Elements of round wells with and without bottom

The construction of external sewer networks is not complete without the installation of wells, since it is in them that the shaped and shut-off valves are concentrated.

Their walls can be built of brick, poured in a monolithic manner, but still, prefabricated reinforced concrete sewer wells are the most commonly designed option, which saves time and money. This is what we will talk about later, using the video in this article.

What types of wells are there?

Depending on its purpose, a concrete sewer well may have one or another diameter and depth; the nuances of its arrangement also differ. Before understanding the nuances of construction, it is necessary to understand what products are used. We'll start with their review.

Structure

So, prefabricated reinforced concrete sewer wells - elements:

- Bottom plate;

- Wall rings - form the body of the well;

- Ceiling (cover) having a hole for installing a hatch;

- Cast iron or plastic hatch.

This is the standard well structure, but there are variations. For example, instead of a slab bottom, a ring with a bottom can be installed at the bottom of the structure.

When the well is located on the roadway, its top element is not a cover, but a base plate, which also has a hole for the hatch.

Unlike the lid, the base plate has a rectangular shape - and this is no coincidence. This form allows you to qualitatively distribute the loads on the soil around the well, minimizing them in relation to its walls.

Reinforced concrete sewer wells can also be standardized. This is a solid cylindrical block with a bottom and a ready-made inlet for the pipe, reinforced with a metal mesh. They are most often used in the construction of storm drainage systems.

Purpose

Since the type of well is determined by its purpose, we will consider each option in more detail:

- Concrete sewer inspection wells are installed in places where there is a turn in the pipeline, two or more networks are combined, a transition is made from one pipeline diameter to another, or simply on long sections of the route.

Construction of a manhole

In these places, it is necessary to carry out a preventive inspection of the pipes and, if necessary, clean them. Therefore, the wells installed here are called observation wells.

For pipe diameter:

- up to 30 cm they are designed every 35 m;

- up to 60 cm - after 50m;

- from 60 to 140 cm - every 75m;

- more than 140 cm - after 150m.

- Storm tanks are designed to collect rainwater from the roadways of streets and sidewalks. It is precisely for their construction that unified wells are most often used.

Storm drainage: concrete well

- Well-chambers for special purposes are installed in those places where the sewerage system intersects with other underground networks. At the same time, other mains are located above the sewer lines.

Sewage well made of concrete rings

- Septic tanks or cesspools are used to clean sewers from suspended (heavy) particles. They are installed only in industrial or household autonomous systems.

Reinforced concrete sewer wells in a system with three settling tanks

- Damper wells (difference) - their function is to allow the flow of water in gravity systems to reduce its speed. Considering that falling water creates certain loads, the depth of such wells can reach 4 m. As an option for pipelines with a large diameter, several wells are built at a distance of two meters from each other.

Differential concrete sewer wells have a depth of up to four meters

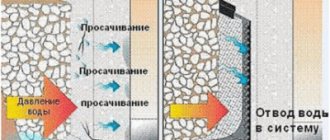

- Drainage (filtering) wells are installed to purify waste water. Instead of a sealed bottom, they have a drainage base, and there are perforations in the walls.

Filtering concrete sewer wells are assembled from perforated rings

There is also such an option as a rectangular concrete sewer well. Unlike cylindrical containers, their internal volume can be used more efficiently.

However, their installation is quite complicated, and they are not so resistant to deformation, so in practice they are used very rarely - and even then mostly for pipelines with large diameters.

Square well

Note: In autonomous home networks, the diameters of the pipelines are small (up to 300 mm), and wells are usually installed from round rings with a meter in diameter. In the private sector, a sewer well made of reinforced concrete rings d=2000 mm can only be used to construct a cellar or mini-pool.

All prefabricated and standardized products intended for the construction of drainage and sewer systems are made in accordance with GOST 8020 from heavy concrete of class B15-B22.5. Its frost resistance in such products cannot be less than F150.

GOST requirements

Like any serial products, all types of reinforced concrete rings must meet all technical standards and regulations. Compliance of products with these conditions guarantees the strength and reliability of the structure, as well as a long service life.

The parameters for all types of reinforced concrete well rings are determined by GOST 8020-90 with Technical Specifications, 2004 edition, as amended by IUS 3-91. These standards regulate:

- basic parameters, linear dimensions and markings for various types of rings;

- indicators of concrete and steel consumption in the manufacture of products;

- requirements for compliance with standards for all materials (concrete, reinforcing steel, steel for mounting brackets);

- parameters of embedded products, their position in structures;

- maximum deviations from the linear dimensions of products;

- requirements for surface quality and appearance of products;

- completeness and marking of structures;

- acceptance of structures based on indicators obtained during testing, preparation of acceptance documents;

- methods for monitoring the basic characteristics of concrete, the dimensions and position of reinforcement and embedded products, as well as the methodology for measuring work;

- conditions for transporting structures;

- storage conditions and storage schemes for various types of products.

The appendix to GOST determines the shape and main dimensions of the wells, as well as the maximum values of the technological slopes of the rings when installing the structure. The standard also contains links to all regulatory and technical documents defining the production and installation of products.

The Code of Administrative Offenses provides for the responsibility of manufacturers for the quality of their products. Violation of technology and technical standards, as well as the use of low-quality materials will inevitably lead to a decrease in the strength and performance characteristics of the rings. Such products are subject to rejection.

Our company offers very affordable prices for concrete rings for sewer or water supply wells.

SNiP requirements for the construction of sewer wells

All structures of external sewer networks, which include wells, are built in accordance with SNiP 2.04.03. Let us briefly describe the requirements of this document.

For manholes

So, we have already found out that inspection wells should be installed at the points of connection of pipelines, changes in their direction, elevation or diameter.

Moreover, the smaller the pipe, the closer the control points should be:

- The size of the well in terms of both industrial and domestic sewerage is also taken depending on the diameter (largest).

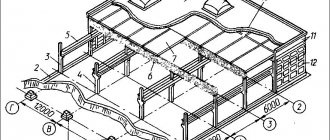

Drawings: reinforced concrete sewer well

The ratio of the diameters of the pipeline and the well looks like this:

- Pipe less than 0.6 m - well diameter 1 m;

- From 0.6 to 0.7m - 1.25m;

- From 0.8 to 1m - 1.5m;

- From 1m to 1.2m - 2m.

If this is a rotating option, then the possibility of placing a tray is also taken into account:

- If for pipelines of small diameter and with a laying depth of less than 120 cm, it is possible to design wells with a diameter of 70 cm, then when the mark is deepened to three meters, the size of the round well in plan should be at least 1.5 m.

- The height from the bottom to the support point of the floor is called the working height. On average, for a sewer well it is 180 cm. In this part, a hanging or stationary ladder or steel brackets must be provided to descend into it. At a depth of one and a half meters there must be a fence.

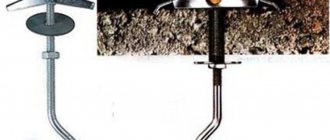

Descent brackets are mounted into the wall of the well

- The well neck is taken as standard - 70 cm, however, at turning points, where blockages most often occur, the dimensions of the manhole are increased to take into account the need to lower the equipment for cleaning.

- Hatches are installed 5-7 cm above the ground if it is a green area; by 20 cm if it is an undeveloped area; and flush with the coating if it is located on the roadway or sidewalk.

On the sidewalk, the hatch is installed flush with the surface

In cases where the bottom of the well is buried below the GWL (groundwater level), it must be waterproofed. The walls are also insulated - at least half a meter above the water mark.

For drop wells

The installation of a differential well makes it possible to reduce the depth of pipes in individual sections of the pipeline, thereby reducing the volume of excavation work and significantly reducing the price of the system as a whole. In such a well, the flow velocity is damped, which prevents the risk of water hammer in the pipeline.

Note: The absence of a damper well is allowed only for differences of less than 50 cm, and for pipe diameters up to 60 cm. In this case, drainage is carried out in an inspection well.

The parameters of the designed differential wells depend on the diameter of the pipeline and the height of the differential. At large differences (up to 6m), the well is a riser, the cross-section of which corresponds to the cross-section of the supply pipe (or slightly larger).

Drawing of a quenching well

- In this case, a receiving funnel is designed above the riser, and in the water part - a pit with a base reinforced with a metal plate. On risers of small diameter (30 cm or less), a guide elbow can be installed instead of a pit.

Option with riser and guide bend

If there is a storm sewer system, then at differences of up to 1 m, drainage wells with water beams or grates can be provided, the number of which depends on the difference in elevations.

There are also certain requirements for rainwater inlets.

There are separate requirements for rainwater inlets and septic tanks, but we will not go into them now. If necessary, open SNiP - and detailed instructions are at your service.

We will look at how to construct round prefabricated reinforced concrete sewer wells from wall rings, since many homeowners strive to do this work with their own hands.

Types of wells

Reinforced concrete wells are most often used to organize a sewer system. These universal products perform very important functions:

- Sewer inspection wells can be found most often in the city. They are necessary so that workers can check the condition of pipeline elements and, if necessary, make repairs.

- Drop concrete ones are needed where two pipelines that are at different heights connect, that is, in a place with a large drop.

- Rotary ones are necessary in places where pipes turn sharply. They help prevent the accumulation of blockages and also serve as inspection rooms.

- Filter wells are exactly the part where all wastewater is directed. Here they are cleaned, passing through filters with holes of different fractions.

- Storage or settling tanks are also involved in the wastewater treatment system. In them, sedimentation of drainage water occurs, as well as sedimentation and floating of suspended substances.

- A standard storm well is necessary to ensure that water accumulated during the rainy season does not flood the city, but is drained into the sewer system.

Heavy equipment is used to install reinforced concrete sewer wells.

In a centralized sewer system, all described types of wells are used. To organize autonomous sewage systems, only treatment facilities are usually used. However, in some cases it is possible to install additional options.

The hatches that you often see in the city are precisely the covers from such wells. They can be large or small, depending on what functions they perform.

Such wells can have different shapes. Sometimes even square and rectangular designs are used. However, more often you can find a cylinder-shaped version, which is why you can see an abundance of round lids in the city.

By the way, a device such as a well is used not only for sewerage equipment. They are also equipped with water and gas pipe systems.

Assembling a well from wall rings

As a basis, we will take a well with a diameter of 1 m and a depth of 3 m, erected on subsidence soils.

Stages of work performed

Any construction production must be properly organized, then the result will be excellent. The work of constructing a well is no exception, and consists of the following stages:

Preparation

In preparation for installation:

- The site for construction is divided;

- The area is cleared of vegetation;

- Interfering structures, if any, are demolished;

- A temporary road or ramp is being laid.

After the preparatory work, you can begin purchasing materials. In addition to the rings themselves - in our case this is KS 10.9 in the amount of three pieces, you will need 1 bottom plate, 1 ceiling, 1 hatch, as well as cement, sand and bitumen mastic.

Installation

Now regarding the construction itself.

The work order will look like this:

- A pit is developed, its bottom is leveled and cleaned;

- To ensure greater soil strength, the base is treated with liquid bitumen and carefully compacted;

- Preparation is made from class B3.5 concrete - 10 cm thick;

- They install trays for pipes that will enter and exit the well, and reinforce them with steel mesh;

- The surface of the rings is coated with bitumen mastic;

- A bottom plate is laid, on top of which rings are installed;

- The joints between the rings are caulked with M50 cement mortar;

- The inside surface of the well is plastered;

- The soil is backfilled, and waterproof locks are installed at the pipe entries;

- A concrete blind area is constructed around the neck - width 1.5 m;

The well must be tested - but only after the construction of the entire section of the network is completed. It is filled with water for a day to create hydraulic pressure. If no water leaks are detected during a visual inspection, then the tank has passed the test - and we can assume that the installation of the sewer system from concrete rings is complete.

Types of well reinforced concrete rings

Externally, these reinforced concrete products are similar to each other, but the design of the rings is different. There are three types:

- KS - called wall or through. The walls from the neck to the bottom are laid out of such elements. Most often, rings are used in the construction of drinking wells. There are modifications with a lock or seam connection. They should be chosen for swampy areas and soils saturated with moisture. KS and quarter rings are needed for better alignment and maintaining a tight seal. Concrete grades M200-M500 are used for production. The wall thickness reaches 10 cm, the standard height is 90 cm, but there are other options.

- KCD is a monolithic structure with a bottom. Allows you not to worry about the contents of the well seeping into the ground, as when using a separate bottom slab. The main area of application is the creation of septic tanks and sewers. Another advantage of the CCD is that there is no need to create a concrete site for installation and speed up assembly work.

- KCO - called the support ring. It has a reinforced design and is placed on the neck. Installation is needed to compensate for vertical loads.

You can select a product by labeling. It consists of letters indicating the type of product (KS, KCD, KTSO) and diameter numbers. For rings, the parameter is indicated in decimeters. If you see additional letters after the diameter designation, they indicate the presence of a lock.

Marking of reinforced concrete wells

Structures may vary in their purpose. And to distinguish one option from another, they are marked.

The marking is as follows:

- Drain wells and their working chambers are distinguished by the abbreviation BC;

- Reinforced concrete wells for receiving rainwater are designated by the letters VD;

- There are wells that are installed simultaneously for water supply and gas systems; they are designated by the abbreviation VG;

- There are also round floor slabs for wells, the hole in which is located on the edge, they are designated PC;

- The same floor slabs, but with a hole in the center, are designated by the abbreviation PVG;

- Well neck rings are marked with the letter K.

Knowing this marking, you can select the right element. As you can see, everything is quite simple here.

Reinforced concrete decks are already being successfully replaced with polymer products. However, due to their high strength and low cost, they are still used to organize sewer networks in the city and in suburban areas.

Advantages of reinforced concrete rings

Let's look at the advantages of constructing reinforced concrete wells from ready-made rings:

- Reinforced concrete rings are manufactured in a factory using modern equipment using vibrocompression techniques. Therefore, the elements are strong and durable.

- Each part is made with special protrusions, so when assembling structures, better adhesion between parts is ensured. This ensures the strength of the chambers and helps maintain its integrity during the melting and freezing of the soil, accompanied by ground movement.

- If you use lifting equipment, installation of the rings is quite simple and does not require much time. For convenient engagement, special holes are made in the rings.

- Using reinforced concrete rings you can build a structure of any depth.

- The rings are made with special brackets that a person can climb down to perform maintenance.

How are wells installed?

At the first stage, it is necessary to prepare a pit for the installation of a reinforced concrete ring. Once the pit is ready, you can proceed directly to installation. The work goes like this:

- The bottom of the pit is covered with clay, and the layer of bedding is well compacted. This operation will increase the degree of waterproofing of the structure.

Advice! Clay backfill is made during the construction of storage wells, and if a drainage well is being built, then the backfill is made of sand and crushed stone.

- A slab is placed in the prepared pit, which will serve as the bottom. The plate can be round or rectangular, its size is determined by the diameter of the rings.

Advice! You can purchase ready-made rings combined with the base. Naturally, such a part is used only for constructing the bottom of the chamber.

- The slab must be laid evenly; the evenness of the laying is checked using a level. The presence of even a slight slope can lead to distortion of the structure, which will reduce its mechanical strength.

- Reinforced concrete rings are laid one after another at the bottom, which will form the chamber of the well.

- If it was not possible to purchase rings with ready-made holes for connecting pipes, then the holes will have to be punched.

- If a manhole is being built, then a special tray is built in it from cement, and on the sides of the tray there are shelves or work platforms.

- After the required height of the chamber has been reached, it is covered with a slab with a hole for installing a hatch.