Brick houses have been built for several hundred years, and many do it with their own hands. Brick is the most common building material today. Both solid and hollow types of bricks are available.

Photo – brickwork

Previously, almost all houses had walls about 1 m thick, which was due to the lack of insulation in those days. It was with brickwork and insulation that the mass construction of warm buildings and structures began.

Brick currently serves only to provide the necessary strength to the building. Insulation is now responsible for maintaining heat in rooms. How to choose the right insulation for brickwork will be discussed below (read also about the advantages of Rockwool Light Butts Scandic insulation).

Insulation between walls

The difficulty of thermal insulation both from the inside and outside is the appearance of condensation. Water negatively affects not only thermal protection, but also the entire structure of the building.

The thickness of the insulation layer used depends on a number of factors, such as:

- location of the building;

- wall material;

- wall thickness;

- type of insulation used.

Modern construction is regulated by the provisions of SNiP 02/23/2003, which precisely indicate the required amount of insulation.

Three-layer wall structure says yes

What's special about this wall? One side of the load-bearing structure is the internal wall of the dwelling. On the other hand, cotton wool is attached to it. During the active heating season, the load-bearing wall is heated by warm air inside the room. From the outside, this structure comes into contact with the cold air of the street. Where these air masses collide, condensation occurs. These are drops of water on the outside of the wall. These drops are absorbed by the insulation and flow down the wall itself.

Stage 5. Insulating the brick walls of the house with polystyrene foam from the outside

We will still fill the air gap that we left between the main wall and the ceramic brick. This is an integral part of lining a house with facing bricks and insulation. The next question is: what kind of insulation should be between the brick wall and the facing brick? To do this, we decided to use loose foam, which is sold in bags. Why this and not sheet foam?

Here's why. The first advantage: if for some reason the walls of the building were not level, then the loose foam plastic will not react in any way when backfilled. But with leafy ones you will have to suffer. The second advantage: mice can get into sheet foam and create a lot of passages and holes for themselves. It is impossible to make a move in loose foam because mice cannot climb on it. As they rake with their paws, they sharpen like a truck in the mud, remaining in place.

Before pouring foam into the wall, you need to close the cracks around the perimeter of windows and doors using mineral wool or sheet foam. Moreover, the latter is better, since when filling slopes it will be easier to apply putty on the foam.

Note: in order to safely insulate the walls of a brick house from the outside in windy weather, I do not recommend pouring polystyrene foam. All the foam will scatter all over your yard in the best case, and in the worst case it will even sweep away your neighbors.

What does the gap do?

An air gap is a small space left between the wool and the brick. It is designed to ventilate the wool and the main wall. Vertical seams in the facing wall are not sealed with mortar. Below and above. The air flow, moving, blows and dries the insulation.

Stage 4. Making an arch

Having installed the frame in the place where the arched window will be, we begin to cover the frame with brick on top.

Only now we will lay the brick not horizontally, but vertically with the butt side on the face of the masonry. But since the length of the brick is 25 cm, and the width of our masonry is 17 cm (brick width 12.5 cm + air gap 4-5 cm), the brick will have to be cut to length. To cut bricks we will use a grinder with a diamond wheel for concrete.

The adjacent bricks of the main wall will also need to be cut at an angle. The arch should be flat in relation to the main wall at the same level or protrude outward by 2-4 cm, this is a matter of client taste. After a day, three arch frames can be safely disassembled. The arch is ready.

Types of thermal insulation materials

If you decide to build brick walls with insulation, then this section will help you decide which one to use.

The price in this case is not taken into account; the comparison is made only by technical characteristics:

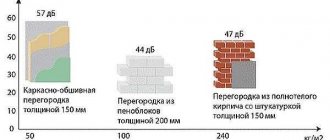

- Mineral wool is one of the most popular materials that has been used for many decades. It has a fairly low thermal conductivity coefficient (within 0.041 - 0.044 W/(m*K)), while having a good compression density (from 20 kg/m3 to 200 kg/m3). Among the disadvantages is high moisture absorption, not like a sponge, but inferior to other materials.

- Polystyrene foam (expanded polystyrene) is also in high demand due to its resistance to high humidity. When insulating a brick house with polystyrene foam, the thermal conductivity coefficient is slightly lower than that of mineral wool, but the strength (density during compression) suffers, and the material is easily damaged. Plus, if it is exposed to fire, it will emit acrid smoke.

- Extruded polystyrene foam is considered an ideal option for both internal and external work. It does not emit toxic fumes, has the lowest thermal conductivity threshold of solid thermal insulation materials, but also suffers from “fragility”.

Note! It, like polystyrene foam, is easy to attach with your own hands; this does not require special equipment or any special knowledge. We will tell you in more detail about the process of insulating brick walls a little later.

- Expanded clay is a bulk material that has excellent thermal conductivity and vapor barrier properties, but is more often used for insulating floors or ceilings. Although, it is ideal for well masonry.

Expanded clay can be poured at any stage of construction

- Warm plaster is another material, only this time liquid. As for any technical characteristics, plaster is slightly inferior to other thermal insulation options. However, there is one advantage - saving useful space; it can be applied directly to a brick wall (on a reinforcing mesh).

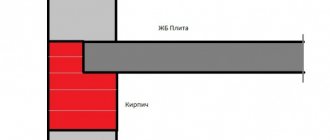

Three-layer masonry

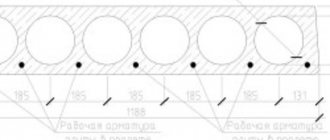

One of the types of insulated walls is three-layer brickwork. Its design looks like this:

- Internal wall made of brick, cinder blocks, aerated concrete, etc. Performs a load-bearing function for interfloor ceilings and the roof of a building.

- Insulation of brickwork. The insulation is placed in internal cavities-wells between the outer and inner walls. Protects the inner wall from freezing during the cold season.

- External wall with brick cladding. Performs decorative functions, giving the facade additional aesthetics.

Subtleties of laying foam concrete walls and brick cladding

We will not consider the process of constructing the walls of a house from foam blocks - in essence it is no different from brickwork. This kind of masonry is even much simpler, i.e.

Because foam blocks are lighter, therefore they have larger dimensions. They are easy to saw and shape.

The only features that should not be forgotten are the mandatory waterproofing of the base under the walls. Both waterproofing and ordinary roofing material can be used for it. It is also recommended to connect foam blocks not with a solution, but with a special glue; it allows you to make very thin seams (up to 3 mm), securely fixes the foam blocks and additionally protects them from being soaked with water.

In the photo: The process of cladding a house made of foam blocks with bricks

In general, laying walls is not the most difficult task; cladding the walls of a house made of foam blocks with bricks is much more difficult and responsible. Here it is necessary to create a kind of layer cake that will protect the walls from heat loss, humidity, mechanical damage and other negative factors.

What are the methods for facing aerated concrete blocks with bricks?

A gas block wall can be covered in several ways. This refers to the distance between the brick and the aerated concrete block, as well as the presence of insulation, if there is a gap between the wall and the cladding. Let's look at each of them in detail.

Dense masonry without gaps and ventilation

The danger of rapid destruction appears when it is planned to use a heated room. That is, the difference in temperatures inside and outside the house will significantly reduce the service life of such a building. When the room is heated from the inside, water vapor will begin to move out through the porous aerated concrete. If there is no gap or insulation, they will accumulate between the gas block and the brick, destroying both materials. In this case, condensate accumulates unevenly, which accelerates the process of decay and deformation of the structure of the gas block. The most cost-effective option would be to use external insulation in the form of mineral wool or wet plaster finishing. A similar finishing of aerated concrete with bricks (without a gap) is applied only to unheated buildings.

Bricklaying at a distance from aerated blocks without ventilation

The rules SP 23-101-2004 (Design of thermal protection of buildings) contain a regulation on the principle of the arrangement of layers between the wall and the cladding surface, which states that the closer to the outer layer of the wall, the lower the vapor permeability of the material should be. In accordance with paragraph 8.8, layers with greater thermal conductivity and vapor permeability should be located closer to the outer surface of the wall. British experts, after conducting a series of studies, explained that it is necessary to arrange the layers so that the vapor conductivity to the outer layer increases with a difference of at least 5 times from the inner wall. If this cladding method is chosen, then according to the rules of paragraph 8.13, the thickness of the non-ventilated gap must be at least 4 cm, while the layers are recommended to be separated by blind diaphragms made of non-combustible material into zones of 3 m.

Thermal insulation of the house outside

Let's consider the insulation process using the example of polystyrene foam, which can be used in any conditions, when mineral wool is effective only when insulated from the inside:

- The first thing you need to do is prepare the wall: seal all the cracks, cover up the crumbled seams of the brickwork.

- Install the sheathing using wooden blocks. The peculiarity of this process is that it is better to maintain a distance between the vertical posts equal to the width of the foam, so there will be fewer joints.

- Cut the material to size according to length.

- Prepare an adhesive base or disc-shaped nails for attaching the insulation.

For your information! There is not much difference, each fastening option is good in its own way, only one is considered dirty (you need to drill for nails), and the second is clean. You just need to apply thick glue and that's it.

- Secure the thermal insulation layer by sealing all joints and cracks with foam.

You can use a ventilated facade system when there is a “emptiness” between the insulation and finishing material

- Cover the top with a windproof membrane, using a furniture stapler as fastening elements.

- Now all that remains is to choose the finishing material and clad the house.

As you can see, the instructions for installing insulation on the street side do not require any special skill. That is why you can easily save on a construction crew by doing all the work yourself.

Conclusion

The use of thermal insulation materials should be accompanied not by simple “I want” and “I can”, but by clear information about whether it will be effective and useful. In any case, even if insulation is installed between the block and the brick, you need to understand how much it saves on heating costs and how long it will take for the work to pay off.

In the video presented in this article you will find additional information on this topic (read other articles on the topic How to insulate the walls of a brick house from the inside).