will be large. It will be a little smaller when pulled out.

Another technique for increasing the load capacity is doubling the number of passes, i.e. the number of blades.

The main purpose of screw piles is use in conditions oversaturated with water and weakened soils.

In the northern regions, when the depth of winter soil freezing is up to 2 meters or more, screw piles are a cost alternative to strip and column foundations.

Internal floor insulation on a pile foundation

View gallery

Insulation of the floor on the described base is carried out in several stages. Vapor barrier for the floor is laid from the outside over the entire area. Insulation like expanded polystyrene is installed on top, which is sheathed with boards. This floor can be used as a finished basement ceiling.

For hydro- and wind protection, modern moisture- and wind-insulating membranes can be used. They are easy and quick to install, but the cost of multi-functional products may put you off.

All elements of a wooden house on stilts are treated with a composition with antiseptic properties. It is important not to forget about the vapor barrier for the floor. It can be a polyethylene film, which is laid on a layer of heat-insulating material.

When installing vapor and thermal insulation, you should not leave gaps between individual elements. This can lead to the formation of cold bridges. In this case, the insulation under the floor can quickly deteriorate during operation. To further protect the interior from the cold, you can use particle boards, floorboards or sheets of plywood, which do not conduct heat well.

What is the best way to insulate the foundation: from the inside or the outside?

It is recommended to carry out external insulation of a log house, since in this case the foundation receives protection from freezing; frost and snow precipitation will not be able to penetrate the thickness of the insulation cake and cause damage to the concrete foundation.

External thermal insulation also protects communications from low temperatures, which ultimately extends their service life. When insulating the outside, waterproofing must be done, which prevents moisture and groundwater from entering the basement of the house during spring floods and seasonal temperature changes.

Insulating the foundation of a house from the inside is rarely done, and only in cases where it is impossible to do it externally. Thermal insulation inside the log house is only a barrier to heat escape, but does not protect the base from freezing and melt water.

As a result of the use of internal thermal insulation, the “dew point” shifts to the boundary of the insulation with the foundation, which will require the installation of an additional layer of vapor barrier. In turn, this can lead to disruption of the microclimate in the basement, where air humidity will greatly increase and forced ventilation will need to be installed. Therefore, in order to avoid unnecessary problems and additional costs, it is best to insulate the foundation from the outside.

Additional recommendations on choosing insulation

Beginning home craftsmen often wonder which insulation to choose - mineral wool or polystyrene foam. The first option has pros and cons. Among the advantages are non-flammability, resistance to chemicals, ease of material when bending corners, resistance to temperature changes, high levels of sound and heat insulation.

But this solution also has its downsides. Among others, it is worth highlighting:

- sagging;

- moisture absorption;

- carcinogenicity of formaldehyde resins;

- inconvenient installation;

- decrease in the effectiveness of thermal insulation over time.

When thinking about the question of which insulation to choose - mineral wool or polystyrene foam, you must remember that the first solution is possible, but requires care during installation, protecting the material from contact with the room and proper waterproofing.