If you are looking for a reliable and time-tested manufacturer from whom you can order and buy a wooden I-beam

of the best quality, then we can say with confidence that you have found such a manufacturer. We have been working in the Russian construction market for more than ten years, and during this time we have become reliable partners for many companies, having won an impeccable business and quality reputation. All our products strictly comply with all GOST requirements - this is an unshakable rule, because we understand our responsibility and do not allow any “savings” on quality. Such savings come at a very high cost.

COMPONENTS AND MATERIALS FOR FORMWORK

Wide range of components and materials for installation and strengthening of floor formwork

- Floor formwork

- Concrete products

- Laminated plywood

- Panel formwork

- Accessories for formwork

- Formwork lubricant

- Wall materials

| In addition, we will help you quickly carry out routine repairs of formwork for monolithic construction - for this we have the entire necessary range of consumables and components. |

WITHOUT INTERMEDIARIES We are manufacturers of BDK-1 beams

COMPONENTS FOR SHIELD FORMWORK

Accessories for installation and fixation of formwork.

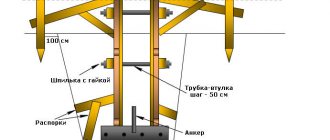

- Tension kits – consists of a tension screw, nut and washer. Some variations include anchor lugs and screw protection tubes. The kits are designed for assembling and fixing shields in the desired position. When choosing a kit, consider the length of the bolt you need; lengths range from 80 to 600 cm.

- Struts are additional reinforcing elements that support the panels in a vertical position under heavy loads. There are single-level and two-level ones; they are attached to the shield using a shoe.

- Mine spreader and tear-off jack - used for dismantling panels and formwork.

Accessories for connecting panels.

- Locks – for aligning and connecting panels. There are different types: wedge, universal, screw; made of steel, cast iron and steel. They differ in the methods of fastening, but they perform the same function.

- Pivots are a reinforcing rod that connects the panels together.

- Leveling beams - are attached between the joints of the panels using fastening brackets for greater leveling. Corner beams are used to level corner structures. The length of the beams is 80-450 cm.

- Laminated plywood for formwork – installed on panels and responsible for the smoothness of the monolithic surface. The main requirements for sheets are that they be moisture resistant and withstand heavy loads.

The surest way to buy a wooden I-beam BDK-1 is to buy it from the manufacturer!

We don't buy or resell - we produce! That is why our wooden I-beam has not only impeccable quality, but also the most attractive price! Our BDK beam

has the highest indicator of water resistance - after all, during the production process it undergoes thorough water-repellent treatment. This makes it possible to use BDK-1 beams regardless of the weather outside - both rain and snow.

We are reliable partners for any monolithic construction! Many construction companies have already been convinced of this - it’s your turn! Buy a wooden I-beam BDK - only from us!

| Our company is a reliable partner in the monolithic construction market; we enjoy success and trust among builders. All company products are certified. |

Beams for formwork of all types

Beam for formwork and other construction tasks available from a warehouse in Moscow. More than 10 types. Only honest and current prices. Rent is possible - from 198 rubles per month for a beam made of birch plywood with a protective cap.

The SeverTrnasMonolit company offers wooden I-beams for monolithic construction. Each beam is designed and manufactured to exceed industry standards to ensure trouble-free use.

| Name | Length, m | Weight p/m, kg | Beam weight, kg | Price per p/m, rub. | Price per beam, rub. |

| 40r*** I-beam wooden chipboard with PLUGS (1.5m; 2.5m; 3m; 3.3m; 3.6m; 3.9m; 4.2m; 4.5m; 6m) | 1,50 | 5,5 | 8,25 | 416,28 | 624,42 |

| 2,50 | 13,75 | 1 040,70 | |||

| 3,00 | 16,50 | 1 248,84 | |||

| 3,30 | 18,15 | 1 373,72 | |||

| 3,60 | 19,80 | 1 498,61 | |||

| 3,90 | 21,45 | 1 623,49 | |||

| 4,20 | 24,75 | 1 748,38 | |||

| 40r*** Wooden I-beam with PLUGSAMIDSP after 2.45 | not standard | 5,5 | 425,26 | ||

| 40 RUB*** Wooden I-beam with PLUGSAMIDSP up to 2.45 | not standard | 5,5 | 435,51 | ||

| 40sch*** Wooden I-beam STM with PLUGS (1.5m; 2.5m; 3m; 3.3m; 3.6m; 3.9m; 4.2m; 4.5m; 6m) | 1,50 | 5,5 | 13,75 | 416,28 | 624,42 |

| 2,50 | 15,95 | 1 040,70 | |||

| 3,00 | 16,50 | 1 248,84 | |||

| 3,30 | 18,15 | 1 373,72 | |||

| 3,60 | 19,80 | 1 498,61 | |||

| 3,90 | 21,45 | 1 623,49 | |||

| 4,20 | 24,75 | 1 748,38 | |||

| 40sch*** Wooden I-beam STM with PLUGS after 2.45 | not standard | 5,5 | 425,26 | ||

| 40sch*** Wooden I-beam STM with PLUGS up to 2.45 | not standard | 5,5 | 435,51 | ||

| 40zh*** I-beam wooden BDU (Plywood) (1.5m; 2.5m; 3m; 3.3m; 3.6m; 3.9m; 4.2m; 4.5m; 6m) | 1,50 | 5 | 8,25 | 383,00 | 574,50 |

| 2,50 | 13,75 | 957,50 | |||

| 3,00 | 16,50 | 1 149,00 | |||

| 3,30 | 18,15 | 1 263,90 | |||

| 3,60 | 19,80 | 1 378,80 | |||

| 3,90 | 21,45 | 1 493,70 | |||

| 4,20 | 23,10 | 1 608,60 | |||

| 40zh*** I-beam wooden BDU (Plywood) after 2.45 | not standard | 5 | 392,33 | ||

| 40zh*** I-beam wooden BDU (Plywood) up to 2.45 | not standard | 5 | 403,00 | ||

| 40z*** Wooden I-beam TAVR 200-DSP (1.5m; 2.5m; 3m; 3.3m; 3.6m; 3.9m; 4.2m; 4.5m; 6m) | 1,50 | 5 | 8,25 | 273,56 | 410,34 |

| 2,50 | 13,75 | 683,90 | |||

| 3,00 | 16,50 | 820,68 | |||

| 3,30 | 18,15 | 902,75 | |||

| 3,60 | 19,80 | 984,82 | |||

| 3,90 | 21,45 | 1 066,88 | |||

| 4,20 | 23,10 | 1 148,95 | |||

| 40b*** Wooden I-beam | 326,98 | ||||

| 40ya***Wooden I-beam BDU (1.5m;2.5m;3m;3.3m;3.6m;3.9m; 4.2m; 4.5m; 6m) | 1,50 | 5 | 7,50 | 295,00 | 442,50 |

| 2,50 | 12,50 | 737,50 | |||

| 3,00 | 15,00 | 885,00 | |||

| 3,30 | 16,50 | 973,50 | |||

| 3,60 | 18,00 | 1 062,00 | |||

| 3,90 | 19,50 | 1 150,50 | |||

| 40ya***I-beam wooden BDU after 2.45 | not standard | 5 | 303,24 | ||

| 40ya***I-beam wooden BDU up to 2.45 | not standard | 5 | 312,65 |

Share link:

- Click to share on Twitter (Opens in new window)

- Click here to share content on Facebook. (Opens in a new window)

Similar

APPLICATION IN MONOLITHIC CONSTRUCTION

Beam BDK-1 is used in monolithic construction to form interfloor slabs

To make a wooden I-beam, use:

The use of the BDK-1 beam with its high load-bearing capacity significantly reduces the number of floor supports, which reduces the number of parts for installation and dismantling of formwork, resulting in reduced working time and increased profitability. The BDK-1 beam is intended for reusable use. A beam with a cross section of 40x80 mm gives stability and makes it possible to drive nails. |

Efficiency of leveling beams

Leveling elements for formwork cope better with the assigned tasks when pouring reinforced concrete structures over a large area. In this situation, they control certain rigidity parameters of the monolith. Large panel panels provide an excellent leveling effect. The material of the channels does not affect the result of their use. Plywood boards and metal sheets are equally well secured in the desired position. High-quality formwork has a long service life.

When constructing formwork, I-beams perform a complex of functions:

- maintain the required parameters of structural rigidity;

- ensure its stability;

- are responsible for the normal perception of dynamic loads;

- guarantee the safety of construction work during the construction of monolithic floors.

Thanks to channels, monolithic structures have a high level of safety. The formwork is durable and retains its original properties for a long time. The geometric shape of the product remains the same until the end of its operation.

Using beams for leveling helps construction workers more accurately calculate the areas to which the load will be transferred (transversely, lengthwise), as well as its force. Calculation work helps to correctly distribute the load and eliminate deformation of the structure. At the time of pouring the cement mortar, the channels do not bend, and the accuracy of the formwork assembly remains high. Due to this, the surface of the monolith is perfectly smooth and solid, without mechanical damage.

Leveling elements speed up construction work without violating safety regulations. Many builders buy or rent H-beams ready-made for reuse. The high load-bearing characteristics of the product allow the number of supports to be minimized. The panels maintain their position and integrity under the influence of high concrete pressure. There are no gaps between the beams through which the solution could leak.

PARAMETERS OF BEAM BDK-1

Everything is in accordance with the requirements and standards of GOST

Complies with regulatory requirements

| Limit deviations from geometric sizes and shapes do not exceed:

| Limit deviations from straightness:

|

Where is it used?

When pouring monolithic floors located horizontally, formwork structures are used that include the following elements:

- I-beams for formwork;

- fasteners;

- telescopic supports with height adjustment.

Wooden beams are used for formwork when constructing vertical structures in the form of walls or columns. The use of such structures is explained by convenience, long-term operation and turnover.

Systems based on beams for floor formwork are often used in construction:

- residential buildings and industrial facilities;

- bridges and tunnels;

- complex structures.

The use of such forms is justified:

- ease of transportation of beams;

- ensuring a high level of load-bearing capabilities;

- equipped with grooves that facilitate installation work;

- the possibility of obtaining smooth surfaces for monolithic structures.

For the production of beam crossbars, a special material is used that can withstand a load of 100 kPa.

Advantages of I-beams

Compared with traditional systems, I-beams are not only easy to install and inexpensive, but also do not require a large number of builders; only 4 people will be enough to install the beams. Benefits also include:

- Beams are not characterized by bends and consistent dimensions;

- Possibility of use on long spans;

- Beams are immune to deformation and shrinkage;

- No need to use special equipment. For beams, builders can make do with regular carpenter's tools.

Main characteristics and types of beams for formwork

Currently, several types of beams are relevant. Among the most popular is the domestically produced beam – BDK-1. This element is made of timber, painted and treated with protective mixtures. In the standard version, the beam has the following parameters:

- length from 1.5 to 4.5 m;

- width - 8 cm;

- height – 20 cm.

Each beam has a shelf 4 cm thick and a shoulder width of up to 2.7 cm. Thanks to the design features and the material used, the finished beam structure can withstand a load exceeding 400 kN.

Beam for floor formwork BDK-1

The BDK-1 beam is made from LVL timber and coniferous wood, glued and treated with synthetic compounds that block the action of environmental factors and parasitic activity. The classic model of this type can be recognized by its characteristic yellow color and corresponding markings. According to GOST, the BDK-1 beam must have a high density (not lower than 450 kg/m3), the moisture content should not exceed 13%, and the weight should vary around 6 kg/linear m. In order for the finished system to meet all requirements, when assembling it, a maximum interval between beams should be maintained, which should not exceed 1.5 meters.

An equivalent analogue of the domestic BDK-1 is the N-20 beam, made of coniferous timber and having a plywood (FSF) core. The dimensions of the beam for formwork of this modification range from 1.8 to 4.5 meters; the formwork assembled on its basis can withstand loads of up to 500 N/linear m. A high-quality beam of this modification must meet the requirements of GOST 20850-84.

GOST 20850-84 Glued wooden structures

Beams are also distinguished by the material from which they are made; in addition to wooden – classic beams – there are beams made of aluminum and plastic. It is also possible to divide them according to operational characteristics. In this case, we can note leveling, load-bearing, forming, auxiliary beams, etc. Each variety has its own parameters, depending on size, design and material.