Floor formwork is used when pouring horizontal and inclined monolithic elements. Its most common type is collapsible, which consists of longitudinal and transverse beams and laminated plywood laid on top. Telescopic stands, “scaffolding” or frames are used as supporting elements.

Formwork diagram for the foundation.

Calculation of floor formwork during the construction of buildings and structures begins with the selection of supporting elements.

Calculation of floor formwork

Grip length:

Working width:

Beam length of main rows:

Beam length of secondary rows:

The grip length cannot be equal to 0. The grip width cannot be equal to 0.

Calculate

Final calculations

| Design area, m2 | 0 |

| Total molding of the main beam, linear meters. | 0 |

| Total molding of the secondary beam, linear meters. | 0 |

| Total molding of beams, linear meters | 0 |

| Number of telescopic stands, pcs. | 0 |

| Number of uniforks, pcs. | 0 |

| Number of tripods, pcs. | 0 |

When calculating wall formwork, engineers will take into account the following factors and conditions:

- features of the selected type of equipment (advantages and disadvantages of each specific type of formwork);

- nomenclature of system elements;

- methods for forming external and internal corners;

- composition of components;

- possibility of using equipment in non-standard situations.

Calculation of floor formwork is no less complex and requires attention, because to select possible options for the equipment used, you should carefully study the initial data, such as:

- floor plan shape;

- shape, size and location of reinforced concrete beams (crossbars), capitals of columns, if any;

- height from floor to ceiling and height differences;

- slab thickness.

Attention!: There are many online calculators that allow you to quickly calculate the required set of formwork. But none of them will be able to take into account all the individual features of your project, the way a qualified engineer would do it.

Proper consideration of all the above conditions will help to avoid possible problems in the future, such as:

- lack of equipment at the construction site;

- local deformation of building elements;

- changing the design shape and size of the building;

- change in the load-bearing capacity of building elements;

- deformation of formwork equipment, which will lead the customer to loss of financial and time resources.

What does formwork calculation mean?

- Accurate calculation of the required amount of equipment for your project;

- Layout of formwork elements for your project;

- Selection of the necessary formwork elements, taking into account the equipment you already have;

- Qualified advice from an engineer on the use of formwork equipment;

- The calculation is carried out in accordance with the conditions of safety, strength and economy.

Our company has its own staff of experienced engineers capable of performing professional formwork calculations. All work is carried out on the basis of recognized software products Euroschal and AutoCAD.

The complexity of the project and the quality of the input data directly affect the calculation time. Design drawings with the location of monolithic walls and contours of floor slabs can be provided as initial data for calculating formwork. We recommend submitting files in AutoCAD format, this will reduce the time it takes to process the project. Calculation of small projects may take only a few hours.

Below we have given an example of ready-made calculations compiled by Our engineers:

- example of layout of a formwork kit;

- specification with the required amount of equipment.

Types of formwork and materials used

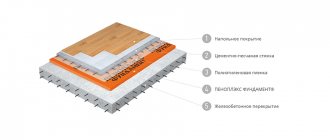

When arranging the foundations for buildings and structures, various types of formwork are used.

These designs are divided into the following categories:

- vertical and horizontal;

- block and panel;

- adjustable, sliding and drive-up;

- removable and stationary.

Formworks are also differentiated according to the materials used. Today, the construction industry uses structures made of metal, wood and plastic. Combination devices are used quite often. As a rule, this happens when installing curved structures.

According to the options for influencing the poured solution, devices are divided into:

- ordinary;

- warming;

- with insulating gasket;

- special.

Based on the frequency of use for their intended purpose, formworks are divided into disposable formworks (disposed of after removal) and inventory formworks, which, after dismantling, are cleaned and put into storage until the next time they are needed.

Any type of formwork consists of the following parts:

- Shields. These products come in different sizes and configurations. Designed to fix concrete in a given shape.

- Supporting and load-bearing elements. These include stops, ties, jumpers and contractions. Necessary in order to fix the boards in the position provided for by the construction project.

- Fastening elements. Serve to give the structure strength, stability and reliability. Nails, screws, ties, bolts, angles and clamps are used.

When making calculations, it is necessary to take into account that the height of the formwork should exceed the concrete pouring level by 5-20 cm, depending on the type of foundation.

In private construction, structures made from boards are always popular, which, after dismantling, are sawn and used for firewood. Depending on the required smoothness of the surface that the hardened concrete will have, a slab or floorboard with selected edges is used in the manufacture of formwork. The second option is more expensive, but allows you to achieve a perfectly flat surface. Its finishing will take much less money than a wall with an abundance of bulges and protrusions. In addition to boards, you need to stock up on a sufficient supply of timber and substandard trimmings. This type of wood is necessary to create the form into which the concrete solution will be poured.

A prerequisite for concrete not to lose strength when hardening is sufficient moisture in the wood. Dry material draws water from concrete, which significantly worsens its properties.

Preliminary calculation of floor formwork

Volumetric wedge post 336 m2 H=7.3 m

| Name | Price | Qty | Sum |

| Vertical elements | |||

| Starting | |||

| Stand-S-2.4 | — | 200 | — |

| Additional | |||

| Stand-D-2.0 | — | 400 | — |

| Horizontal elements | |||

| Rigel-1.5 | — | 1080 | — |

| Rigel-1.25 | — | 80 | — |

| Rigel-1.0 | — | 80 | — |

| Support elements | |||

| Jack 600x350 | — | 400 | — |

| Accessories | |||

| Unifork | — | 200 | — |

| I-beam 2.0 m, running meters. | — | 100 | — |

| I-beam 3.3 m, running meters. | — | 181,5 | — |

| I-beam 3.6 m, running meters. | — | 576 | — |

| I-beam 3.9 m, running meters. | — | 214,5 | — |

| Laminated plywood 18x1220x2440mm, m3 | — | 6,108 | — |

| Total | 0 | ||

How to calculate formwork for a foundation?

Formwork is one of the essential elements in the construction of the foundation of any building. All types of foundations require its arrangement. The formwork is designed to cope with the pressure of the concrete base and ensure that the original shape of the entire structure is maintained.

Not so long ago, builders had only wood at their disposal. Today, there are a lot of options for arranging the formwork for the foundation of a building to choose from. In any case, you should responsibly approach the issue of calculating the foundation formwork in order to determine the required amount of material to solve the problem.

Wooden formwork can be made from either solid wood boards or plywood. This material is affordable and easy to install. Expanded polystyrene formwork is very convenient. The structure is constructed from separate blocks that are securely joined together. Metal formwork is quite expensive and requires the use of steel sheets 1-2 mm thick.

Fixed formwork can be made in any of the following options:

- reinforced concrete;

- metal;

- wooden;

- from expanded polystyrene.

Reinforced concrete is considered the most expensive. At the same time, the constructed structure is highly durable.

Removable formwork is usually made of wood. To enhance the power of this design, spacers are used.

Calculation of foundation formwork is carried out using several methods. Both of them are based on elementary mathematics. How the calculation is made, using what formulas, is described below.

In both cases, the first thing you will need to do is measure the perimeter of the trench where you plan to pour the foundation. For this operation, a regular tape measure or a range finder or measuring wheel is used. Having determined the appropriate foundation height for yourself, you need to add an additional 20 centimeters to it. In any case, the formwork should have a greater height in comparison with the foundation. It is worth using meters as a unit of measurement. Next, you need to measure the thickness of the material used to organize the formwork. For wood, this parameter is usually 25-30 mm.

Wall formwork kit BUILDING 3

Area 951 m2

| Name | Square | Qty | Price | Sum |

| Shields height | 3m. | 148 pcs. | — | — |

| Linear shield | 1.2 m. | 12 pcs. | — | — |

| Linear shield | 1.15 m. | 4 things. | — | — |

| Linear shield | 1.1 m. | 12 pcs. | — | — |

| Linear shield | 1.05 m. | 7 pcs. | — | — |

| Linear shield | 1m. | 4 things. | — | — |

| Linear shield | 0.95 m. | 28 pcs. | — | — |

| Linear shield | 0.9 m. | 15 pcs. | — | — |

| Linear shield | 0.8 m. | 5 pieces. | — | — |

| Linear shield | 0.7 m. | 30 pcs. | — | — |

| Linear shield | 0.6 m. | 148 pcs. | — | — |

| Linear shield | 0.5 m. | 5 pieces. | — | — |

| Linear shield | 0.4 m. | 10 pieces. | — | — |

| Linear shield | 0.3 m. | 20 pcs. | — | — |

| Internal corner shield | 0.3×0.3 m. | 18 pcs. | — | — |

| Internal corner shield | 0.3×0.5 m. | 2 pcs. | — | — |

| Stripping board | 0.3×0.3 m. | 12 pcs. | — | — |

| External corner panel | 0.5×0.5 m. | 7 pcs. | — | — |

| Corner element | 1 PC. | — | — | |

| Accessories | ||||

| Wedge lock | 704 pcs. | — | — | |

| BFD lock | 78 pcs. | — | — | |

| Tie bolt 0.8m. | 633 pcs. | — | — | |

| screw | 1266 pcs. | — | — | |

| Washer | 1266 pcs. | — | — | |

| Scaffold bracket | 163 pcs. | — | — | |

| 2-level strut 3.0m. | 103 pcs. | — | — | |

| Total | 0 | |||

| Total per m2: | 0 | |||

| Name | Qty | Price | Sum |

| Floor formwork | 420 | — | — |

| Telescopic stand 3.1 m, pcs. | 375 | — | — |

| Unifork, pcs. | 375 | — | — |

| Tripod, pcs. | 230 | — | — |

| Beam 1.5 m, running meters. | 75 | — | — |

| Beam 3.0 m, running meters. | 1503 | — | — |

| Laminated plywood 18x1220x2440 mm, m3 | 7,609 | — | — |

| Total: | 0 | ||

To receive a free estimate, you can fill out the form below. Please provide valid phone numbers so that engineers can contact you if you have any questions.

Calculation of wooden formwork for a strip foundation

To calculate the formwork, we find out the geometric parameters of the monolithic tape:

- The length of the foundation base - we measure the perimeter and add to it the length of all load-bearing walls, if they are provided.

- Thickness of the strip base.

- Height. This part of the calculation can be difficult, since often the formwork is erected only on the surface of the soil, and the buried part is poured directly into the trench. But it is worth considering that such construction of foundations is applicable only for shallow structures. If the foundation is deep, then the formwork for it is made to the entire height of the tape, since such a structure requires a special approach - good insulation and high-quality waterproofing.

- Board sections. It comes in three sizes - 100, 125, 150 mm. The cost of the material depends on the choice of lumber thickness.

Important! Take into account and comply with the norms for the construction of formwork. If the width of the base is large, then boards made of 100 mm boards will not be enough when pouring concrete. Under the weight of the foundation, a board of small cross-section will move.

You need to approach the choice of material rationally. Before pouring concrete, we perform insulation. This will help keep the board suitable for further use.

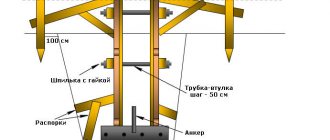

Installation of inventory formwork

To install an inventory table, you will need a minimum set of hand and measuring tools - a hammer, tape measure, rule/level, cord, markers. To tie the perimeter you will need a drill with BM dowels Ø 6 100 mm.

Attention! Make sure the table stand installation location is secure. Subsidence under one rack while applying load to the table (laying concrete) can cause destruction of the entire structure and injury to workers.

The initial condition for all options is that the walls are laid with high quality, the top row is laid out “on the horizon” and can serve as a guide.

Operating procedure

1. Move the horizon line to eye level along the walls.

2. Fix a 100x25 mm board along the inner perimeter of the walls at a height of 20 mm below the edge of the wall. The dowel pitch is 500–800 mm.

Attention! The perimeter piping is not a support, but a beacon, which will also facilitate dismantling and prevent laitance from leaking.

3. Extend the racks to the required length and secure with a lock or stop while tightening the jack nut. The approximate height of the rack is the distance from the floor to the top of the wall minus 20 mm (plywood), minus 200 mm (beam) and minus 200 mm (crossbar). In our case: 2700 – 420 = 2280 mm.

4. Install crossbar racks along each room. There are 3 racks per crossbar line (with tripods and uniforks).

5. Install the inventory beams into uniforks along the length of the crossbar. The overlap of beams on the support is 300 mm.

6. Place the cross beams up and lay them flat in increments of 400–600 mm on the crossbars.

7. Using a hydraulic level, transfer the horizon marks to the stationary part of the post (sleeve).

8. Measure the required distance from the horizon to the bottom plane of the crossbar. Make an L-shaped template.

9. Set the height of the crossbars according to the template using the sleeve nuts.

10. Install the formwork beams in the design position (on edge).

11. Lay sheets of plywood over the beams, fixing them at the corners with 50–70 mm nails. Or sew up the plane with a board.

Attention! There is no need to attach the plywood to the beams too firmly - vertical loads do not affect the fasteners. At the same time, an excess of nails will significantly complicate dismantling. The plywood joints must be on the beam, especially the longitudinal ones.

12. Cover the remaining areas with consumables.

13. Check the integrity of the formwork and, if necessary, block holes and openings.

14. Install the remaining racks in 800 mm increments under the crossbars.

Sometimes the surface is coated with a thin layer of technical oil - this makes dismantling much easier.

Attention! When using oil, make sure that it does not come into contact with the fittings.

At this point, the installation of the inventory table of the floor formwork is completed and all other operations - reinforcement, flanging, concreting - coincide with any other method.

Dismantling of formwork

The floor formwork is removed no earlier than 28 days from the moment of concreting. This is the most dangerous part of the job, especially if the ceiling height exceeds 2.5 meters. The table should be disassembled with great care, gradually removing the posts and being in a safe place.

Cost of 1 m3 of reinforced concrete flooring

| Name | Unit change | Quantity per 1 m3 | Unit price, rub. | Price 1 m3 |

| Concrete M100 (B12.5) | cube m | 1 | 2500 | 2500 |

| A3 fittings Ø 16 | linear m | 117,8 | 25 | 3000 |

| Total for material | 5500 |

Prices for installation and concreting services

| Rent of formwork (approximately) full set | 80 rub./day/sq. m |

| Concreting with inventory formwork | 2500 rub./cubic. m |

| Concreting with homemade formwork | 3000 rub./cubic. |