55

The foundation, regardless of type, is subject to serious loads. The influence is exerted by processes occurring in the soil, sudden atmospheric changes, and the weight of the building.

Basis for a private home

Any existing defect leads to gradual destruction of the structure. The only way to strengthen it is by knitting reinforcement.

Features of the base

The basis of the foundation is concrete. A common affordable material in construction, characterized by good characteristics.

Base - concrete

The main disadvantage of concrete is its fragility. Against the backdrop of climate change and heavy loads, it is gradually cracking.

Cracks in concrete

The strength of the material was increased more than 200 years ago - it’s not difficult to guess how many disasters there were in the past.

After strengthening the base material, an analogue, reinforced concrete, began to be used in construction.

Reinforced concrete

Combines the characteristics of concrete and metal.

When designing suburban structures, a strip foundation is usually chosen as the foundation. Preparation usually takes up to 35% of the cost of all construction work. The reason for the popularity of the base is an advantageous combination of qualities:

- no special equipment required;

- the design of the base is light and simple;

- The foundation is suitable for a building with a basement and reinforced concrete floor.

The foundation is not always effective for the following reasons:

- a certain form when calculating a project during the construction period may require changes;

- the optimal shape is laid along the perimeter of the building. You need to focus on the walls (load-bearing), interior partitions;

- You can use the base if the house is built on dried soil.

Peaty soil

Such a foundation cannot be laid on problematic soil. Peaty, heaving soil is called problematic. Otherwise, you have to fill it to a greater depth - it is unprofitable.

Classification of methods

Installation of any frame or mesh structures involves the use of one of three methods of tying reinforcement:

- Welding rods with electrodes;

- Overlap connection;

- Wire connections.

The most common reinforcement has a cross-section of 3.2 cm.

Electrode welding of rods, as stated above, has a negative effect on the safety margin of the finished structure.

If special vibrators are used to compact the concrete mixture, the risk of damage to the welded reinforcement mesh is quite high. This type of work requires a welding machine and sufficient experience. Therefore, welding of rod fragments is not widely used. The second and third methods of tying reinforcement are more common in construction. On the scale of construction sites, these methods are automated, but in private house-building they are used in a manual version.

Manual knitting methods

To perform this operation, the master needs a special tool (hook or pliers), wire with a 1 mm diameter. Sometimes wire clamps can be replaced with plastic material. Algorithm of actions:

- A piece of 30 cm is cut from a coil of wire;

- Folds in half;

- The junction of the rods is wrapped with wire diagonally;

- The hook is threaded into the resulting loop;

- The ends of the wire are placed under the hook;

- The hook rotates in the direction of the clock hand;

- The operation stops when there is a sufficient level of reliability.

Important detail: a columnar foundation requires the use of smooth reinforcement. It is more difficult to knit with wire, because during the process of twisting the hooks begin to bend. Experts advise using a specialized tool in such situations - a reinforcing gun.

Overlapping reinforcement ties

An equally common way of tying reinforcement rods is with an overlap. The type of wire determines the amount of allowance at the junction of the threads. In addition to the characteristics of the knitting material itself, other factors are taken into account:

- Brand of cement being poured;

- Nature of work;

- Places of future connections.

The overlap should always exceed 25 cm. If the height of the reinforced frame is sufficiently high, it is necessary to use scaffolding, scaffolding or removable-lifting mechanisms. The work algorithm is as follows:

- The fittings are prepared for installation (cleaning with a wire brush to remove dirt, leveling with a hammer);

- Slinging;

- Supplying the element to its location;

- Leveling the rods strictly according to the drawing;

- Bundle of reinforcement.

If the reinforcement cage is installed in a well, trays or special traverses are used.

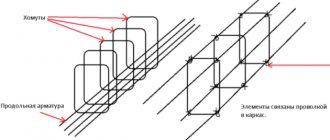

Strip foundation: how to knit a reinforcement cage?

All types of strip foundations are reinforced. The design and brand of material used are recorded in the construction project. Typically, the installation of reinforcing bars is carried out in 2 rows. Installation algorithm:

- Preparatory procedures: cleaning the rods, aligning them;

- Implementation of temporary connection of reinforcement - slinging;

- Transfer of elements to the installation site;

- Correction of details in strict accordance with design documentation;

- Knitting connections.

If reinforcement cages are located at a height exceeding 3 meters, lifting equipment or special devices are used.

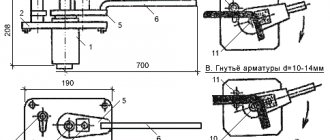

Using a pistol

Manually joining the pieces with a crochet hook takes 10 to 15 seconds each. To automate this operation, a semi-automatic hook is used. Using this device allows you to spend 2 times less time on the same operation. Tying reinforcement requires the master to have sufficient experience in this area. The first time it is especially difficult to do this on your own. Using a wire tying gun makes difficult work easier. With this device, even a beginner can cope with a reinforced frame in a few hours.

Using a knitting gun, the reinforcement is knitted automatically. Wire charges in cassettes allow you to do everything quickly and efficiently. Feeded through a special hole, the wire is tied in 1 second. The use of this miracle device replaces the work of an entire team of workers.

There are often manual versions of crochet hooks on the market, after using which the edges of the wire must be trimmed.

Reasons for reinforcement

Reinforcement is carried out in order to compensate for the loads acting on the foundation.

Reinforcement is the most important stage of construction

A high grade of concrete is used to construct the foundation to avoid destruction of the structural integrity.

Steel reinforcement

A steel rod turns ordinary concrete into reinforced concrete. The base acquires the highest resistance to loads and snow.

The strip base is a monolithic reinforced concrete frame.

Groundwater

The soil on which the foundation is built is quite heterogeneous. Affect:

- jumping atmospheric pressure;

- grass;

- snow;

- water (ground);

- moisture.

When the soil moves, it affects the foundation. The lower part is affected by tension, the upper part is affected by compression.

A steel rod, while maintaining its integrity, can withstand ten times more loads than ordinary concrete.

Steel is a fairly flexible material that tends to elongate. By connecting together, steel and concrete cope with existing loads.

Sometimes, only the lower part of the foundation is reinforced, poured with concrete mixture into a trench dug for filling. It is determined by the load of the structure, which does not allow the beam to sag.

According to builders, the approach is incorrect; the lifting force of wet, expanding soil and the force of frost heaving when water in the ground freezes are not taken into account.

The resulting load is much greater than the load provided by the structure. Tension occurs in the upper parts of the base. Leads to destruction of the foundation structure.

DIY hook for tying reinforcement: video

How to make a HOOK for KNITTING REINFORCEMENT

© Text: A. Kunaeva

TOOLS FOR CRAFTSMAN AND CRAFTSMAN, AND HOUSEHOLD GOODS VERY CHEAP. FREE SHIPPING. THERE ARE REVIEWS.

Below are other entries on the topic “How to do it yourself - for a homeowner!”

- We cut and knit the reinforcement with our own hands. We work with reinforcement and wire. Before...

- Do-it-yourself supports for tomatoes How to make supports for a garter...

- Do-it-yourself garden figurine (cat) from wire How to make garden figurines from…

- How to make thread from plastic bottles with your own hands. Thread from old bottles with your own...

- Do-it-yourself metal “clapper” for a carpet METAL RUGGER FOR YOUR OWN…

- DIY bird feeder in the form of a Japanese gazebo Homemade bird feeder in…

- DIY gypsophila wreath for a wedding - master class and photo How to make a white wedding wreath...

Subscribe to updates in our groups and share.

Let's be friends!

With your own hands > How to choose or how to make > Tools > Hook for automatic tying of reinforcement - application and use

What should the reinforcement be?

When laying the foundation, the safety factor is taken into account. A mandatory requirement is maximum resistance to climatic and mechanical factors.

Foundation frame

Requirements for fittings:

- It is allowed to replace the supporting rods. Possibly, if the load in the calculation does not exceed SNIP;

- with the correct construction of the base frame, it will not interfere with pouring;

- when installing reinforcement, the design step must be taken into account;

Anti-corrosion coating

- the structure must have an anti-corrosion coating;

- Movable “floating” connections of rods at frame intersections are not allowed. Applies to any connection method.

Materials

The main materials used for foundation reinforcement:

The most important material is fiber

| Material | Description |

| Fiber | Another name is synthetic fiber. Made from polypropylene, low carbon steel wire. In concrete, the element binds the components into a single whole. Fiber improves the mechanical strength of the foundation and the water resistance of concrete. The risk of cracks is reduced. Fiber is introduced into concrete in dry form. In 90% of cases it is used to prepare lightweight concrete mortar. |

| Reinforcement (steel) | Material of any diameter is used. Steel reinforcement improves the properties of concrete. Even under heavy bending loads it does not collapse. Corrosion of the reinforcement does not occur. It is kept in the same form as before the start of construction work. Depending on the job, sometimes the fittings require straightening. |

| Mesh (metal) | Classic reinforcement. The mesh helps to maximize the filling of the concrete space. The mesh diameter is quite small. Must be made of very high quality metal. |

| Wire (steel) | Stainless steel wire is used for the foundation. Diameter – 2-8 mm. Durable, reinforces concrete. The most important thing is to alternate transverse and longitudinal positions. The main disadvantage of the material is its high price. Usually, they are replaced with steel wire. |

Types of fittings

The fittings are divided into:

- profile. Reinforcement with a smooth profile is used as connecting jumpers in 70% of cases. There is a material with a periodic profile - it has a relief surface, improves adhesion;

Composite reinforcement

- material. Classic - high-quality steel fittings. It bends and rolls up well. Composite reinforcement is used, which contains fibers of glass, basalt, and carbon. Lightweight, affordable. The advantage is immunity to corrosion. It cannot be welded because it does not bend.

What materials should be used

For reinforcement the following are usually used:

Electric gas welding seams

- welds. The welding process is fast, but a rigid connection is formed. It differs in density from the material used for making reinforcement. The downside is instability with respect to corrosion. When the load changes, they begin to burst. The strength of the foundation gradually decreases;

Welding wire

- knitting wire. The elements are connected by welding units;

- couplings;

- fasteners, clamps made of stainless, anti-corrosion material - plastic for quick installation. The advantage is corrosion resistance.

Tools

Screwdriver

You will need:

- hook. Visually it resembles a bent nail that has previously been carefully turned. It is used as an attachment and is clamped in a screwdriver chuck. The screw hook is the most efficient;

Knitting gun

- knitting gun;

- pliers. Used if there is relatively little work.

An option is a pistol, although it has a lot of disadvantages. Inconvenient when you have to knit reinforcement in difficult areas. More wire is consumed.

It is better not to use pliers at all - they affect the strength characteristics of the structure.

Reinforcement of the base of a strip foundation

On soils with not very high bearing capacity, on heaving soils or under heavy houses, strip foundations are often made with a sole. It transfers the load to a larger area, which gives greater stability to the foundation and reduces the amount of subsidence.

To prevent the sole from falling apart under pressure, it also needs to be reinforced. The figure shows two options: one and two belts of longitudinal reinforcement. If the soils are complex, with a strong tendency to winter baking, then two belts can be laid. For normal and medium-heaving soils, one is enough.

Reinforcement rods laid lengthwise are working. They, as for the tape, are taken in second or third class. They are located at a distance of 200-300 mm from each other. They are connected using short pieces of rod.

Two methods of reinforcing the base of a strip foundation: on the left for foundations with normal bearing capacity, on the right for not very reliable soils

If the sole is not wide (rigid design), then the transverse segments are structural and do not participate in load distribution. Then they are made with a diameter of 6-8 mm, bent at the ends so that they cover the outer rods. They are tied to everyone using a binding wire.

If the sole is wide (flexible), the transverse reinforcement in the sole is also working. She resists the soil’s attempts to “collapse” her. Therefore, in this version, the soles use ribbed reinforcement of the same diameter and class as the longitudinal one.

Main settings

The parameters are shown in the table:

| Parameter | Description |

| Anti-corrosion protection | The reinforcement frame must be completely filled with concrete. The optimal distance from the formwork is 60-80 mm. |

| Rods | There are 2 types of rods - clamps, working reinforcement. Clamps can be vertical or horizontal. Serve to bind the frame into a single whole. The optimal clamp cross-section for reinforcement is 10-15 mm. The profile is periodic, used as a supplement to clamps. |

| Vertical components | Designed to connect and support both layers of the foundation. Placed every 400-900 mm. The load is insignificant, so the optimal cross-section for the rods is 5-10 mm. |

| Horizontal components | The rods are laid out overlapping. If the foundation is shallow, the optimal number of layers is two. Each has from two to four rods. If the base is deep, 3 layers are used. The distance must not exceed 300-400 mm. |

How much materials are required?

The quantity is calculated in linear meters, kilograms. You need to take as a basis:

- reinforcement schemes;

- foundation parameters.

Preparatory work

We will assume that you have already figured out how much reinforcement is needed for the foundation and have purchased the required number of meters of this material. We will also need knitting wire, the footage of which is calculated based on the number of reinforcement joints. This value must be multiplied by 0.3 m (this is exactly how much wire is needed for one connection). If it is known that the reinforcement frame will not be walked on while pouring concrete, then plastic clamps (the kind used when tying cables) can be used instead of wire. And to twist the wire, you need to purchase a special hook for tying reinforcement - a cheap tool that will greatly facilitate the work.

How the reinforcement is knitted (diagram)

Correctly knit the reinforcement using the “cage” technology. It is assumed that the corners are secured in any way. The angle is 90 degrees.

How the reinforcement is knitted

Knitting pattern:

- Bend a piece of wire (250-300 mm).

- Overlap the rod. The correct placement is diagonal.

- Use a hook to hook the wire at the bend.

One of the knitting elements is wire

- Trace another wire tip where the rods intersect.

- Place over the hook.

- Twist the wire 3-4 turns. The procedure is performed with crochet.

- Remove the hook.

- Bend the ends of the wire into the inside of the structure.

Bent rods are used to knit corners. To strengthen the corner fragment - anchors.

A simple overlap of rods is not used when reinforcing corner sections.

Welding or strapping

At the initial stage of laying the reinforcing elements, when constructing a preliminary frame, the skeleton of the reinforcing belt, you can use a welding machine. This will significantly speed up installation work. They are carried out using the tack method using welding equipment at low currents, up to 150 amperes. After installing the guides, the so-called trolls, the joints of the reinforcement are completely tied with a special wire, manually or mechanically.

Class A-3 steel has two stiffeners, which are very easy to damage (melt) during welding. Because of this, the bearing capacity of the reinforcement section deteriorates. For example, 12mm rods will be just as effective in concrete as 10mm diameter metal. This cannot be allowed.

In addition, the use of welding for reinforcement in a strip foundation is not justified; it will not be possible to save much. You shouldn’t risk the load-bearing parameters of the frame by speeding up the delivery time of the project or making your work easier.

Typical reinforcement schemes.