The floor is a part of the interior for which characteristics such as practicality and durability are especially important.

If you want to install not just a stylish, beautiful, but reliable and high-quality floor, then vinyl laminate is ideal for you. It appeared on the market not so long ago, but has managed to become the most popular among other floor coverings.

Composition and structure

The main criterion for the strength of this material is vinyl, which is used to treat the base in order to increase wear resistance.

The laminate plank consists of two layers : protective and bottom.

The top protective layer is usually made of polyurethane or aluminum oxide. This layer gives the surface an aesthetic appearance like stone, wood or parquet; it can also imitate the appearance of leather, sand in three-dimensional quality.

The bottom layer, also known as the base , is made of vinyl, which is the key to the strength of this type of floor. The thickness of the vinyl layer is about 0.5 mm.

Between these layers there is a middle in the form of stone chips , and vinyl backing

Which underlay is best to use when laying

Studying the markings on the packaging of the material will help you determine the answer to the question - do you need a quartz vinyl laminate underlay or not? Most manufacturers include this information directly on the packaging film or include paper instructions inside the bag with the slats.

In the case where the manufacturer insists on the use of a lining layer, it is recommended to choose a substrate from the following materials:

- Cork. The use of a cork backing allows for good leveling of small base errors. This natural material perfectly absorbs sound, which means that the interior will be protected from outside noise, and the neighbors will not hear the clicking of heels on the floor of your apartment. When installing a cork backing under vinyl slats, use 2 mm material. A thicker backing will be pressed under the weight of the furniture.

- Foamed polyethylene. The most inexpensive material. For laying under quartz-vinyl lamellas, a 3 mm thick substrate is used. Under load, the substrate will sag by 1 mm, but at the same time it will effectively eliminate unevenness of the base.

- Composite substrates. Consist of two layers of polyethylene. The bottom layer is perforated, allowing air circulation and vapor removal, and the top layer provides waterproofing protection. For vinyl slats, a thickness of 2 mm is recommended.

- Coniferous substrates. Like cork products, coniferous substrates are considered environmentally friendly materials. These substrates do an excellent job of absorbing noise and ensuring uniform distribution of thermal waves within the flooring.

Which substrate option to choose depends on the capabilities of the customer and the requirements of the instructions from the laminate manufacturer.

Advantages and disadvantages

Due to its multi-layer nature, vinyl laminate is in many ways superior to other types of coatings, and this is what makes it different. Not only this “sandwich” structure, but also the materials from which the floor is made help it withstand heavy loads , including heavy sports equipment and furniture.

It is also important that the coating resists moisture , detergents and does not slip. Resistant to possible damage. It is important to note that such a floor initially has sound and heat insulating qualities due to its composition.

Plus, when heated, vinyl will not emit harmful substances .

Laying will also greatly benefit from other coverings - vinyl tiles are easily separated, which allows you to lay them evenly next to each other.

Let's summarize by collecting all the advantages of vinyl laminate:

- strength;

- durability;

- sound insulation;

- thermal insulation;

- wear resistance;

- ease of care;

- original design, large selection of coatings;

- ease of installation;

The strength of quartz vinyl tiles is due to the inclusion of up to 80% quartz sand in its composition and reinforcement with fiberglass.

The tile is poorly abraded and scratched, so it is considered durable.

Possessing good thermal insulation properties, this material is widely used for the manufacture of heated floors.

Vinyl laminate contains mineral chips or quartz sand, which ensures high wear resistance of the material. Usually correspond to class 34-43.

The tile is characterized by antibacterial and antiseptic properties; it is easy to clean, which makes it easy to care for.

The original design of the outer surface of the material makes it possible to create an imitation of ceramics, parquet, and granite.

This floor will look great in any room and is easy to maintain. Vinyl laminate, unlike the usual type, is safe for health , so it is recommended and widely used in schools, hospitals, kindergartens and other preschool institutions.

In addition, due to its moisture resistance, vinyl laminate, like no other, is suitable for use in rooms with high humidity. This could be a swimming pool, a gym, some kind of basement, and even a bathroom or bathhouse. Vinyl laminate has disadvantages , but are there any? It is difficult to identify problems with such a floor covering, so we will only note its cost. It is several times higher than the price of both conventional laminate and coatings made of other materials.

In addition, there is one trick that not all users know. Despite the resistance to stains, upon contact with rubber , the floor begins to lose its color . A chemical reaction occurs that can permanently change the color of the floor.

Any rubber mat is contraindicated for this floor. The heel of a rubber shoe can cause similar damage to the surface.

As already mentioned, the service life of vinyl coating is much higher than any other and is more than 25 years. But, despite such a long period, any thing is prone to wear and tear. Direct sunlight can lead to fading and significant lightening of the floor, therefore, if the vinyl laminate has served you for a long time, yellowing will inevitably appear on it.

And yet, despite the vinyl, it is still laminate. And like any other, it is not a fireproof material .

If vinyl laminate does not emit harmful substances when heated slightly, it becomes toxic when it catches fire. Therefore, it is not recommended to place it in the kitchen and other areas with an increased risk of fire.

Cons of vinyl flooring

Vinyl laminate flooring also has its disadvantages:

- it contains chemical components, and sometimes some coatings, during the first time after installation, can release toxic substances that cause irritation to the mucous membranes of the eyes and respiratory tract. The safety level of a particular floor is determined by its chemical composition and service life;

- unstable to solvents;

- reacts with rubber products, causing noticeable marks to remain - do not allow the coating to come into contact with rubberized rugs, rubber soles of shoes and pads on furniture legs;

- A hot object or an unextinguished cigarette butt will leave a mark on the vinyl;

- a product of low quality and a low price category is less resistant to ultraviolet radiation (may turn yellow) and mechanical damage (at the same time, the floor is not very repairable - with a locking connection, you can still change the damaged lamella, but with adhesive installation there will be difficulties);

- it is fireproof and does not support combustion, but if the temperature rises to extreme values (a fire occurs), the coating will begin to release toxic compounds into the air - it is not recommended to lay it in rooms with sources of open fire (stoves, fireplaces, gas stoves).

Flooring options

If a “warm floor” system is connected, it should be turned off 2 days before installing the vinyl laminate. But the room temperature should not be lower than +18°C. If adhesive installation is carried out in an unheated room, it is recommended to heat the adhesive tape using a hair dryer.

The top layer on vinyl floors protects the surface from stains and other contaminants.

Kinds

Vinyl laminate is easiest to immediately divide into two types: by installation method and by composition .

The installation method can be of two types: using glue or a locking system.

Adhesive

Not the most popular type of laminate. It is rarely found in stores, installation is extremely difficult, there are no special devices, and the glue itself is also a rare find for such purposes. But if you still find and use good glue, it will adhere so tightly that such a coating is no longer afraid of moisture and damage.

The coating becomes perfectly smooth and durable.

But there is a catch here too. If one laminate panel is damaged, it cannot be replaced . Replacing the panel will cause damage to other areas of the floor, the edges will be damaged and all this will ultimately lead to the need to replace the entire floor.

The demand for the self-adhesive type is small, so it is more profitable for manufacturers to completely abandon supplies with adhesive joints.

Castle

Much more popular than adhesive and is the most common. First of all, because such a floor can be disassembled or restored many times if one tile is damaged.

Installation does not require a large number of tools, usually these are:

- roulette;

- square;

- pencil;

- hacksaw;

- circular or carpenter saw;

- hammer and electric drill.

Everything is the same as when laying the adhesive coating.

Material with a locking system can have click and lock connections .

The first is a collapsible lock, and the second consists of latch locks. Compared to adhesive, locking is susceptible to moisture .

A laminate with an increased level of strength is quartz-vinyl laminate . Quartz gives this coating a special hardness.

Its production occurs through hot pressing, which contributes to a more dense laying of all layers, the top of which is an aesthetically pleasing polyurethane .

Based on the manufacturing method and composition, vinyl laminate is also divided into vinyl-PVC . In addition to layers of vinyl, resin, stabilizers and plastic, such tiles contain an additional layer of PVC that protects the floor from a variety of damage and environmental influences.

Laying

Installing vinyl laminate flooring is essentially no different from installing regular laminate flooring. The main feature is lightness and simplicity.

Vinyl flooring can be installed on any old ceramic, concrete or linoleum surface. The process is divided into stages

- The base for installation is carefully leveled and putty is applied.

- The surface is cleaned of moisture, dust and dirt. The material itself is cleaned using the same system and kept indoors for about two days.

- Before installation begins, the room temperature is checked. It should be no lower than +18 degrees.

- Section of the planks. The laminate planks are separated using a hacksaw or scissors. After separating the boards, special glue is applied to them.

- Laying begins from the corner of the room; the planks should be connected at an angle of 45 degrees.

Very fast installation. Just a few hours.

It is also important not to forget about the deviation of the planks from the wall by 4-5 mm. Everything is carefully checked for possible cracks and uneven joints.

The same applies to laying interlocking laminate. First, the panels are joined at the specified angle, then lightly pressing downwards are snapped into place.

At the end of the work, the floor is once again checked for unevenness and the strength of the connection of the planks. To do this, it is best to use a special rolling roller.

Vinyl laminate installation

Installing vinyl laminate flooring is not a hassle. Before you begin, you need to measure the room, taking into account the direction in which the flooring will be laid.

Vinyl floors can be installed in a so-called floating floor system or in a click system. Floating vinyl floors can be installed on hard surfaces such as cement screed, ceramic or wood.

The floor covering must be smooth, stable, flat and dry. The maximum deviation from the plane should not exceed 3 mm per 2 meters in length. Any unevenness should be removed using self-leveling cement floors.

You should also check the moisture content of the base. In the case of a cement floor, this value should be less than or equal to 2%, and for an anhydrite floor (screeds made from a special type of gypsum called anhydrite) no more than 0.5%. Before installation, ensure that the subfloor has been insulated. It is necessary to make an additional layer of insulation from moisture using polyethylene film with a thickness of at least 0.2 mm.

These tools will come in handy:

- electric saw or sharp knife,

- spacers-limiters,

- pencil,

- ruler or tape measure,

- polyethylene film,

- light hammer,

- scotch.

Rules for assembling vinyl laminate flooring

- It is necessary to leave 10 mm clearances from walls and columns.

- Before installation, you should carefully measure the length and width of the room, and plan the exact location of the panels. This is especially important when installing plates with decor. The preferred installation is parallel to the direction of light.

- The panels in the last row should not be narrower by more than 5 cm. If necessary, the panels in the first row must be shortened.

- We must also remember that it is better not to install vinyl laminate flooring on a stationary basis using nails or glue, it is better to have it floating. The panels must be installed in such a way as to ensure the free functioning of the floor.

- Make sure you have a complete set of panels and tools before assembly. You should save receipts and instructions so that you can later purchase the same type of panels if necessary.

- Vinyl laminate flooring should be stabilized to room temperature in sealed containers placed in a horizontal position. They should be stored in closed containers placed next to each other at normal room temperature (18-25°C) for at least 48 hours before installation. They should not be stored in an upright position, in dusty areas or at extremely high/low temperatures.

Installation procedure for vinyl floor panels

- Clean the floor from dust, spread the film. Make sure all panels are undamaged. Do not install panels with damaged surfaces or edges. Inspect each panel thoroughly before and during installation, ensuring good lighting.

- The installation of the first three rows is the base. Floor installation starts from the corner of the room. We install the first board so that the tenon is facing the wall and the groove is facing the room.

- Using a limiter in the space between the front board and the wall, it is necessary to create an expansion gap of 10 millimeters wide.

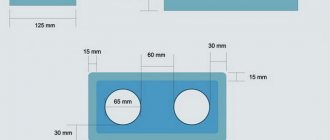

- Then, taking the next panel in your hands, bring it at the correct angle to the already installed board (the angle is indicated in the product instructions). Now simply insert the tenon into the groove and place the panel on the floor. Thus we finish laying the first row. The panels can be easily cut with a utility knife. At the same time, by cutting it, you can break off the desired piece, as shown in the figure.

- We start the next row from the panel that remains from the first row. However, make sure that there is at least a 300mm offset between the leading edges of adjacent rows of boards. This way we lay the entire floor.

Laying such a floor is not a dusty and labor-intensive task that you can do yourself, and it will not take you much time. Where a durable floor with a low height is required, vinyl flooring is a good choice. It comes in a variety of design options with attractive decors imitating wood or stone. Vinyl flooring can be used wherever there is a need for beautiful design, high functionality, as well as high durability. This coating features a clean and quick installation.

Reviews

“We recently installed regular laminate flooring in our home. I really regret that I didn’t find out about vinyl laminate earlier, as I definitely would have preferred it. All the benefits of vinyl make it so different from ordinary vinyl. Moreover, I have now set a goal to replace the floors in a couple of years and install vinyl laminate.” Olga, Krasnodar.

“On the advice of a friend, I installed vinyl laminate. I was surprised that it is absolutely no different from parquet. The top covering is designed to look like parquet, and at a much lower price than the real thing. Nowadays, you can believe the advertising: why pay more for parquet if you have vinyl laminate?” Vladimir, Saransk.

“I laid the floor myself. At first, I chose any laminate in the store, but settled on vinyl. I didn’t know about its advantages, I relied on the ease of installation, consulted with the sellers and they suggested vinyl laminate as the easiest for these purposes. The boards are light, it’s clear how and where they are attached, for each square meter I spent only 500 rubles. This is the best choice for the price." Vitaly, Voronezh.

“We chose the gender as a family. The renovation budget was minimal. The qualities of vinyl flooring are ideal: environmentally friendly, durable and, according to specialists, should last a very long time. But still, the choice of vinyl laminate hit our wallet. We paid 1,800 rubles per square meter. We hope it pays off." Julia, St. Petersburg.

We have a child at home, he is still six months old. That's why I took a long time to choose the floor. Based on reviews and characteristics, vinyl laminate flooring was suitable. I decided what would be the safest for the child, and I was not mistaken in my choice. Plus the floor is very practical. All the time some kind of moisture gets on the surface, which is a common occurrence with a child, I have never noticed any damage.” Lana, Moscow.

What is the maintenance of vinyl trim?

For those housewives who consider cleaning one of their least favorite activities, vinyl floors are an excellent option. Caring for such a coating is reduced to periodic wiping with a damp cloth. In this case, you can use any household chemicals intended for cleaning floor coverings. Most often there is no need for this.

Most types of vinyl products are coated with an antistatic layer, which prevents the rapid accumulation of dust on the floor surface. Complex stains can be removed with a regular soap solution, which guarantees the absence of unpleasant stains throughout the entire period of operation of the flooring.