The production of gas silicate blocks is based on specialized silicate mixtures with aluminum powder as one of the components used. The silicate foaming process is the result of a chemical reaction that occurs in a water mixture. The silicate foam obtained in this way is cut with special metal strings, forming blocks of different sizes from it. The next step is baking them in autoclaves, exposing the workpieces to high temperatures.

Applying blocks

Considering the great demand for this type of materials from construction organizations and their wide range of applications, different manufacturers are taking on the production of not only wall blocks, but also slabs for organizing partitions. Among the gas silicate blocks supplied for sale on the market, the widest range of geometric sizes is presented. This is a good opportunity for their more flexible use in construction and the construction of rather complex and extraordinary structures. The simple machining process and easy installation provide the widest range of application possibilities for builders.

Product sizes

Thanks to the large number of manufacturers of gas silicate blocks and the healthy competition that exists among them, it has become possible to produce products of a wide variety of sizes. That is, today the dimensions of produced building materials completely depend on the manufacturer and brand of concrete used in production. The market is overflowing with products from a variety of companies offering consumers a wide range of varieties of aerated concrete elements. There is a fairly wide range of designs that differ in shape, including:

- classic rectangular shape;

- a form that has protrusions and risks to ensure the easiest possible assembly;

- blocks with a “U” shape, creating a stiffening belt that serves as supports for wooden floor beams.

There are wall and tray gas silicate blocks. In this case, the first variety is divided into ordinary forms in the form of a parallelepiped and a groove-ridge. It should be taken into account that with the help of a tongue-and-groove structure, the masonry is provided with additional strength due to increased adhesion of the structural elements. In turn, this characteristic allows you to save the binder solution during laying.

Technical characteristics of gas blocks

The physical and technical properties of aerated concrete blocks are strikingly different from their analogues. The table below shows the main indicators in comparison with ceramic bricks and foam concrete.

Table 1. Technical characteristics of materials for private housing construction

| Name | Autoclaved gas silicate concrete | Solid brick | Foam concrete |

| Density, kg/cubic. m | 350-700 | 1550-1700 | 400-1200 |

| Weight 1 sq. m. walls, in kg | 300-700 | 1800 | 200-900 |

| Water absorption, % of the total mass | 20 | 12 | 12 |

| Frost resistance, cycles | 15-50 | 20-25 | 15-50 |

| Vapor permeability, mg/(sq. m*h*Pa) | 0,14 | 0,11 | 0,11 |

| Compressive strength, MPa | 1,5-10 | 2,5-25 | 1,5-17 |

| Thermal conductivity, W/sq. m. | 0,10-0,28 | 0,6-0,95 | 0,12-0,38 |

| Acoustic characteristics for a wall 30 cm thick, dB | 30-47 | 55-64 | 45-58 |

As you can see from the table, the thermal conductivity of gas silicate blocks is several times lower than that of brick; therefore, insulation for regions with a mild climate and average winter temperatures down to -7 ° C is not necessary.

Thus, the total price of the building is reduced by the cost of the heat insulator - a good way to save.

The density of gas silicate blocks plays an important role in their classification. Products are distinguished:

- Structural, compressive strength grade from D700 and higher. Load-bearing walls are built from them;

- Structural and thermal insulation – D500-D700. Used for interior partitions, walls up to two floors high;

- Thermal insulation – D400. They are used for the construction of mixed walls, improving their thermal characteristics.

Various types of gas silicate

Until recently, the frost resistance coefficient for gas blocks adopted in Russia corresponded to F35. However, many factories claim that thanks to the introduction of special surfactants and some additives, they managed to raise it to F100. Of course, there are no data from independent examinations yet, mandatory certification has been cancelled, so you should refrain from purchasing untested products.

How much does a gas silicate block weigh? This depends on its dimensions and density (Table 2).

Table 2. Dimensions and weight of the gas silicate block

| Block dimensions, cm | Volume of 1 block, cubic meters m | Weight, kg | |||

| Length | Thickness | Height | D500 | D600 | |

| 60 | 20 | 10 | 0,012 | 8,6 | 10,8 |

| 25 | 10 | 0,015 | 9 | 11,2 | |

| 20 | 15 | 0,018 | 11,7 | 14 | |

| 20 | 25 | 0,03 | 19,5 | 23,4 | |

| 20 | 30 | 0,036 | 23,4 | 28 | |

| 20 | 40 | 0,048 | 31,2 | 37,4 | |

| 25 | 10 | 0,015 | 9,8 | 11,7 | |

| 25 | 15 | 0,0225 | 14,5 | 17,6 | |

| 25 | 25 | 0,0375 | 24,4 | 29,3 | |

| 25 | 30 | 0,045 | 29,3 | 35,1 | |

| 25 | 37,5 | 0,056 | 36,5 | 43,9 | |

| 25 | 40 | 0,06 | 39 | 46,8 | |

| 25 | 50 | 0,075 | 48,7 | 58,5 | |

The most popular block sizes: 600x100x300 mm (half-block) and 600x300x200 mm. They are produced in all brands - from D400 to D700.

Positive characteristics of blocks

Due to the fact that the pores in cellular concrete are filled with air, another positive characteristic of the blocks is excellent thermal insulation. Along with this remarkable quality, there are a number of other equally important characteristics. Among them: high strength indicators; vapor permeability; low density values – range 350-700 kg/m3; excellent linear qualities and low percentage of thermal conductivity. The thermal insulation characteristics of the blocks have the highest indicator. The use of this building material can save money, materials and electricity. Overall, the costs of constructing the building depend entirely on this.

Types of gas silicate products

The production of masonry gas silicate material is constantly being improved, and more and more varieties of blocks are going on sale. Among the product range you can find products for walls and partitions. The structure and technical parameters of the materials are identical, only the dimensions and shape differ: thinner blocks are used for the construction of internal walls, which saves living space.

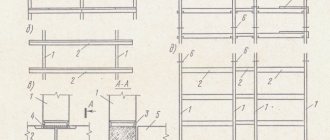

There are several types of masonry products:

Types of gas silicate blocks

- standard (ordinary type);

- tongue-and-groove (provide reliable joints between structural elements, without the occurrence of “cold bridges”);

- U-shaped (suitable for constructing lintels and reinforcing belts).

There are also other types of cellular concrete blocks available for sale. Builders pay increased attention to modules with special handles, which allow them to be securely grasped by hand. This form of building material is very convenient to use: erecting a building becomes even simpler and faster.

The dimensions of gas silicate blocks determine their application and density characteristics

- With a density of 700 kg/m3, the blocks are used for the construction of three-story cottages.

- With a density of 500 kg/m3 – construction of buildings up to three floors high.

- Materials with a density of 400 kg/m3 are used for the construction of load-bearing walls.

- If the density is less than 400 kg/m3, this is more of an insulating material used during the installation of load-bearing walls.

The decision to use blocks of a particular thickness and height is determined depending on their purpose. If the task is to provide the premises under construction with warmer walls, in this case it is recommended to use blocks with dimensions exceeding the thickness of classic samples. This is especially important to take into account in cold climates, where sub-zero temperatures can freeze the usual wall thickness.

Hand calculations

It is much more reliable to calculate the amount of required building materials using mathematics. So, for this procedure you will need:

- roulette;

- knowledge about the concept of volume.

Advantages of walls made of gas silicate blocks.

Gas silicate blocks are produced with different linear parameters, so let’s consider the general methodology for calculating their quantity by volume in cubic meters.

First you need to find out the length and width of the building along the outer perimeter. We multiply both parameters and get the area that the building will occupy from the outside. The same procedure must be done for the interior of the building. Now we determine the difference between the resulting areas. This will be the support area of your building. Next, you need to multiply the resulting difference by the expected height of the building.

As a result of the actions performed, you will receive the volume of the walls, respectively, and the volume that the gas silicate blocks will occupy. It should be noted that you calculated the full volume of the walls, without the presence of openings for windows and doors. This means that you should also subtract the volumes of all necessary openings from the overall result. This is done simply: we multiply three parameters (the length and width of the opening, as well as the estimated wall thickness) and get the exact result. Now subtract the corresponding volumes of all openings from the previously obtained total volume, and you will get the net volume of the building.

What is used for masonry?

Manufacturers are not limited to producing only aerated concrete itself. For high-quality masonry, an adhesive has been created for gas silicate blocks, the use of which allows you to avoid many problems. For example, masonry using a standard concrete mixture M200-M400 does not exclude the appearance of cold bridges in the connecting joints. The consequences of this are predictable: condensation appears on the inside of the facade in winter. It accumulates, the walls become wet, and fungus and mold begin to grow.

If adhesive for gas silicate blocks is used for masonry, the appearance of cold bridges is excluded. In addition, it allows you to reduce the thickness of the seams to 3 mm. Thus, the higher cost results in savings. This generally makes construction cheaper, but its quality improves.

It should be noted that glue for gas silicate blocks differs between regular and winter. In the second case, components are added to it that give it frost resistance. This composition allows you to build houses from aerated concrete at air temperatures from +5ºC to -10ºC.

Standard sizes according to GOST

This building material is produced in standard sizes, determined by GOST 21520-89. He determines that a 200x300x600 mm gas silicate block is optimal for the construction of houses in terms of its physical parameters. Used for laying on glue or mortar. However, some manufacturers have adopted their parameters that exceed the height and length data. This is not a violation, since the standard sizes specified by GOST are not mandatory.

That is why on the construction market you can purchase wall gas blocks 250x300x625 mm from the Mozhaisk plant or 300x400x600 mm from the Lipetsk plant. It is also important to consider the density of the material and its weight. For facades, it is recommended to use blocks with a density of D500-800 . At the buyer's request, manufacturers cut the material to obtain a thickness of 10, 15, 20 mm. This thickness is acceptable for its use, for example, as insulation.

Advantages of silicate blocks, user opinions

The popularity of this material, according to reviews, is due to its many positive properties:

- Relatively low cost compared to its ceramic counterpart.

- Efflorescence does not form on silicate blocks, no matter how long ago the masonry was laid. Ceramic brick cannot boast of such properties.

- A silicate block has more pronounced strength characteristics than a ceramic block, which develops cracks over time and begins to crumble.

- The material is easy to work with. To lay a white brick wall, no special instructions are required.

- This brick is used for the construction of partitions in manufacturing industrial enterprises, as it has good soundproofing characteristics.

- Since the block is made from natural materials, it is environmentally friendly and does not emit harmful substances over time.

- The material is quite durable: during 50 years of operation it does not lose its quality.

- A house made from a silicate block has a finished, attractive appearance due to the excellent design qualities of white brick.

- Due to the non-firing technology, it has a lower cost compared to red brick.

- Despite the fact that sand-lime brick is inferior to other products in terms of frost-resistant qualities, the situation changes over time: frost resistance and strength increase due to air carbonization of the material.

- Hollow products significantly reduce the weight of building structures, therefore reducing the load on the base.

- This material has many varieties; its small size makes it possible to construct various architectural combinations.