The design of the steps to the house, although important, is not the most complex. Making a porch on your own is not a very difficult and time-consuming job. If you choose a material with which you have sufficient general knowledge and skills in construction, then success will be guaranteed. For example, when using blocks as the main material, it is enough to have the skill of masonry operations and the ability to knead and use mortar. The photo shows an excellent example of a house where foam block was used as the main material.

Benefits of blocks

Why is it worth paying attention to this material when deciding what to make a porch from? The answer may be a list of advantages that blocks have:

- Light weight. This does not carry a functional load, but using a foam block reduces the labor intensity of the process;

- Easy to install. The foam block is larger in size than a brick and, accordingly, less of it is needed individually. This simplifies construction and all the work can be done without much experience;

- Speed. According to this indicator, foam block has few competitors. Pouring concrete formwork or laying a brick porch takes much more time;

- Durability. If the porch is not subjected to destructive loads during use, then it is impossible to accurately determine its service life. Some other elements of a house's structure deteriorate faster than foam blocks naturally. The porch will last as long as the strongest, load-bearing part of the building;

- Price. Construction costs will not place a heavy burden on the owner, since both the block itself and its installation are perhaps the cheapest and most accessible way to build a porch with your own hands;

- Safety. The foam block does not contain harmful substances. By definition, he cannot single them out. A porch made from this material will be environmentally friendly, non-flammable and not fireproof.

Building with blocks is perfect for independent work, since you don’t need any special skills when laying. Almost any man can make a porch with his own hands and without help. The photo shows one of the stages of building a porch.

Important! Despite the relatively low weight, the structure will be massive, so the place is carefully prepared.

Compacts in good soil. If necessary, a screed is made or piles are installed.

Staircase design

In a situation where it is planned to construct a flight of stairs using concrete, work should begin with careful calculations and design. When constructing wooden or metal structures, in case of an error, the ladder can be disassembled, and most of the material will be quite suitable for recycling.

Note! Concrete does not forgive mistakes. Despite the fact that it is, in fact, the most budget-friendly material for construction, an error in the design can lead to serious material costs. Not a single element of an incorrect staircase can be used in the construction of a new structure.

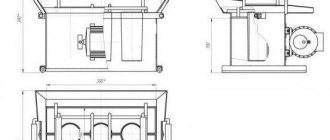

Before starting work on constructing a concrete staircase, it is necessary to draw up a detailed design drawing

Main Dimensions

There are calculated building codes for stairs that should be followed when constructing stepped structures.

Instructions for designing a span, regardless of whether you are building a staircase in a house or erecting porch steps, involve determining the initial dimensions:

- Span width . Taking into account the needs of all residents of the future home, it is necessary to assume that this size should exceed 90 cm. This distance is comfortable for one person to move. If the size of the room allows, then you can expand the flight of stairs to 130-140 cm, so that two people can separate on the steps.

- Step size . This indicator includes 2 elements: tread and riser. The height of the step or riser should be within the range of 13 -20 cm. The tread (horizontal plane) is made at least 26 cm. This takes into account the size of the overhang, which should not exceed 3 cm.

- Number of steps . It has been experimentally determined that for the greatest comfort, movement up the stairs should begin and end with one foot. That is why the number of steps in a march should be odd.

- The slope of the stairs . Here a lot depends on the dimensions of the room itself. Ideally, the span should be located at an angle from 25 to 400. The steeper the staircase, the more difficult it will be to use the structure. This is especially true for children and older people.

Incline angle of stairs for various purposes

For the entrance group

All of the above indicators are also valid for porch steps. But in the case of designing the entrance group, it is also necessary to clarify 2 points:

- Structure height. This is the value from the foundation to the top point of the site, including the thickness of the finishing material. This size will allow you to correctly form the slope angle. It must be taken into account that the upper platform should be 4 - 5 cm below the door threshold. This gap is made in order to ensure unhindered opening of the door leaf even in seasonal rainfall conditions.

- Dimensions of the upper platform. This distance should allow a person to be on the site with the door open. Taking into account the standard canvas size of 80 - 90 cm, the size of the platform should not be less than 120-130 cm.

After all the indicators have been calculated and a design for concrete stairs has been drawn up, you can begin building the structure.

We will consider 2 methods:

- monolithic pouring into formwork;

Forming a flight of stairs by pouring concrete into the formwork

- construction of steps using cellular concrete blocks.

Staircase structure assembled from aerated concrete blocks

Types and features of foam blocks

The following products are classified in this segment of materials, any of which is suitable if you need to build a porch:

- By size. A very wide choice, but when making a porch, preference is given to blocks that have a edge of no more than 200 mm. In this case, each layer will be equal to the height of the standard step. The recommended width of 300 mm will give the optimal angle of inclination of the staircase. A do-it-yourself porch will be convenient and safe to use;

- Material of manufacture. The substances included in the composition play a decisive role in the density of the product. This is not of decisive importance in the construction of the foundation for the porch, but it is much easier to work with lighter blocks. Thus, the density of standard bricks is from 2000 kg/m³. Concrete has an even greater volumetric weight. The density of foam blocks ranges from 400 -1300 kg/m³. An extension made from expanded clay concrete blocks will be 2 times lighter than one made from brick. Sand is not always or to a limited extent used as a filler. The best qualities were noted when using expanded clay and other mineral additives and chemical additives. For example, in aerated concrete blocks a special foaming agent is used, which saturates the solution with air bubbles;

- Form. Foam blocks are offered with both flat and profiled surfaces for reliable fixation. There are also radial products if you plan to build an arched porch. It is better to purchase high-quality blocks with exact dimensions, as in the photo.

Material for making a porch

- Cement grade 400

- Sand, preferably river sand (more resistant to moisture)

- Crushed stone of small or medium fraction

- External coating material

- Formwork or components for it

- Sizing and marking the territory

The size of the porch depends on your wishes. However, there are several factors to consider. Firstly, the porch should not be too small. After all, it is not beautiful and not convenient to use. Set the porch size to be proportional to the size of the house. It is worth considering the number of people who will use it regularly. If the family is large, then a porch “for one” will not be very convenient.

Marking begins with identifying the center of the circle. This should be a point exactly in the center of the line of the front door. How symmetrical the finished porch will be depends on the correct determination of the center of the circle. From the point you need to draw the radius of the circle. You can do this with a compass on paper, and only then transfer it to the work surface in the desired size.

If raising the front door allows, it will be possible to add several steps to the porch. To plan further actions, you need to measure the distance from the ground to the bottom of the door. Based on this, it will become clear to you how many steps, and therefore how many layers of the porch you will need to make. Of course, ideally, the steps should be the same for ease of use.

The standard step sizes are:

- Width from 27 to 32 cm;

- Height from 15 to 18 cm.

Project and construction costs

When planning a porch, you should determine its dimensions and finishing style. Appearance is as important as functionality, so special attention is paid to the combination of materials. The simplest solution is to make a porch from expanded clay concrete or similar blocks the same as the finishing of the house at this height. If the foundation is tiled, then the steps can be made of a similar material, with one caveat. The surface must be safe in wet weather and frost. Special floor, street and facade tiles with appropriate coating are suitable for this. The porch will meet the requirements. Structurally, the following recommendations must be observed:

- It is not advisable to make the width of the stairs less than 1 m. A smaller porch can be made in utility and outbuildings;

- As mentioned above, the optimal dimensions of the steps are determined by the following dimensions - height no more than 200 mm, and width no less than 300 mm. A wide range of sizes is provided for both expanded clay concrete blocks and products with other fillers;

- When planning the installation of handrails and railings on the porch, they think about a system for their fastening. Foam block is a fairly fragile material, and in some cases it is better to install embedded elements into the structure or make cavities for subsequent pouring with concrete. There are also special anchors and dowels on sale that reliably fix the foam block and the fastening element. Some of the models are shown in the photo;

- If the porch has a height of more than 800 mm, then it is recommended to reinforce it. A structure where the block has no more than 4 layers does not need to be strengthened.

A house made of expanded clay concrete blocks, as well as a porch to it from the same material, is made relatively easily, but without finishing it is used exclusively for household needs. Housing requires additional funds and time to achieve the desired appearance. The foam block has excellent heat and sound insulation characteristics, but requires additional finishing operations. The photo shows the house and porch after installation.

To fix the blocks together, you can use either a traditional sand-cement mortar or glue. The last option is preferable. The connecting layer will be thin and the foam block will retain heat better in this case. The porch will be stronger and more reliable. How to work with foam block and glue correctly is shown in the video presented.

A thin layer also reduces glue consumption, and the connection of the elements is guaranteed to be strong. The photo shows how glue is applied and the block is installed.

When choosing a shape, you can abandon traditional balusters. Their function will be performed by columns of foam blocks on which the railings are mounted. The porch will turn out to be massive, but this will also have its own plus. Feeling of reliability and practicality. It is recommended to lay the foam block at a temperature from +5° C to +25° C. If the air is cold, close to zero or below, the solution loses its quality. At temperatures above +25° C, moisture leaves the adhesive composition and enters the block too quickly. In this case, it is advisable to wet the surface with water. Depending on the facade of the house, the porch can be finished with both wood and metal. Technological blanks will help you finish the foam block with your own hands.

Having decided on the form and additional elements, you can begin to count the costs. The price of a foam block is usually indicated per piece. If it is necessary to purchase missing materials, then transportation costs will be added to the estimate. Comparing with similar projects, you can be sure that a porch where foam block is chosen as the main material is cheaper, is made faster and lasts longer than many other options. The process of building a house is recorded in the photo, where construction of a closed porch began on a specially prepared site.

The nuances of building a porch from blocks yourself

Following the project exactly and observing the dimensions of the structure, the master faces some inconveniences associated with the large size of the block. It is not always reasonable to change the proportions, which were determined by a harmonious combination with other elements of the facade. The porch will have different dimensions, and the stylistic organicity will be disrupted. The foam block is easy to process, including sawing. Using a hacksaw on wood is impractical. It will not be possible to use it for its intended purpose, and after several cuts across the block, performance will noticeably deteriorate. There are special hacksaws for this type of work. If this cutting method is chosen, then it is better to make circular markings. You can use a square or accurately mark each edge from the base plane. It is also recommended to file in a circular manner to avoid the hacksaw blade being pulled away. The photo shows how the foam block is cut with a special saw.

It is better to do cutting before diluting the adhesive composition on which the block is laid, since its action time is limited, depending on the brand, from 15 minutes to 2 hours. It is easier to make the order of laying individual parts (if the porch is complex in shape and there are many parts) by marking each finished element. The foam block cut into pieces is marked. The layer and serial number are indicated. You can change the project as much as possible if it does not contradict the design idea. The formation of steps can be done by shifting each subsequent layer to the required width. The foam block is perfect for this job and this can be seen in the photo.

In terms of labor intensity, it is difficult to classify a porch as a complex and time-consuming operation, so you can saw off the block with an ordinary grinder. You can use a standard metal cutting disc, but it works slowly. A stone cutting tool with a diamond edge is much more effective at cutting. The disadvantage of this method is a large amount of dust, but the porch is made on the street, so there is nothing scary about it. Grinders with a small disc will not work. The foam block is too large an object for them and there will not be enough cutting depth when working. A disc with a minimum diameter of 250 mm is required. With such a tool, you can make any porch with your own hands using a foam block.

Important! Don't forget about safety precautions. Working with glue is done with gloves, and operations with an angle grinder wear glasses.

A porch made of lightweight material, which is a foam block, is reliable and durable, but the elements themselves are quite soft in structure. If subsequent finishing requires the construction of sheathing or installation of fasteners, then it is worth checking the reliability of their fixation. The foam block has a porous structure, so satisfactory results are not always achieved by using plastic plugs and dowel nails. Sometimes a positive result is achieved by using anchor bolts or embedded elements. A porch finished with tiled materials does not require additional reinforcement. As an example, the photo shows a porch in the construction of which a block was used, and the decorative finishing was made with paving stones.

Using foam blocks, you can not only make a porch with your own hands, but also build more serious buildings - a summer kitchen, a bathhouse, a barn. Confidence in your qualifications will allow you to take on the construction of a residential building.

Comparison of stairs made of different materials

| Material | Fire safety | Noise level | Perception | Price | Care | Usage |

| Tree | susceptible to burning | dry out over time and creak | pleasant | expensive option | requires updating the varnish coating, labor-intensive maintenance | cannot be used in rooms with high humidity and temperature fluctuations |

| Monolith | fireproof | silent | opaque | high price | require special care | must rest on concrete floors and the wall material must be made of brick, concrete, foam concrete, etc. |

| Glass | fireproof | silent | security risk | high price | require special care | |

| Metal | fireproof | noise when walking | welding seams are visible, heat up in summer, cold to the touch in winter | expensive option | require special care | |

| ytong aerated concrete blocks |

A staircase on the street is a necessity if the site is on a slope. It is possible to build a staircase structure of this type yourself - there are no special subtleties, as in the case of an internal staircase.

Moreover, there are a lot of materials from which an external staircase can be made: brick, stone, wood, etc. If you are not a builder, but an ordinary owner of a site with a slope, of course, you will want the staircase on the street to be like could be simpler to construct. But, at the same time, reliable.

Simple and durable street stairs are made from building blocks (any kind - concrete, aerated concrete, cinder blocks, etc.). In principle, laying them on the mortar is simple, the geometry of each block is basically accurate - it’s difficult not to cope. In principle, it’s not even a matter of masonry, but of preparing the foundation. How to lay blocks on a slope to make the stairs on the street comfortable? Here are some general rules to follow when constructing an outdoor staircase on a slope.

Building a brick porch

In order for the street staircase to be absolutely uniform in color, you need to immediately buy a sufficient amount of brick for its construction.

Important: For the porch of a country house, only red or brown material is suitable. The fact is that apricot and yellow bricks are made with the addition of lime. Therefore, it has a high degree of moisture absorption.

At the first stage, using the “Egyptian” triangle method, markings are made for the foundation of the porch according to the project.

Marking under the porch is carried out using the “Egyptian” triangle method

Tip: To make cast-offs, it is better to use non-thick metal rods and non-elastic cord.

Construction of the foundation

According to the markings, a pit is dug to the depth of the foundation of the house. Next, formwork is installed into it. After this, a sand “cushion” (10 cm) is poured and crushed stone is laid (in a layer of 5 cm). Then a five-centimeter layer of concrete is poured. A day later, the reinforcement frame is installed. Next, the foundation itself is poured.

Brick porch. Photo of preparing a pit for pouring concrete

Important: The frame is knitted from 12mm rods using wire. Welding is not used in this case, since the places of such connections begin to rust very quickly.

How to lay a brick porch at a dacha

So, how to make a porch out of brick? The standard brick size is 25*12*6.5 cm. A more or less acceptable height of the steps will only be achieved if the material is laid on the bed in two rows (6.5+6.5+2=15 cm, where 6.5 cm is the thickness of the brick, 2 cm is thickness of two seams).

Closed porch of a brick house. Photo of the march construction process

If you lay them using the “brick” method, you can get a quite comfortable step depth of 25cm. In the bottom row of each step, the material is placed with a spoon, two at a time. In the top - poke along one at a time.

Now let's see how to lay a brick porch. They begin its construction by laying both parapets. They are usually made as thick as a brick.

Having laid out the first step, the space remaining up to the base of the house is filled with cement mortar or covered with stone. After the concrete pad has hardened, the second step is laid out. The resulting “trough”, fenced with it, the walls of the parapet and the base of the building, is again filled with concrete mortar. Then lay out the third step and so on until the upper platform. The latter is laid out in two rows of solid bricks.

First the parapet is laid out

The laying of a semicircular brick porch is done a little differently. In this case, the elements of both rows of steps are stacked with butts. In this case, the seam thickens from the inside out.

Beautiful porch of a brick house. Photo of a design with semicircular steps

Important: Concrete slabs must be reinforced with a frame made of 10-12 mm rods. The laying of both straight and semicircular steps is carried out with bandaging of the seams and their jointing.

You can also lay out a kind of formwork from bricks, arranging lintels of different heights from parapet to parapet, install reinforcement and fill everything with concrete. In this case, you will get a more comfortable porch with a step width of 32.5 cm (6.5 +25+1 cm per seam).

Brick house porch design. Photo of a staircase with a brick parapet and concrete steps trimmed with tiles

Since the most convenient step depth is still considered to be 30 cm and a height of 17 cm, often only the porch parapets are laid out of brick. The march is made of poured concrete.