A high-quality concrete floor is a strong, reliable and durable foundation. However, such a surface is not without drawbacks. The main one is the formation of large amounts of dust during operation, which negatively affects human health and the operation of equipment and mechanisms. Dust removal from the concrete floor will help eliminate this problem; methods for doing this can be found in this article.

During the operation of a concrete base, a large amount of dust appears; the problem is solved by removing dust from the floor with special impregnations.

Reasons for the formation of concrete dust

The cause of dust on the surface of a concrete floor is associated with erosion of its top layer. The structural structure of hardened concrete is represented by a pronounced conglomerate mixture, which contains dissimilar components. They differ not only in size, but also in chemical composition. The process of maturation of cement stone involves the formation of a silicate crystal lattice. It intersects with coarse-grained insoluble fillers of gravel and sand origin.

Erosion of the top layer of a concrete floor leads to dust on its surface

Concrete consists of many microscopic and large pores that are filled with air, water and a gel cement substance. There are also unbound chemically active substances present here, which cause erosion processes in the upper layers of concrete. This occurs with constant mechanical impact on the concrete surface, the top porous layer of which begins to collapse. Unbound particles of cement and chemically active substances turn into dust.

In addition, during the ripening process of concrete, cement laitance comes to the surface. When it hardens, it forms a weakened layer, which is often the main source of dust.

To prevent a concrete floor from becoming dusty, it is necessary to harden it, bind the top layer with a polymer mesh, crystalline components, or completely remove the upper unstable surface. To do this, there are three methods for removing dust from the surface. This includes strengthening the base using topping, treating the coating with special impregnations and sanding the floor.

Important! The best result is obtained by the comprehensive use of all technologies for dust removal of concrete surfaces.

To remove dust from a concrete floor, you can use methods such as grinding, hardening with topping, and treatment with special impregnations.

How to remove dust from concrete floors?

To complete this procedure, you will have to carry out a number of sequential measures:

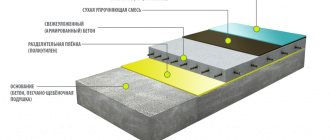

Scheme for cleaning and removing dust from a concrete floor.

- Concrete grinding. First of all, dust and concrete residue are removed from the floor surface. If necessary, remove unevenness and imperfections on the surface. Dry grinding is used using mosaic grinding mechanisms with diamond parts, using a forced-type dust extractor.

- Elimination of damage. To remove defects in damaged floor areas, polymeric substances containing epoxy resins and the addition of fine-grained quartz sand or compositions special for repair are used.

- Impregnation application. Impregnation strengthens the surface concrete layer and evens out the tensile strength of the porous material. A layer of protection is formed that is resistant to chemical influences and keeps the base material free from dust. Impregnation may be necessary if you intend to subsequently apply primer or a thin-layer coating for decoration.

- Sealing cracks in concrete foundation. Repairing damaged seams, mechanical damage that occurred at the time of pouring or during the use of a ready-made concrete base. Eliminate “sagging” in areas adjacent to walls, load-bearing support and other structural elements on the base of the concrete surface.

- Dust removal of concrete. The dust generated from grinding and sealing the existing concrete base is removed using specialized concrete pumps. The quality of work at this stage will determine the future properties of applying decorative or protective materials.

- Primer. Weak concrete grade, the presence of many irregularities and defects, and subsequent high physical loads require treatment with polymer (polyurethane, epoxy) primers with the addition of quartz sand.

- Varnishing. After grinding the concrete surface, it is filled with a composition containing marble or granite chips, which makes the texture of the concrete attractive. Here it is permissible to perform grinding with abrasive segments and apply decorative polymer-based varnish.

The work is carried out on the floor, the surface of which should be +5° C (and no less).

Why is concrete floor dust removal done?

Dust removal is the strengthening of a concrete coating using toppings, impregnations or grinding, which is carried out to extend the period of its reliable operation.

If surface erosion processes are not stopped in time, they will eventually affect deeper layers of concrete. This can lead not only to partial, but also to complete destruction of the screed.

Cement dust that forms on the surface has a negative impact on human health. Tiny particles of cement and chemicals get into the eyes and skin, causing itching. Inhalation of substances can provoke respiratory diseases and cause allergic reactions.

When the concrete floor installed in workshops, garages, and warehouses becomes dusty, the dust has a negative impact on the coordinated operation of the equipment and mechanisms installed there. This will lead to rapid wear of tools and units, which will soon fail. A crumbling concrete floor needs constant cleaning - otherwise it will have a sloppy and untidy appearance.

Dust removal of a concrete coating not only extends the period of reliable operation, but also improves its aesthetic appearance

If a concrete floor is used as a subfloor, even in this case the surface should be dust-free. If this is not done, over time the coating will begin to crunch and creak, which will cause inconvenience when using the surface.

Dust removal of concrete floors and surfaces

Concrete as a building material has been known for more than 2600 years. Despite the high strength, efficiency and other positive characteristics, the material is not without drawbacks. One of them is dusting.

The main causes of dust are:

- Carbonization of concrete. Carbon dioxide contained in the air interacts with calcium hydroxide, which is formed during the hydration of cement. As a result of this reaction, calcium carbonate is formed, which is tiny particles.

- Low quality of raw materials or violation of technology. Low-grade concrete is characterized by a short service life, and therefore quickly begins to deteriorate and generate dust.

- The presence of cement particles in the capillary-porous structure of concrete that have not reacted with water. Such particles freely enter the air.

- Intense mechanical impact (abrasion).

A person who spends a long time in a room with dusty floors is exposed to enormous danger. Concrete dust penetrates his lungs, which, due to its chemical nature, is hazardous to health.

If we talk about industrial warehouses, dust settling on goods can make them unsuitable for further use. Therefore, dust removal of floors is an important task. Dust-free floors are a solution not only to an aesthetic issue, but also to the creation of an environment safe for human life.

Testing of Tiprom POL composition

To remove dust and strengthen concrete floors, special impregnations are used - dust removers. There are 2 types of compositions that allow you to remove dust from a concrete floor: organic and inorganic.

Organic impregnations include acrylic, epoxy and polyurethane impregnations. These compounds, penetrating deep into the concrete, fill pores and capillaries, as well as defects in the concrete structure (cracks, cavities), and reliably bind to the surface layer of concrete, ensuring dust removal from concrete surfaces.

You can also remove dust from a concrete floor using inorganic compounds. These include fluates. Fluates enter into chemical reactions with calcium and magnesium salts contained in cement-sand products and form Ca and Mg fluorides and silica, insoluble in water. Dust-free floors, in this case, are the result of the reactions described above.

Thus, dust removal from concrete is, in essence, dust removal from the surface.

If we compare the effectiveness of organic and inorganic compositions, then, despite the almost equal efficiency in removing dust from the concrete surface, the waterproof properties of concrete treated with organic impregnations are significantly higher.

In addition to hydrophobicity, many people associate dust removal of concrete surfaces with oleophobicity. Oleophobic coatings are coatings that protect the surface from the penetration of oils and gasoline. Dust removal of concrete floors, which provides oleophobic properties, is especially important when protecting concrete surfaces of garages and parking lots. Dust removal of concrete with organic compounds makes it possible to achieve oleophobicity, but not with fluates.

Among the many compounds on the market, Tiprom POL dust remover has a set of unique properties:

- removes dust and strengthens concrete floors;

- increases wear resistance (by 54%) and reduces abrasion of surfaces;

- gives concrete surfaces waterproof properties;

- provides surfaces with oil and petrol resistance, resistance to dilute solutions of acids and alkalis;

- prevents concrete corrosion;

- enhances the color saturation of concrete surfaces and gives them a semi-matte shine.

Tiprom POL is a ready-to-use composition, which is a composition based on acrylic copolymers and modifying additives and provides dust removal from floors.

The area of application of the dust remover is concrete floors of internal areas: warehouses, production workshops, garages, parking lots, shopping centers, markets and other objects with increased pedestrian and traffic load.

The impregnation is environmentally friendly, does not have a pronounced odor, and therefore can be used to remove dust from concrete floors in facilities with increased sanitary requirements.

Dust removal from concrete surfaces is not a complicated process. Before applying the impregnation, remove cement laitance, efflorescence and dirt from the concrete surface using the Lepta Himfrez cleaner. After cleaning, rinse the surface with plenty of water. If the surface does not contain cement laitance and contaminants, it is sufficient to pre-dust the surface using any available method (using compressed air or a simple brush).

Upon completion of cleaning (if required), Tiprom POL dust remover is applied to a dry and clean surface. To do this, use a low-pressure sprayer or brushes (soft bristles). If brushes are used, the dust remover is applied by pouring it from a container and then spreading the material.

When removing dust from concrete surfaces, it is recommended to use safety glasses, rubber gloves, a respirator, and special clothing. If the product gets into your eyes, rinse them with water. Impregnation should be kept away from children and animals.

Use of dust-free floors is allowed no earlier than 24 hours after treatment. In case of intense loads - no earlier than 7 days.

According to the results of tests carried out by JSC NIIMosstroy, the use of the Tiprom POL dust removal agent allows not only to remove dust from a concrete floor, but also to significantly strengthen the surface layer of the concrete surface. The abrasion resistance of a dust-free floor coating is at least 20 kg/mg, which corresponds to the level of high-quality varnishes for protecting floors and paints for road markings.

In addition, the use of Tiprom POL, along with dust removal of concrete, gives its surface waterproof properties. The water resistance of concrete, measured using the SAZI software method, is 120 mm water. Art.

Thus, surface dust removal is one of the main tasks when installing industrial and civil floors. Dust removal of a concrete floor with Tiprom POL is a simple, effective and economical process.

How to cover a concrete floor to prevent it from collecting dust in a garage or other room

The destruction of the upper unstable layer of concrete leads to the constant formation of dust on the base. You cannot get rid of it instantly by sweeping it off the surface, since the next layer begins to collapse. It is best to eliminate this problem at the stage of curing the concrete screed, which is fixed with special compounds for removing dust from the concrete floor, which strengthen the surface and prevent its destruction throughout the entire period of operation.

Toppings and impregnations are used to prevent concrete from becoming dusty and to increase its strength. Such hardeners penetrate deeply into the pores of concrete, clogging them, blocking the paths for the formation and removal of dust. Such sealing eliminates not only the process of leaching of concrete, but also the destruction of its thickness as a result of exposure to moisture and chemicals that can penetrate it.

Dust-free floors are characterized by increased strength, durability, wear resistance, moisture resistance, and the ability to withstand any loads and intense impacts. Concrete bases with a hardened coating have an aesthetic appearance, which is achieved thanks to a smooth, even surface, tinted if necessary.

Toppings and impregnations will help you get rid of concrete dust in your garage forever

How to coat a concrete screed to avoid dust: features of topping compositions

When deciding how to cover a concrete floor to avoid dust, you should pay attention to innovative technology in the form of topping. This protective mixture consists of Portland cement, mineral additives, plasticizers and dyes. The first component serves to bind all the elements of the mixture, which contributes to the effective filling of concrete pores and adhesion to the coating, eliminating peeling of the material.

Topping provides increased strength and wear resistance of the concrete floor. This protective composition prevents the penetration of moisture into the thickness of concrete, which can cause destruction of its structure with subsequent leaching of the surface. A floor with a topping coating withstands the effects of chemical components, so it can be safely used in garages, production halls and workshops.

The composition penetrates deeply into the pores of concrete, clogging them, as a result of which the service life of the coating is extended, which is not destroyed by mechanical loads and other negative influences. Such a means for removing dust from a concrete floor has an acceptable cost, which makes it possible to inexpensively harden the coating. The cost of the process can be reduced to a greater extent by using low grades of cement to create the floor, the shortcomings of which can be compensated for by a heavy-duty protective composition.

The topping is available in the form of a dry powder or liquid composition. The powder is evenly scattered onto the surface, then compacted and sanded. When using dry substances on a concrete floor, seams are formed. This is a budget topping option. The liquid composition is evenly applied to the surface, forming a durable and reliable protective film that is resistant to moisture and chemical compounds. It turns out homogeneous, even and smooth.

The topping can be either in the form of a dry powder or a liquid composition.

Types of topping coating for concrete floors against dust

Modern topping is represented by three compositions: quartz, corundum and metallized. For rooms with average intensity of use, a composition based on quartz sand is used. This mixture not only provides dust removal and strengthening of the concrete surface, but also gives it an attractive appearance due to the presence of coloring pigments in its composition.

Quartz topping is suitable for arranging flooring in residential buildings, educational institutions, and warehouses. Another advantage of this option is the reasonable cost of the composition.

How to treat concrete to prevent dust in rooms where heavy equipment is located and where there is heavy traffic and people traffic? In these cases, it is better to use corundum topping, which includes a mineral additive in the form of corundum chips. This coating is characterized by high strength, wear resistance, resistance to abrasion, moisture and aggressive chemical compounds.

The most reliable hardener is metallized topping, which is made on the basis of metal shavings. It provides effective dust removal of the floor, which will maintain the integrity of the structure for many years. In addition, this topping increases the strength of the concrete surface by 2.5 times.

The liquid topping mixture can be applied both to a fresh concrete screed and to an old floor

It is advisable to use such a composition in rooms with high vibration, where massive, heavy equipment is installed, which requires constant movement of heavy equipment. The disadvantage of metallized topping is the high cost of the composition.

Treating concrete screed with topping

Timely dust removal will help stop the erosion of the upper layers and preserve the concrete screed. The technology of strengthening the floor covering with topping is the rubbing of the surface of poured concrete with special strengthening mixtures.

In addition to cement, they contain fine-grained additives that help improve the structure of the screed and increase its strength. Depending on the use of certain additives, the topping can be quartz, corundum or metallized. Each of them has its own characteristics and recommended areas of application. Dust removal from a concrete floor with quartz topping is carried out when the floors will be subjected to moderate loads. Quite often, the quartz sand included in its composition is pre-treated with dyes, which makes it possible to achieve a certain decorative effect. The advantages of mixtures of this type include their relatively low cost.

Important! Quartz mixtures reliably protect concrete from moisture, so they are recommended for finishing floors in bathrooms, showers, baths, and swimming pools.

An example of the use of quartz mixtures for dedusting concrete

Corundum topping includes crushed corundum chips. Thanks to the strength and abrasion resistance of this mineral, the floor coated with the composition becomes at least twice as strong. Corundum topping is recommended for use in rooms with intense loads.

Painting concrete floors

The most durable is the metallized topping, which contains metal shavings. It is used exclusively in industrial construction. Concrete pavement treated with this type of mixture can be used to install heavy equipment. The required amount of material is calculated based on the norm of 3-5 kg of material per square meter.

Topping technology

Processing concrete with strengthening mixtures is a rather labor-intensive process. To properly coat the surface of floors with the composition, not only certain skills are required, but also special equipment. When doing work with your own hands without professional training, the quality of the coating may suffer if the technology is not followed, so it is better to entrust it to specialists.

Trolley with dispenser for applying topping mixture

First, the selected mixture is evenly distributed over the concrete, and then thoroughly rubbed in using a trowel. The work is carried out in two stages. The first treatment is carried out 5-6 hours after pouring the concrete. To check the readiness of the floor, a mark is left on it. If its depth does not exceed 3-5 mm, you can start adding topping. Two-thirds of the planned amount of material is evenly distributed over the concrete. As soon as it begins to be saturated with cement laitance, it is immediately rubbed down with a machine.

Important! During the application and grouting of hardening compounds, it is strictly forbidden to additionally moisten the floor covering!

Immediately after completing the first stage, it is necessary to add the remaining mixture and machine the floors again. To further protect the concrete, you can coat the fully cured floor with a moisture-retaining compound.

Sanding and polishing

Another way to make dust-free concrete floors is by sanding. This technology involves removing the most damage-resistant top layer of the screed. The benefits of grinding include the following:

- defects and unevenness of the screed are eliminated;

- the moisture resistance of the floor increases;

- adhesion to building mixtures and finishing materials increases.

Sanding is used both as a finishing touch and as preparatory work before installing a decorative coating, pouring polymer mixtures or painting.

Grinding technology

Grinding is carried out on a moistened or dry surface. The wet method is less popular due to its high labor intensity. It is rarely used by professional builders and is even less suitable for doing the work yourself. Most often, concrete screed is sanded using the dry method. Its only drawback is the formation of a large amount of dust.

Enamels for concrete floors

Laying the topping with a sander

For sanding large areas, it is recommended to use a mosaic grinder. By replacing the attachments on the rotating discs, you can not only remove the top layer of concrete, but also polish the surface. In small rooms, it is recommended to do the work with hand tools. If it is necessary to treat a freshly poured floor, sanding should begin no earlier than a week after pouring. After the first pass, wait for the concrete to fully mature and process the screed again (no earlier than after 3 weeks).

To obtain dust-free floors, sanding is performed in three stages. First, remove the top layer susceptible to destruction using nozzles with a grain size of 30-40 units. Next, a special hardening impregnation is applied, and after complete drying, it is sanded with segments with a grain size of 100 units and above. This technology allows you to create a smooth and dust-free floor surface.

How to remove dust from a concrete floor: arranging a topping coating

How to treat a concrete floor to prevent dust in a garage, workshop, industrial, warehouse, public or residential area? The most correct solution is to arrange a topping coating. The composition can be presented in dry or liquid form, which determines the technology of its application.

The liquid mixture is applied to a fresh concrete screed or to an old floor. First of all, prepare the surface. It should be cleaned, all existing defects should be repaired and sanded. The topping is applied to the floor using a sprayer or roller. The layer thickness is 2-3 mm. The mixture is quickly absorbed and hardens.

The dry composition is evenly distributed over the entire surface area 5-6 hours after pouring the concrete screed. The process is carried out using a dosing trolley. Immediately apply 2/3 of the total volume of material. The composition begins to interact with moisture. This is how the crystallization process occurs. The completion of the reaction is indicated by complete and uniform darkening of the entire surface. It's time to sand the base with a sander. When rubbing the mixture is finished, you should wait until the surface sets.

The topping on the market is represented by three compositions: corundum, quartz and metallized

Important! To obtain a high-quality base, it is important to saturate the topping with cement laitance as much as possible without drying out the surface, while additionally moistening it with water is strictly prohibited.

The next step in treating the concrete floor from dust is applying the remaining amount of material. After 48 hours, the surface is cleaned using blade knives. The procedure is performed in several stages until a smooth, mirror-like base is achieved.

The final process is the application of a solution in the form of curing, which will eliminate the possibility of moisture evaporation from the concrete. The material is distributed over the surface using a roller or sprayer. Upon completion of the process, expansion joints are cut to prevent cracking of the concrete floor when the base hardens. The seams are filled with sealant. The cost of dust removal from concrete using topping starts from 1000 rubles/m².

Sequence of impregnation application

This type of processing is considered the simplest and most suitable for doing it yourself. Before covering a concrete floor with any impregnation, you should read the manufacturer's instructions and recommendations. The surface to be treated is first cleaned of debris and dust, preferably using a powerful vacuum cleaner. The concrete must be impregnated evenly; for this, the impregnation is poured in strips and distributed with a roller or squeegee. After spreading the mixture, there should be no dry areas or puddles left.

Depending on the type of impregnation, the application technology may differ slightly. So, some of them are applied in two stages, and there is a need to use a trowel and remove excess (sodium silicate solution). Organic impregnating mixtures are also applied in 2-3 stages (if you cover the concrete base in several layers, you will be able to achieve a more complete filling of the cavities). The easiest to use are lithium mixtures. They simply need to be applied to the floors in the required quantity and distributed over the surface.

The integrated use of different technologies will help to enhance the effect of the treatment.

How to treat a concrete floor so that it does not generate dust: characteristics of special impregnations

To do it yourself to remove dust from a concrete floor, you can use special liquid impregnations on an organic or inorganic basis. They penetrate deeply into the thickness of concrete, forming a strong and reliable connection. Organic impregnations are presented in several varieties, namely in the form of epoxy, polyurethane, acrylic composition.

Polyurethane impregnation helps both dust removal of the floor and its complete sealing

The polyurethane mixture not only helps to remove dust from the floor, but also completely seals the base, which entails an increase in the strength, wear-resistant, impact-resistant and chemical-resistant characteristics of the surface. If it is used to remove dust from concrete M350 (or more), the required penetration depth of the impregnation is 2-3 mm, and for compositions M150-M350 this value increases to 5 mm.

Important! The polyurethane mixture has a strong, unpleasant odor, so it is recommended for use as an impregnation for outdoor concrete.

The epoxy mixture is produced completely odorless. It is represented by a two-component composition, the basis of which is epoxy resins. This impregnation ensures the creation of a strong, reliable, moisture-resistant, frost-resistant, durable base that is highly hygienic. The disadvantages of this mixture include its high cost.

Acrylic impregnation is preferable for surfaces that do not tolerate strong mechanical loads. It is used for concrete grade M200 (and more). Such a dust-free and strengthened base will be characterized by increased moisture resistance and high hygiene.

Acrylic impregnation is used to treat surfaces that do not withstand strong mechanical loads

Inorganic mixtures are represented by fluates, which include sodium, potassium and lithium polysilicate compounds. The impregnation penetrates deeply into the porous structure of concrete, causing chemical reactions in its upper layer that last up to 15 days. This leads to the formation of insoluble, crystalline glassy bonds that clog the pores, hardening and removing dust from the surface.

Important! Any impregnation may contain a coloring pigment, which gives the finished coating a more attractive appearance.

Strengthening and removing dust from the concrete base

The concrete base is not highly wear-resistant and therefore requires additional processing. Strengthening of concrete in industrial and civil construction is carried out using various strengthening and dust-removing impregnations.

Without special measures, concrete will easily allow water or chemical solutions to pass through. In addition, this material is subject to mechanical stress, which causes the appearance of cement dust and various defects. Concrete generates dust when the surface dries out during use, resulting in the release of parts of unbound cement, sand and other aggregates that settle on the floor and in the air.

Strengthening and dust removal of concrete: stages of work

The main stages of the work carried out when

strengthening the concrete surface and removing dust:

- Concrete preparation. Cleaning of debris, dirt, removal of visible dust. If necessary, it is necessary to sand the seams, eliminate unevenness, etc. To perform this stage of work, you can use mosaic-type grinding devices with diamond discs, industrial vacuum cleaners. Previously, iron screeds were used to strengthen the floor. To do this, dry cement was poured onto the surface, and then it was rubbed into the top layer. Such reinforcement cannot be considered reliable because its service life is very short. Liquid formulations do not have this disadvantage.

- Elimination of damage using polymer compounds based on epoxy resins and other special compounds.

- Treating the floor with dust removers. Dust removers strengthen concrete and create a protective layer that is chemical resistant. They are especially necessary for the subsequent installation of, say, a thin-layer screed for decoration.

- Surface priming. When using concrete with a low cement content, various defects are visible, which will only worsen during operation. This can be stopped by treating the surface with polymer primers. Prepare the primer composition according to the instructions. In a two-component impregnation, mix all the ingredients with a construction mixer. The primer should be made in small portions and used immediately.

- Varnishing. After grinding, fill the concrete with a composition containing crushed granite (possibly with marble chips). This will give the concrete an aesthetic appearance and protect it from abrasion. Sanding can be done with abrasive elements followed by the application of polymer-based decorative varnish.

Materials for strengthening and dust removal

To solve the problems of strengthening floors, iPolymer offers the following types of primer for removing dust from concrete and strengthening it, as well as impregnations and wear-resistant finishing paints:

- Polyurethane primers. They remove dust and seal the base, increase chemical resistance and wear resistance, help strengthen old concrete , etc.

- Epoxy primers. Epoxy primer for dust removal of concrete is widely used on objects with increased requirements for wear resistance and resistance to aggressive influences, and is easy to apply.

- Concrete dust removal can also be done with deep penetration impregnations to strengthen the concrete . Impregnation is a penetrating material used to strengthen the base. Such concrete strengthening fluids are sold by iPolymer and are designed for use in difficult conditions and are resistant to high mechanical loads. In the manufacture of impregnations, we use imported raw materials from world leaders in the chemical industry - 3M, Akzo Nobel, BASF, BYK-CHEMIE, Dupont, Union Carbide.

- Finish wear-resistant paints. Without a finishing coat, concrete becomes covered with dirt and dust stains. The thickness of the paint layer determines the aesthetic perception of the surface, covering stains and other defects. All our paints have enhanced decorative properties and high strength characteristics, chemical wear resistance, and are easy to apply.

concrete strengthening products from us

We are aimed at long-term cooperation and are ready to offer our clients:

- high quality of manufactured materials - service life is at least 15 years;

- production of both small batches of products and large wholesale ones through our own production;

- financial benefit - buy impregnation for strengthening concrete from us cheaper than from competitors, because our prices are 15-30% lower.

Is concrete dust removal required? prices from our managers, who are always in touch. We will provide competent consulting support and answer all your questions.

Result

As a result of hardening with concrete strengthening compounds, the surface becomes dust-free and durable. To strengthen concrete floors, it is recommended to use innovative developments from iPolymer - they are suitable for imparting strength to floors in retail, warehouse and industrial premises, commercial and public buildings, giving surfaces wear resistance and an aesthetic appearance. Dust removal of concrete with our impregnations and primers will create a very durable top layer, ensuring the hardness and reliability of the coating.

primer

Share:

Surface dust removal technology using impregnation

Before applying impregnation to concrete, the floor must be treated with a grinding machine. This is done to remove the top destroyed layer, cement laitance, traces of dirt and oils, while simultaneously leveling the surface.

Sanding can be done on a damp or dry base. The latter option is characterized by high productivity and the ability to control the process. The wet sanding method produces a well-polished surface.

Before treating a concrete floor with impregnation, it must be sanded

Important! Treating the floor with a grinding machine helps open the pores of the concrete base, which improves the efficiency of penetration of the composition into the thickness of the surface and forms persistent chemical compounds.

Any impregnation is applied using a fluffy roller, brush or spray. The composition is poured onto the prepared base in strips. It is necessary to ensure uniform filling of the entire surface area. There should be no places where the composition is quickly absorbed into the concrete, or areas with minimal saturation where puddles have formed. The inorganic composition is applied in one layer.

The base must be coated twice with polymer impregnations. The composition is evenly distributed over the surface using a squeegee or silicone roller. After 30-50 minutes, a second layer of the mixture is applied. The surface must dry for 20 minutes. After time, all excess impregnation should be removed with a rag.

After 24 hours, the hardened and dust-free surface can be painted with polyurethane-based enamel, which is applied in two layers. After 24 hours, the surface is suitable for use. The price for dust removal of a concrete floor using impregnations starts from 800 rubles/m².

Concrete floors must be treated with polymer impregnations twice

Important! The surface dust-free by impregnation is characterized by several times increased strength, which depends on the quality of the original concrete base.

What is the best way to remove dust from concrete floors?

Scheme for dust removal and impregnation of a concrete floor.

Please note: when preparing the base for painting, fluate is used as a dust removal agent. The latter is a concentrated composition. Before using it, dilute it with water.

When painting is not provided, specialized impregnations are used, the purpose of which is to cover wooden floors.

Particularly noteworthy is the point regarding personal safety precautions. Remember that the preparations used for dust removal belong to the category of chemically active agents. Therefore, when carrying out actions with them, you need to protect yourself: wear rubber gloves and boots that protect against acids. Dust removal solutions are applied exclusively in containers made of plastic. If X-rays come into contact with unprotected skin areas, they are immediately washed with clean water.

Dust removal with fluate

Having decided on the answer to the question of how best to remove dust from concrete floors, they begin to take action. Fluate is an inorganic type of impregnation and is most often used when preparing a concrete base for painting.

Sequencing:

Dust removal with fluate is carried out before painting the concrete floor.

- First of all, fluate is diluted in water according to the attached instructions from the manufacturer. Then the solution is poured onto the floor surface. Consumption is approximately 20 ml per 1 m² of floor.

- Using rubber scrapers, achieve uniform distribution of inorganic matter over the surface. The liquid composition is rubbed in until the concrete completely absorbs it.

- During the work, be careful to ensure that no puddles form. Excess solution is quickly transferred to the place where absorption occurs at a more accelerated pace.

- Correctly calculating the amount of solution will keep the floor moist for 20 minutes.

- Excessively applied fluate is removed with a dampened cloth. A fluate solution that gets on concrete causes a reaction that leads to compaction of the top layer of concrete. The duration of the reaction is 1 month.

- It is prohibited to apply paint or other impregnation to the coating immediately or for one day after treatment with fluate.

- As a result of this operation, concrete gains the necessary degree of impact resistance and resistance to chemical reagents. There is protection against abrasion.

How to remove concrete dust: method of grinding and polishing the surface

When deciding what to do to prevent the concrete floor from collecting dust, you can use another technology, which is surface grinding. It can not only precede further surface treatment using toppings and impregnations, as mentioned above, but also be the final stage for preparing the surface for use.

Sanding can be done dry or on a damp surface. The first method is in great demand. The grinding process can be controlled visually. In this case, there is no need to wait for the surface to dry. The main disadvantage of this method is the formation of a large amount of dust during work.

Helpful advice! To facilitate the dry grinding process, it is recommended to connect a washing vacuum cleaner to the grinding equipment.

You can dust off a concrete floor using a grinder on both the old and freshly laid base.

Concrete dust removal using a grinding machine can be carried out on a moistened base, which is used mainly when arranging mosaic floors with granite or marble coating. The surface is perfectly flat, smooth, close to polished. However, the process is characterized by high labor intensity and low productivity, which is associated with the rapid clogging of abrasive elements with wet sludge, which are difficult to remove in a timely manner.

How to remove construction dust from a concrete floor using a sander

Grinding is carried out with a mosaic grinding machine, which is a heavy-duty unit equipped with an electric drive. The working part is equipped with one or more rotating disks with corundum or diamond segments, which differ in grain size.

Helpful advice! To sand a small area, they often use a special attachment for an angle grinder.

You can dust off a concrete floor using a grinder on the old base or on a freshly laid screed. In the latter case, the first stage of the process begins a week after pouring the floor, which will allow the resulting layer of cement laitance to be removed, exposing more durable layers. Finishing work is carried out after the concrete has completely set, which occurs after 28 days.

Grinding of a concrete floor occurs both on a moistened surface and in a dry way.

Surface grinding is carried out in several stages. First of all, it is necessary to remove the loose top layer, which is accompanied by exposure of the filler and preliminary leveling of the surface. On the old base, the grinder completely removes eroded areas of the concrete floor. This stage involves the use of segments with a grain size of 30-40 units.

Subsequently, the base is strengthened using special impregnations. This type of work may not be performed if the topcoat is sanded. The final stage is surface treatment with abrasive segments with a grain size of 100-400 units. to obtain a smooth, even, dust-free floor.

In case of urgent need, the floor surface is polished using diamond segments with a grain size of 1500-3000 units, which allows you to obtain a mirror-like, moisture-resistant, dust-free base.

To process the old base with a grinder, segments with a grain size of 30-40 units are used.

Technology for installing polymer-coated floors

The technology for installing a thin-layer polymer coating depends on the age, brand and quality of the concrete coating itself. If the floor is of good quality, then simply sand the concrete floor, remove dust and apply several layers of floor covering. The time between applying layers of polymer coating depends on the ambient temperature, air humidity and the coating itself. Usually it lasts several hours. If the original floor contains large unevenness and slopes, then before the grinding operation it is necessary to mill the floor in order to bring the floor itself into compliance with SNIPs. Further procedures are the same as for good quality flooring.

We have covered all aspects of the concrete floor dust removal procedure. In conclusion, we note that dust removal of a concrete floor, in addition to giving such floors a pleasant appearance, also provides increased resistance to transport and pedestrian loads. The floors repel moisture and are not affected by oils, gasoline, or moderately aggressive chemicals. The cost of cleaning such a room is significantly lower than just a concrete floor.

You can find out more about the service and price of concrete floor dust removal HERE.