Installation of any type of foundation begins with the assembly of formwork. It can be of two types: removable and non-removable. The first is usually made of boards or sheets of plywood for strip foundations. The second is most often made from ready-made polystyrene foam blocks or asbestos-cement pipes (for columnar options). What material to choose is up to everyone to decide for themselves.

Formwork diagram for strip foundation.

Materials for foundation formwork

To shape the strip foundation, the following are used: removable, permanent and combined formwork.

- The removable version can be used several times if properly used. Parts of the structure are dismantled after the concrete has completely hardened. In industrial construction, elements of such structures can withstand dozens or even hundreds of construction projects. In private practice, a removable frame is built from boards or plywood.

- The non-removable option remains with the foundation forever. This practice is widespread in industrial construction. The material for such structures is extruded polystyrene foam. Subsequently, this material serves as insulation and sound insulation. Ready-made sets of polystyrene foam parts simplify the assembly process and reduce construction time.

- Combined formworks are used for construction on loose soil. They combine internal non-removable and external removable parts, which prevent soil from shedding.

There are two ways to calculate how much wood will be needed to construct the formwork.

First way:

- The length of the foundation is multiplied by 2, since the shields go on both sides of the trench.

- The resulting value is multiplied by the height of the foundation plus the allowance.

- The result remains to be multiplied by the thickness of the board (in meters). It will become known how many m³ of boards will be needed.

Second way:

- Let's find out the dimensions, standard factory board: width 100–150 mm, thickness 25–30 mm, length 6 m.

- The perimeter of the foundation is divided by the length of the board. The height of the future base is divided by the width of the wooden panel.

- The obtained values are multiplied, the result is the number of boards.

For the construction of permanent formwork with your own hands, sheets of fiberboard, fiberboard, hollow concrete blocks or pipes and wood are suitable. The construction of the structure consists of the following steps:

- They dig a pit or trench, based on the size and features of the future foundation. For this purpose, a project is first drawn up.

- A gap of 1 to 3 cm wide is left between the formwork and the ground (it facilitates installation). After the structure is completely installed, the gap is filled with earth.

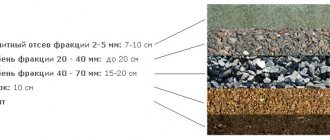

- The bottom of the trench is covered with sand and crushed stone, and the layers of backfill material are carefully compacted.

- To give additional strength to the foundation, a mesh of reinforcement is placed on the backfill layer.

- The formwork consists of adjusting the frame elements. Fasteners are selected depending on the material. If the structure is wooden, beams are first driven into the ground, and then boards or sheets of plywood are nailed to them.

- It is easier to align the parts along the line, periodically checking their position with a level. After installing the boards, they are connected to each other on top with wooden blocks. This will prevent the boards from sagging or swelling as the concrete is compacted.

- After adjusting the parts and securing the structure, pouring the solution begins.

The pressure of the solution on the walls of the formwork depends on the height of the structure. The higher the foundation, the stronger the wooden frame.

After preparatory excavation work, the construction of wooden panels begins:

- The support beams are placed so that they are outside the structure.

- When installing the assembled shields in the trench, they are strengthened with pegs and struts. In addition to boards, plywood, chipboard, fiberboard or OSB sheets are used.

- The parts are connected with self-tapping screws or nails. To add additional rigidity, studs are used (if a large amount of solution is poured).

- All walls are set strictly vertically.

- Seal cracks and gaps exceeding 4 mm. Place the plastic film so that it covers the wooden panels and bends outward. A furniture stapler will allow you to fix polyethylene or other insulating material.

- All nails are first removed from the boards. In addition, the wood must be damp (22% humidity).

- After installation, the frame is checked for strength; the wall must withstand a kick.

- Dismantling of the removable structure is carried out in a month to a month and a half. During this time, the foundation gains a sufficient level of strength. The gaps remaining after removing parts of the formwork are filled with earth or filled with mortar. In hot weather, when concrete dries quickly, dismantling is possible within two weeks. A sign that it is time to remove the removable parts are the cracks that have appeared between the frozen foundation and the formwork wall.

Columnar foundations are used as a basis not only for gazebos, but also for other buildings that are not massive and have high pressure on the ground.

We suggest you read: How to make a foundation for a stove in a bathhouse with your own hands

The pillars of such a foundation can have different cross-sectional shapes: square or rectangular, round or even sometimes polygonal.

Most often, pillars, especially for installing a gazebo, have a round or square cross-section. And only in rare cases, usually caused by some original design decision, can the foundation columns be given a polygonal, one might say, non-standard shape.

The columns themselves can be prefabricated, for example, made of brick or blocks. But still, it is more often practiced to create monolithic pillars, with their lower part going into the ground and protruding from above to the required height, for further installation of the trim or lower crown beam. And if it is planned to make all the elements of the foundation entirely from concrete, then it is impossible to do without arranging formwork for pouring the mortar. It is with its help that the intended shape of the foundation pillars with the required cross-sectional size is formed.

When constructing columnar foundations, three types of formwork can be used for work.

Reusable formwork, that is, collapsible, fastened in different combinations. They can be used for the construction of various types of columns. Moreover, one formwork can be used to erect several foundation pillars, if time permits.

Different materials are used to make reusable collapsible formwork. To make it convenient to work with such structures, as well as transport them from place to place, it is recommended to choose materials that have a low mass.

A well-known way to create formwork is to assemble it from plank panels

- Boards from which panels of the required size are assembled. These panels can be temporarily fastened together using self-tapping screws, nails, special twists, and all this is usually reinforced with spacers. The last method of fixation (shown in the illustration) can be used if the dug pit has walls made of durable soil.

Formwork built from boards is called panel construction.

— A similar design is formwork made of plywood with a thickness of 12–15 mm. This version of a prefabricated container for pouring concrete can be produced much faster than plank panels. And it’s much easier to work with such formwork, since it will have much fewer cracks.

Prices for gazebos

Alcove

It’s unlikely that anyone would think of using metal collapsible column formwork for a gazebo.

— Metal removable formwork is most often used in industrial construction or in the construction of large massive houses. Recently, it has become possible to rent such structures, however, when building a gazebo, it is quite possible to get by with more affordable and lightweight options.

— Collapsible plastic ready-made formworks for columns are similar to metal ones, but only much lighter. True, there is talk about their lack of reliability. However, there are many very positive reviews.

To assemble such formwork, it will be necessary to invite specialists. It is necessary to work with this material carefully, using special tools, so it is usually impossible to do without professional craftsmen. Plastic formwork is usually rented from construction organizations.

An example of a universal plastic formwork block for pouring columns. The fastening system for structural parts is clearly shown

The convenience of such systems lies in the fact that many blocks are universal, allowing you to set the required cross-sectional dimensions of rectangular columns in a certain range. The parts of the block are fastened with special locks, and for greater reliability, the opposite sides are also tightened with pins made of reinforcement, which are fixed using special washers. After pouring and hardening of concrete, these pieces of reinforcement remain in the monolith and serve to increase the strength of the foundation pillars.

Prefabricated reusable structures are also convenient because they can be used to form formwork for poles of different heights, which is the best option if you plan to install a gazebo on a slope.

However, plastic collapsible formwork on the scale of building a regular gazebo also seems like a big overkill.

Boards or plywood can be used to construct a columnar foundation if you plan to make the pillars square or rectangular in cross-section. For supports with a round cross-section, other available methods are used to create a form for concrete mortar.

Disposable formworks with a fixed shape and section size. The use of such devices is perhaps the most convenient and simplest method of pouring.

— As a disposable structure, cylinders specially made for this purpose from durable cardboard or plastic, with a thickness of 3 to 22 mm, are used. The diameter of cardboard tubes can vary from 110 to 1250 mm, and the length of such forms can reach 12000 mm. Moreover, such formwork is not very heavy. Thus, one linear meter of cardboard formwork, which has the largest diameter and the largest wall thickness, is 40 kg.

edged board

Cardboard disposable pipes are an excellent solution for creating column formwork

The cylinders do not have a longitudinal connecting seam, since the cardboard that forms the walls is wound in a spiral. This gives such products the required resistance to internally directed loads.

How to attach the film

Before concreting, the inside of the structure is lined with a durable polyethylene film for formwork, which must be secured with a stapler. Construction is best done using self-tapping screws. In this case, it can be easily disassembled, minimizing damage to the formwork boards.

After dismantling the formwork, I put a 30x120 mm board on the sheathing. Before this, I cleaned the surface of the boards from staples. The main thing is to disassemble everything carefully.

My house roof is assembled from 40-gauge boards left over after pouring and dismantling the formwork. Before pouring, I covered it with film, I didn’t saw the boards sticking out in the corners, I assembled everything with self-tapping screws. After disassembling the boards were like new!

Mistakes during the construction of formwork

Inexperienced builders often make typical mistakes when constructing a form-building structure.

- Saving on materials. You should not assemble shields from thin boards or other fragile materials. Under strong pressure, deflection occurs, and it is very difficult to strengthen a structure filled with concrete mixture.

- Incorrect assembly. All parts are connected in such a way that there are no cracks or gaps left or liquid concrete leaks. Then the hardening will be uneven. In addition, the height of the shields must exceed the design markings by at least 10 cm.

- Lack of waterproofing material. Protects against moisture: polyethylene or bitumen mastic.

- The absence of additional connections between parts of the prefabricated structure, supports and slopes to prevent overturning. If this moment is not provided for, the pressure of the foundation will lead to visible deformation of the contour.

- Loose wedges that level the side shields may not withstand vibration from special leveling equipment. As a result, the walls will fall apart.

Tags: pouring, formwork, hand, your own

« Previous entry

How to make a structure from boards

Forum members advise how to make formwork panels. To assemble horizontal panels, it is recommended to use an edged board measuring 100x25 mm and 150x30 mm, and for vertical panels, take a 100x50 mm beam, resting it against the panel with its edge .

The vertical installation step is transverse (beam 50x100 mm) - from 70 to 100 cm. To make the formwork more rigid, two 50x100 mm beams are installed horizontally on each side, top and bottom.

With a well-thought-out design and competent execution, the strength of boards of these standard sizes is sufficient to withstand the pressure of large volumes of concrete mixture on the walls of the structure.

When choosing boards for this design, you must immediately consider the option of their further use. Because formwork for the foundation will require more than one cube; it is irrational to use boards only once. In order for the boards to remain “industrial wood” after dismantling, it is necessary to protect them from direct contact with concrete.

Fixed devices

This structure is characterized by ease of installation and high speed of construction. After pouring the concrete solution, the formwork is left as part of the foundation.

It is usually constructed from available materials. It can be wood, metal or polystyrene foam. When making formwork for columnar structures, you can use asbestos or metal pipes.

The positive characteristics of such products include the ability to strengthen the base with the help of the material used. Such devices are easy to install.

Working with soil takes less time. Subsequently, there will be no need to carry out dismantling work. No additional supports or struts will be required during assembly.

Why do you need a formwork device?

The main purpose of the device is to give a certain shape and sufficient strength to the future building. It must have the following properties:

- Withstand the force of concrete pressure on its surface;

- Have the ability to maintain a given shape when forming the foundation;

- Simple and easy to manufacture, hermetically isolate the concrete solution from the ground.

The material for manufacturing can be a reusable frame made of wood or steel. A disposable structure can also be used.

Pouring concrete into formwork - the whole process from A to Z

Pouring concrete into formwork

How to pour concrete into formwork? If there are large volumes (when the solution is delivered from the factory on a mixer), concrete is poured immediately along the entire perimeter to a predetermined height. At home, it is usually not possible to prepare a large amount of solution. There are two methods for correctly pouring concrete into formwork using hand-prepared portions of mortar:

- pouring the entire perimeter of the formwork with concrete to a thickness of up to 0.5 meters, while the presence of too thin layers is not allowed;

- Filling a separate area with mortar to the entire height of the formwork. The side edge of the poured concrete should be beveled for more reliable adhesion between the individual parts of the structure.

How to pour concrete into formwork? Concrete supply is carried out:

- manually, carrying buckets of solution;

- direct pouring from a concrete mixer;

- imported concrete is poured directly from the mixer tray; if necessary, the tray can be extended with wooden or metal gutters.

When the entire volume of the pouring solution has been moved into the formwork, air bubbles formed during mixing and pouring of concrete are removed from it. To do this, it is compacted with a deep vibrator or shovel. You can pierce the concrete layer with reinforcement every 0.4–0.5 meters and gently tap the formwork walls with a sledgehammer.

The concrete surface is leveled with a shovel or building rule. If for any reason the work on filling the formwork with mortar is stopped for more than 24 hours, it can be resumed only after the concrete has completely dried. Before starting new concreting, the concrete working seam is wiped with a brush and washed with water.