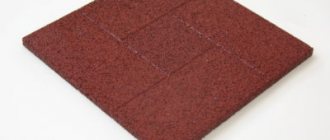

Rubber tiles for laying sidewalk paths appeared relatively recently, but have already gained popularity among both builders and consumers. Rubber paving slabs have a large number of advantages that distinguish them from other types of coatings for garden paths, recreation areas, etc. The simplicity of the installation process allows you to do this work yourself without hiring hired workers, which significantly reduces the costs of installing a hard surface. During operation, rubber paving slabs do not require special care, and their service life is quite long.

Advertisement

Another excellent quality of this material that is worth noting is that in the production of rubber tiles, recycled materials are used, namely, worn-out car tires, which has a beneficial effect on the environment. Also, due to the use of recycled materials, the price of rubber paving slabs compares favorably with other types of coating. We will tell you further how to properly lay this material with your own hands.

Scope of application of rubber paving slabs

Due to its unique qualities, the scope of application of rubber paving slabs is quite wide:

- Construction of sports grounds. Rubber coating, unlike concrete or asphalt, has better traction with sports shoes, which makes it the most optimal for constructing sports facilities. Treadmills in stadiums are also produced using this technology. Unlike a lawn, which requires constant maintenance, or parquet, which is not intended for outdoor installation, rubber tiles can be installed anywhere and do not require additional attention and maintenance.

Construction of children's playgrounds. If a hard surface is required on a playground, it is difficult to find a better material than rubber tiles. It is not as traumatic as concrete material or asphalt pavement. In addition, a large number of colors makes it possible to make the coating bright and interesting for kids.

-Paths by the pool. Even when too wet, rubber tiles have sufficient traction and non-slip properties, so they can prevent a person from falling into the pool, which often happens on slippery ceramic surfaces.

-The floor in the garage. Rubber tiles are not afraid of moisture, frost, falling heavy objects, and retain their properties for a long time. That is why it is often used as garage flooring.

The dimensions of the tiles and their scope of application can be found in the table:

Types of garden paths

Depending on what kind of coating is used, there are types of garden paths:

Stone

Natural stone, due to its naturalness and naturalness, will fit into any design of a country landscape. Garden paths made of stone are particularly durable and strong. They do not collapse, are resistant to climatic influences, do not slip, and puddles do not form on them. The surface of the stone does not fade in the sun. To create a stone covering, flagstone is used - different rocks (limestone, slate, sandstone), divided into slabs up to 3 cm thick. Manufacturers offer flagstone with raw edges, with smoothed edges and ready-made paving slabs for the design of garden plots. The only disadvantage of a stone garden path is the high price of the raw material and its delivery.

Wooden

Wooden garden paths are affordable, provided there are forests in your region. Wood is a natural and environmentally friendly material. Not as durable as stone. If you properly treat and protect the surface of the wood from moisture, it will last for many years. There are tree species - larch and oak - that are resistant to rotting without additional treatment. Since ancient times, wood has been used to build pavements. Nowadays, in remote cities you can find sidewalks made of wood.

Rubber

Rubber tracks for dachas are made from modern materials and meet all operational requirements. They have a rough surface, do not slip, and water does not accumulate on the surface, since the coating has a porous structure. The rubber sheet is not interesting to rodents; weeds and plants do not grow through the coating. Climatic conditions are tolerated without negative effects. It is made from crumb rubber, which is combined with a polymer composition that is harmless to humans and the environment. The form of coating can be very diverse:

- Rubber tracks in rolls have different widths and lengths. You can, for example, place a narrow roll of cloth between the beds. Using a sharp knife, cut off the excess. And then the coating will smoothly go around the garden flower bed or other elements of landscape decor. To lay the rolled fabric, no special effort is required. It can be placed both on the ground and on the lawn. It is desirable that the surface be smooth, without holes or bumps. Can be easily rolled up and stored in winter. Although there is no need for this.

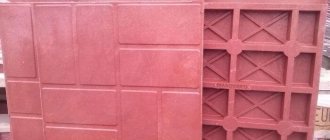

- Rubber tiles and rubber paving stones are varied in color, shape, size and color scheme. They are resistant to moisture and do not fade when exposed to sunlight. It is absolutely injury-proof, which is why such tiles are used for children's playgrounds. High shock-absorbing properties will protect against abrasions when falling. Types of rubber tiles are shown in the photo.

- Summer residents are especially willing to build garden paths from tires, since they do not require large financial investments. Garden paths made from tires do not look as impressive as finished rubber mats. Although at the same time they are in no way inferior to it in properties. Resistant to temperature changes and precipitation of any kind. The surface does not deform from heat or frost and does not slip. The rubber sheet is easy to care for.

Concrete

Concrete is a cheap material, durable and resistant to mechanical stress and adverse weather conditions. The service life is long if you follow the base preparation technology. Concrete gives room for creativity. You can get different colors by adding a coloring pigment to the solution, or make paving stones from a concrete-sand mixture at your dacha with your own hands. Installation of the concrete sheet will require some time and adherence to technology to avoid cracking in the future.

What are rubber paving slabs for a summer residence made of and how are they produced?

The production of paving slabs is not a very complicated technological process, which is somewhat reminiscent of the production of similar concrete products, namely, by pressing the finished mixture. As mentioned above, the main raw material for its production is rubber from worn-out car tires.

The order of production work:

1.The first step is to remove the metal cord from the tires. In the future, it will also be recycled. This is done using a special device.

2.Then the remaining part of the tire, which is pure rubber, is crushed to a fine fraction to produce crumb rubber.

3.After this, polyurethane binder and dyes are added to the crumbs and mixed until a homogeneous mixture is obtained. For this, special mixers are used.

4.The last step is to produce tiles of the required size and density using the cold or hot pressing method. The difference between the two methods lies in the temperature and time of exposure to the raw materials. So, with cold pressing, a temperature of +80°C is used and the mixture is “cooked” for 4 or more hours, and with hot pressing, the temperature is over +140°C, but the time for producing the material is about 15 minutes. Contrary to the disputes of many experts, in both cases the quality and performance characteristics of the materials are the same.

Stages of laying rubber tiles on a concrete base

1. The surface is thoroughly cleaned of dust and debris. It is recommended to use a vacuum cleaner in addition to a broom.

2. Using a notched trowel, the glue is evenly distributed over the surface (alternately by zone).

3. Layout should begin from the middle of the working surface. To do this, 20 mm thick tiles are laid and pressed to the base.

4. The following fragments are laid with a minimum gap. Any glue that gets on the front side must be removed immediately.

5. Leave the surface to dry for 2 days. The site cannot be used during this period.

When laying, you need to make sure that no air remains under the tiles. You can drive it out by pressing firmly on the surface of the rubber product.

Designing pedestrian paths in the garden

- width;

- length;

- form;

- route, etc.

- border;

— water drains;

We invite you to familiarize yourself with DIY garden decorations made of wood

- garden lanterns;

— drainage gutters and other structural items that make the path more practical, functional and safe.

Tire border

Composition and characteristics of safety rubber coatings

Rubber tiles are produced in factory conditions with strict adherence to technology and composition formulations.

It contains crumb rubber obtained by crushing various brands of rubber and synthetic rubbers. The binding composition is polyurethane glue. The tiles are produced in the form of squares with a side of 300 mm and a thickness of 6 to 50 mm. The greater thickness of the tiles provides more reliable protection against injury. Some models of rubber floor tiles have a ready-made dovetail grip. A wide variety of colors is achieved by using various coloring pigments. In addition to tiles for finishing floor coverings, we produce shock-absorbing noise/vibration-absorbing underlays for floor coverings, curbs and coverings for stair steps. The tiles have been certified and approved for indoor use.

Laying technology on sand or soil

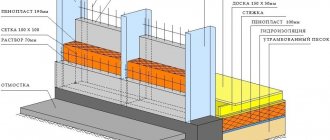

It is allowed to lay material with a thickness of more than 40 mm on a sandy or soil base, as well as the surface of their screenings or sand-cement mixture. The technology for laying on a loose base is as follows:

- digging a hole in the soil surface;

- backfilling a crushed stone layer 60-70mm thick into the excavated recess and subsequent compaction;

- backfilling a sand layer 60-70mm thick on top of the crushed stone, then pouring it with water and compacting it;

- laying the coating directly on the surface of compacted sand.

As practice shows, for this method of laying it is best to use material with a thickness of more than 40 mm with a special embossed base that can significantly increase adhesion to the sand cushion.

A high-quality product must be equipped with special plastic bushings that prevent the displacement of all elements relative to each other during operation. To increase the reliability of the connection, it is recommended to glue the end part with polyurethane glue. Cutting of elements, if necessary, is done with an electric jigsaw or a fine-toothed hacksaw.

Production in our own garage

Find out how to make rubber tiles, plastic windows, dishes, toys and much, much more at home...

Article navigation

- Best Garage Business Ideas

- Preparatory activities

- Ideas from China

- Making wooden souvenirs

- Manufacturing of ceramic products

- Packaging of goods

- Printing documents at home

- Design production

- Decoupage furniture

- Ideas from Europe

- Restoration of vintage cars

- Forge at home

- Foundry in garage

- DIY wooden toys

- Printing on tiles

- Designer cards

- Making badges

- Garage production ideas

- Antifreeze production in the garage

- Making rubber tiles in the garage with your own hands

- Production of nails and screws

- Furniture manufacture

- Welding business in a garage

- Growing mushrooms in the garage

- Greenhouse production

- Smokehouse in the garage as a business

- Production of plastic windows

- Mini production ideas

- Is it possible to open a store in a garage?

When a person has an irresistible desire to become independent, his imagination begins to actively work. What could be better than working for yourself, because at home you can set your own daily routine, make management decisions and generally be the boss. The question immediately arises of where exactly to conduct business. It happens that there is simply no money to rent a room, especially at first. But the solution often suggests itself: do a business with your own hands in your garage.

Everyone decides for themselves what exactly to do, based on their inclinations, previously acquired skills, available equipment or other factors that determine the profile of the future enterprise. Perhaps someone is at a crossroads, and does not yet know what goods or services are in demand, and what to specialize in, but you can achieve a lot in your garage.

Suffice it to remember that it was in this magical place that the first personal computers were assembled, and Walt Disney filmed his cartoons.

However, there are many other ideas. You just need to choose the one that you like the most.

Advantages and disadvantages of tire tracks

Many owners of country houses prefer to improve the territory themselves. In particular, this applies to travel routes and parking lots. The ideal material for their creation would be tires that are subject to recycling.

Waste tires become acceptable material for garden paths

This option does not require any special financial costs. But there are other positive aspects of using tires:

Rubber does not absorb moisture (even after heavy rain it dries instantly) and it is impossible to slip on it. Caring for rubber tracks is easy - just walk over them with a broom or spray them with water from a hose. Well, the most significant plus is the ease of installation.

Along with this, there are also disadvantages:

If you don’t have unnecessary tires in your garage, you can go to the nearest tire shop or ask your car enthusiast friends.