Why protect concrete from water?

Neglect of waterproofing issues, lack of competent study of the zero cycle of buildings and structures (basement, foundation, plinth) provokes water penetration into the lower part of buildings. This causes basement dampness to develop, which increases humidity in other rooms. This .

Dampness in concrete is a fairly favorable environment for the development of mold and mildew.

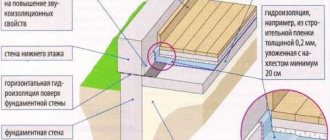

Plus, moisture has a negative effect on the capillary-porous structure of artificial stone. Gradually penetrating the structure from the bottom, groundwater migrates through pores and capillaries, helping to moisturize the enclosing structures . The walls begin to collapse due to alternating freezing and thawing.

In addition, the water contains impurities of salts and bicarbonates. These substances are capable of hydration and crystallization, multiplying in volume. In general, this leads to destruction of load-bearing concrete structures, peeling, and deformation of finishing coatings.

Water can also act from above, coming from precipitation . Such exposure leads not only to mechanical damage, but also to chemical consequences. For example, rainwater is a real chemical acid solution, especially in megacities. It has a destructive effect on artificial stone, increasing the number of pores and capillaries, which further intensifies the foci of aggression.

That is why not only residential construction projects, but also a significant number of other concrete structures require waterproofing protection. These can include cooling towers, reservoirs, water engineering structures, industrial floors, underground garages and swimming pools, not to mention facades, interior walls and floors.

Coating waterproofing based on synthetic resins

Waterproofing compounds, which are an aqueous dispersion of synthetic resins, can be considered a serious competitor to bitumen and bitumen-containing materials.

Litokol Hydroflex. A paste made from an aqueous dispersion of synthetic resins using inert fillers. Does not contain solvents. Sold ready to eat. It is thixotropic, which means it does not slip on vertical surfaces.

The elasticity of the coating is not affected by ambient temperature; the material retains its properties at temperatures ranging from –30°C to +100°C. In addition, waterproofing copes with structural loads and vibration. An important point is that the composition is resistant to the leaching effects of water. Litokol Hidroflex is the best coating waterproofing for bathrooms under tiles. Used as an elastic membrane to prevent cracks in ceramic tiles.

Litokol Aquamaster. The composition is intended for waterproofing bases that are planned to be faced with ceramic tiles, natural stone or mosaics. It is used for finishing swimming pools, hot tubs, shower cabins, and rooms in SPA centers.

The finished coating does not require additional waterproofing materials, fiberglass mesh or special tapes for sealing corners and junctions. This makes the surface treatment process less expensive both in terms of money and time.

The paste dries quickly, the next layer can be applied after 30 minutes, and the surface can be covered within a day. After the coating waterproofing dries, a seamless waterproof membrane is formed, which can withstand constant exposure to chlorinated water.

Mapelastic AquaDefense. The elastic waterproofing membrane from Mapei is designed for both indoor and outdoor use. The composition is a quick-setting paste made from synthetic resin in aqueous dispersion. One of the main advantages of AquaDefense is its drying speed. The coating becomes resistant to pedestrian loads after 3 hours, and to rainwater after 1 hour after application.

Coating waterproofing under tiles is ideal, because it is compatible with any type of tile adhesive.

The waterproofing membrane is not afraid of base deformations caused by temperature changes and vibration.

Coating waterproofing for concrete

Coating waterproofing materials are gradually replacing rolled bitumen-based varieties. This is due to the fact that cement, polymer and mixed waterproofing mixtures provide a high degree of adhesion to concrete , that is, they form almost a single whole with the base.

There is a wide range of similar materials on the domestic market, but when choosing, it is better to respond not to advertising, but to the actual guarantee of a set of waterproofing properties.

Coating waterproofing of concrete should provide:

- waterproof against pressure, which is important in tanks and pools, and against tear-off. The latter property works especially actively in recessed rooms and basements;

- resistance to cracking under dynamic loads;

- vapor permeability;

- strength in terms of adhesion;

- ease of processing and technology, the ability to process wet concrete;

- reliability, durability.

Cement based waterproofing

Today, one of the best materials for this are cement waterproofing materials. However, as such, there is no Russian experience in using this method in technical terms. This method is underdeveloped, but quite effective. This has been proven by foreign construction experience. Namely, cement-based waterproofing has advantages over, for example, bitumen-based mastics or other rolled substances. Its main advantage is that it is absolutely environmentally friendly. Thus, it can be used to treat both indoor surfaces, swimming pools and potable water fills. It also has an advantage in physical and mechanical indicators. These materials have high interaction and retention of surfaces of various liquid and solid bodies. In addition, cement waterproofing has great strength. Therefore, the resulting surface can perceive various types of loads (static, dynamic). An important feature when using these materials is the combination of the functions of waterproofing and adhesive, intended, for example, for facing tiles.

Another problem that can arise when processing wet surfaces is the formation of swelling and bubbles. And polymer-cement based waterproofing materials will cope well with this problem. Also, these materials increase the service life of the building and maintain a suitable appearance for the next renovation for as long as possible.

Cement waterproofing can be applied to both wet and dry surfaces. Sometimes, before applying waterproofing materials, it is simply necessary to moisten the repair object. Thus, cement-based materials are very convenient to use and have high productivity in applying the mixture.

Mineral coating waterproofing (cement based)

Such compositions provide a whole range of water- and moisture-protective properties. Essentially, these are dry mixtures based on special cement, quartz sand, and additives. After mixing with water, a homogeneous paste-like mass is obtained.

The material is applied to the base in 2-3 approaches using hard brushes, after which smoothing can be carried out with rollers. When the composition hardens, a waterproofing hard layer will be formed on the concrete. Cement coating waterproofing can be plaster or penetrating .

The average consumption of cement-based mineral coating waterproofing is 3.5 kg/m² per 2 mm layer

Scope of application : protection of vertical and horizontal concrete, incl. plastered surfaces, hydraulic structures, underground, above-ground structures, old buildings, floors, ceilings, walls, bathrooms. .

Brands : Aquafin-1K, Lakhta, Koster, Mapei, Hydrosmart

Advantages:

- cement works for high adhesion to concrete;

- the finished layer provides high strength and resistance to mechanical stress;

- high-quality protection from moisture, including in critical structures.

Flaws:

- mineral mixtures are not elastic, so the finished layer does not withstand vibration loads well.

Specifications

| The basis | Cement, sand, synthetic additives |

| Density of the finished solution | 1.85 kg/l |

| Bulk density | 1.438 kg/dm³ |

| Mixing time | 3 minutes |

| Viability | 60 minutes |

| Operating temperature | +5 +30 degrees |

| Waterproof | Up to 7 Bar |

| Cleaning the instrument | By water |

What does cement waterproofing consist of?

In the building materials market, cement-based waterproofing can vary in composition, purpose, price and density. There are one-component and two-component mixtures with polymer additives. One-component formulations are usually offered ready-made and can be applied immediately after purchase. Two-component mixtures are dry powder, which before preparation is mixed and diluted strictly according to the manufacturer’s instructions.

Modern cement waterproofing products contain three main components:

- cement. This is the astringent base of the coating, which is responsible for strength and resistance to mechanical damage. The more cement in the solution, the stronger the hydrophobic coating will adhere;

- fine quartz sand – increases resistance to mechanical damage and increases the hydrophobic properties of the solution;

- polymers in cement mortar improve the adhesion of the protective coating to the base and penetrate into the thickness of the cement coating. Thus, all microscopic pores where moisture can collect are clogged. Thanks to polymer additives, the coating of waterproofing cement mixtures perfectly withstands water pressure and does not lose its waterproofness over time.

Some types of cement-based coating waterproofing can set to the surface and polymerize in a few minutes. This makes them indispensable in emergency situations, when it is necessary to quickly eliminate a leak, but it is impossible to stop the water penetrating through the destroyed coating.

Polymer-mineral waterproofing (cement-polymer)

This solution is in demand if the concrete structure is subject to dynamic loads, which is fraught with the appearance of cracks. Unlike the previous version, the composition contains modern elasticizers, most often based on rubber. The result is a unique material in its own way .

The resulting composition after mixing is similar to a paste, which is applied in 2-3 approaches to a flat, matte, moistened surface using brushes. Once cured, a continuous, seamless, elastic waterproofing seal is formed. By the way, the layer is capable of bridging cracks up to 1 mm. This type of mixture is compatible with tap water.

Scope of application : protection of concrete structures, structures of various shapes and purposes, incl. tanks, swimming pools. The materials used are prefabricated and monolithic reinforced concrete, screeds, and plastered concrete. For carrying out external and internal work, incl. in bathrooms, cellars, basements, walls, tanks. Average consumption – 3.5 kg/sq.m. at 2 mm layer.

Advantages:

- monolithic waterproofing that covers cracks;

- the compositions differ in hydraulic setting;

- application to all surfaces with load-bearing capacity;

- rapid resistance to precipitation;

- environmental friendliness;

- manual or mechanized application;

- vapor permeability;

- frost resistance;

- resistance to dynamic and static loads;

- base for finishing layers - tiles, plaster, under screed;

- water resistance – 7 bar.

The main brands of polymer-mineral waterproofing are Koster, Lahta, Hydrosmart, Ceresit

Flaws:

- does not work on the roof.

Specifications

| The basis | Powder + dispersion |

| Density | 1.5 g/cm³ |

| Viability | 1 hour |

| Adhesion | 1.5 MPa |

| Tensile strength | 1.3 MPa |

| Tension at break | 42% |

| Vapor permeability | 1000 |

| Cleaning the instrument | By water |

Cement waterproofing hydrostop

This method also applies to the coating version of insulating compounds, which is impermeable to water and not susceptible to cracking. It is freely applied with a spatula and is used for external and internal work. Hydraulic insulation is used on brick and concrete bases, as well as on plasters.

This composition freely tolerates air humidity, therefore it is used for insulation work in reservoirs up to 5 meters deep and in the basements of buildings. When applied to the external parts of a building, it is used for protective work on façade and basement parts. The composition is applied in a 1-2 mm ball on all sides of the coating in a slightly damp room, and 2-3 mm in stronger contact with water. If there is constant contact with water masses, an application of 3-5 mm should be made. Per square meter with a 1 mm ball, 1.8-2 kg are consumed. The prepared composition should not be stored in an open container for more than three hours.

Polymer-bitumen, polymer, bitumen waterproofing of concrete

Polymer-bitumen and polymer materials behave well during external waterproofing work. This can be the protection of an exploited roof, foundations, open terraces, balconies. The point is that the high elasticity of the finished waterproofing significantly reduces the risk of deformation of the material under conditions of serious temperature changes . However, purely bitumen coating waterproofing loses its frost resistance, which requires protection.

Classification:

- cold-applied water-based bitumen mastics – the composition includes materials such as polymers and emulsifiers. Such emulsions are safer and more environmentally friendly compared to analogues;

- cold applied bitumen mastics based on solvents are one of the usual methods of coating waterproofing. These mastics are ready to use and are ideal for various applications;

- hot-applied bitumen mastics are the most common method of bitumen waterproofing, one might say completely time-tested. Before use, the material is heated to 160-180 degrees. Hot mastic is applied to a base coated with a primer. When cooled, an elastic and durable coating is formed. It is gratifying that the material is one of the few that does not shrink further;

- polymer elastic waterproofing - the material is designed to protect roofs, basements, foundations, bathrooms, swimming pools, and technical rooms. The basis is aqueous dispersions of polymers. This type provides high elasticity and can be used in almost any room, providing biological and chemical resistance. Consumption per layer – 0.200-0.400 kg/sq.m. This type of waterproofing can be tinted according to the RAL scale.

Brands: TechnoNIKOL, Lakhta, Koster

Advantages:

- excellent elasticity;

- operation up to 25-50 years;

- spot sealing of the base or the formation of a continuous coating is possible;

- resistance to negative influences;

- quick readiness for use.

Bituminous waterproofing agents allow both spot sealing and the formation of a continuous coating

Flaws:

- the price is higher than that of analogues;

- bitumen mastics do not like high temperatures;

- low environmental friendliness.

Specifications

| Type of waterproofing | Bitumen-polymer | Bituminous | Elastic polymer |

| Adhesion, MPa | 0.6 | 0.1 | 1.0 |

| Adhesion between layers, MPa | 0.3 | — | — |

| Elongation at break, % | 500 | — | 110 |

| Water absorption,% | 0.4 | 0.4 | 0.4 |

| Dry residue, % | 50 | 65 | |

| Heat resistance, degrees | 110 | 80 | 130 |

| Crack resistance | Eat | Eat | Eat |

Types of cement waterproofing

According to their purpose, cement waterproofing is divided into several types:

- Coating waterproofing;

- Suture;

- Plastering;

- Penetrating waterproofing;

- Repair mixture;

- Waterstops;

- Additives to concrete.

Coating waterproofing

Compositions based on modified cement or bituminous materials. Existing varieties of such waterproofing products make it possible to choose a solution for the treatment and protection of structures subject to deformation, contact with drinking water, and those located in aggressive environments.

Elastic suture insulation

Used for sealing joints of prefabricated reinforced concrete structures of basement walls and tanks, as well as in areas where there is a high probability of cracks.

Plastering

Used for waterproofing surfaces that are not subject to any deformation. These are mainly foundations, basement and basement walls, floors, pools and liquid storage tanks. Can be used both externally and internally.

Penetrating cement mixtures

They contain a large number of polymers that can penetrate deeply into the surface being treated, crystallizing in microcracks and pores. A special property of penetrating insulation is that, under the influence of moisture, it is able to penetrate deeper into the treated material, while simultaneously strengthening its strength over many years.

Repair compounds

Special compositions based on cement and modifying additives. They can be used both for local restoration and for repairing the entire surface of a structure. In addition to eliminating mechanical damage, they can increase the strength and waterproofing properties of the structure.

Waterstops

Designed for sealing structural joints. Since such areas are subject to deformation changes, waterstops are made from elastic PVC compositions. They can be installed on all types of underground, above-ground and flooded structures, including those under constant pressure.

Additives to concrete

They refer to modifying mineral and polymer components for a concrete mixture, introduced at the stage of its preparation. Allows you to achieve uniform hydrophobicity throughout the entire structure. Simultaneously with the increase in water resistance, the frost resistance of reinforced concrete is also increased.

Tools and equipment

The choice of tools and equipment is based on the method of applying waterproofing and the assigned tasks for preparing concrete for work.

The standard set is formed as follows:

- equipment for preliminary preparation of the base - you can choose from sandblasters, grinders, high-pressure machines, jackhammers, hard metal brushes, construction vacuum cleaners;

- equipment and tools for applying solutions - these are fur rollers, brushes, spatulas, squeegees, brushes, sprayers, with a capacity of 120-240 m²/h, power from 0.9 kW;

- tools and equipment for mixing solutions - low-speed construction drill with a mixing attachment, clean containers;

- material for waterproofing protection - most often polyethylene film or any non-woven material is used;

- protective clothing and personal protective equipment (goggles, gloves, respirators).

Surface preparation

If external concrete structures, interior rooms and basements with high humidity are to be protected, preliminary preparation is required.

A number of operations are as follows:

- removal of organic deposits (fungus, mold). Biocides are used for this;

- fluation - as a result of this process, soluble salts are converted into sparingly soluble ones. The work is carried out using special liquids;

- priming – primers act as primers. This stage is required when applying bitumen mastics (and their varieties), since without this the required adhesion will not be ensured.

Primers additionally strengthen concrete and bind small particles and dust.

Principles of using sanitizing solutions against mold, algae, fungi

Contaminated concrete is treated with sanitizing material using a sprayer or brush. Depending on the work conditions, its activity begins after 24-72 hours. If necessary, the treatment is duplicated.

Severely affected concrete:

- the biocide is applied with a brush or sprayed;

- the base is left for several hours;

- Concrete is cleaned with high pressure water;

- apply a second layer of biocide, but without further cleaning;

- After drying, proceed to the next stage of work.

On slightly damaged concrete, first clean with high-pressure water, after which a sanitizing solution is applied. After drying, begin waterproofing. After completing the operation, the instrument is washed with water.

Principles of concrete fluting

Fluate treatment is used in the repair of saline concrete walls as a concomitant measure for waterproofing. Before treatment, areas with damaged plaster contaminated with efflorescence are removed. Seams and walls are thoroughly cleaned with metal brushes .

Fluate is diluted with water 1:1 and applied to the base 1-2 times until completely saturated. Between passes there is a technological pause of 7 hours. After a day, the dried concrete is cleaned of converted salts with brushes. When mixing fluate with water, do not use metal tools or containers. After coating, the equipment is washed with water.

Priming principle

The base is cleaned of dirt, loose layers, protruding and sharp edges, and corners. The primer is mixed with a construction mixer until a homogeneous mass is obtained. The material is spread over the concrete with brushes or fur rollers. The latter method significantly increases the speed of work, ensuring the most uniform layer possible.

The composition dries from 10 minutes to 12 hours, which depends on the type of primer, humidity, air temperature . The surface is considered completely dry if it is not sticky. The average consumption of bitumen, bitumen-polymer primer is 0.15-0.35 l/sq.m.

Next, they begin waterproofing and finishing work.

B-Isol HYDRO cement waterproofing coating type

Coating-type cement waterproofing

KEY PROPERTIES – WATERPROOF – CRACK RESISTANT – EASY TO APPLY WITH A SPATULA AND BRUSH – FOR INTERNAL AND EXTERNAL WORK

APPLICATION AREA:

Base type:

Brickwork Concrete, reinforced concrete Cement screed Cement, cement-lime plaster

Scope of work

Rooms with normal humidity Rooms with high humidity Swimming pool up to 5 m deep Basements Exterior work: facade, basement

Scope of work Wall Floor Ceiling* (*use of the mixture is possible with minimal water consumption)

Application characteristics Mixture consumption per 1 m2 with a layer of 1 mm: 1.8-2 kg Recommended application thickness: 1-5 mm Pot life of the finished solution in an open container: 3 hours Further work (painting, tiling, etc.)* *: 48 hours. Carrying out work at base temperature: from +5 to +35 °C

Operating characteristics:

Compressive strength (after 28 days): no less than 30 MPa Bending strength (after 28 days): no less than 6 MPa Adhesion strength to the base (after 28 days): 1 MPa Waterproof grade: W10 Operating temperature: from -50 to +70 °C (**- under normal hardening conditions (ambient temperature 20 o C, humidity 60%)

COMPOSITION Cement binder, fractionated sand, mineral fillers, modifying polymer additives, water-repellent additives. PURPOSE For waterproofing vertical and horizontal non-deforming structures inside and outside buildings. It is used to protect the base from the effects of water in such areas as: waterproofing bathrooms, showers, swimming pools (up to 5 m deep), fountains, water tanks, artificial reservoirs, basements and plinths, foundations (including underground parts), balconies, terraces, etc.

PREPARATION OF THE BASE Before starting work, make sure that the window and door openings are closed, there are no drafts in the room, the air temperature is in the range from +5 to +25 0 C and this temperature condition was maintained in the room for at least 5 days before starting work and three days after application. In the case of outdoor work, it is necessary to avoid direct sunlight on the base and on the surface of the applied waterproofing. The base temperature should not exceed +25 0 C, the outside air temperature +30 0 C. It is prohibited to carry out work at a wind speed of more than 10 m/s, as well as during precipitation. Clean the surface from dirt and dust, peeling old coatings and oil stains - anything that can impair the adhesion of the material to the base. The prepared base must be treated with Bergauf primer (PRIMER or TIEFGRUNT - depending on the type of base). Cracks, sinkholes, depressions, and brickwork seams must be leveled. The strength of the base must be at least 15 MPa. Concrete and brick foundations must be cured for at least 3 months, plastered ones - for at least 28 days and have a compressive strength of at least 12 MPa. In the corners it is necessary to make fillets (roundings) with a radius of 3-4 cm, using cement-sand mortars. The fillet design eliminates the possibility of cracking. If the base surface is not primed, the following consequences are possible: reduction or loss of waterproofing properties due to cracking and general loss of strength. ATTENTION! — It is not allowed to apply waterproofing to surfaces that have leaks. — Before applying waterproofing, the base should be moistened. PREPARATION OF THE SOLUTION The properties of the product are guaranteed only if the proportions of mixing with water and the procedure for preparing the solution are strictly observed. Use clean containers and tools to prepare the solution. 1. Mix the mixture with water (from +5 to +25 ° C) in the following proportion: The dry mixture is gradually added to the water and mixed at the same time. For application with a brush: - per 1 kg of mixture - 0.23 - 0.25 l of water; - for 25 kg of mixture - 5.75–6.25 liters of water. For application with a spatula: - per 1 kg of mixture - 0.18 - 0.20 l of water; - for 25 kg of mixture - 4.5 - 5 liters of water. 2. Stir until smooth***. 3. Wait 5 minutes until all chemical reactions are completed. 4. Mix again. *** Mixing is recommended to be carried out using a special mixer for dry mixtures or a conventional drill with an attachment, the number of revolutions not exceeding 500 rpm. At a high number of revolutions, a large amount of air will be drawn into the mixture, which can adversely affect the quality of the surface. ATTENTION! Before starting the main work, it is recommended to carry out a test application of the mixture (approximately 1 sq.m.) on the most difficult areas of the surface in the maximum layer thickness. OPERATION PROCEDURE 1. Work is carried out at air temperatures from + 5 to + 35 ° C 2. During work, the surface must be protected from precipitation, direct sunlight and drafts. 3. Waterproofing is applied to the moistened base in 1-3 layers. Depending on the application method, the total thickness of the waterproofing layer should be 1-5 mm. 4. When installing a multi-layer coating, each subsequent layer must be applied after the previous one has hardened (after 24 hours). In this case, the direction of movement of the spatula or brush should be perpendicular to the direction when applying the previous layer (for example: the first layer is horizontal movements, the second is vertical). 5. Further work: The surface is suitable for: - tiling of all types and sizes - after 2 days**; — coloring — after 7 days; (residual humidity of Bergauf B-Isol HYDRO should be no more than 8%). Coating type waterproofing is recommended for use in a system with Bergauf HYDROLENTA (waterproofing tape) for waterproofing joints and corners. When using Bergauf HYDROLENTA, it is necessary to lay the waterproofing tape along the joint/corner on a freshly applied layer of Bergauf B-Isol HYDRO coating type waterproofing. The area where the waterproofing solution is applied should be several centimeters larger than the width of the tape being applied. The next layer of waterproofing coating type Bergauf B-Isol HYDRO is applied over the perforated edge part of the tape with a slight overlap on the elastomer. More detailed information can be found on the Bergauf HYDROLENTA packaging or on the website www.bt.bergauf.ru ATTENTION! Subsequent finishing work must be carried out after checking the absence of surface defects and water filtration (after 48 hours). If surface defects are detected (delamination, water filtration), these areas must be opened and waterproofing work repeated. RECOMMENDATIONS The applied mortar mixture should be protected from drying out too quickly. To do this, we recommend covering it with film or moistening it with water for 1-2 days. Bergauf B-Isol HYDRO coating must be protected from mechanical damage by tiling, plaster or screed.

Type of load Recommended application thickness

Damp room with a probability of one-time leakage 1-2 mm Constant or periodic contact with water without pressure (showers, mini-2-3 mm fountains) Constant contact with water under pressure (swimming pools, tanks) 3-5 mm

STORAGE The guaranteed shelf life in a dry place and in closed original packaging is 14 months from the date of manufacture. The product complies with TU 5745-001-71576152-2014

—

Technology of applying mineral (cement) waterproofing

The concrete to be processed must have load-bearing capacity, be smooth, and free of contamination. The pores must be open. The presence of foreign elements, sharp corners, and nests is unacceptable. Sludge residues and cement paste are removed. Sinks and voids, more than 2 cm deep, cracks are repaired with cement-sand mortar . On its basis, fillets are arranged in diverging corners. The surface is moistened before applying waterproofing.

Any water that comes to the surface during operation and curing must be removed.

Preparation of the composition:

- the composition is prepared by mixing with clean water;

- The material is placed in a clean container, water is added to the required consistency. Proportions: 25 kg of dry powder – 6.7 liters of tap water;

- the composition can be spread with brushes or sprayers;

- waterproofing is applied in several layers at a consumption rate of 1-2 kg/sq.m in one pass;

- fresh coating protects from frost, rain, drafts, and sun.

Technology of applying polymer-mineral waterproofing

The outer surface of the concrete must be finely porous, without materials that impede adhesion, smooth, and with load-bearing capabilities. If the base is large-porous, preliminary filling with cement mortar is carried out. The surface is moistened to a matte damp state.

According to the technology, it is impossible to work in strong solar radiation . If the concrete is too dry and dusty, it is dusted with a construction vacuum cleaner and wetted, but without the formation of water films. When working with polymer-mineral waterproofing, a primer is not required.

Application of waterproofing:

- surfaces not involved in work are protected;

- about 50-60% of the liquid component (polymer dispersion) is poured into a clean container;

- with constant stirring with a low-speed drill, gradually introducing cement powder;

- the mixture should not contain clots. Then the remainder of the liquid component is introduced;

- kneading is continued for about 2 minutes, maximum 300 rpm;

- waterproofing is applied with a roller, spatula or sprayer in two approaches;

- subsequent layers are applied after the previous ones have set. During the curing process, the concrete should not be exposed to water load;

- The finished insulation can be plastered or coated with vapor-permeable paints without solvents.

When carrying out work, maintain a consumption of no more than 2 kg/sq.m per layer. Otherwise, there is a risk of cracks due to excess binder.

In the base-wall area, fillets are laid using cement mortar. After hardening, waterproofing is installed

If it is necessary to install fillets or process divergent corners, use waterproofing tape. The tape is embedded in fresh waterproofing at floor-to-wall joints and in areas of vertical corners . An alternative can be fillets.

Treatment of expansion joints of a monolithic foundation slab:

- waterproofing tape with a loop is also placed on the seams;

- The material is glued using epoxy adhesive and covered seamlessly with surface insulation.

Protective plates, drains:

- protection from mechanical damage and ultraviolet radiation is provided with polyethylene film or other slippery non-woven material;

- You can use special protective drainage elements. They are glued after the waterproofing has completely dried.

Technology for installing bitumen, polymer, bitumen-polymer waterproofing

The progress of work depends on the location of the work and the material used.

Roof protection

This option is in demand if the roof has a complex geometry, when the method of fusing rolled materials is excluded due to fire safety requirements.

Carrying out work:

- the cleaned base is primed with an emulsion or bitumen primer;

- Mastic is applied in 3-4 approaches. Use the pouring method and uniform distribution with a squeegee or brush;

- to obtain a waterproofing thickness of 2 mm, approximately 4 mm of cold mastic should be applied. In fact, it is about 1-1.3 mm per layer;

- if you want to save money, it is recommended to use the airless spray method;

- Between each approach, a layer of reinforcement is laid on the waterproofing layer - fiberglass, fiberglass. Each layer must be thoroughly dried;

- the finished system is protected with protective reflective mastic, which will protect it from temperature changes and ultraviolet radiation.

Waterproofing of buried structures

This solution is optimal for protecting concrete that is constantly in contact with water. These are tanks, pools, basements, canals, foundations. The material forms a film that retains moisture. In this case, there is no deformation of the bases.

Work order:

- the base is cleaned and primed with bitumen or emulsion compounds;

- Waterproofing is applied layer by layer, in two layers. Spatulas are used;

- observe the drying time of each layer - 1-24 hours (the surface should not be sticky);

- the resulting layer is protected with insulating protective boards mounted on adhesive mastic.

Sprayed mastic application technology

This type of waterproofing is effective for treating basements, balconies, and floors in wet rooms. One layer consumes 4.5-5.5 kg/sq.m. Training and protection requirements remain typical.

The material is applied mechanically using an airless spraying machine

Waterproofing of concrete screed and interior spaces

Here we are talking about the treatment of all concrete bases exposed to various effects of liquids. This could be bathrooms, floors, etc.

Work order:

- An emulsion primer is applied to the cleaned base;

- emulsion mastic is applied in layers using a brush or roller. Apply 2 layers;

- Drying time for each layer is up to 5 hours;

- Self-adhesive sealant tape is used at seams and joints. Or they use geotextiles, embedding them in the first layer of waterproofing;

- when the layer has dried, the following finishing work can be carried out on the screed.

Coating waterproofing technology

Preparatory work for the foundation

The surface on which bitumen coating waterproofing is applied must be completely dry, cleaned of foreign debris and primed. Any, even the most durable concrete has tiny micropores, microcracks, capillaries - i.e. The surface of almost any structured material is porous. Often such pores cannot be distinguished with the naked eye. Corners, sharp protrusions and edges are rounded using a grinder with a radius of at least 3 cm, since in the future, mechanical pressure from structures or soil causes damage to the outer layer of waterproofing. When an internal corner is to be covered, fillets with a triangular cross-section are made - they reduce the pressure on the waterproofing layer from backfill. Seams and cracks are opened to a solid base and then sealed with cement mortar. Existing sinks are sealed with cement mortar, since when the product is applied, air remains in them, and subsequently a bubble is formed, during the rupture of which the covering layer of waterproofing is damaged

Primer application process

The adhesion of the base and the waterproofing film is better when primers are used - a primer designed for a specific type of coating. For bitumen mastics with a base made of organic solvents, a primer with the same type of solvent is used; for water-based compositions, a water-soluble primer is used. Primers are applied using a roller onto a prepared base that has been cleared of existing debris and dust; each corner is additionally coated with a brush. The drying time of primers is generally several hours at positive ambient temperatures.

The process of applying quick-drying bitumen varnishes to the foundation

Under bitumen and bitumen-polymer mastics, the first layer is applied with a quick-drying bitumen varnish, which ensures good adhesion. The varnish is applied with a brush, vertical strokes, or spraying over the entire surface of the foundation. Wait for it to dry completely

The process of preparing mastic

The one-component mastic is stirred and, if necessary, diluted with an appropriate solvent. Mastic with a two-component composition is mixed according to the accompanying instructions located on the packaging

Applying the first layer of mastic to the foundation

The first layer of mastic is applied with a spatula, wide brush or roller. The mastic is applied without intervals, the corners are coated very carefully to form a solid and tear-free coating. The direction of application of strokes is vertical. Apply two or three subsequent layers of mastic in the same way, but be sure to wait until it completely hardens. When work is carried out in conditions with sub-zero temperatures, the mastic is pre-heated slightly, this increases its ductility

Protection of applied waterproofing

When constructing a new building, it is necessary to reinforce the waterproofing; this is done to prevent its damage during shrinkage. Typically, fiberglass or fiberglass is used for this; they are glued to the first layer of mastic, and the materials must be completely moistened with it. In the same way, all corners of the foundation of the building, its sharp chamfered protrusions and fillets are reinforced

To prepare bitumen mastic, first melt it over a fire.

Bitumen mastic for hot use is preheated in a metal container to a temperature of 160 -180 °C. It is applied using a regular spatula and leveled with a hard brush. Bituminous hot mastic is usually used for horizontal waterproofing of foundations, when a thick layer of waterproofing and its rapid hardening are required

Important:

When working with coating waterproofing, you should not dilute a large amount of the mixture, as they quickly set and quickly lose their suitability for use.

Important:

Coating waterproofing is also used as additional protection for the foundation of a building and as a sublayer under adhesive waterproofing. In this case, the foundation surface is prepared in a similar way: an acute corner is rounded and chamfered, fillets are installed, and the surface is primed and coated with the first layer of mastic or varnish. Then we carry out adhesive waterproofing

Important:

When backfilling soil, you need to be careful not to damage the waterproofing coating

Safety precautions

Waterproofing work is always carried out taking into account safety standards. External work is carried out mainly in dry weather . If the material can be applied at sub-zero temperatures, there should be no ice or snow on the base.

According to GOST 12.3.040-86, SNiP 111-4-800, compliance with fire safety standards, industrial sanitation, and rules for working with electrical equipment is required.

Workers working on mechanisms, mechanical devices, and equipment must follow the instructions for use and safe operation. If work is carried out at a height of more than 1.3 meters, install reliable scaffolding with fencing.

Persons over 18 years of age who have undergone instruction and medical examination are allowed to carry out waterproofing work. The work site must be equipped with water, fire extinguishers, sand boxes and shovels.

Cost of coating waterproofing for concrete

The actual cost of waterproofing works depends on the characteristics of a particular object.

However, the average prices are:

- waterproofing of the roof, foundation, basements – 520-580 r/sq.m.;

- waterproofing of internal premises - from 200-350 r/sq.m.

Minimum materials costs:

- cement - from 924 RUR/10 kg;

- polymer – from 2.8 tr/10 kg;

- cement-polymer – from 7 tr/25 kg.

conclusions

Coating waterproofing really wins over rolled analogues. These are universal materials that are convenient to apply to concrete of any configuration. Plus, the base gets cracks sealed, and preliminary priming is not always required.

Polymer coating waterproofing is used both outside and indoors. This type has frost resistance, high adhesion, waterproof and elasticity

When choosing a mastic, you should pay attention to its base - cement, bitumen, polymer. Bituminous varieties are often used for interior work, as they are weak in terms of frost resistance and exposure to extremely high temperatures (or appropriate additional protection is required). But at the same time they demonstrate high adhesion and excellent water resistance. It is this material that successfully resists mechanical and chemical loads.

Cement mastics are sold in dry form . The solution is prepared immediately before spreading over the concrete. The solvent is water or a special emulsion, which is supplied in the kit. The material has high adhesion, is resistant to mechanical stress and is durable.

The principles of working with coating waterproofing and its advantages are covered in the video:

Application of cement waterproofing

The predominant area of use of cement-based waterproofing is to protect foundations, basement walls, basements, swimming pools and other structures located underground or in water from moisture.

Its main advantages are low cost and technological ease of use. Cement-polymer materials have high adhesive properties to almost any mineral building base, as well as to steel surfaces. For this reason, cement-based water barriers are widely used to protect many steel structures, including water tanks.

The properties of cement compositions make it possible to apply them to moistened surfaces of damp basements. They are able to withstand significant fluid pressures acting on the protective layer in both the forward and reverse directions, which makes it possible to process concrete tanks from their inside and outside.

There are also repair mixtures with a narrow specialization (quick hardening) that can eliminate a small leak from a prefabricated seam or a crack in monolithic reinforced concrete within a few minutes.

The disadvantage of most types of cement insulation is their tendency to crack along with the treated material. However, for deformable bases this problem is easily solved by using elastic two-component polymer-cement compositions.