Considering that prices for gas and electricity are constantly rising, the issue of home insulation becomes very relevant. And this is quite understandable.

After all, if the walls in the house are properly insulated, then:

- Firstly, you save money that goes towards paying for heating.

- Secondly, the room heats up much faster, and the heat itself is distributed more efficiently.

Photo of a house with aerated concrete walls

Simply put, with an insulated facade you will actually warm the house, not the street. However, the most important thing here is not just to insulate the walls, but to be able to do it correctly!

And it is especially important to properly insulate aerated concrete walls from the outside - after all, this material has certain characteristics and unique features that are very different from the properties of standard brick walls. Therefore, keep in mind that not every insulation will “work” effectively on an aerated concrete façade.

Example of a gas block wall

In this article we will look at which technologies are suitable for such walls and which are not. Then we will choose the best and most suitable option, which we will try to implement step by step with our own hands.

But first, it’s probably worth familiarizing yourself with the features of aerated concrete walls in order to better understand why this or that technology can be used, and why, on the contrary, not.

So, a brief overview of the material and walls made from it.

What is aerated concrete

Before you start insulating a house made of aerated concrete from the inside, you should familiarize yourself with what this material is. It is a lightweight cellular concrete, in the production of which gas-forming agents are used. The ingredients may include not only cement and sand, but also:

- lime;

- gypsum;

- ash;

- slags

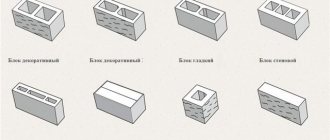

According to their purpose, blocks can be:

- structural;

- thermal insulation;

- structural and thermal insulation.

Classifications can also be made according to hardening conditions. In the first case, after pouring the solution, the material is exposed to saturated steam, while in the second the solution polymerizes under natural conditions.

More about the advantages of aerated concrete

Less significant, but still important advantages of the material are:

- Relatively low cost.

- A light weight.

- Ability to pass steam and gas.

- Low thermal conductivity.

- Strict linear dimensions of blocks.

Walls made of aerated concrete blocks must be constructed so that the permeability of the surface to steam decreases towards the inner layer from the outer one. Insulation of aerated concrete walls from the outside should be carried out taking this into account.

If you neglect this point, the steam that accumulates in aerated concrete blocks will lead to increased humidity, which will negatively affect not only the quality of the building material, but also the entire structure. Additional advantages include frost resistance and fire safety

Why is it necessary to insulate such houses?

Insulation of aerated concrete walls is required for the reason that sufficiently strong blocks used to build a house do not have the required level of heat-saving capabilities. If products for construction are not so important, they do a good job of retaining heat indoors, but will not be strong enough to withstand the load from walls, ceilings and roofs.

Insulation from the inside is carried out quite rarely. But if you still decide to carry out such work, you should know that thermal insulation of gas-block houses is also required for the reason that cement is often used in the masonry process, which makes the seams quite thick. These masonry areas become cold bridges through which cold enters the house.

If you are planning to insulate the house from the inside, you must be prepared for the fact that the dew point will shift to an abnormal position for it, which can cause moisture to penetrate the walls, where it will remain, and then freeze, turn into ice and begin to destroy the material. And over time, the internal surfaces of the premises will become covered with mold and mildew, which can only be gotten rid of by properly insulating the building.

Nature of the material

Although aerated concrete is a material with low thermal conductivity and performs not only structural but also thermal insulation functions, it still needs insulation. But it is better to insulate aerated concrete walls not from the inside, but from the outside. The thickness of the protective layer may vary depending on the thermal conductivity of the products. If they are in a dry state, then this indicator is 0.12 W/(m K).

Manufacturers achieved this thermal insulation effect thanks to the air inside. If you want to reduce heating costs, you can do it inside such a house, saving about 25% on your bills. In connection with this, one cannot fail to mention the heat-accumulative properties. This suggests that the material accumulates heat, receiving it from the sun's rays. This means that such a house will be comfortable not only in winter, but also in summer.

In the latter case, the rooms will remain pleasantly cool. If we compare the thermal conductivity of these blocks with brickwork, then the former can be laid in a wall with a thickness of 375 mm, which in terms of thermal conductivity will be equal to a 600 mm brick wall.

Why insulate such structures?

Insulation of aerated concrete blocks is mandatory. It is better if such a layer is located not from the inside, but from the outside, then you will not encounter problems with the accumulation of moisture in the walls and their subsequent destruction due to mold and crumbling of concrete. Although cellular concrete reduces heating costs, it will still have to be insulated, and not only for the reason that it is necessary to protect the material from negative external influences. Insulation is recommended to further give the walls the ability to retain heat.

Material selection

For thermal insulation of aerated concrete, different materials can be used. It could be:

- warm plaster;

- basalt wool;

- mineral wool.

One of the most suitable solutions is mineral wool, as it allows air to pass through well and does not create the risk of condensation. Basalt wool will cost a little more, but has similar characteristics to mineral wool and is more practical to use. Plaster has a lower vapor permeability, which can increase the risk of condensation. To improve the corresponding properties, you can add to the solution:

- paper;

- sawdust;

- perlite

Types of materials for insulation

It is not enough to select the material - to ensure that it correctly performs its functions, it is necessary to carry out the installation according to technology. For example, polystyrene foam is a big question, but can still be used on the inside of aerated concrete walls, providing a ventilation gap so that the walls can breathe.

Styrofoam

This material almost does not allow air to pass through, which means it is important to install it correctly if you intend to use such a layer from the inside. Such insulation also threatens aerated concrete by the fact that rodents can live in the walls.

If installed from inside the home, the material may pose a fire hazard. This is expressed in the fact that although the thermal insulation does not ignite, when exposed to open fire it begins to emit harmful gases.

Penoplex

If you are working with autoclaved aerated concrete, before insulating it, you must wait until all the moisture from the material has evaporated. Then you can start working from the inside. For this purpose, penoplex is often used, which must be installed in accordance with the rules of thermal protection. The slabs are installed in a spacer in a wooden or metal frame so that there is no free space between the products. The surface can be covered with plasterboard or covered with plaster. When insulating, there should be space left between the penoplex and the gas block for ventilation of the materials.

Mineral wool

This material is very durable and has good vapor permeability, which makes it compatible with cellular concrete. The room will maintain a normal level of humidity. This material is good because it has a long service life, reaching 70 years. After installation work, a fiberglass mesh is installed on the surface, over which you can plaster the base and apply paint on top.

Polyurethane foam

Sprayed polyurethane foam, which is an organic material, can be used as insulation for aerated concrete. The formed layer breathes, therefore it is suitable for aerated concrete. Thermal insulation does not decompose, does not rot, and continues to maintain its integrity after decades. It does not contain formaldehyde, so it can be used indoors. The material is fireproof and releases carbon monoxide when exposed to flame.

Reinforcing mesh

The reinforcing mesh protects the plaster, which is applied to the heat-insulating material, from cracking.

Thermal insulation coefficient, strength, moisture resistance and other performance characteristics depend on the density of the material used. The better the insulating properties of the material, the lower the density. This means a shorter service life. It is very important to take all this into account when choosing insulation.

Insulation of a structure begins with the facade. The material used for thermal insulation of walls must be environmentally safe. This is exactly what polystyrene foam is.

A good insulation must be hygroscopic, water-permeable, breathable, fire-resistant, plastic, strong and durable; biologically and chemically resistant.

Extruded polystyrene foam is used not only for external wall insulation. It is also used for paving, insulating facades and much more. Road insulation using this material reduces the negative impact caused by soil freezing and damage to the road surface during its operation.

More on this topic on our website:

- Insulating the foundation of a wooden house from the outside with extruded polystyrene foam Everyone knows that insulating the walls of a house is a necessity, the same can be said about the foundation. This will become especially relevant in areas with very...

- Insulation of walls in a wooden house is designed to provide it with a long service life, a favorable climate and aesthetics. As a rule, the most commonly used type of insulation involves the placement of heat-insulating material...

- The issue of wall insulation is one of the most pressing for every happy owner of a private home. After all, comfort depends on how airtight and warm the building is...

- The well-known foam plastic, which once competed exclusively with glass wool, today itself has a lot of derivative materials, which, by the way, often give way to other modern types of insulation. By the way,…

Simple home insulation technologies

To insulate aerated concrete from the outside, you can use many solutions. Among others, it is worth highlighting:

- wet application;

- material facade;

- ventilated facade.

If the work is carried out outside, you can install siding on top of the insulation, for which a frame is previously created. Foam or polystyrene foam can be laid between the structural elements. Sometimes materials with good vapor permeability are installed directly on the walls using a layer of adhesive.

Capital ventilated insulation

Such a thermal insulation system must include careful selection of mechanical fasteners, since cellular concrete is a fairly soft material. Reliable fixation can be obtained if you use:

- dowel-nails;

- chemical anchors;

- spring dowels;

- mechanical anchors.

Attention! The most effective way to fasten the frame is with a dowel. It is well suited for aerated concrete block. First you need to mark and make holes for the anchors. The interior space is cleared of dust to hammer in the dowels.

Next, the paronite gasket and brackets are installed. The anchor bolts are tightened well, and holes are made in the mineral wool slabs. This will allow you to install the material without glue. Thermal insulation is installed on brackets, the plates are joined together. Due to the frame they will be removed from the main wall.

Interior finishing of aerated concrete

For internal cladding of aerated concrete, you can use one of several options, namely:

- drywall;

- plaster;

- paint;

- wallpaper.

As for drywall, it can be installed on the frame with the formation of an intermediate air layer. If you need to carry out internal insulation, you can install basalt or fiberglass slabs.

Attention! Before choosing plasterboard for interior cladding, you should pay attention to the fact that it is offered in three varieties, namely:

- standard;

- waterproof;

- fire resistant.

The choice will depend on the operational characteristics of the room.