The external environment does not spare even the highest quality materials used for construction or repair. Premature wear, cracks, destruction of surfaces, the formation of efflorescence and mold not only spoil the appearance of buildings, but also directly affect the durability of structures. Special impregnations - water repellents for concrete, brick, stone and paving slabs - can avoid constant repair costs and prevent wear and tear on facades.

Water repellents help prevent premature repairs of buildings

Hydrophobization: what is it and what is it used for

In construction, the term hydrophobization is understood as giving a material properties that reduce its ability to be wetted by water. This need arises due to the porous structure of façade cladding materials and their ability to absorb groundwater and precipitation. The main negative consequence of this phenomenon is an increased risk of structural failure due to the formation of cracks, gradual leaching of material and premature aging.

Hydrophobization helps protect the material from moisture penetration inside

In addition, precipitation and groundwater are mixtures of salts of various compositions, which, when interacting with building materials, form new chemical compounds. The result of their influence can be visually observed in the form of large-scale efflorescence, making the façade of the building very unsightly. Purposes of using hydrophobization:

- protect the material from penetration of moisture into it;

- increase the thermal insulation characteristics of the treated surface;

- completely protect against the formation of efflorescence;

- increase the resistance of structures to corrosion and low temperatures;

- prevent the formation of lichen and mold colonies on the surface;

- strengthen the structure of materials and, as a result, increase their strength.

Important! Hydrophobization reduces water absorption by materials by 15-25 times.

Depending on the type of application, hydrophobization can be:

There are two types of hydrophobization: surface and volumetric

- surface, when a special treatment composition is applied only to the top layer of the material - such protection lasts about 10 years;

- volumetric, when special holes are drilled for better impregnation with a special composition - performed once, for the entire life of the structure.

What is used for hydrophobization of building materials

To increase the water-repellent properties of materials in construction, special surface treatment compounds are used - these are water repellents. Let’s try to figure out what’s special in their composition and how they can protect the surface in this article.

The operating principle of the special impregnation is that it does not remain on the surface of the material being processed, but is absorbed by it. Therefore, protection from water is not superficial, but internal in nature, aimed at isolating the capillaries of the material. Water repellents are capable of penetrating to a depth of 15-20 mm - this forms a protective insulating layer.

To impart water-repellent properties to materials, special impregnations are used, which are called water repellents.

Features of the properties of water repellents:

- the ability to treat the surface of any building material, with a distinction being made between universal impregnations (used for a number of surfaces) and narrowly targeted impregnations (work only on one type of surface);

- practically do not reduce vapor permeability (loss of 10-15%), which allows the materials to maintain air exchange and eliminate the formation of fungus and mold;

- help protect the surface from dust and dirt and can be easily removed by rain;

- versatility of use, allowing the mixture to be used independently or as an additional component when forming facade surfaces;

- due to their transparency, they do not change the appearance of structures, and in some cases even help improve it;

- endow building materials with additional qualities, such as frost resistance (3-5 times) and corrosion protection (1.5-2 times);

- they are pushing back the deadlines for subsequent repairs: the next treatment will be required after 10 years, and in some cases it can be avoided altogether;

- the price of water repellents is significantly lower than the cost of other waterproofing options.

Water repellents penetrate 15-20 mm into the material and form a protective insulating layer

Specialized impregnations for surface materials are produced by industry in mixtures or concentrates and diluted in certain proportions with water, but there are those that are completely ready for use. Based on their chemical composition, they are divided into water-based and silicone substances. Silicone water repellents are considered the best, since they have advantages in chemical and thermal resistance and have the ability to penetrate deeper into the material. They are less susceptible to external influences, which means they form more durable protection.

Important! Hydrophobization must be carried out at the stage of construction of structures in order to immediately provide for the protection of the facade from the destructive effects of water.

Modern water repellents and technology for their application

There is a huge selection of compounds, impregnations, and mastics on the market. To figure out which water repellent is good and which is better suited for protecting brick or stone masonry, let’s look at their composition according to table No. 2.

Table No. 2. Classification of water repellents by composition

| Composition of hydrophobic impregnation | |||

| Alkyl siliconates | N-siloxanes | Silanesiloxanes | |

| Potash | Sodium | ||

| Water-based, soluble in water. They are often added at the production stage of building materials. Follow the recipe, otherwise there may be efflorescence. | Improved modification. Not for limestone. Does not change the color of the base. The water repellent is suitable for silicate and ceramic bricks. | The best water-repellent properties. Deep penetration. Long-lasting water repellent. A “wet stone” effect is possible. | |

| Low price. Low efficiency. Partially block the pores. Mainly for volumetric hydrophobization. | The price is lower than that of potash. They swell with water. It is highly undesirable to use it! | ||

Basic rules for applying a hydrophobic solution to brickwork in compliance with safety precautions:

- clean the surface from dust, dirt, old paint, efflorescence;

- eliminate façade defects;

- dilute the composition in accordance with the instructions;

- Apply the solution with a roller, brush, or spray.

Depending on the porosity of the material, the water repellent penetrates 2-20 mm deep.

Water repellents for concrete: solving various problems

Concrete is one of the most popular building materials for the construction of buildings and structures, therefore its properties and composition are important for the further operation of objects. The construction of foundations, walls, platforms, use in laying bricks and forming reinforced concrete structures, etc. leave a certain imprint on the requirements for concrete. The material is durable, but has a low moisture resistance threshold due to increased porosity. Water entering these pores actively contributes to the destruction of the concrete structure and the formation of mold, provoking frequent repairs. The basement parts of buildings and foundations are especially affected.

Thanks to water repellents, concrete is less susceptible to destruction and does not require repair for a longer period

Water repellents can be added to concrete in two ways: at the stage of its production and by application to the surface of finished structures and structures. The use of an impregnation agent as an additive to a concrete solution can additionally reduce costs when organizing thermal insulation.

In addition to general properties, all hydrophobic additives for concrete have the following additional characteristics:

- increase the density of the solution and help increase the compressive strength of concrete (by 30% of the starting standard values);

- can become a replacement for plasticizers that are used in the mixture to impart plasticity;

- eliminate repair costs, as they significantly extend the life of buildings;

- raise the water resistance of concrete to grade W;

- increase frost resistance;

- if a reinforcing frame is used with concrete, then the additives simultaneously protect it from corrosion.

The Internet is replete with various ideas and recipes, and there are also tips on how to make a water repellent for concrete with your own hands. You can, of course, try, but there is a high probability that the result will be worse than you imagine, or will be completely absent. Therefore, it is recommended to buy a ready-made water repellent for concrete, which one is better to choose - in this matter, you must proceed from the purpose and the desired end result.

Water repellents can be added to concrete at the manufacturing stage or applied to the surface of finished structures

Helpful advice! When choosing an impregnation for concrete, be sure to pay attention to its purpose. Water repellent for aerated concrete and for concrete are liquids with different properties.

The price of a water repellent for concrete depends on the chosen brand and manufacturer. It can also be influenced by the multicomponent nature of the mixture, which allows for more positive qualities to be obtained for the surface being treated. Silicone-based liquids will cost more, but they have higher protective properties.

Water repellents for bricks: combating porosity

Brickwork is a clear indicator of the influence of environmental conditions on the destruction of building surfaces and structures. No matter how the density properties of brick are enhanced, it still remains a rather porous material that requires special processing. Hydrophobic impregnation for brick can help protect this material from moisture and dirt, premature destruction, and cracks.

Brick is a fairly porous material, so it needs hydrophobization

Efflorescence most often forms on brick facades, spoiling the appearance. To eliminate them, special control agents are applied, which temporarily eliminate the problem. However, to consolidate the cleaning effect and prevent the reappearance of efflorescence, it is recommended to treat the brick with a water repellent. Only he is able to cope with such a task.

There is a wide selection of water repellents for bricks on sale. Which one is better to choose: universal for all surfaces or used only for this material? If there is a need to treat exclusively brickwork, then you should take a closer look at specialized impregnation agents. They are differentiated by concentration, level of protection and take into account the type of cladding. The price of water repellents for bricks will depend on these factors.

When treating brick surfaces to give them water-repellent and other protective properties, the visual characteristics of facades can be simultaneously somewhat improved. For this purpose, water repellents with a “wet stone” effect are used. Tiprom M is one of these products that can give brickwork a slight gloss and highlight the color of the brick base.

Helpful advice! Before applying a water repellent with a “wet stone” effect to a brick surface, test the product on a sample and wait 3-5 days until the protective layer is completely formed.

For bricks, you can use water repellents with a “wet stone” effect.

Which is the best water repellent for bricks?

The reliability of water repellents depends on the composition and quality of manufacture. Taking into account the opinions of experts and users, you can choose the most famous brands. They differ in their characteristics, reducing the water absorption of bricks by 25-40 times. The best compositions can last for more than 20 years without re-treatment.

Siloxyl

Among domestic developments, the hydrophobizing composition Siloxyl stands out. It is based on organosilicon copolymers. The solution is prepared by mixing with water, without the use of solvents, which ensures environmental friendliness. The composition is non-toxic and also fireproof. Its water absorption is no more than 3%. Density - 1.02 kg/l. The solution is applied with a roller, brush or spray gun.

The properties of Siloxyl are retained for about 10-11 years, then the masonry is re-treated. Builders highlight the low price (from 32 rubles/kg), but significant consumption during impregnation. In monetary terms, hydrophobization costs in the range of 6.4-22 rubles/m2 of brickwork. Increased alkalinity is noted (pH more than 11.5).

Aquasil

Modern Russian water repellents for bricks are represented by Aquasil solution based on silicone and soda, mixed in water. It is versatile and therefore suitable for processing any building materials. Has low alkalinity.

Experts note low consumption (for different types of bricks - 55-95 g/m2) and increased service life (more than 20 years). At a price of 210 rubles/kg, the cost of impregnation is around 6.2-20 rubles/sq.m.

Hydroshield-Super

Another universal domestic water repellent is “Gidroshield-Super”. Plasticizers and an antiseptic are introduced into its organosilicon base. It belongs to the budget category, its consumption does not exceed 500 g/m2. Cost - from 42 rubles/kg.

Its purpose is interior decoration of rooms with high humidity. According to numerous reviews, “Gidroshield-Super” resists mold and fungi well. It retains its protective properties for at least 10 years.

Neomid

One of the effective means for hybrophobization of bricks is the organosilicon mixture Neomid H20 Stop. It is sold in the form of a thick solution, which is diluted with water in a ratio of 1:2 before use. The composition is used for finishing internal and external walls.

Consumer reviews prove that the amount of Neomida required for brick is 250-450 g/m2. With an average price of 130 rubles/kg, savings are achieved by reduced consumption. Builders recommend using the product to protect areas of brickwork adjacent to the ground.

Ceresit

The silicate water repellent Ceresit CO-81 stands out for its high German quality. It is characterized by a large penetration depth and the ability to block capillary channels up to 0.4 mm in size. Consumption when processing bricks does not exceed 400 g/m2. Price - from 100 rubles/kg.

The solution is transparent and has no noticeable tint. This property is not very popular with novice craftsmen, who do not immediately notice missed spots when processing large surfaces. Among the advantages, experts note the possibility of priming small defects in brick and stone surfaces.

Optimist

The water repellent Optimist C405 is made from a mixture of silicone and antiseptic. It fills micropores, and the surface film is invisible. Has universal abilities. The composition belongs to the economy category. Consumption is 200-300 g/m2. Capable of providing protective functions for 9-10 years. Experts do not recommend using this water repellent in regions with cold climates.

What are stone water repellents used for?

Artificial and natural stones are often used for external cladding of facades, fences, when organizing paths, as well as for interior textured decoration of premises. The material may have a different structure - polished or embossed, but each of them has the ability to absorb moisture. Active moisture absorption negatively affects the appearance, leading to the formation of mold and overgrowth with moss or lichen, especially if the outer surface is embossed. When the temperature drops, moisture that penetrates the stone leads to cracking. To combat these negative factors, protection is used by applying hydrophobic agents.

A water repellent for artificial or natural stone is selected depending on the type of surface and the desired effect. There are universal products that are suitable for all types of surfaces. They are beneficial when it is necessary to process a façade made of combined materials, including a stone covering. No less effective are specialized liquids used exclusively for application to stone. They can be intended exclusively for indoor use and be safe for food. This is important for treating sinks and countertops in the kitchen.

Helpful advice! When choosing a hydrophobic product for external treatment, pay attention to whether it has UV protection, thanks to which the material will last longer.

Water repellents for stone can be intended only for protection or include additional options such as creating a “wet stone” effect. After processing, the top layer acquires a slight glossy coating, which makes the stone surface brighter. Packages with water-repellent liquid always indicate similar properties. For this purpose, for example, the water repellent Optimist is suitable. It has positive reviews, especially regarding the processing of external stone cladding.

For artificial and natural stone, water repellents must be selected depending on the type of surface

Before large-scale application of a water repellent to a stone surface, test its effect on the remains of the cladding or in an inconspicuous place. This way you can evaluate the degree of drying, processing speed, the need for a second coat and the quality of the “wet” effect (if you have chosen such a product).

Water repellents for paving slabs: protection against water and pollution

The basis for the production of paving slabs is concrete. It is this that determines the basic properties of this facing material, that is, porosity. The danger is that water seeps into the paving slabs through numerous pores. It causes the greatest harm to this material in winter, when, freezing, it increases in volume and contributes to the formation of cracks of various sizes, up to the complete splitting of the tile. If ice forms on the surface of the material, then if it is not carefully chipped away, the coating will often become deformed.

The advantage of paving slabs is that, if necessary, you can replace damaged material with new one. However, to avoid frequent repairs, it is more advisable to use a water repellent for paving. The special product has protective properties that protect against the effects of water, frost, sunlight, salts, and fungi. After treatment, dirt and ice are easily washed off from the sidewalk, and the appearance of the material is completely preserved.

Important! Water repellents will not be able to protect paving slabs if they are constantly under water.

In order for paving slabs to serve for a long time and not need frequent repairs, it is recommended to treat them with water repellents

Not every product on the market is suitable for processing this material. In most cases, the instructions for universal concrete products indicate their ineffectiveness for horizontal surfaces. Therefore, it is worth selecting special liquids for paving slabs, for example, water repellent GKZh 11, which actively fights moisture and efflorescence. If the product is sold in concentrated form, it must be diluted with water in accordance with the instructions, otherwise unaesthetic stains will form on the surface.

Protecting the base from rain and moisture

When building houses, the following types of protection are used:

- Pasting.

- Coating.

- Screen.

- Clay castle.

- Plasters with modifiers.

Perhaps you are very interested in what a clay castle is? This is a method in which a ditch is created around the foundation. To strengthen the bottom and walls, liquid clay is used. After this, the ditch is filled with gravel, and a blind area is built on top of it. Screen protection from moisture and rain is the installation of overlapping bentonite mats. Clay lock and screen flashing are used to protect the basement brickwork. Work must be carried out during the construction phase of the building. But these are not all waterproofing options. For example, plasters with hydrophobic modifiers reliably protect masonry from groundwater. Coating waterproofing is bitumen mastics. By adding synthetic resins to them, you can easily increase the protective properties of mastics. The mixture can only be applied to a previously cleaned surface. Pasted waterproofing is a fiberglass-based material that protects the basement, foundation and plinth from groundwater.

Basic criteria for choosing waterproofing liquids

To choose a specific waterproofing liquid, you should decide on the following questions:

- what surfaces will be processed (material, wet or dry base);

- the level of positive properties that it is desirable to achieve after treatment;

- versatility of use;

- manufacturer or brand.

Universal water repellents Aquasil, Ceresit and Optimist

The versatility of application is relevant when it is necessary to treat different surfaces and provide them with identical hydrophobization properties. For these purposes, the domestically produced water repellent Aquasil is suitable, which is produced in concentrated ready-made solutions and has an affordable price. It is suitable for all materials used for roofing or foundations; it reduces the water absorption of concrete, foam concrete, natural and artificial stones by 10-15, and brick by 15-40 times. At the same time, the decorative qualities of the processed materials do not suffer. The warranty without additional repairs is 10 years, but in some cases, updating the coating may not be necessary for up to 30 years of operation.

Optimist water repellents are suitable for treating a variety of surfaces

Helpful advice! Always follow the exact recipe for diluting the water repellent. An error in concentration can lead to the formation of streaks and efflorescence.

The water repellent Ceresit is, as a rule, chosen because the brand is famous, which guarantees the quality of building mixtures. In this case, this is also legal. The manufacturer has a series of several water-repellent impregnations with universal action, each of which enhances one of the characteristics. The most popular is Ceresit CT 13 for highly absorbent surfaces, except horizontal ones (paving slabs). It perfectly isolates internal small cracks up to 0.2 mm and provides an 8-12 year warranty period, during which re-impregnation is not required.

To treat various surfaces of building structures, we use the water repellent Optimist. It is not as rich in additional options as Aquasil and Ceresit, but it copes brilliantly with the task of protecting against water and dirt. In addition, the product line includes special formulations for individual processing of materials, for example, stone, wood. To protect against mold, to ensure plasticization, frost resistance of concrete, etc., special products are produced. The liquid is completely ready for use.

Main types of water repellents

There are three main types of hydrophobic compounds: surface, bulk and cut-off.

The surface hydrophobic solution is applied with a roller or brush. The liquid is colorless and absorbs quickly. After an hour, reapply. As a result, the facade is protected from moisture, frost, and graffiti.

Volumetric hydrophobization is carried out at the production stage of the building material. For example, for bricks, when making a mortar, a water repellent is mixed into the water.

Combining these two types gives maximum effect.

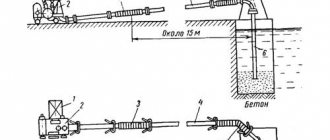

Cut-off hydrophobization is used to enhance the waterproofing of the foundation by injection.

Siloxyl . Water-based organosilicon compounds (silicones). Slightly toxic and non-flammable. It is odorless and colorless.

Aquasil . A new generation of domestic organosilicon compounds based on soda in aqueous solution. Available in the form of a concentrated composition. Designed for surface, volumetric and cut-off protection. Service life more than 10 years.

The hydraulic shield is super . Composition of water-based organosilicon polymers for environments with high humidity. Has antiseptic additives.

GSK-1 . Universal water-based impregnation with antiseptic properties for use both outdoors and indoors. Used for plaster, brick, concrete, wood, aerated concrete, etc. Available in two versions: regular and frost-resistant.

GSK-2 . Gasoline-based impregnation. The composite is intended for use in more severe conditions. It is an excellent material for applying cut-off hydrophobization. When applied it is toxic and flammable! After drying it is safe and has a hygienic certificate. It is also used for fabrics.

Ceresit (tsirezit) ST 13 . Aqueous dispersion of silicones. Products of the German company Henkel. They process vertical surfaces of concrete, ceramic, sand-lime and clinker bricks, plaster, facing stone, roofing tiles, etc. Service life 8-12 years.

Deumical . Surface impregnation with deep penetration to combat efflorescence and fungi on brickwork (contains solvents). Suitable for both external and internal processing. The manufacturer is the Italian company Index SpA