Reinforcement detector in concrete

Device for finding reinforcement in concrete

Not long ago, finding reinforcement in concrete structures was a difficult task. This was done either by opening up sections of the concrete structure, or by using magnets. But technology does not stand still and today there are many methods and devices that simplify this process. Most often, today's devices use a magnetic scanning method.

Why do you need to look for reinforcement in concrete?

When carrying out construction and repair work and maintenance of a building, it is imperative to know where the fittings are located. For these purposes, a reinforcement detector in concrete is used. It establishes exactly where the reinforcement goes, its diameter, as well as the thickness of the concrete layer. This need arises because when a drilling or other tool collides with reinforcement, not only the equipment is damaged. This can damage the structure of the reinforcement or, in the case of minor damage to the rod, lead to subsequent corrosion of the reinforced concrete panel.

According to GOST, searching for reinforcement in concrete structures and measuring the thickness of the protective layer is carried out using the magnetic method. How to find the threads for the metal rods depends on the thickness of the concrete layer. After all, you can use both an ordinary powerful magnet and hypersensitive devices. But in accordance with regulatory requirements, these parameters are set only by certified devices that are included in the State Register of Measuring Instruments.

Using this method, the subtleties of the protective layer are established, underfilling concrete during construction of the structure, the location of the reinforcement, and its approximate diameter. This method of control allows you to complete the task without violating the integrity of the structure.

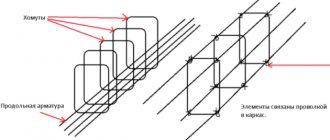

To carry out the task, the controlled plane is scanned. As a result, all the necessary parameters are displayed. To clarify the indicators about the diameter of the rods, control areas are opened. Reinforcement installation technique:

- scan the surface using a magnetic or geophysical method;

- determine the location of the reinforced mesh on the surface, the thickness of the protective layer and the location of the rods;

- They open control areas and help determine the accuracy of these devices.

Search devices

The principle of operation of such devices is to register changes in the electromagnetic field when colliding with metal objects.

Elcometer P120

Elcometer P120 Reinforcement detector in concrete.

One of the easiest and fastest devices to use. It establishes the location of the rods, the direction, and the thickness of the protective concrete layer. The size of the search head of the device is 10 cm. It notifies you of search results using a loud sound signal, as well as data on the scale. Data is not distorted when working near large metal objects.

The sensitivity of the Elcometer P120 makes it possible to quickly and accurately determine the vertical and horizontal direction of reinforced rods. After detecting the reinforcement, it is necessary to move the device in the direction of the rod to determine the maximum minimum signal level. The minimum signal means that the fittings pass at an angle of 900 to the handle of the device. There is also a headphone jack, which allows you to work in crowded and noisy places.

Characteristics:

- detectable reinforcement diameter 0.8-3.2 cm;

- measured concrete layer 1.2 - 1.6 cm.

Elcometer P100

Despite the low price, this device is lightweight, reliable and accurately determines the required parameters (reinforced rods, pipes, stainless steel ties, etc.). The search head size is 10 cm. It notifies you of scanning results using a loud sound signal. Elcometer P100 allows you to set the direction of the valve.

PROFOSCOPE

Using PROFOSCOPE, they carry out operational monitoring of the protective layer in concrete and the location of reinforcement bars. It makes it possible to save measurement data, including automatically. It is programmed with several storage modes, which allows you to choose the one more convenient for use and saves time on manually recording results. The sensor is built into the body of the device, which ensures a small size.

The lightness and convenience of the device allows you to work with one hand, which makes it possible to mark reinforced rods in parallel.

It notifies you of the results of the study using audio signals and video data. Its sensors can show the bars in real time, their diameter, direction and position, as well as the thickness of the protective concrete layer. PROFOSCOPE can determine where exactly the device is located relative to the rods (between them or above one of them). Thanks to this, it takes significantly less time and money to complete all the work, and the accuracy of the results is not distorted.

Characteristics:

- the determined diameter of reinforced rods is 0.5–5.7 cm;

- measured concrete layer 0.5-18 cm;

- operating temperature -100C - 600C.

Search-2.51

The device sets the thickness of concrete and the diameter of reinforced rods in 2 measurements, automatically and manually determines the steel grade, and also has the function of saving data. Using Search-2.51, areas are found in which there is no reinforcement, so that in these areas the strength of the concrete structure can be checked using appropriate methods. It meets all GOST requirements. Has 3 memory modes.

Advantages of use:

- linear indicator, digital data and sound signal for searching reinforced rods;

- accuracy in determining the thickness of the concrete layer;

- small size;

- the sensor's protective rods slide easily along the plane being tested;

- built-in battery with charger.

Characteristics:

- calibration in the device is performed automatically;

- backlit graphic display;

- the ability to search for previously saved results by dates and numbers;

- 6 systems of use: search for reinforcement at great depths; installation of projections of reinforced rods onto the plane being tested; measuring the diameter of the rods with a known protective layer of concrete; measuring the protective layer of concrete; measurement with unspecified reinforcement parameters.

NOVOTEST Armaturoscope

These devices have three operating modes:

- the main one is to determine the concrete layer with a known diameter of reinforced rods and vice versa;

- scanning;

- deep search.

To search for reinforcement, the plane is scanned by the device. To do this, the sensor can be rotated around an axis, which is how the thickness of the concrete layer is determined. The distance to the reinforced rods is displayed on the display and linear indicator. The device also has a sound search feature, which makes it possible to determine the direction of the rods, despite the display (the closer the fittings, the more frequent the sound signal).

NOVOTEST Armaturoscope determines the diameter of reinforcing bars using a dielectric spacer. The device consists of a block and a sensor, which is attached using cables. Operation is provided by conventional rechargeable batteries.

Conclusion

Determining the exact location of reinforcement bars in concrete is an important task when performing construction and repair work, because damage to the reinforcement bars of a structure can make it not only less strong, but also cause damage to the entire structure.

Today, the most common search method is magnetic scanning. There are many devices for this that vary in price. Technical characteristics and accuracy of results.

kladembeton.ru

Buy a reinforcement detector in concrete at a minimal price - an indispensable device when carrying out repair and construction work

Home > Concrete thickness meters and reinforcement detectors

Searching for reinforcement in concrete structures and reinforced concrete products until recently was a very difficult process. To complete it, partial damage or even destruction of structures was required. Today, non-destructive testing methods can solve the problem, in particular magnetic scanning using a detector of reinforcement in concrete - a modern innovative device.

The main scope of its use is construction, repair work, maintenance of facilities in operation, and so on. In this case, you may need another device for working with concrete: sclerometer, concrete strength meter, ips

Purpose of the rebar detector

In addition to determining the location of elements used to strengthen structures, a reinforcement detector in concrete will help determine:

- thickness of the protective concrete layer;

- underfilling of concrete during the construction of buildings, structures and other objects;

- diameter of the reinforcement used.

The research procedure consists of scanning the surface of the structure. If it is necessary to clarify the obtained parameters, the control sections are opened.

To clarify the strength of a building material, AnalitPromPribor offers its customers to buy forms for concrete samples here.

analytprom.ru

Rebar detectors

Display: list/grid

Rebar detectors are often used in construction. This is the name given to devices designed to conduct an operational search for various foreign elements located in walls, ceilings, floors, etc. Such devices are characterized by a fairly wide range of applications. They can be used both at home and during professional construction work. In particular, reinforcement detectors are actively used, for example, when finishing walls.

Rebar detectors can be used to solve a wide range of problems. The main one is the task associated with searching for reinforcement of various natures in the walls of construction sites. With the help of such devices it is possible to detect metal objects and structures from the smallest to the largest. Working with fitting detectors, the operator can easily find pipes, pins, nails and even electrical wiring. In fact, searching for such objects is a very important task. Timely detection of various inclusions will help avoid a considerable number of unforeseen situations in the future. For example, it will prevent possible drilling of the most important reinforcement elements. Thus, the use of detectors will make further finishing or repair work safe, which is important for builders.

Among modern fittings detectors there are many types. The simplest classification of such devices comes down to the fact that all fittings detectors are divided into universal devices, locators and detectors designed to search for electrical wiring. Let us consider the most important distinctive features of each of the listed types in more detail.

Let's start with detectors, which are used to determine the location of electrical wiring. From the name of this class of devices their purpose is clear. Let’s just say that modern devices of this type are capable of reacting to virtually all possible metals.

Locators have slightly more advanced search capabilities. Working with such devices will allow the operator to quickly not only detect the location itself, but also determine some additional parameters. For example, its depth, as well as the size of the underlying object, its diameter. It should be noted that such devices are already somewhat more expensive, but the control capabilities implemented with their help are also much wider. This makes reinforcement locators widely applicable when carrying out finishing, repair, and reconstruction work.

Universal rebar finders are distinguished by the fact that they can detect not only metal or conductive products, but also objects made of materials such as wood and plastic. Using such devices, it becomes possible to find a wide range of objects of a very different nature, which is certainly an advantage of work carried out using universal locators or reinforcement detectors.

Also, all detectors are divided into household and professional. It is clear that the first of them are characterized by the presence of the most basic functions that allow them to detect objects located not too deep. If we talk about professional devices, then these are more advanced devices, characterized by the presence of much more developed functionality, with the help of which you can conduct the most complete search for fittings, while receiving maximum information about the location, shape and size of the object.

When choosing a device, it is extremely important to first determine the tasks for which it is being purchased. After all, it is clear that to search for objects located in walls that are not very thick, there is no need to buy professional expensive reinforcement detectors. Conversely, to solve more complex problems, it is better to purchase a professional device.

world-ndt.ru

Rebar detectors

Sort by price: Sort by popularity:

Reinforcement detectors are widely used in construction and repair work. Essentially, these are metal detectors that have specific properties, in this case, to determine the location of metal objects in the thickness of concrete. Most often these are reinforcing bars, however, depending on the model, these devices are capable of detecting wiring, pipes made of various metals or power cables and other inclusions.

Rebar detectors are most often used in construction and renovation before drilling into walls, ceilings or floors. They are able to not only detect a metal frame, but also determine its depth, direction (horizontal or vertical) and even diameter. Many of the most advanced (and therefore expensive) are equipped with the function of detecting and differentiating magnetic and non-magnetic metals, as well as determining their localization within a non-magnetic and non-conducting environment. Some models save the received data and display it on the display with the possibility of further transferring it to a PC for processing.

A device consisting of a sensor, which is moved along the surface under study, and a generator, reports found metal inclusions using an audio and visual signal. To work in difficult conditions, some devices are equipped with headphones and backlighting. When choosing, you also need to pay attention to sensitivity: for example, not all models of fittings detectors are able to differentiate between two parallel pipes; many can identify them as one large one. However, manufacturers also offer devices that determine the depth (sensitive over 180 mm) and direction of metal rods or pipes with their visualization in real time (for example, Profoscope reinforcement locator).

t-ndt.ru

vest-beton.ru

Main functions

- Determination of projections of reinforcement onto the concrete surface, measurement of the protective layer , estimation of diameter

- Automated instrument calibration before taking measurements

- Display information on a highly informative graphic display with backlight

- Archiving of 1500 results and measurement conditions, accelerated search for results in the archive by dates and numbers

- Russian and English language for menus and text messages

- USB connector for working with a computer and charging batteries

Ferroscan PS 250 System – Detectors

- Hover over the image to enlarge.

Click on the picture to enlarge.

- Hover over the image to enlarge.

Click on the picture to enlarge.

- Hover over the image to enlarge.

Click on the picture to enlarge.

- Hover over the image to enlarge.

Click on the picture to enlarge.

- Hover over the image to enlarge.

Click on the picture to enlarge.

- Hover over the image to enlarge.

Click on the picture to enlarge.

Click on the picture to enlarge.

www.hilti.ru

Concrete reinforcement locator TC100 | Concrete control

Concrete reinforcement locator TC100

TC100 – designed to determine the depth of reinforcement in the protective layer of concrete and the diameter of the reinforcement. In addition, the device has the function of detecting and localizing magnetic material and electrically conductive material in a non-magnetic and non-conducting environment. It is an intelligent non-destructive testing equipment with automatic detection, data storage and information display functions.

Peculiarities:

• Concrete thickness measurement to steel reinforcement and metal pipes • Reinforcement location and diameter detection • Large backlit graphical display • High level alarm and audible alarm for greater accuracy • Concrete cover depth detection and rebar placement up to 180mm • Graphical display on screen in real time • Data processing software compatible with Windows 95/98/2000/Me/WT/XP • Auto calibration, system error correction • Three scanning modes: lattice scanning, profile scanning and large area scanning

Specifications:

| Concrete cover thickness measurement range | Range I: 6mm~90mm | |

| Range II: 7mm~180mm | ||

| Range of measurable diameter of reinforcement | ?6 mm ~ ?50 mm | |

| Tolerance on the thickness of the protective layer | Band I | Range II |

| ±1 mm | 6mm~59mm | 7mm~79mm |

| ±2 mm | 60mm~69mm | 80mm~119mm |

| ±4 mm | 70mm~90mm | 120mm~180mm |

| Working temperature | -10оС ~ +40оС | |

| Relative humidity | ||

Equipment

| • Device | 1 | • Key | 2 |

| • Sensor | 1 | • User manual | 1 |

| • Signal cable | 1 | • TIME certificate | 1 |

| • Carrying strap | 1 | • Warranty card | 1 |

| • AA battery (LR6) | 6 |

techdiagnostica.ru

Completeness

Table 4 — Completeness of the measuring instrument

| Name | Designation | Quantity, pcs. | Note |

| Concrete protective layer meter POISK-M | 1 PC. | ||

| Dielectric gasket | 1 PC. | By order | |

| USB charger | 1 PC. | ||

| USB cable | 1 PC. | ||

| PC communication program | 1 PC. |

| Name | Designation | Quantity, pcs. | Note |

| Verification method | MP 408313-100 | 1 PC. | |

| Manual | NKIP.408313.100RE | 1 PC. | |

| Transport container | 1 PC. |

Elcometer P120 Concrete Rebar Detector

Elcometer P 120 Rebar Detector

The ability to detect reinforced steel bars and metal pipes is very important in the construction, maintenance and repair of buildings and structures. Contact between the drill and the pipe can result in costly repairs. Contact between the drill and the reinforced rod will not only damage the drill, but it can also seriously weaken the reinforced rod, which can lead to structural damage.

Before any routine repairs, it is very important to determine the location, orientation and depth of subsurface metal structures.

Purpose of the Elcometer P120 Rebar Locator

The Elcometer P120 Concrete Cover and Reinforcement Locator is designed specifically to determine the location and orientation of reinforced bars and other subsurface metal structures, and is designed specifically to determine the depth of concrete cover at a specific point above rebar and other subsurface metal structures.

Additional features of the Elcometer P120 Concrete Cover Meters include reinforcement location, orientation, and bar diameter determinations.

The Elcometer P120 Concrete Rebar Detector is perhaps the easiest and fastest way to determine the presence of rebar in concrete. The Elcometer P120 Cover Meter is widely used to find "safe spots" before drilling into concrete and not only determines the location and direction of reinforcement, but also provides an indication of the depth of concrete cover. The Elcometer P120 Rebar Finder comes with a 100mm search head, leather case and batteries. Distinctive features of the device for measuring the thickness of the protective layer of concrete and searching for reinforcement in concrete ElcometerP100

- Fast, Accurate - Loud beep and clearly visible analog scale for fast, accurate scanning.

- Focused scanning field - The Elcometer P120 maintains measurement accuracy even when working very close to the center of reinforced bar or metal objects, such as metal window frames.

- Highly directional scanning field - The Elcometer P120 allows you to quickly and easily differentiate between horizontal and vertical rebar.

- Headphone jack - Clearly detects rebar in noisy areas.

Detection and orientation of reinforcement

The Elcometer P120 allows you to differentiate between horizontal and vertical bars. After identifying the steel reinforcing bars, rotate the search head until the minimum and maximum signal levels are found. The maximum signal shows that the bar runs parallel to the search head handle, the minimum signal shows that the bar runs at an angle of 900 to the search head handle.

nd-testing.ru

When constructing, or repairing and maintaining buildings, the ability to search and detect various subsurface metal objects is extremely important.

Measuring the thickness of the protective layers of concrete and identifying areas with reinforcement elements are mandatory procedures before carrying out repair and construction work. To solve this problem, a thickness meter is used. Armaturoscope is a non-destructive testing device that operates on the basis of the interaction of electromagnetic fields.

With the help of an Armaturoscope, the location of the embedded parts and the top row of reinforcement is revealed, and the size of the protective layer is determined. The device also provides the opportunity to estimate the approximate diameter of the reinforcement and its position with an unknown protective layer, which allows for the necessary work to mark out structures for subsequent tests. The thickness gauge plays an irreplaceable role when it is necessary to restore lost reinforcement documentation.

The concrete cover meter operates in four scanning modes, is equipped with a backlit graphic display and sound sensors.

The size of the protective layer of concrete has a significant impact on the durability of the reinforced concrete structure. The protective layer protects the reinforcement from moisture, oxygen, aggressive substances and gases. Reinforcing bars that have a small protective layer or significant defects in it are susceptible to corrosion first.

The thickness of the protective layer of concrete is a very important indicator when constructing or inspecting any structure. It is installed depending on the type and diameter of the reinforcement, the size of the element sections, the type and class of concrete, the operating conditions of the structure, etc.

For example, the thickness of the protective layer of concrete for longitudinal reinforcement, non-tensioned or with tension on stops, must be no less than the diameter of the rod or rope; in slabs and walls up to 100 mm thick - 10 mm; in slabs and walls with a thickness of more than 100 mm, as well as beams with a height of less than 250 mm - 15 mm; in beams with a height of 250 mm and more - 20 mm; in prefabricated foundations—30 mm.

The ability to detect rebar and other subsurface metal objects is essential in the construction, maintenance and repair of buildings and structures. For example, to determine areas of the surface of structures free from underlying reinforcement, to measure strength using methods: ultrasonic, shock-pulse, separation with chipping and rib chipping.

When carrying out repair work, contact of a tool with a metal object not only causes damage to the tool, but can also seriously weaken the structure due to the destruction of reinforcement. The result of this will be structural damage and the emergence of a corrosion center due to partial destruction of concrete. Before any routine repairs, it is very important to determine the location, orientation and depth of subsurface metal structures.

To solve these problems in non-destructive testing of building materials, devices called concrete protective layer thickness meters or reinforcement scopes are used.

These devices implement a magnetic control method, which is regulated by GOST 22904-93. This method is based on the interaction of the magnetic or electromagnetic field of the device with the steel reinforcement of a reinforced concrete structure. The method makes it possible to establish the size of the protective layer, identify the location of the top row of reinforcement bars and embeds, and also, if the protective layer is unknown, approximately estimate the diameter of the reinforcement.

The use of the magnetic method makes it possible to clarify the compliance of the execution of reinforced concrete structures with design solutions in terms of compliance with the diameter and position of the reinforcement used; restore lost design documentation for reinforcement; mark the structure to test the strength of concrete using tear-off, rib chipping, ultrasonic methods or when drilling cores; evaluate the relative position of reinforcement and cracks extending to the surface of the structure, etc.

The NOVOTEST concrete protective layer meter Armaturoscope, produced by LLC Scientific and Technical Center "Industrial Equipment and Technologies", Novomoskovsk, Ukraine, meets all the requirements for accuracy and functionality put forward for devices of this class.

The device has four modes:

– main mode – measuring the depth of reinforcement with its known diameter or determining the diameter of the reinforcing bar with a known protective layer;

– scanning mode;

– deep search mode;

– mode for measuring the diameter of reinforcement with an unknown protective layer.

The search for reinforcing bars is carried out by scanning the monitored surface with a sensor in combination with rotation around the sensor axis until the minimum possible reading of the thickness of the protective layer is obtained for a given case. The search process is displayed on the display by the distance to the reinforcement and a linear indicator. For ease of use, the device provides sound search. It allows you to determine the orientation of reinforcing bars without continuously monitoring the device display by changing the frequency of the sound signal. As the sensor approaches the reinforcement element, the frequency of the sound signal increases.

The device allows you to determine the unknown diameter of the reinforcement using a dielectric spacer. In this case, the first measurement is performed without a gasket, the data is recorded in the device’s memory, then the second measurement is performed with a gasket and the device displays the diameter of the reinforcement

NOVOTEST Armaturoscope consists of an electronic unit to which a sensor is attached using a cable. The device is powered by two AA batteries, which ensures continuous operation of up to 10 hours. All search and measurement results are displayed on a backlit graphic display. In terms of size and weight, the electronic unit is comparable to a large smartphone and fits into the palm of your hand without any problems.

As a result of the work of Ukrainian developers, the result was a device that is in no way inferior in functionality and metrological characteristics to Russian analogues produced by SKB Stroypribor and NPP Interpribor LLC, and in terms of price/quality ratio it can successfully compete not only with Russian devices, but also with European ones and Chinese manufacturers.

Proceq Profoscope/rebar detector in concrete

Proceq Profocsope is a universal, comprehensive device for detecting the location of reinforcing bars and a device for measuring the protective layer of concrete. This is a compact and lightweight sampler that can be operated with one hand.

Profoscope has a unique technique for visualizing reinforcing bars in real time, giving the user the ability to virtually “see” the location of reinforcing bars up to 180mm below the surface of the concrete layer. The device is equipped with indicators indicating the location of the bars, as well as optical and acoustic means for determining the position of the reinforcement.

The device combines these unique technologies to quickly and efficiently locate reinforcing bars. The diameter of the bars is determined by the exact search range specified.

Profoscope is very easy to use. The device's intuitive interface allows you to quickly set the location of reinforcing bars.

You can also buy an improved version of Proceq Profoscope plus from us

Below is a video demonstration of the Proceq Profocsope/Rebar Detector

Benefits of the Proceq Profoscope detector

- Real-time rebar detection

- Visual representation of reinforcing bar locations at close range

- Ability to determine the location of reinforcing bars, the midpoints between them and their orientation

- Visual and acoustic recognition of the location of reinforcing bars, warning signal about the minimum protective layer

- Correction for closely spaced adjacent rods

- Setting local values (metric, imperial)

- Wireless control of the device with one hand

- Switchable display backlight for working in dark areas

- Language-independent pictographic menu

- The starter test kit allows the user to familiarize themselves with all functions in a comfortable environment, so as not to waste time while working on site.

Fields of application of the detector

- Rebar detection (used by general contractors, construction contractors, drillers, electrical contractors)

- Measuring concrete cover (used by general contractors, building contractors, civil engineers)

- Measuring the diameter of reinforcement cover (used by educational institutions, building inspectors, construction contractors)

- Checking minimum concrete thickness (used by building inspectors, building contractors)

- Construction of reinforcement mesh and coating for corrosion research (Canin+) - (used by building inspectors)

- Assessment of reinforcement network for planned loads of the structure (used by construction contractors, construction contractors)

Proceq Profocsope rebar detector in action

Technical specifications of the Proceq Profoscope

| Nutrition | 2 x 1.5v AA (LR6) batteries |

| Voltage range | 3.6 V to 1.8 V |

| Technical data | |

| Size | 205 x 92 x 210 mm (8″ x 3.6″ x 8.3″) |

| Weight | 330 g (12 oz) |

| Battery life | |

| Backlight off | 50 h |

| Backlight on | 15 h |

| Downtime | |

| Standby mode | 30 s |

| Automatic shutdown | 120 s |

| Environmental conditions | |

| Temperature range | -10º to 60º C (14º to 140º F) |

| Humidity range | 0 - 100% rH |

| Protection class | IP54 |

| Applicable standards and regulations | BS1881 part 204- DIN1045- SN 505 262- DGZfP B2 |

Verification

carried out according to the document MP 408313-100 “Measurers of the protective layer of concrete POISK-M. Verification methodology”, approved by the Federal Budgetary Institution “Chelyabinsk Center for Mathematics and Mathematics” on November 19, 2020.

The main means of verification: caliper ShTs-11, measurement range from 0 to 250 mm, measurement error ±0.05 mm. Registration number 22088-07;

It is allowed to use similar verification tools that ensure the determination of the metrological characteristics of the verified measuring instruments with the required accuracy.

The verification mark is applied to the verification certificate.