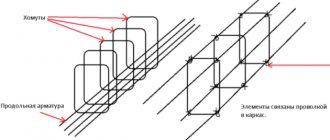

Recently, fiberglass reinforcement is increasingly used in the construction of reinforcing frames for various concrete structures. Although the material is still considered innovative, working with it is quite simple, since fiberglass reinforcement can be knitted using exactly the same traditional methods as when working with steel rods (with the exception of welding):

- fastening with a knitting wire using a hook (simple or semi-automatic) or pliers;

- using an automatic knitting gun (economically feasible only when carrying out large volumes of work);

- using a homemade electric crochet hook based on a screwdriver, and so on.

However, many professionals recommend using plastic fasteners for tying fiberglass reinforcement: special clips or mounting clamps.

Knitting fiberglass reinforcement with clips

For proper tying of fiberglass reinforcement, special plastic clips are successfully used. Structurally, the product is a strip with clamps in which composite reinforcement rods are tightly fixed. This method of knitting is the simplest, most convenient and fastest. The entire structure of the reinforcing frame can be easily mounted in prepared formwork; or prepare individual fragments, lower them into the formwork (compared to steel rods, this will be much easier to do) and tie them together. The reinforcing bars are fastened together with clips at an angle of 90˚: the frame design is smooth and neat. Anyone, even an untrained person, can cope with the work, since you just need to insert the rod into the groove of the plastic clip and press it until it clicks.

The cost of one clip is 0.7÷0.9 rubles. Of course, knitting with regular wire will be cheaper, but using clips has a number of undoubted advantages:

- high speed of work and ease of installation;

- reliability of fastening;

- non-flammability of clips;

- non-susceptibility of products to corrosion and the influence of chemically active substances;

- immunity of clips to temperature changes;

- affordable price.

Attention! To make the frame strong and rigid, the clips must match the diameter of the fiberglass reinforcement used.

How to unwind fiberglass reinforcement?

Composite reinforcement is supplied either in coils (when the volumes are very large) or in cut rods (when the volumes are in normal quantities). If you work on your own, you will need a coil unwinder. It will greatly simplify the whole process. Having placed the reinforcement in the unwinder, you need to remove the materials that hold it in the bundle (adhesive tape, wire), and then find the end and slowly begin to unwrap it. If you work in pairs, then your partner can hold the coil and prevent it from unwinding on its own, but this is still not very convenient.

At the moment of unwinding the reinforcement, it will become clear whether all the rules of the technological process were followed during its creation. It must straighten out and become perfectly level, otherwise the manufacturing standards have been violated and this can lead to many other problems besides the fact that it simply is not level.

Knitting with plastic clamps

The use of mounting plastic clamps is the second simplest and fastest method of tying composite reinforcement. This knitting option will cost a little less than the method described above: one clamp costs about 0.5÷0.6 rubles per piece. To tie composite reinforcement with plastic clamps, we proceed as follows: simply tighten the clamp with force at the crosshairs of the reinforcing bars. The connection is strong and reliable. In some places, to provide additional rigidity to the frame, we use two clamps at once, wrapped crosswise around the rods. It is better to remove the excess “tails” remaining after tightening using wire cutters. If this is not done, a capillary will form around the end of the clamp protruding from the concrete structure, through which moisture will get inside (this negatively affects strength and durability).

Main characteristics

Composite reinforcement is a type of product that in appearance resembles ordinary metal wire. A distinctive feature of these products is the use of certain substances in their manufacture.

Composite reinforcement is obtained from several types of fibers, which are connected to each other in a certain way. The material here can be certain products:

- glass;

- basalt rocks;

- aramids and many others.

All of them can be specially processed, which gives them high strength and reliability. The outer surface resembles ordinary metal reinforcement with non-ribbed inclusions.

Knitting composite reinforcement when reinforcing screeds

When reinforcing concrete floors, thick screeds or slab foundations, tying fiberglass reinforcement is very simple using special plastic racks. In addition to the fact that each rack itself is a vertical reinforcing element, it is also used to knit longitudinal rods. Crimp latches located along the edges of the rack securely fix the rods at right angles. In this case, there is no need to cut small pieces of reinforcement and then knit them between horizontal layers. One such rack is quite expensive (14–15 rubles), but the convenience and speed of work compensate for all costs.

Attention! To reinforce thin ties, you can use special C-shaped clips for fiberglass reinforcement. The shape of this fastener allows for sufficient clearance between the base and the reinforcing mesh made of composite rods.

How to properly transport and unwind TSA

Transportation of fiberglass reinforcement, the diameter of which is less than or equal to 10 mm, is carried out in coils. Considering that the weight of ASP is much less than the weight of steel reinforcement, its transportation to the construction site does not cause any problems and can even be carried out in the trunk of a regular car.

Fiberglass reinforcement has one unusual property. If there were no violations of the technological process during its manufacture, then when it is released from the clamps, the “memory effect” inherent in it will work and the product will straighten itself into a perfectly straight line. The main thing is not to interfere with this process and follow simple rules:

- You need at least two people to work with a coil of fiberglass reinforcement. One person is engaged in gradual unwinding of the reinforcement, and the second holds the freed end. There is no need to rush while working, the process should be smooth and continuous;

- if there is no second person, then you need to think in advance about what device will be used to fix the end of the TSA. The fixation must be reliable and the end must not break off when unwinding.

If this operation has to be performed quite often, then you can think about making or purchasing a special device that will facilitate the process of unwinding the ASP. The “unwinder” may look like a cross-shaped base that has four corners attached to its edges. A coil with fiberglass reinforcement is installed on the device and they begin to unwind it. The process will proceed in such a way that only a quarter of the ring will be unwound in one movement, which will serve as a guarantee of safety during operation.

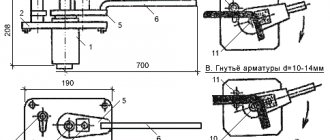

Bent elements made of fiberglass reinforcement

Since plastic reinforcement is supplied in rolls (50 or 100 m), there is no need to bundle longitudinal supporting rods: you can simply cut a piece of the required length. When arranging a reinforcement frame for a strip foundation, □-shaped vertical clamps are often used as transverse reinforcing elements, and L- and U-shaped additional elements are needed to strengthen the corners and junctions. It is impossible to independently produce such bent elements from straight fiberglass rods (the reinforcement will either break or return to its previous state after the bending force is removed). It is possible to give any shape to a fiberglass rod only at the stage of its production in a factory. Therefore, it is necessary, in accordance with the sketch, to purchase the required number of ready-made bent elements. Knitting of additional fastening elements of the reinforcement frame can be done using knitting wire and a regular hook or plastic clamps.

On a note! If you do not find bent fiberglass elements of the required sizes or shapes on sale, you can make them yourself from ordinary steel reinforcement (you will have to purchase a small amount).

The variety of fastening elements that are used for tying fiberglass reinforcement allows you to choose the method that will be convenient for you (both in a technological and material sense).

Creating a foundation with fiberglass reinforcement

After the master has finished knitting the reinforcement, you can proceed directly to the reinforcement.

For a strip foundation, rods with a diameter of 8 mm are used, which is comparable to metal reinforcement with a cross-section of 12 mm.

Important! The foundation is made on a perfectly flat surface.

The algorithm of actions is as follows:

- Installation of glassine-treated formwork

- Designation of the level to which the solution is poured. This is done using a water level and taking measurements in several places.

Important! The reinforcement mesh must be completely immersed in the formwork and not reach its edge by approximately 5 cm.If this condition cannot be met, then you can place bricks under the reinforcing mesh.

- Laying fiberglass reinforcement on the prepared brick covering.

- Pouring the finished structure with high-quality concrete.

When pouring, concrete must be compacted to avoid empty cavities. Important! The amount of concrete is calculated as follows: multiply the perimeter of the strip foundation by the height and width. - The finished foundation is covered with a film, which is fixed with bricks or bars. After 2 - 3 weeks, construction work can be carried out.

Fiberglass reinforcement is a relatively new construction product, but it has already become quite popular among those involved in private construction. In addition, fiberglass reinforcement is also carried out on an industrial scale in the construction of roads, bridges, shore strengthening, and construction.

Knitting reinforcement with your own hands is a simple process that can be easily completed if you have all the necessary materials. Even an untrained person can do this, just try it on a few elements. This distinguishes fiberglass reinforcement from steel, to create a frame from which you need a welding machine and experience working with it.

- We build a house from foam blocks with our own hands

- Floating foundation

- DIY foundation formwork

- Foundation for a stove in a bathhouse